Solid tantalum electrolytic capacitor and manufacturing method thereof

A technology of tantalum electrolytic capacitors and capacitors, which is applied in the field of solid tantalum electrolytic capacitors and its manufacturing, can solve problems affecting product applications, circuit function changes, damage, etc., to reduce surface contact resistance, reduce high-frequency ESR values, and improve application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

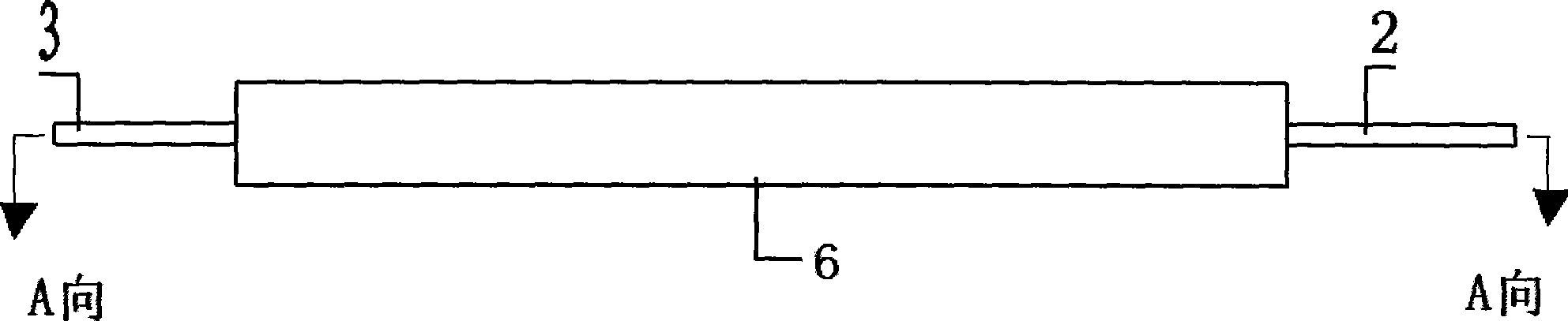

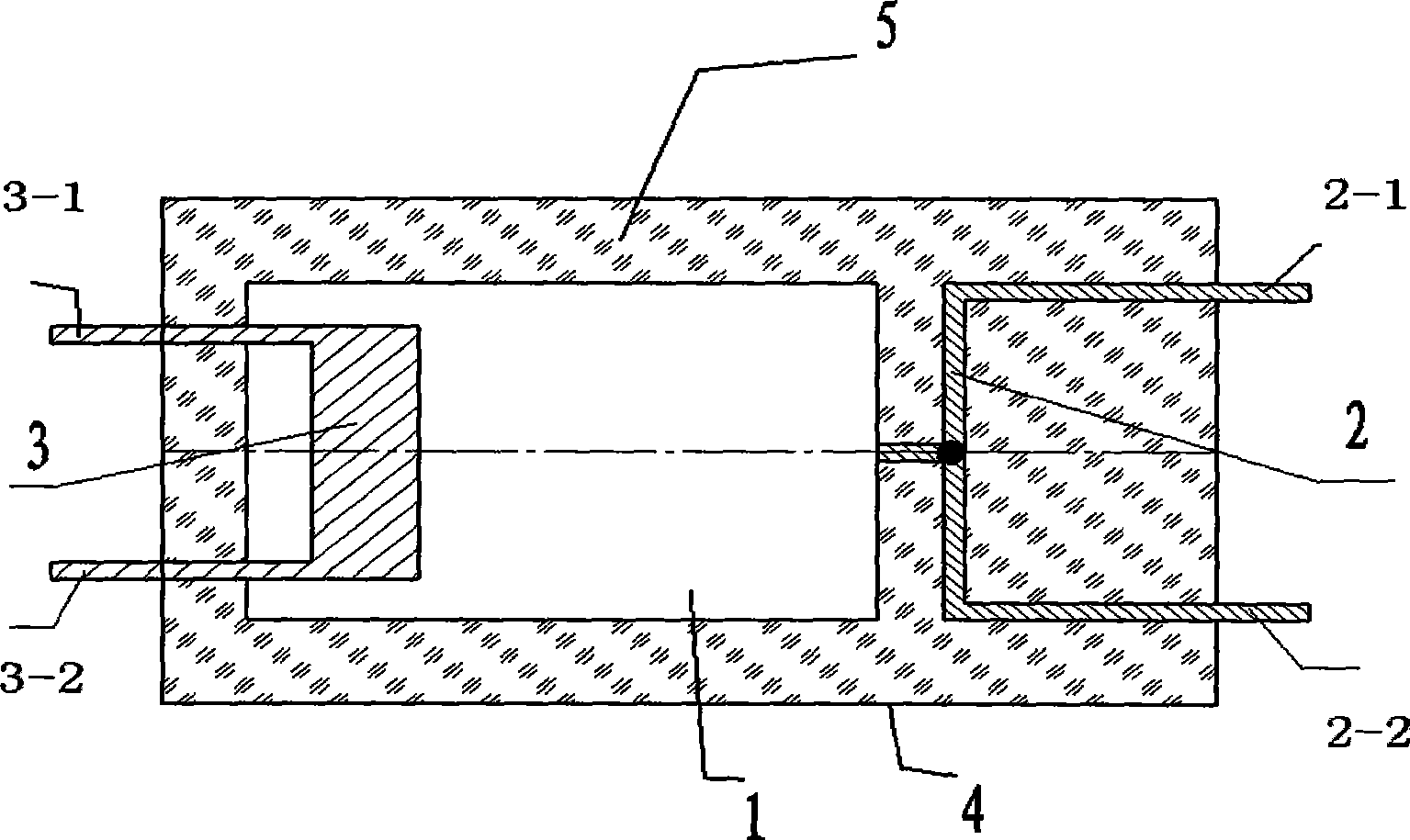

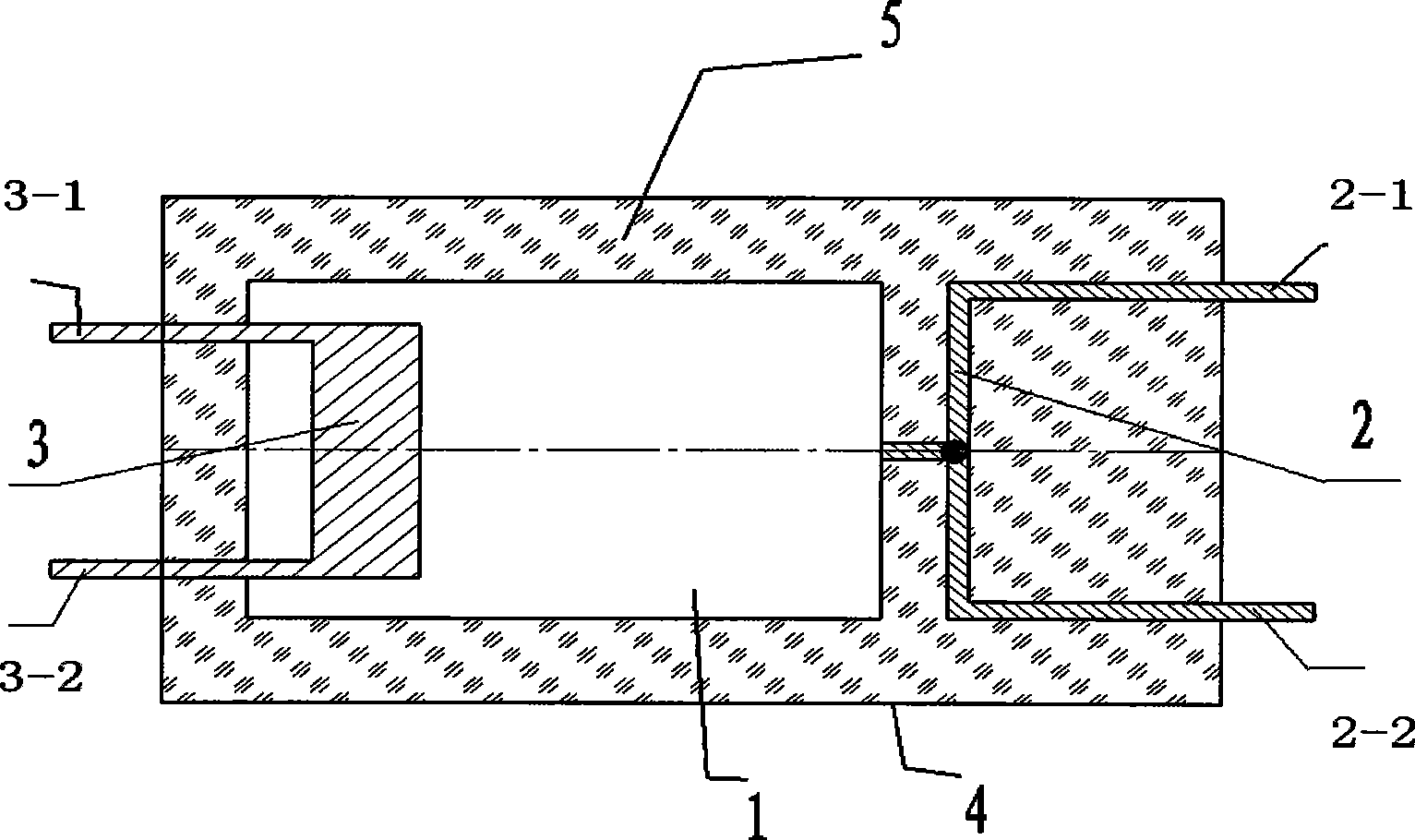

[0015] like figure 1 , 2 The solid tantalum electrolytic capacitor shown is composed of a flat cuboid capacitor body 6 composed of a flat cuboid tantalum core 1, an insulator 5 and a metal shell 4. The flat cuboids in the shape of a 匚 are respectively drawn from the anode end faces and cathode end faces at both ends of the body. The cathode double-ended lead wire 3 and the anode double-ended lead wire 2; the two ends 3-1, 3-2 of the cathode lead wire are vertically bent and the bent ends are parallel to each other, and the two ends 2-1, 2-2 of the anode lead wire are vertically bent The bent ends are parallel to each other; the middle part of the anode double-ended lead is connected to the tantalum core 1, the bent end is perpendicular to the anode end face of the capacitor body, the cathode double-ended lead is bonded to the tantalum core, and the bent end is connected to the cathode of the capacitor body The ends are vertical.

[0016] like figure 1 , 2 The solid tantalu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com