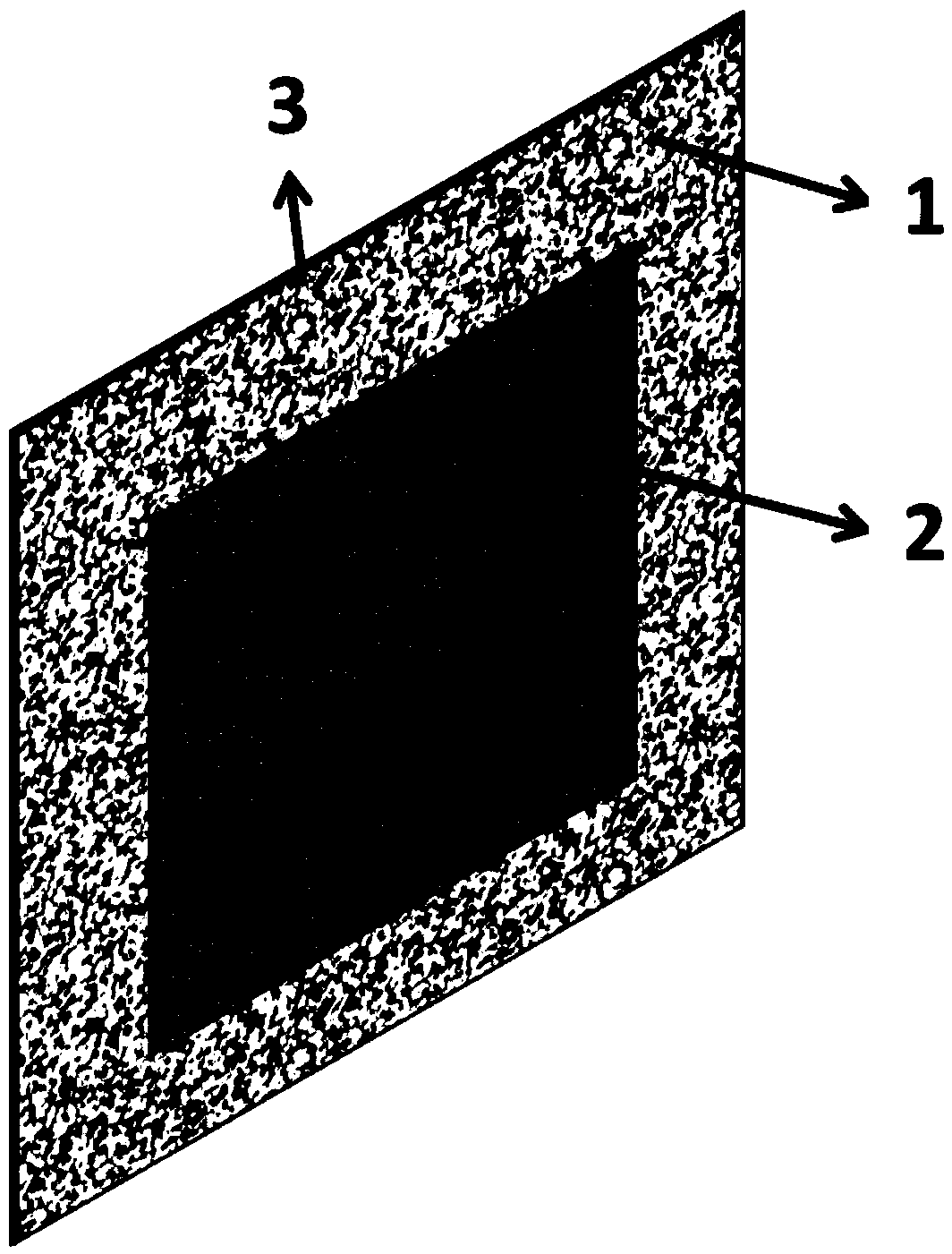

Weldable bipolar plate for flow battery and preparation and application thereof

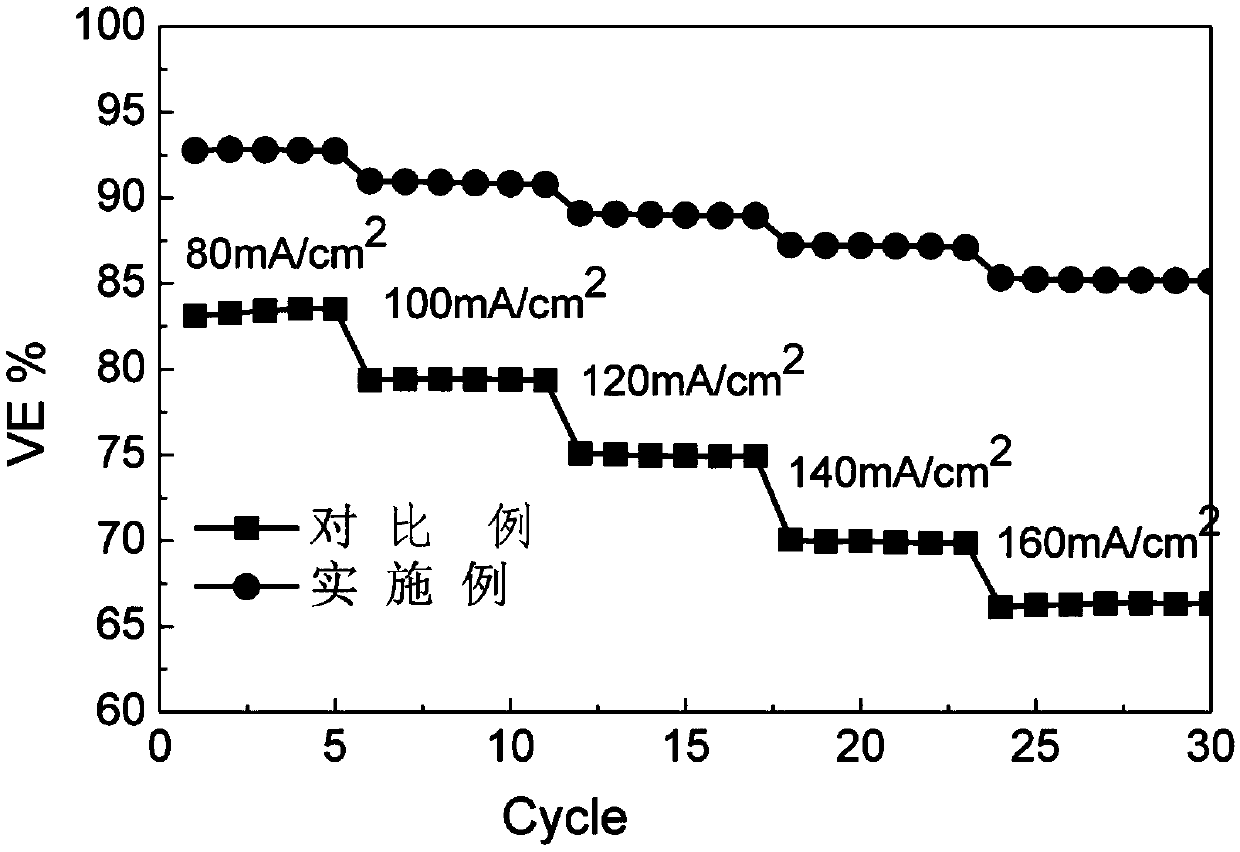

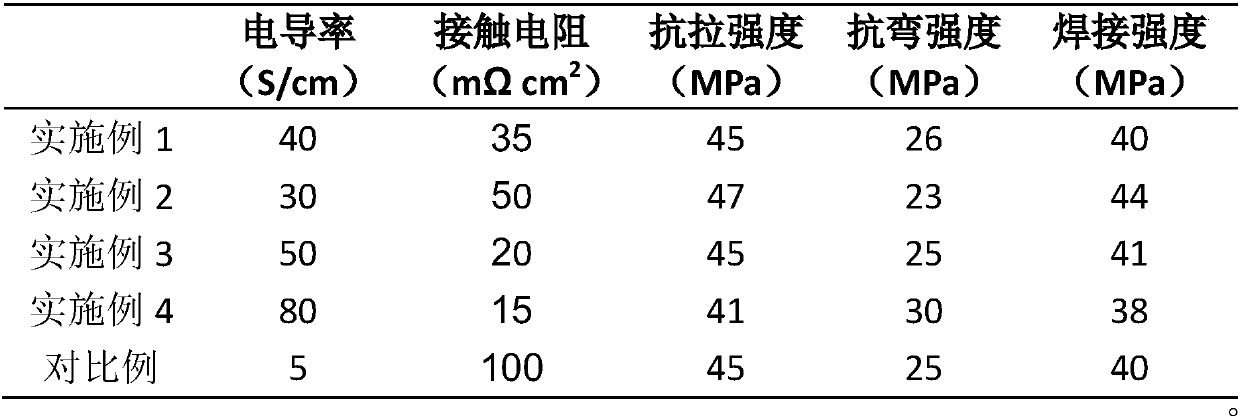

A technology of flow battery and all-vanadium flow battery, which is applied to fuel cells, regenerative fuel cells, and components of fuel cells, etc. Inability to form conductive paths and other problems, to achieve the effect of easy production process, improved voltage efficiency, and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take by weighing high-density polyethylene (melt index is 0.5) 0.78kg, carbon nanotube 0.2kg, titanate coupling agent 10g, polyethylene wax 5g, zinc stearate 5g, wherein, carbon nanotube diameter is 20- 30nm, length 15-50μm, purity 99%, specific surface area 160m 2 / g. After mixing the above materials, put them into the banbury mixer, the banbury temperature is 200°C, the rotor speed is 40r / min, and the banbury time is 20 minutes. Then, the evenly mixed banbury material is pulverized by a pulverizer and then sent to a single-screw extruder. The barrel temperature of the extruder is 200°C, the speed of the main engine is 15rpm, and the die temperature is 230°C. The sheet is extruded and calendered. A carbon-plastic composite bipolar plate with a thickness of 0.8 mm was formed.

[0034] Weigh 90g of nano-graphite powder and 10g of PVDF, add it to 1L of ethanol, stir and mix evenly, use a 100μm spatula to scrape it on the surface of the carbon-plastic composite board, an...

Embodiment 2

[0038] Weigh high-density polyethylene (melt index is 0.05) 0.83kg, carbon nanotube 0.15kg, aminopropyltriethoxysilane coupling agent 10g, polyethylene wax 5g, zinc stearate 5g, wherein, carbon nanotube The diameter of the tube is 15-30nm, the length is 15-30μm, the purity is 99%, and the specific surface area is 200m 2 / g. Mix the above materials and put them into a banbury mixer, the banbury temperature is 200°C, the rotor speed is 45r / min, and the banbury time is 20 minutes. Then, the evenly mixed banbury material is pulverized by a pulverizer and sent to a single-screw extruder. The temperature of the barrel of the extruder is 200°C, the speed of the main engine is 15rpm, and the temperature of the die is 230°C. The sheet is extruded and calendered. A carbon-plastic composite bipolar plate with a thickness of 1mm was formed.

[0039] Weigh 88g of carbon fiber powder and 12g of PVDF, add it to 1L NMP, stir and mix evenly, scrape it on the surface of the carbon-plastic com...

Embodiment 3

[0041] Weigh respectively high-density polyethylene (melt index is 1) 0.8kg, carbon nanotube 0.18kg, aluminate coupling agent 10g, calcium stearate 10g, wherein, carbon nanotube diameter is 20-30nm, length is 15 -50μm, purity 99%, specific surface area 160m 2 / g. After mixing the above materials, put them into the banbury mixer, the banbury temperature is 220°C, the rotor speed is 50r / min, and the banbury time is 20 minutes. Then, the homogeneous mixing material is pulverized by a pulverizer and sent to a single-screw extruder. The temperature of the barrel of the extruder is 230°C, the speed of the main engine is 8rpm, and the temperature of the die is 200°C. The sheet is extruded and calendered. A carbon-plastic composite bipolar plate with a thickness of 0.5 mm was formed.

[0042] Weigh 95g of graphite powder and 5g of PVDF, add it to 1L of NMP, stir and mix evenly, use a 150μm spatula to scrape it on the surface of the carbon-plastic composite board, then dry and remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com