Copper-based electrical contact material for low-voltage electrical appliances and preparation method thereof

A technology of electrical contact material and low-voltage electrical appliances, which is applied to contacts, circuits, electrical switches, etc., can solve the problems of low electrical conductivity, high contact resistance, poor oxidation resistance and arc burning resistance, and improve electrical conductivity. , strong enhancement effect, highlight the substantive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The first step, the preparation of raw material mixed powder:

[0024] Weigh 150-mesh electrolytic Cu powder, 150-mesh pure Cu-20Ce alloy powder and TiO with an average particle size of 10nm as required 2 doped SnO 2 Nanopowder carries out batching, makes Ce element account for 0.05% (mass percentage) of above-mentioned three kinds of raw material gross weights, TiO 2 doped SnO 2 Nano-powder accounts for 0.1% (mass percentage) of above-mentioned three kinds of raw material gross weights, and all the other are Cu, then mixed powder is placed in the stainless steel ball mill tank, after filling with absolute ethanol, seal, ball mill on planetary ball mill for 5 hours, ball mill The ball-to-material ratio used in the method is 10:1, and the rotating speed of the ball mill is 300 rpm. After that, the mixed powder is taken out and placed on the filter paper to stand for 3 minutes, and the preparation of the raw material mixed powder is completed and set aside;

[0025] Th...

Embodiment 2

[0029] The first step, the preparation of raw material mixed powder:

[0030] Weigh 200-mesh electrolytic Cu powder, 200-mesh pure Cu-20Ce alloy powder and TiO with an average particle size of 15nm as required 2 doped SnO 2 Nanopowder carries out batching, makes Ce element account for 0.05% (mass percentage) of above-mentioned three kinds of raw material gross weights, TiO 2 doped SnO 2 Nano-powder accounts for 0.3% (mass percentage) of above-mentioned two kinds of raw material gross weights, and all the other are Cu, then mixed powder is placed in the stainless steel ball mill tank, after filling with dehydrated alcohol, seal, ball mill on planetary ball mill for 6 hours, ball mill The ball-to-material ratio used in the method is 10:1, and the rotating speed of the ball mill is 300 rpm. After that, the mixed powder is taken out and placed on filter paper to stand for 4 minutes to complete the preparation of the raw material mixed powder. Stand-by, the adopted Cu -20Ce allo...

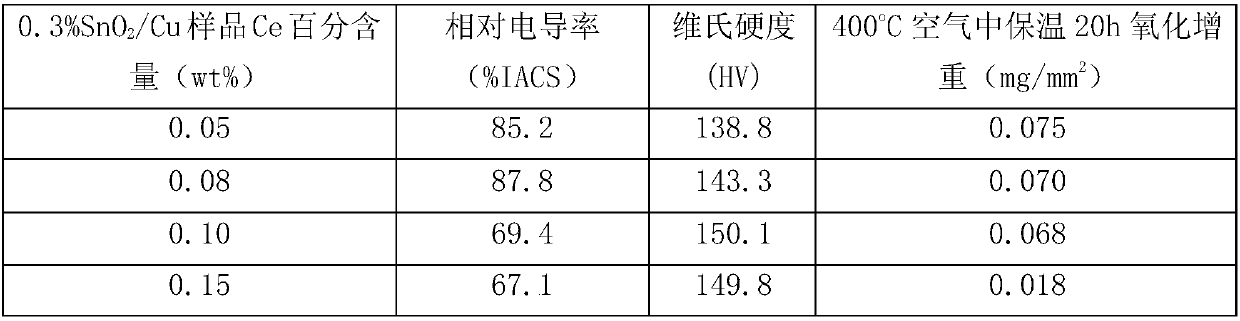

Embodiment 3

[0036] Except that 200-mesh pure Cu-20Ce alloy powder is added in the first step, so that Ce accounts for 0.08% (mass percentage) of the total weight of the three raw materials, the others are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com