Surface treatment method of rivet electric contact, grinding material and grinding material preparation method

A technology for surface treatment and electrical contacts, applied in heat treatment equipment, heat treatment furnaces, grinding/polishing equipment, etc., can solve problems such as short circuit faults, welding of electrical contacts, affecting the safe and reliable operation of electrical systems, and reduce contact The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] Preparation Example of Cylindrical Abrasives

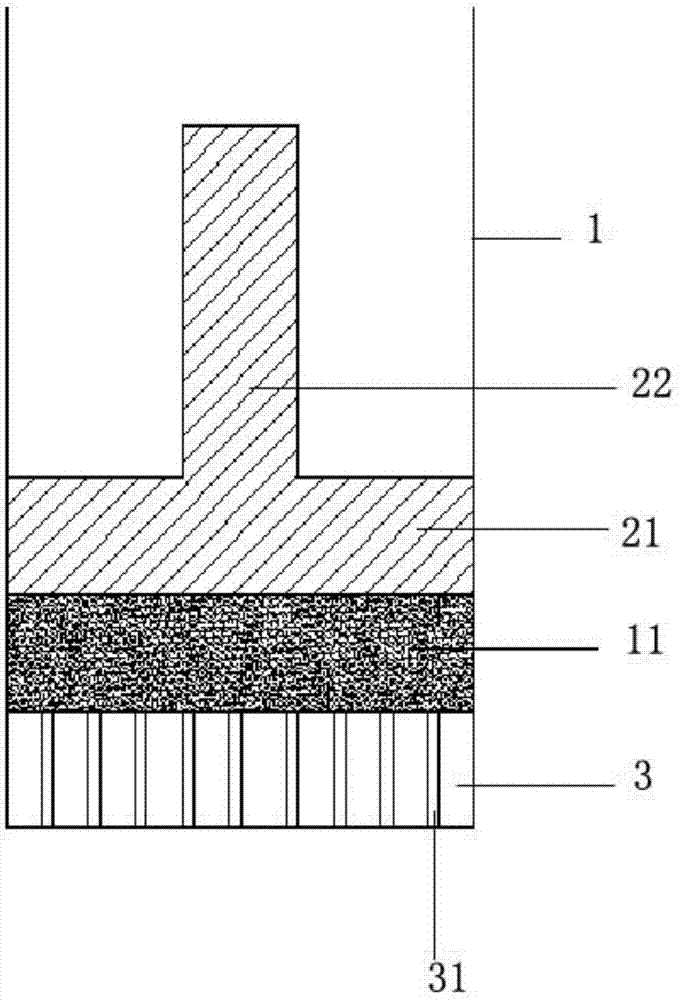

[0058] Such as figure 1 As shown, the extrusion molding device includes a cylinder body 1, a material cavity 11 is arranged in the cylinder body, and an extrusion piece disposed in the material cavity is slid by a piston. The extrusion piece includes an extrusion head 21 and is fixedly connected to the extrusion The extrusion drive rod 22 at the rear end of the extrusion head, the outer end of the material chamber relative to the extrusion head is provided with a molding template 3, and the molding template is provided with a plurality of points along the extrusion direction of the extrusion head Cylindrical extrusion holes 31 distributed in arrays, the diameter of the cylindrical extrusion holes is 1-3 mm, preferably 1.5 mm; the length of the cylindrical extrusion holes is 3-10 mm, preferably 5 mm.

[0059] The preparation process is to put the mixed powder and epoxy resin in a mixer, take out the colloid after stirring, ...

Embodiment 1

[0076] Put the abrasive into the sizing agent, the sizing agent described in this embodiment is sulfonic acid, a kind of organic acid, the general formula R-SO3H, R represents a hydrocarbon group, strong acidity, relatively large water solubility, used for making dyes, medicines, Detergent, acidic, add water to 70%~80% of the volume of the grinding tank, put it into the centrifugal grinder, set the speed at 1200r / min, take it out after about 10min, rinse and separate the product. Dry the product containing burrs and ring marks and put it into a vacuum furnace for annealing, set the temperature at 400°C, keep it for about 50 minutes, and then follow the furnace to room temperature and take it out. Use dilute sulfuric acid to pickle the product, remove the surface scale or other foreign matter, and then rinse it clean. The product is smoothed with a rolling and polishing machine, and then the product is rinsed clean. Put the product into the ultrasonic cleaning equipment for ul...

Embodiment 2

[0078] Put the abrasive into the sizing agent, add water to the position of 70%~80% of the volume of the grinding tank, put it into the centrifugal grinder, set the speed at 1200r / min, take it out after about 15min, rinse and separate the product. Dry the product containing burrs and rings and put it into a vacuum furnace for annealing, set the temperature at 300°C, keep it for about 90 minutes, and then follow the furnace to room temperature and take it out. Use dilute sulfuric acid to pickle the product, remove the surface scale or other foreign matter, and then rinse it clean. The product is smoothed with a rolling and polishing machine, and then the product is rinsed clean. Put the product into the ultrasonic cleaning equipment for ultrasonic cleaning. The cleaned product is then dried, dried, and cooled to a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com