Manufacturing process for silver tin oxide calcium oxide electrical contact and electrical contact product

A silver tin oxide, manufacturing process technology, applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems of not reaching the expected effect and service life, high surface contact resistance, contact base pollution, etc., to achieve good arc extinguishing performance, low surface contact resistance, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. According to the mass ratio of components: tin: 5%; calcium: 1.5%; cerium: 0.03%; the balance is silver. The ingots are melted to form silver-tin-calcium alloy ingots.

[0032] 2. The silver-tin-calcium alloy ingot is heated and extruded into a wire, and then drawn to a wire with a diameter of φ1.5mm.

[0033] 3. On the cold heading machine, the wire material of 2 and the silver wire are cut into small sections with suitable lengths by the cold heading machine and made into a sheet contact product of φ3㎜×0.8㎜.

[0034] 4. Pour the contact product of 3 into an argon electric furnace in a vacuum state of 480°C for diffusion annealing for 60 minutes, and then cool down to 80°C with the furnace to take out the product.

[0035] 5. Put the product of 4 into an electric furnace with an oxygen flow pressure of 1.2 Mpa, firstly oxidize at 620°C for 6 hours, and then heat up to 700°C for 6 hours with the furnace. The finished electric contact is obtained after being cooled ...

Embodiment 2

[0037] 1. According to the mass ratio of components: tin: 7%; calcium: 3%; cerium: 0.05%; the balance is silver. The ingots are melted to form silver-tin-calcium alloy ingots.

[0038] 2. The silver-tin-calcium alloy ingot is heated and extruded into a wire, and then drawn to a wire with a diameter of φ2.5mm.

[0039] 3. On the cold heading machine, the wire material of 2 and the silver wire are cut into small sections with suitable lengths by the cold heading machine and made into a sheet contact product of φ5㎜×1.3㎜.

[0040] 4. Pour the contact product of 3 into an argon electric furnace for 90 minutes in a vacuum state of 500°C for diffusion annealing, and then cool down to 80°C with the furnace to take out the product.

[0041] 5. Put the product of 4 into an electric furnace with an oxygen flow pressure of 1.2 Mpa, firstly oxidize at 630°C for 18 hours, and then heat up to 710°C for 16 hours with the furnace. The finished electric contact is obtained after being cooled ...

Embodiment 3

[0043] 1. According to the mass ratio of components: tin: 8%; calcium: 4%; yttrium: 0.02%; the balance is silver. The ingots are melted to form silver-tin-calcium alloy ingots.

[0044] 2. The silver-tin-calcium alloy ingot is heated and extruded into a wire, and then drawn to a wire with a diameter of φ3mm.

[0045] 3. On the cold heading machine, the wire material of 2 and the silver wire are cut into small sections with suitable lengths by the cold heading machine and made into a sheet contact product of φ6㎜×1.5㎜.

[0046] 4. Pour the contact product of 3 into an argon electric furnace for 90 minutes in a vacuum state of 520°C for diffusion annealing, and then cool down to 80°C with the furnace to take out the product.

[0047] 5. Put the product of 4 into an electric furnace with an oxygen flow pressure of 1.2 Mpa, firstly oxidize at 630°C for 22 hours, and then heat up to 720°C for 20 hours with the furnace. The finished electric contact is obtained after being cooled t...

PUM

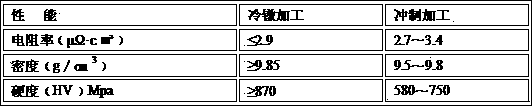

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com