Preparation method of polyaniline-base composite coating applied to stainless steel bipolar plate

A polyaniline-based, composite coating technology, applied in the fields of new energy, electrochemistry and material science, can solve the problems of weakening the durability of PANI coating, reducing the shielding effect of corrosive ions, etc., to achieve excellent corrosion protection performance, improve the use of Effects of life and power output, excellent corrosion resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

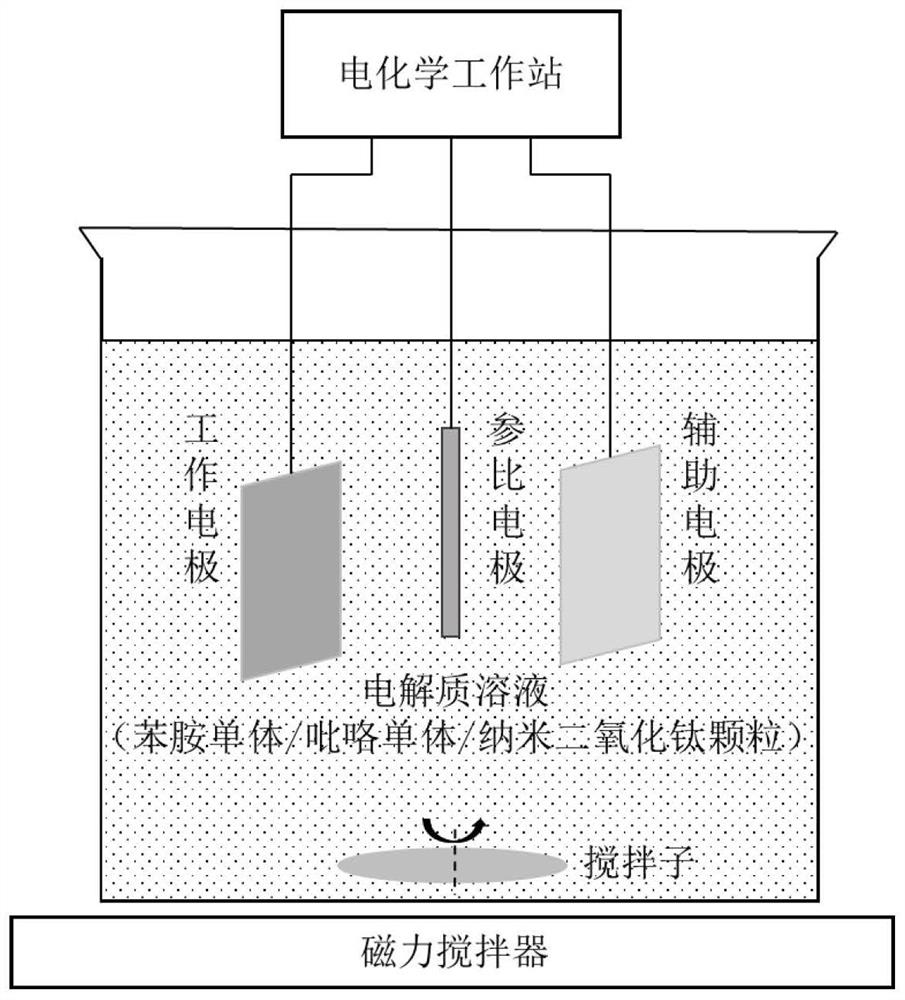

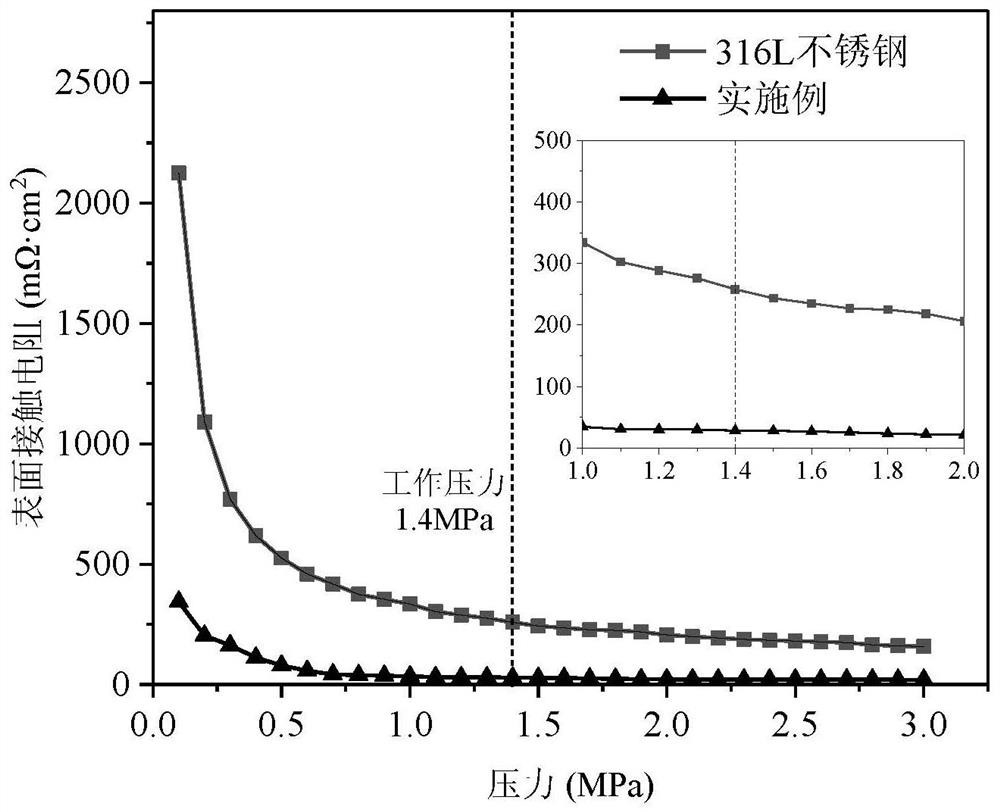

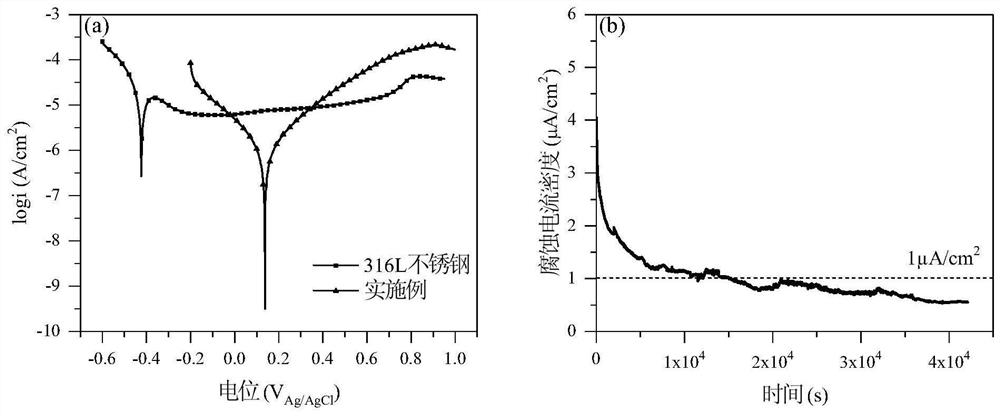

[0026] Examples: A method for preparing high resistance, conductive polyaniline-polypyrrole-nano-titanium dioxide composite coating includes the steps of:

[0027] (1) Take 0.3 mol of anhydrous oxycaric acid, 0.1 mol 胺 monomer, 0.04 mol pyrrole monomer in 1 L deion water, to obtain an aniline-pyrrole solution; nano-titanium dioxide particles having a 1 g particle diameter of 5-10 nm Add aniline-pyrrole In the solution, 100 mg of sodium dodecyl sulfonate was added, and the magnetic stirrer was placed, and then the container was sealed with a tape; ultrasonic 10min, subsequently dispersed by magnetic stirring, stirring for 3 h to obtain an electrolyte;

[0028] (3) 316L stainless steel tie up to 10cm × 10 cm size, including 600 mesh, 1200 mesh, 2400 glutinous silica sandpaper, polished to scratch, mirror effect, then use acetone ethanol volume ratio 1: 1 Mixed solution Ultrasound washed 10 min; a 316L stainless steel tie after the squeezed 316L stainless steel is 1 cm × 1 cm size, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com