Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Reduce production power consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for producing maleic anhydrid(e) by benzene gas-phase oxidation with high load and high yield

InactiveCN101284242AReduce production power consumptionIncrease production capacityOrganic chemistryPhysical/chemical process catalystsRare-earth elementGas phase

The invention relates to a catalyst for manufacturing maleic anhydride through the high-load and high-yield benzene gas-phase oxidation. A fixed-bed tubular reactor sequentially comprises an A section and a B section which are composed of catalysts with different performances along the inlet direction of reaction mixture gas; the A section is 40 to 60 percent of the total bed height, and the B section is 60 to 40 percent of the total bed height. The catalyst in the A section has the active phase composition that the ratio of V2O5:MoO3:P2O5:Na2O:NiO:Re2O3 equals to 1:(0.4 to 0.9):(0.01 to 0.08):(0.05 to 0.100):(0.005 to 0.500):(0.0001 to 0.0010), wherein, Re is any two of following rare earth elements that are Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb or Lu. The catalyst in the B section has the active phase composition that the proportion of the Re2O3 is 2 to 3 times of that of the Re2O3 in the A section, the proportion of the P2O5 is (0.005 to 0.040)mol, and the proportions of other oxides are the same with that in the A section. The catalyst can lead maleic anhydride production equipment to increase about 25 percent production capacity without increasing any investment, and the benzene consumption and the energy consumption can be obviously reduced.

Owner:TIANJIN BOHUA ZHONGHE CHEM +1

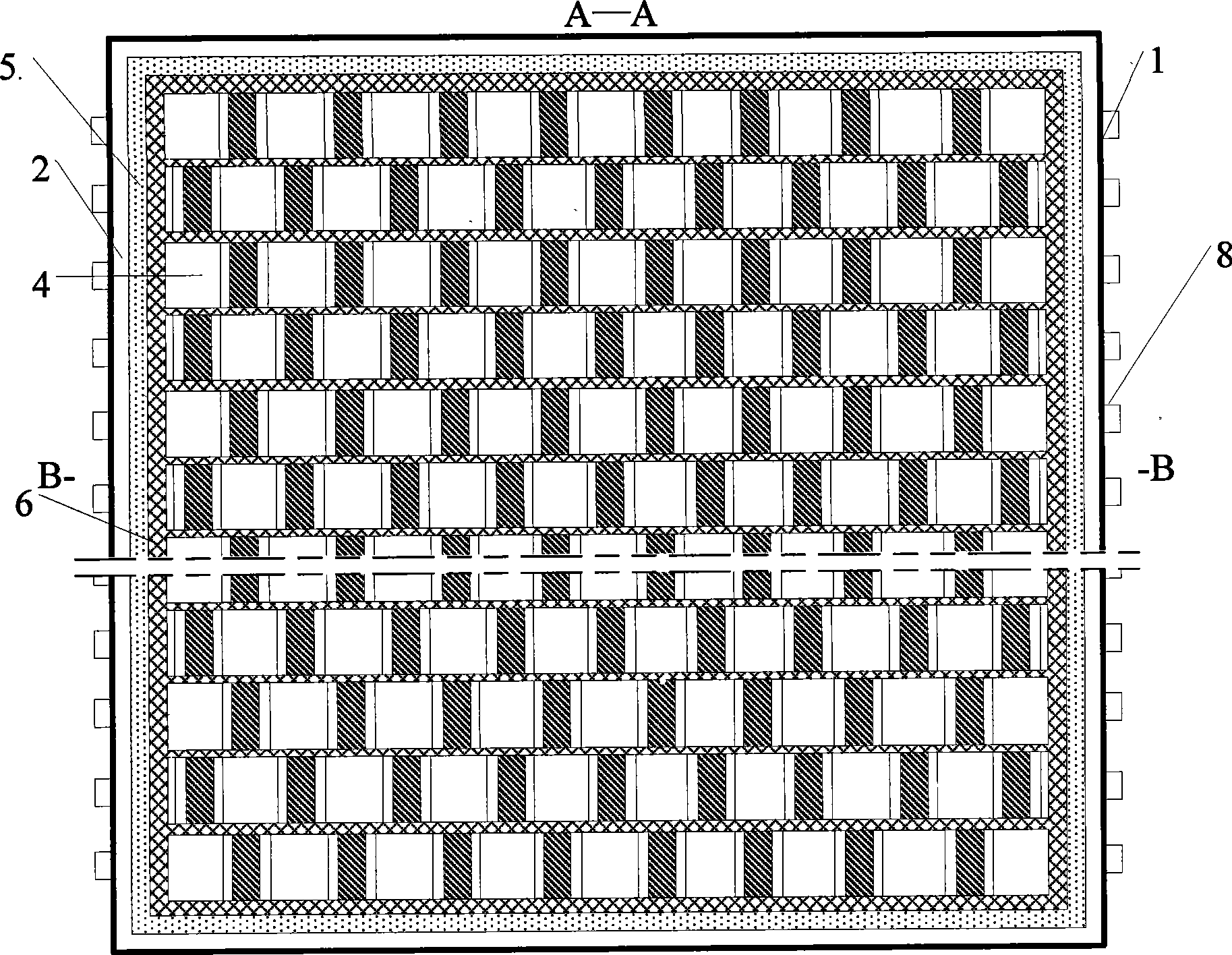

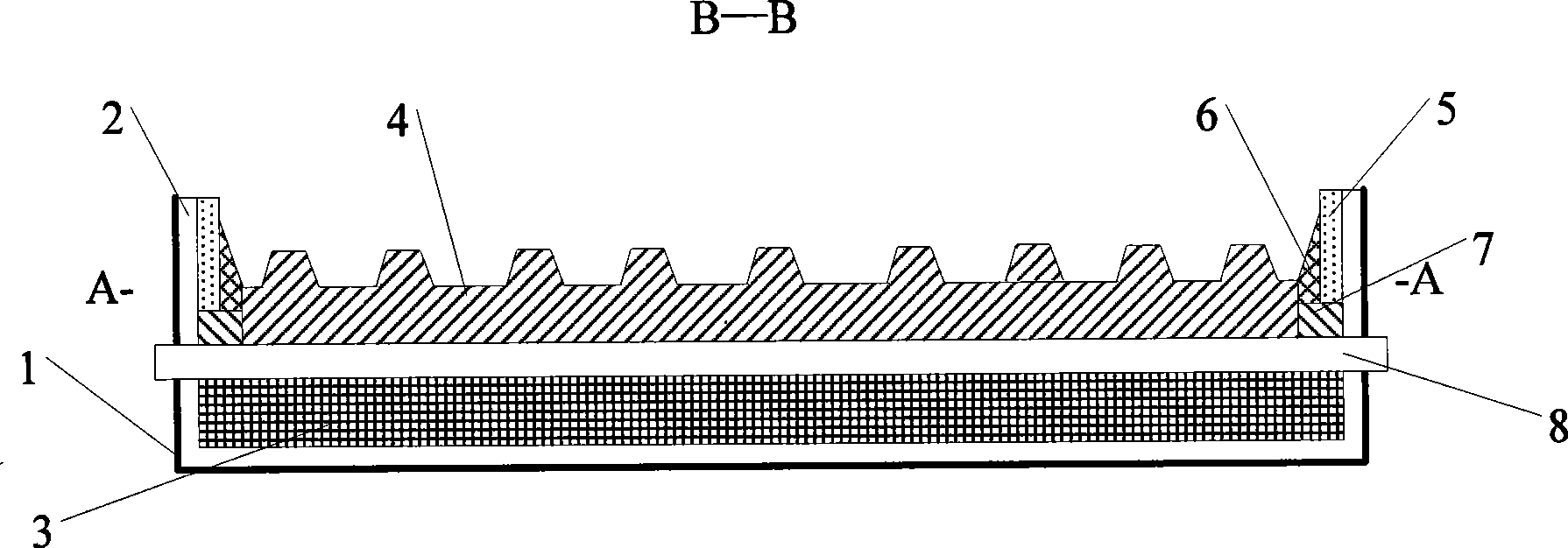

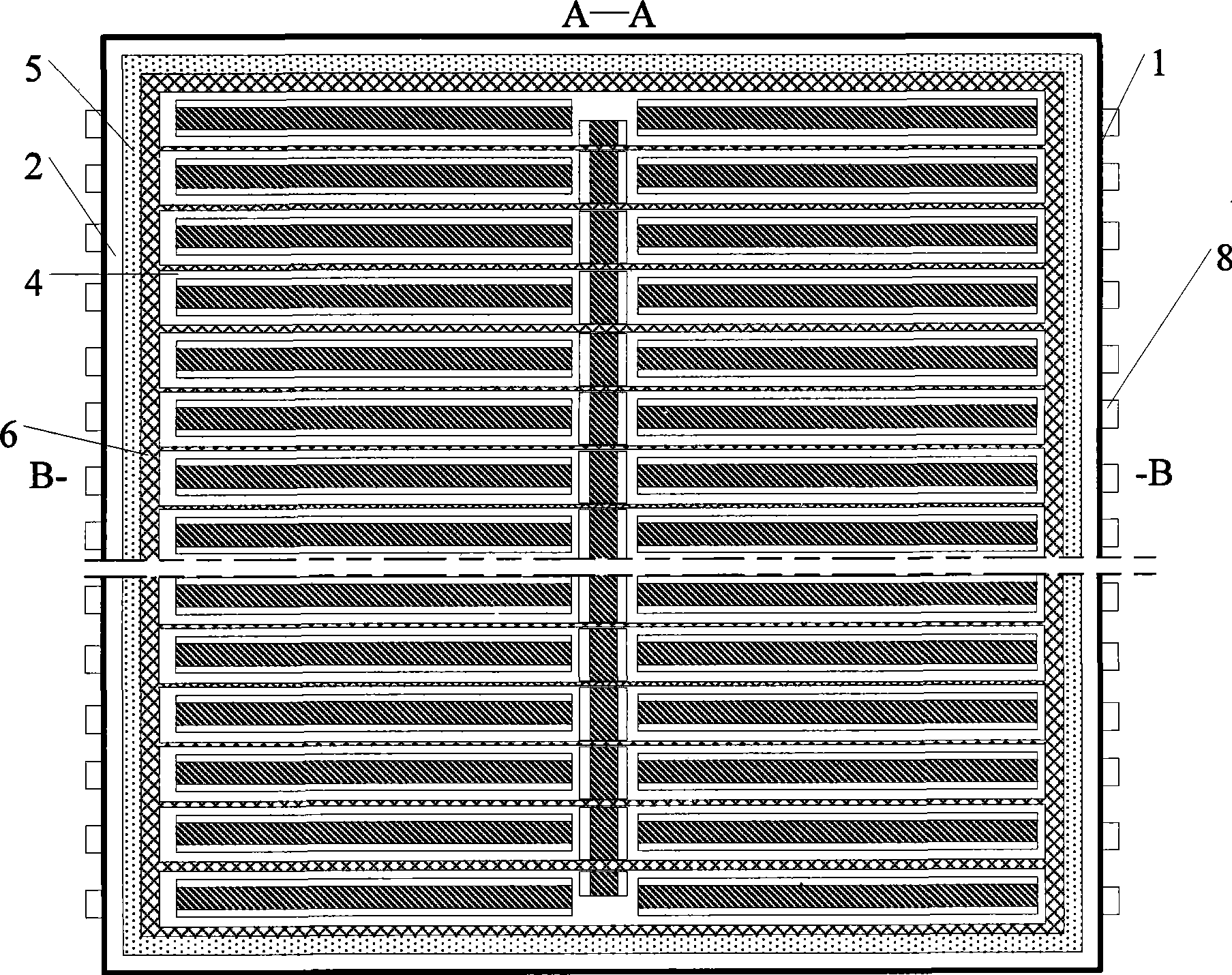

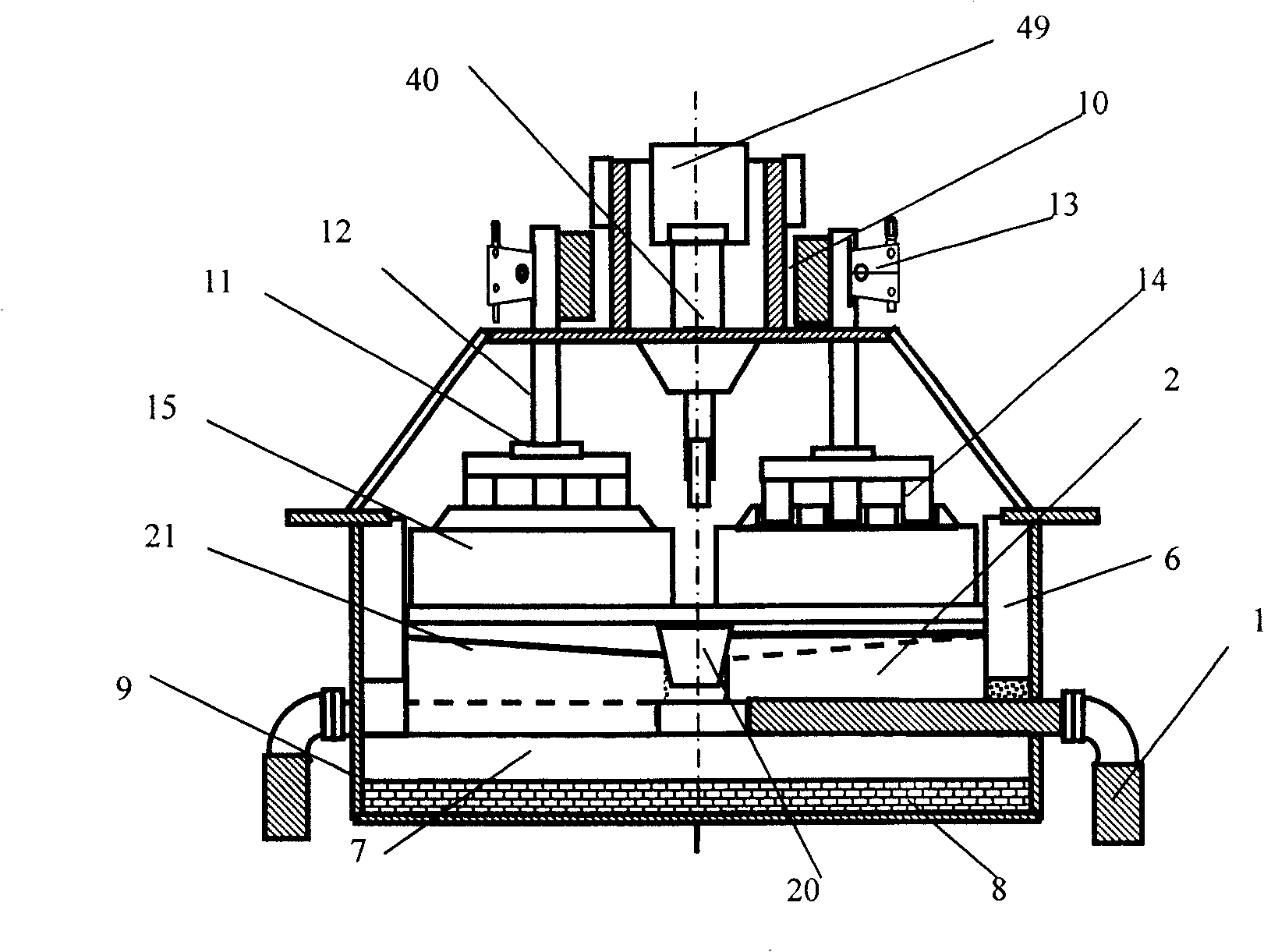

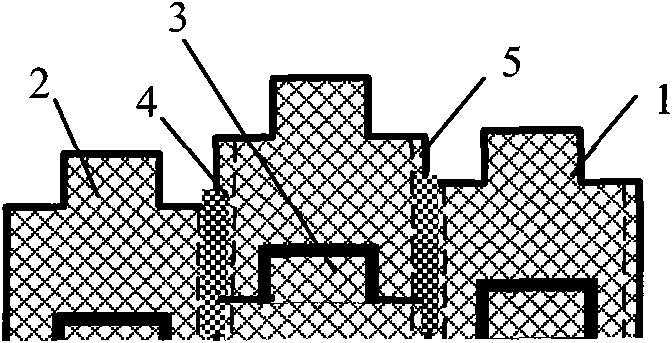

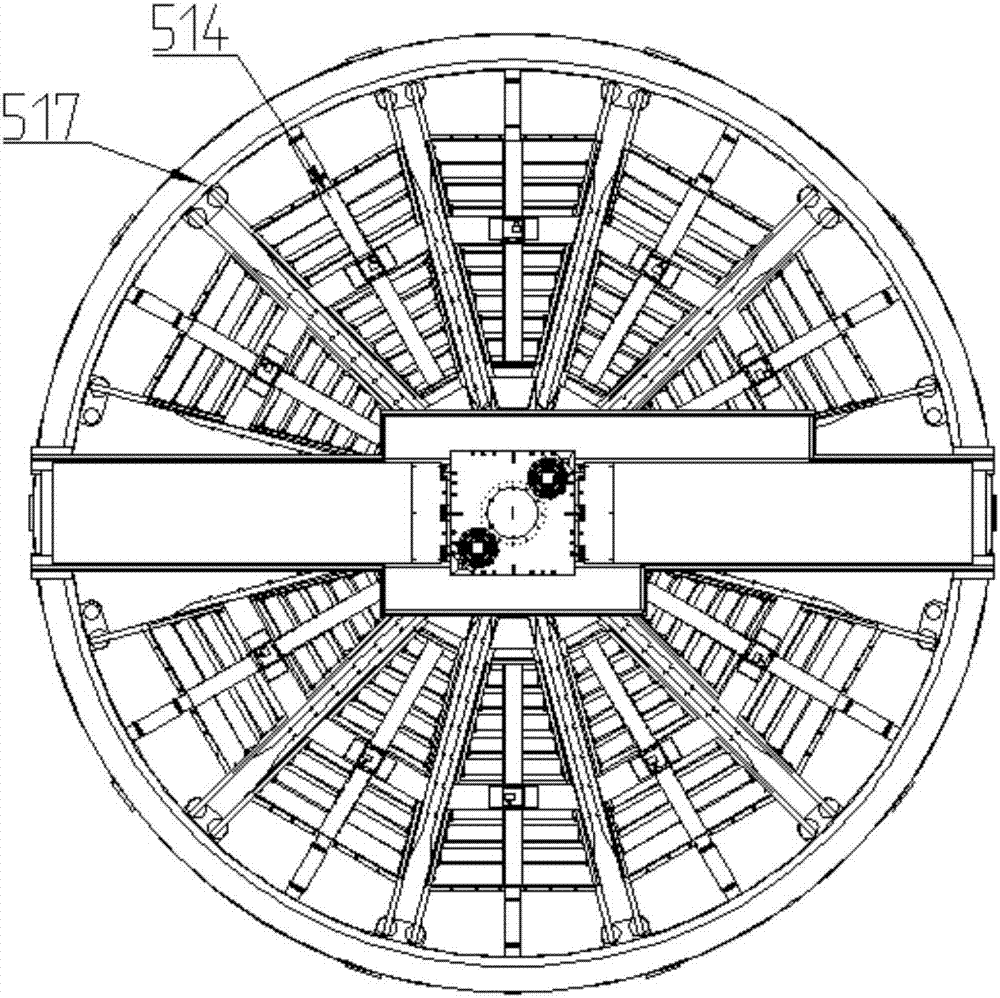

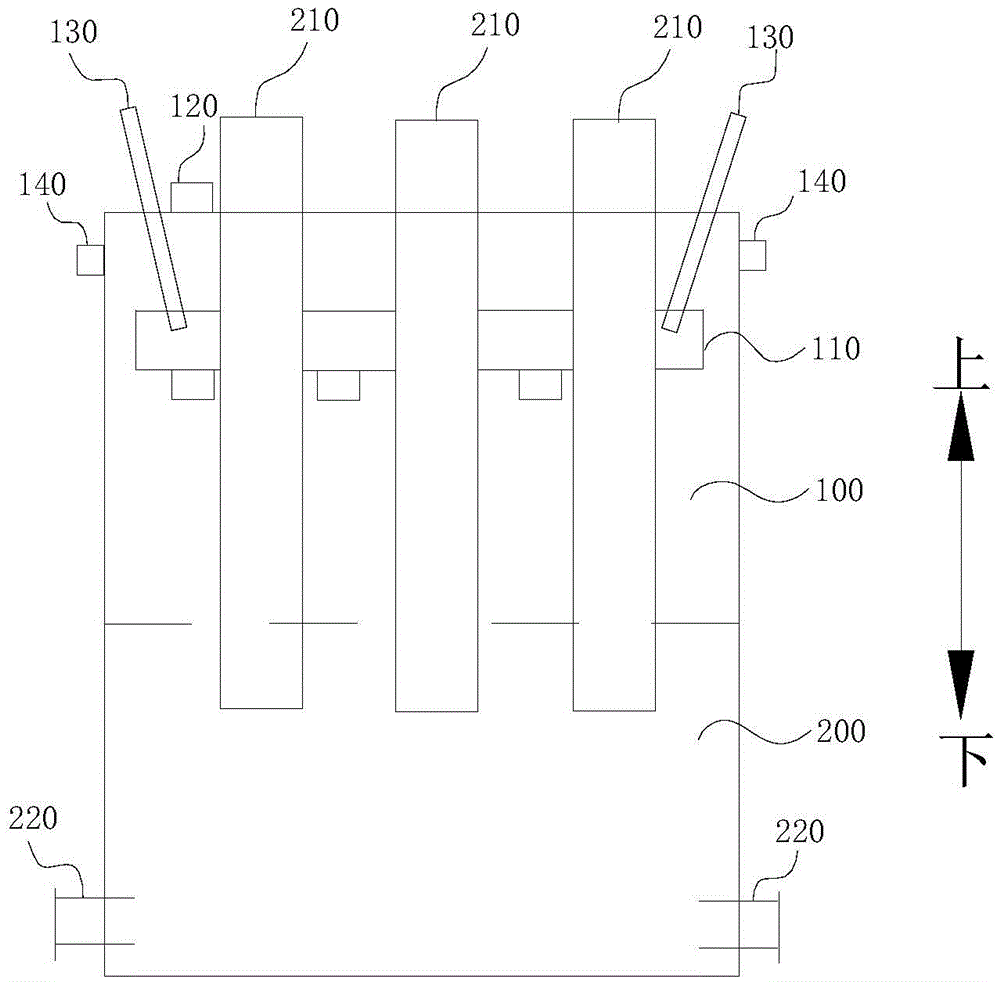

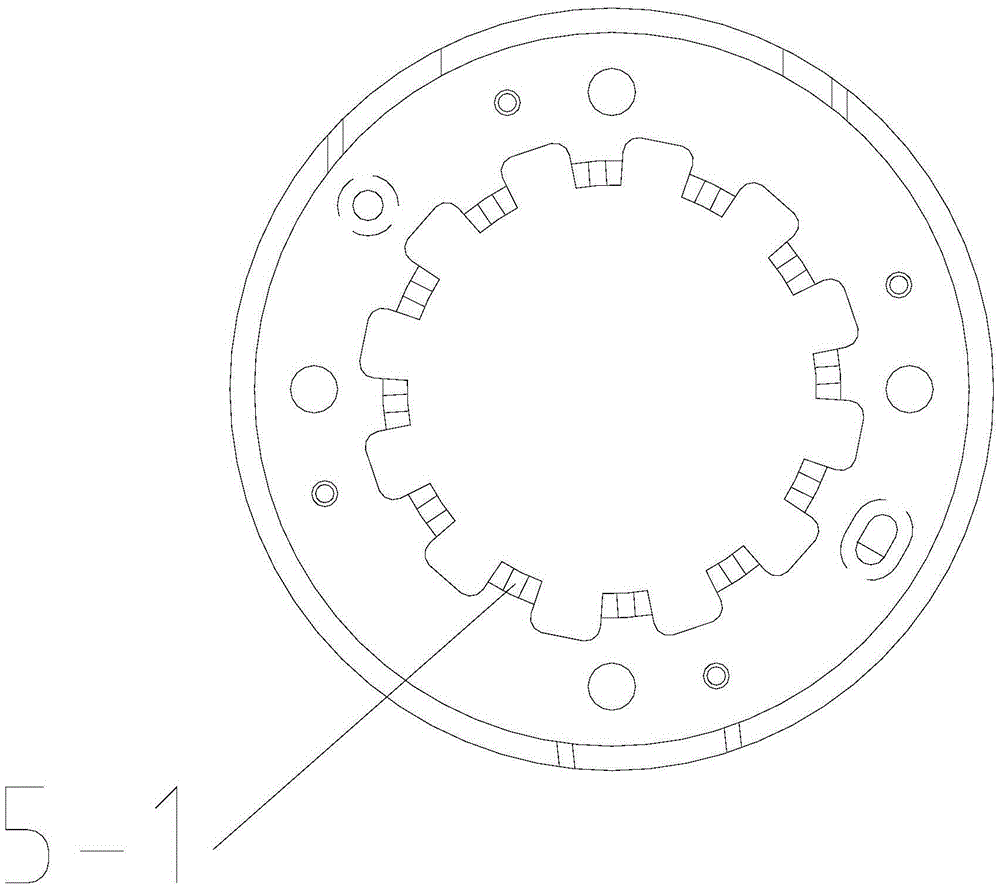

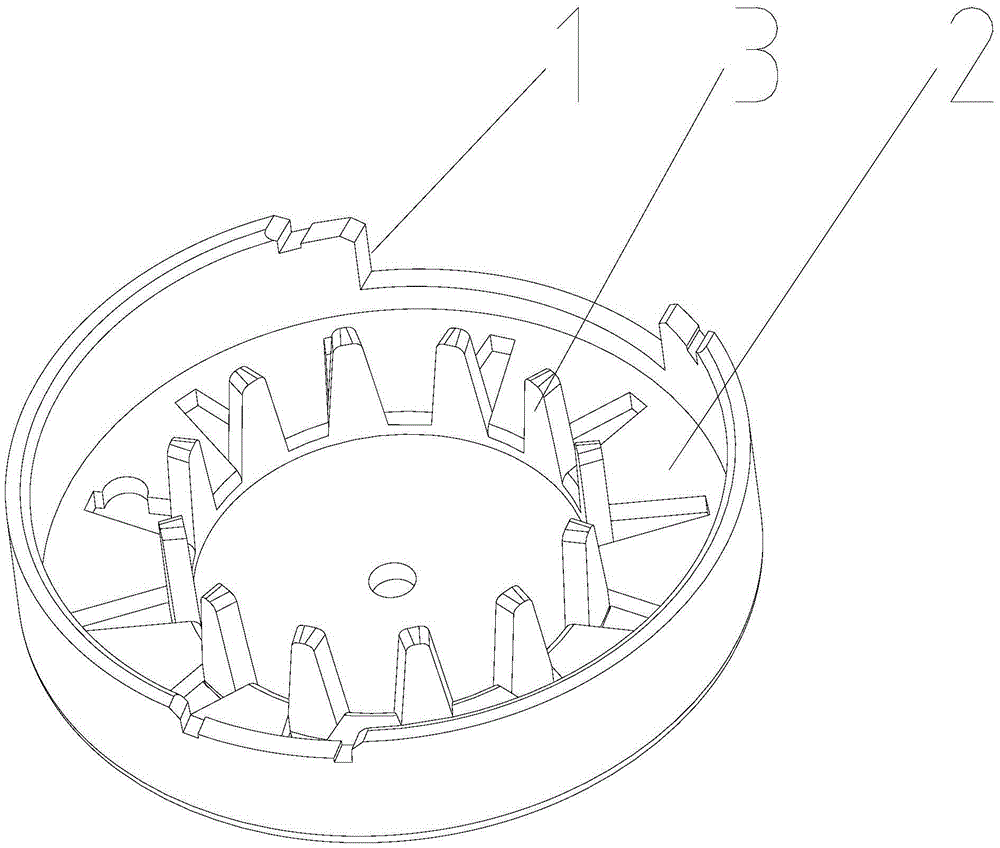

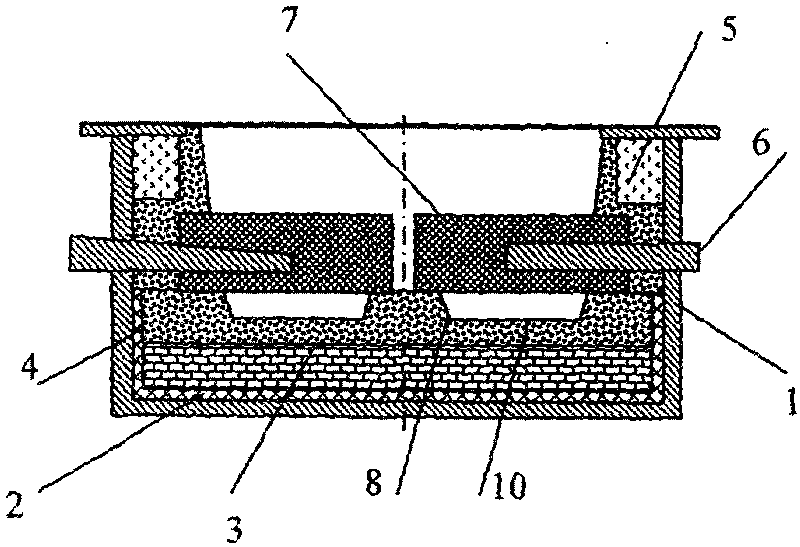

Novel cathode structured aluminum cell with longitudinal and transversal wave damping functions

The invention relates to a novel cathode structure aluminum electrolysis bath with longitudinal and transverse wave decreasing functions, which comprises an electrolysis bath shell, an electrolysis bath lining, a fire-resisting material, a cathode carbon block, a lining carbon brick, carbon tamping paste, fire-resisting concrete, and a cathode carbon bar. The cathode structure aluminum electrolysis bath is characterized in that the top surface of the cathode carbon block is provided with more than one raised structures each of which is connected with the cathode carbon block integrally, and the arranging mode of each raised structure is to be parallel to the axial direction of the cathode carbon block, vertical to the axial direction of the cathode block, or adopt a mixed mode of the two. The novel cathode structure aluminum electrolysis bath with the longitudinal and the transverse wave decreasing functions can slow down the flow speed of cathode aluminum fluid in the transverse direction and the longitudinal direction in the electrolysis bath and reduce the fluctuation height of the aluminum fluid surface in the transverse direction and the longitudinal direction, improve the stability of the aluminum fluid surface of aluminum, reduce the solution loss of the aluminum, reduce the electric energy consumption for aluminum electrolysis production, and prolong the service life of the novel cathode structure electrolysis bath.

Owner:SHENYANG BEIYE METALLURGIGAL TECH CO LTD

Process of producing iron alloy with low carbon and chromium

The invention discloses a preparing craft of low-micro carbon chromium iron alloy, which comprises the following steps: 1) loading high carbon chromium iron into medium-frequency induction furnace; melting; heating-up at above 1600 deg.c; pouring into tank; 2) transferring the tank to station; air refining; 3) taking-up oxygen gun; inserting argon oxygen gun into solution liquid level 300-400mm of tank; setting the discharge of oxygen at 300-500 L / min; blowing at 5 min with argon oxygen ratio at 1 : 3; blowing at 5 min with argon oxygen ratio at 1 : 2; blowing at 5 min with argon oxygen ratio at 1 : 1; adding into silicon iron; 4) transferring the tank into vacuum chamber; switching in argon oxygen pipe at the bottom of tank; blowing into argon oxygen mixed gas; controlling the discharge capacity of argon gas at 150-250 L / min, discharge capacity of oxygen at 40-80 L / min, vacuum degree at 5-200Pa and time of air refining at 20-30 min; 5) relieving the vacuum; hanging the tank to casting position; casting; getting the product. The good effect of this invention is: simple producing craft; high productive efficiency; low power; good environment; low cost.

Owner:刘巍

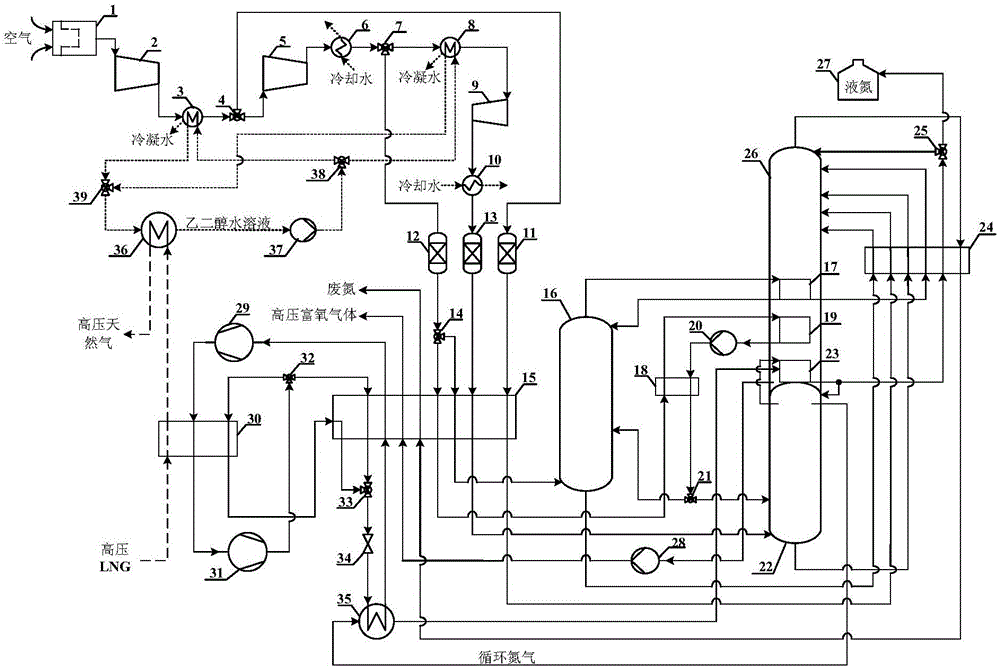

Air separation method utilizing liquefied natural gas cold energy to produce high pressure oxygen rich gas

ActiveCN105783424AReduce power consumptionLow investment costSolidificationLiquefactionHigh pressure oxygenEngineering

The invention belongs to the technical field of liquefied natural gas cold energy utilization, and particularly relates to an air separation method utilizing liquefied natural gas cold energy to produce a high pressure oxygen rich gas. The method specifically comprises the steps of (1) air compression and purification; (2) air liquefaction; (3) air rectification; and (4) LNG cold energy utilization. According to the air separation method, on one hand, a medium pressure tower and a medium pressure air condenser are additionally arranged for performing heat integration with a low pressure tower on the basis of a conventional double-tower air separation process, so that a part of raw air can be separated after being compressed to medium pressure, and the power consumption of an air compressor is greatly reduced; and circulating nitrogen is adopted as an intermediate medium, and the liquefied natural gas cold energy is utilized to condensate nitrogen at the tower top of a high pressure tower to provide cold energy for the air separation process, so that through utilizing the method, a quite high oxygen extraction rate is achieved, the liquefied natural gas is prevented from leaking and entering an air rectification unit, and the safety performance of a system is high.

Owner:JINAN UNIVERSITY

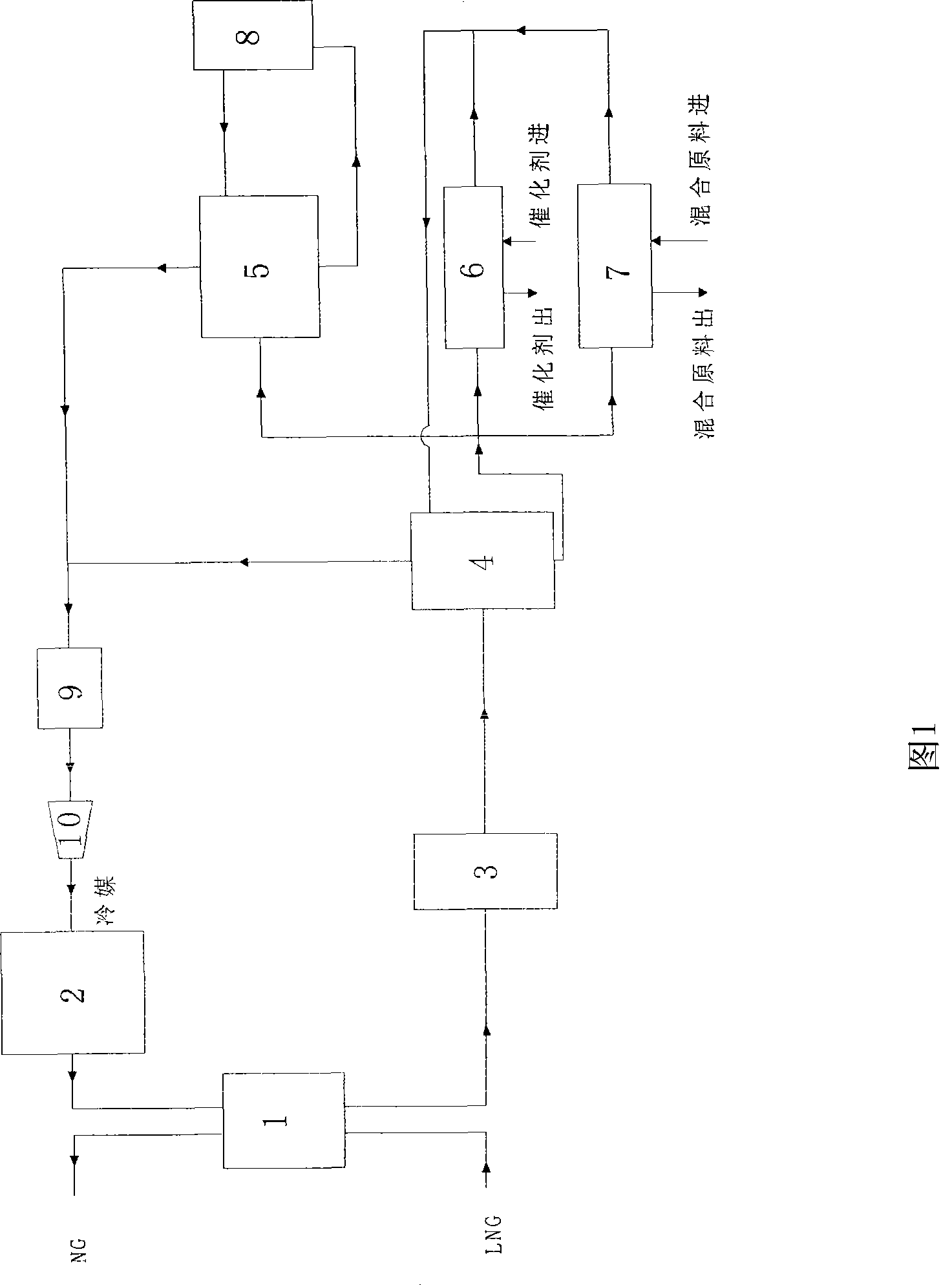

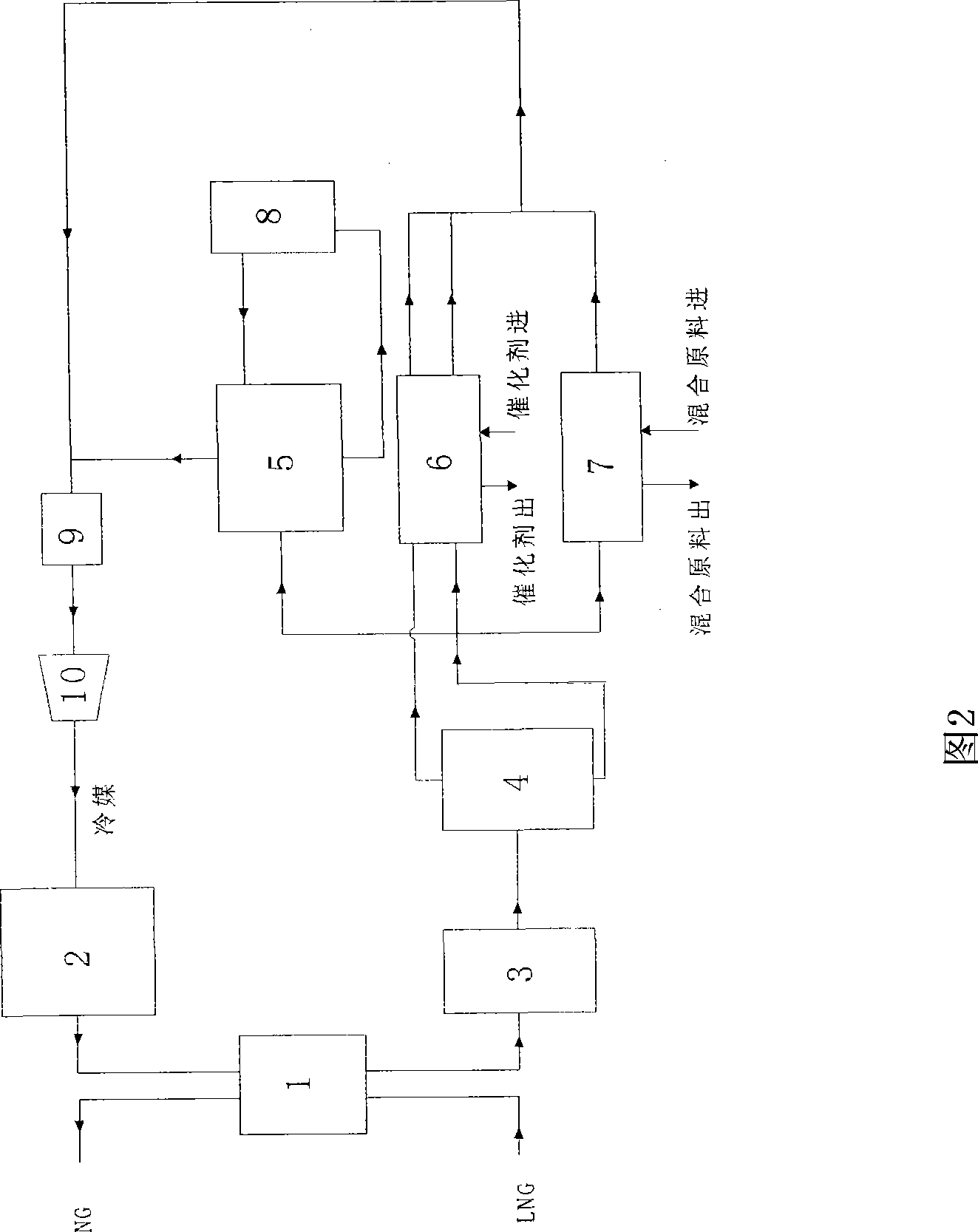

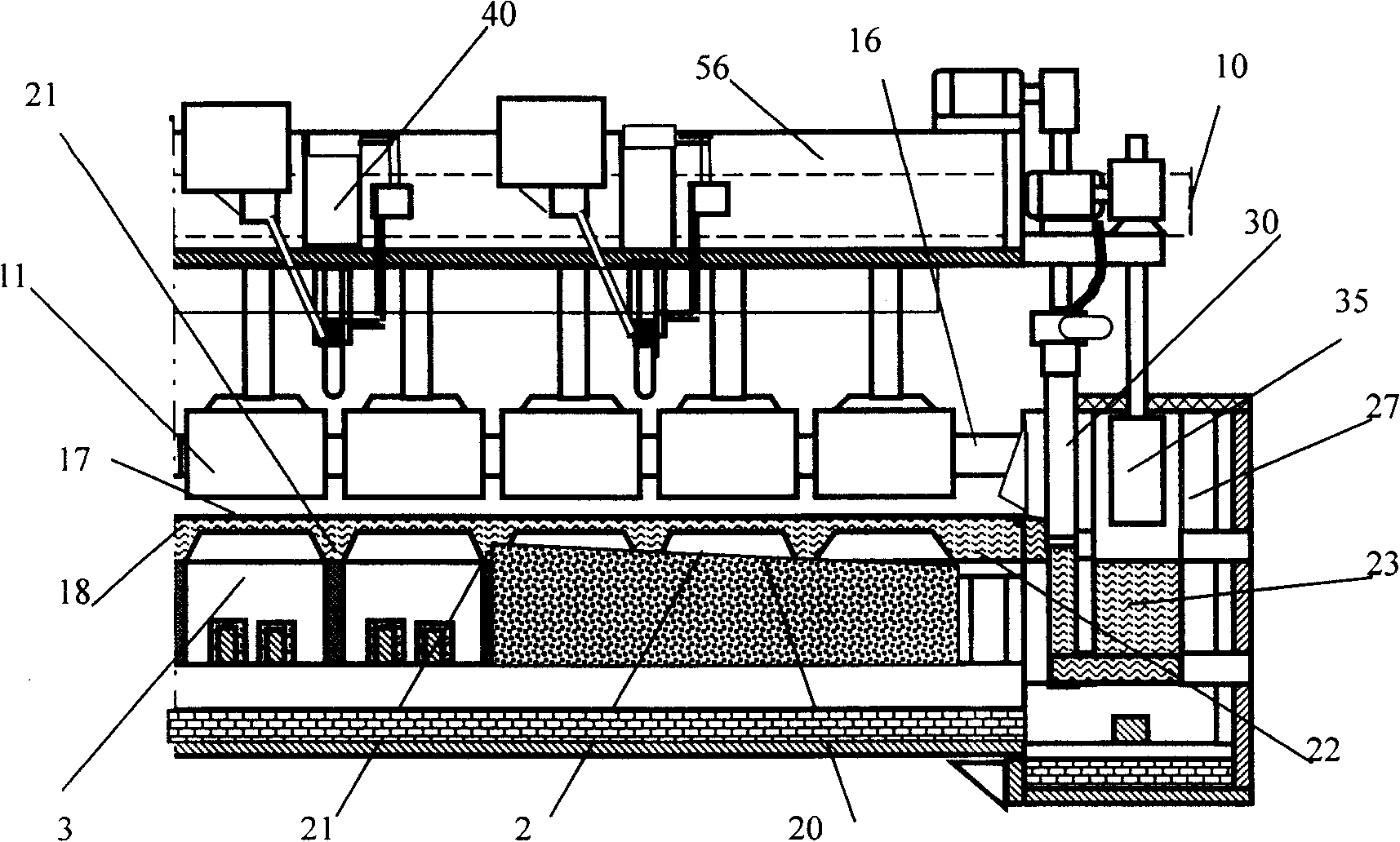

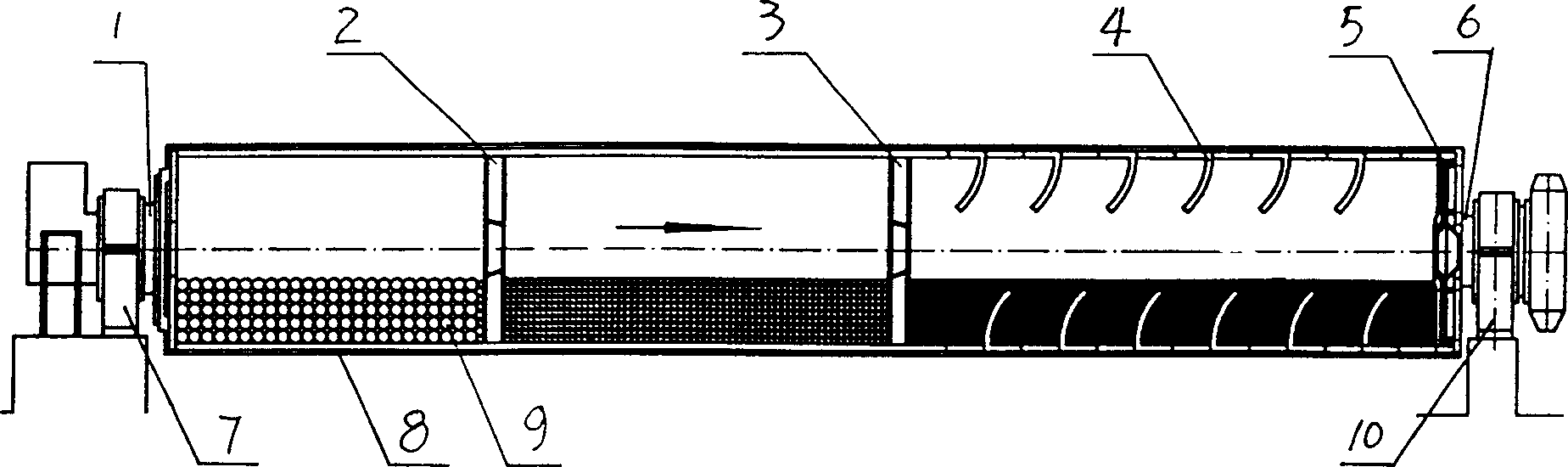

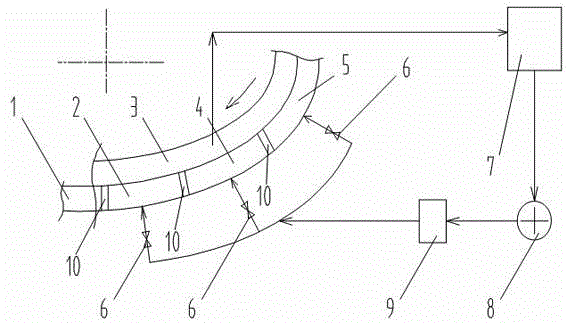

System and method for applying LNG cold energy to butyl rubber synthesis

ActiveCN101423579ASimplify the cooling processReduce production power consumptionPressure vesselsContainer discharging from pressure vesselsProcess engineeringCold medium

The invention relate to a system for synthesizing butyl rubber through LNG cold energy and a method thereof. The system is characterized in that the system comprises an LNG heat exchanger 1, a gaseous cold medium buffer tank 2, a liquid cold medium storage tank 3, a flash tank A-4, a flash tank B-5, a catalyst heat exchanger 6, a material heat exchanger 7, a polymerizer heat exchanger 8, an air temperature device 9 and a compressor 10; the method comprises the following steps: a cold medium such as ethane or ethene which meets the requirement of a butyl rubber synthesizing process and an LNG interface condition is selected; low-temperature cold energy contained in the LNG is permuted through the cold medium; and the low-temperature cold energy in the cold medium is used for cooling a catalyst solution and a mixed material and removing heat of polymerization reaction through corresponding heat exchange equipment so as to meet the requirements of the butyl rubber synthesizing process on temperature and cold quantity.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Energy-saving type low voltage set aluminum cell

An energy-conservation low-voltage set aluminum electrolytic bath has a structure that a bath structure is provided with a cut-off device which can adjust the height of an interface of an aluminum liquid layer generated inside the electrolytic bath and can control the flow rate of the aluminum liquid, as well as an aluminum liquid storing tank which can carry out electrode heating for an aluminum liquid inside an aluminum containing tank and ensure that the generated aluminum liquid inside the electrolytic bath flows into the aluminum containing tank through a diversion hole under the control of the aluminum liquid cut-off device. The energy-conservation low-voltage set aluminum electrolytic bath solves the problems that the prior commonly used electrolytic bath can not realize continuous timely discharge and manual adjustment and control of the generated aluminum liquid; meanwhile, a feasible design proposal for the energy-conservation low-voltage set aluminum electrolytic bath is provided in order to realize timely discharge of the generated aluminum liquid inside the electrolytic bath under the condition of an electrolytic operating mode, to eliminate the negative influence on electrolyte height, namely high polar distance and high voltage set caused by a magnetic field and a magnetic rotational flow generated by an aluminum liquid layer, and to reduce the electricity consumption during manufacturing electrolytic aluminum under the condition that the electrolytic bath is in an operating mode of low polar distance and low voltage; moreover, the design proposal for the feasible energy-conservation low-voltage set aluminum electrolytic bath ensures that a voltage of the tank can be set lower than 3.75mV.

Owner:高德金 +1

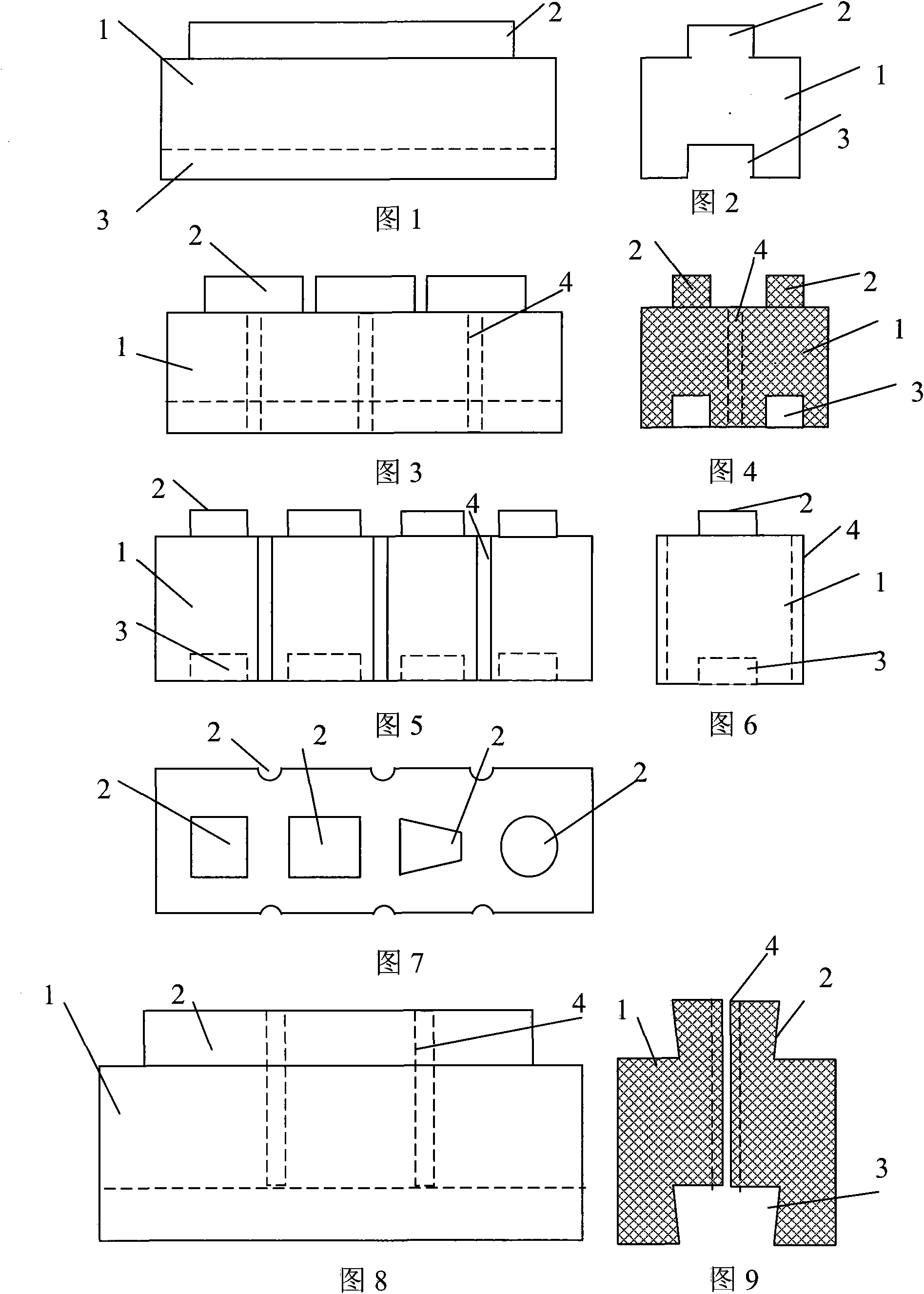

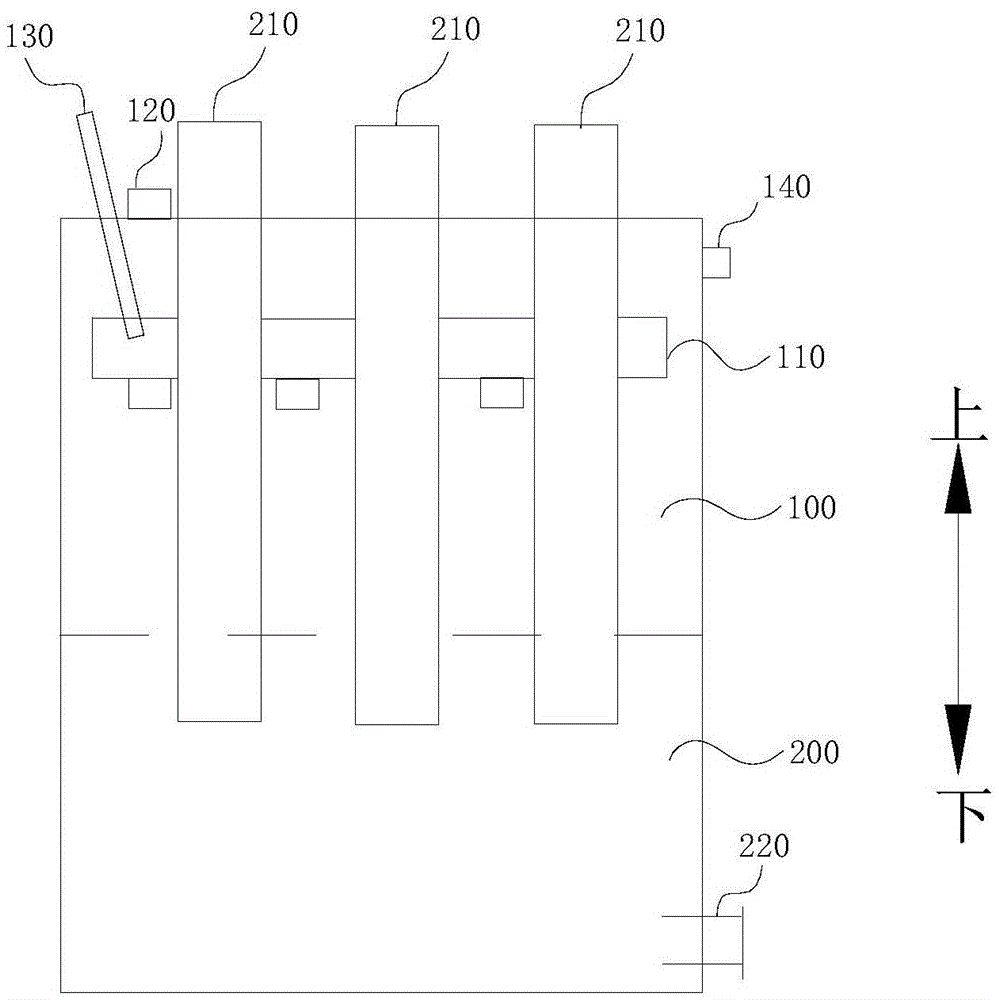

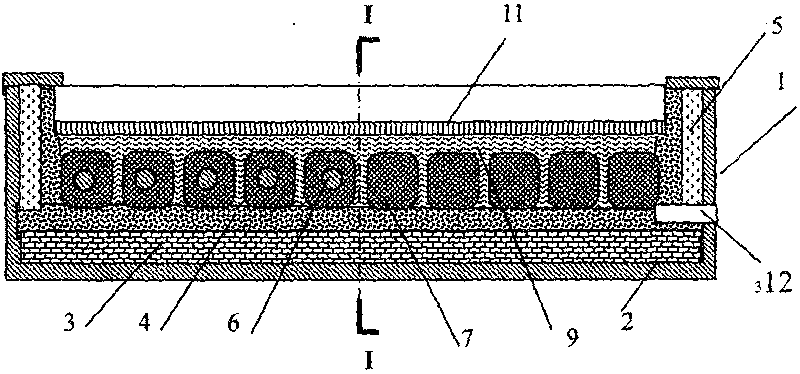

Prebaked anode carbon block structure of aluminum electrolysis cell

The invention discloses a prebaked anode carbon block structure of an aluminum electrolysis cell. An anode carbon block is provided with a convex table and a concave groove which can be used for a metal conductive clamp for conductive connection operation and heightening the bottom carbon block for penetration buckling connection, so that a plurality of anode carbon blocks are assembled and heightened on the aluminum electrolysis cell to form an overall anode structure, and continuous production of the aluminum electrolysis cell can be performed without replacement of an anode or anode scrap. Thus the structure has the advantages of replacing the process mode for eliminating the connection and assembly among an anode steel talon, a ferrophosphorus ring and the anode carbon block, reducing the production cost of relative technical processes, improving the utilization ratio of conductive aluminum of the anode carbon block and reducing the electricity consumption for the production of the electrolytic aluminum and the technical cost.

Owner:高德金

Production technology of high quality steel slag breeze

InactiveCN1718746AReduce energy consumptionReduce manufacturing costRecycling and recovery technologiesMagnetic separationSlagCrusher

A technology for preparing the breeze from steel slag includes such steps as cooling, removing iron by electromagnetic sucking disc, breaking by alligator, removing iron by ferroelectric magnetic iron remover, breaking by impact crusher, removing iron by ferroelectric magnetic iron remover, pulverizing by post grinder, removing iron by ferroelectric magnetic iron remover, pulverizing by rod grinder, removing iron by ferroelectric magnetic iron remover, pulverizing by tube grinder, and removing iron by iron removing system. The product has low content of Fe and large specific surface area.

Owner:WUHAN UNIV OF TECH

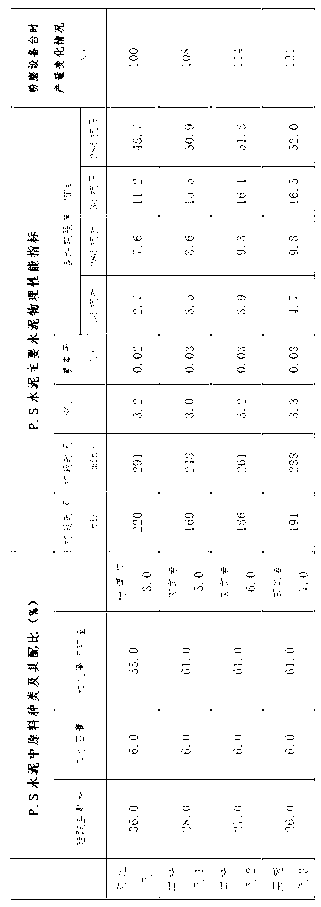

Catalyst for producing maleic anhydrid(e) by benzene gas-phase oxidation with high load and high yield

InactiveCN101284242BReduce production power consumptionIncrease production capacityOrganic chemistryPhysical/chemical process catalystsRare-earth elementGas phase

The invention relates to a catalyst for manufacturing maleic anhydride through the high-load and high-yield benzene gas-phase oxidation. A fixed-bed tubular reactor sequentially comprises an A section and a B section which are composed of catalysts with different performances along the inlet direction of reaction mixture gas; the A section is 40 to 60 percent of the total bed height, and the B section is 60 to 40 percent of the total bed height. The catalyst in the A section has the active phase composition that the ratio of V2O5:MoO3:P2O5:Na2O:NiO:Re2O3 equals to 1:(0.4 to 0.9):(0.01 to 0.08):(0.05 to 0.100):(0.005 to 0.500):(0.0001 to 0.0010), wherein, Re is any two of following rare earth elements that are Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb or Lu. The catalyst in the B section has the active phase composition that the proportion of the Re2O3 is 2 to 3 times of that of the Re2O3 in the A section, the proportion of the P2O5 is (0.005 to 0.040)mol, and the proportions of otheroxides are the same with that in the A section. The catalyst can lead maleic anhydride production equipment to increase about 25 percent production capacity without increasing any investment, and thebenzene consumption and the energy consumption can be obviously reduced.

Owner:TIANJIN BOHUA ZHONGHE CHEM +1

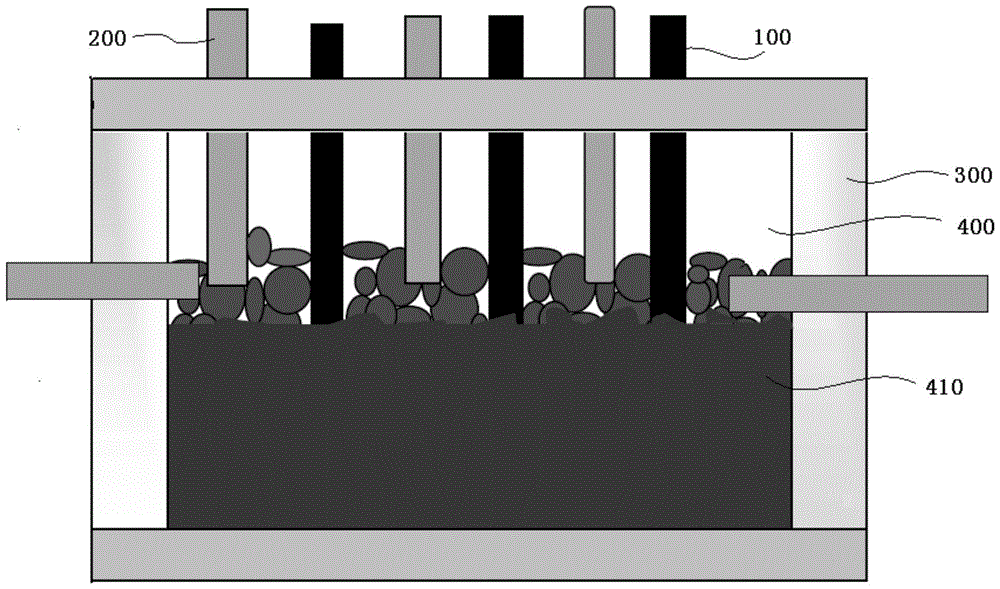

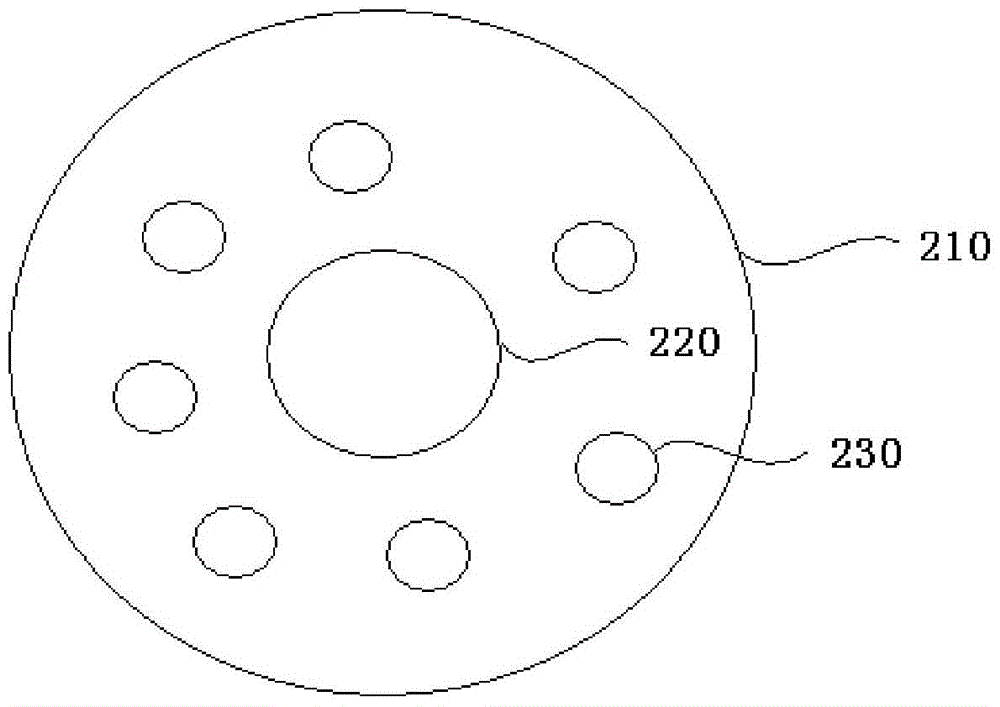

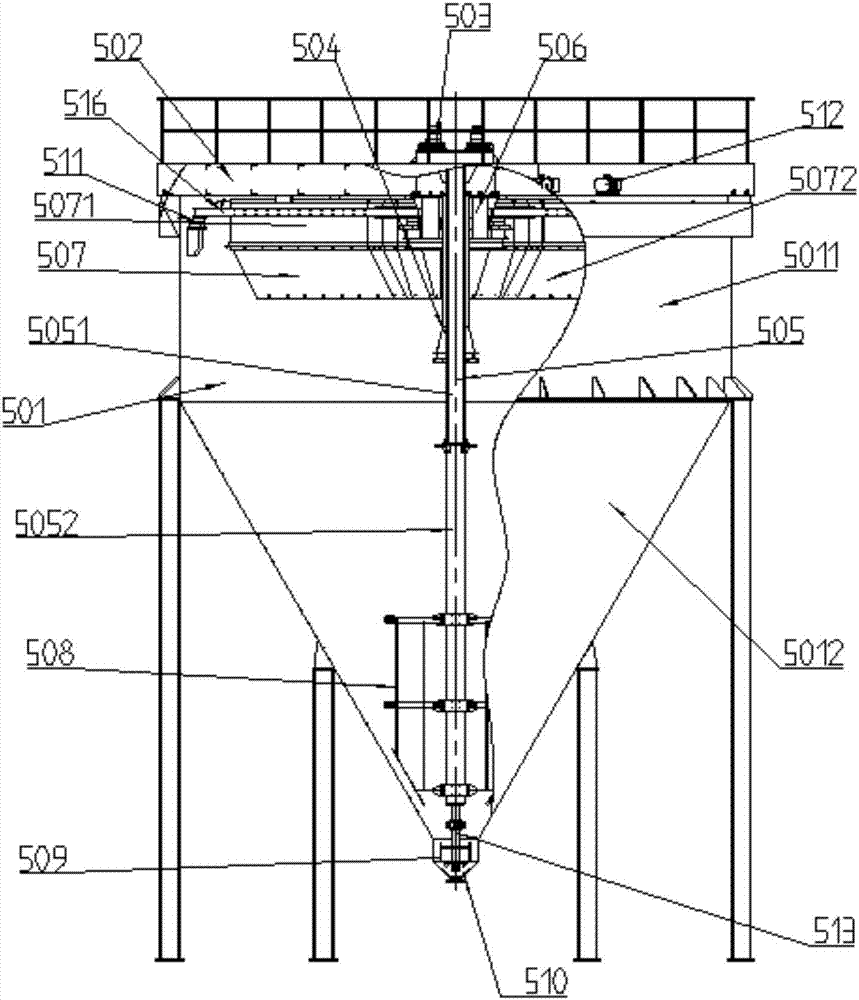

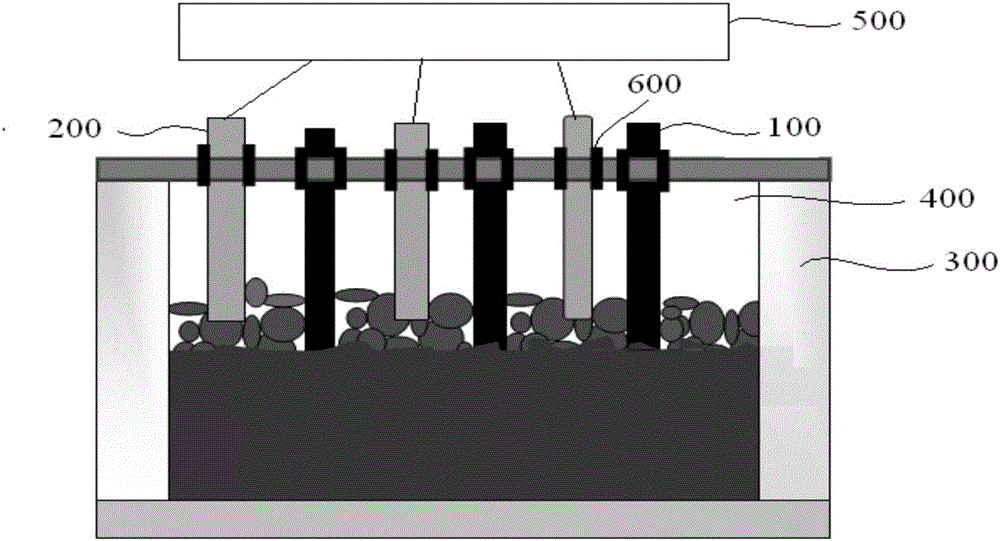

Calcium carbide furnace and method for preparing calcium carbide

The invention discloses a calcium carbide furnace and a method for preparing calcium carbide. The calcium carbide furnace comprises a furnace body, a plurality of electrodes and a plurality of spray guns. A calcium carbide production space is defined in the furnace body. The electrodes are embedded in the calcium carbide production space through the top wall and / or the side wall of the furnace body and are suitable for providing heat for the calcium carbide production space. The spray guns are embedded in the calcium carbide production space through the top wall and / or the side wall of the furnace body and are suitable for providing coal dust and oxygen for the calcium carbide production space so that heat generated through combustion of the coal dust and the oxygen can be supplied to the calcium carbide production space. Due to the fact that the spray guns are reasonably arranged between the electrodes on the top wall and / or the side wall of the furnace body of the calcium carbide furnace, heat in the calcium carbide furnace is evenly distributed.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

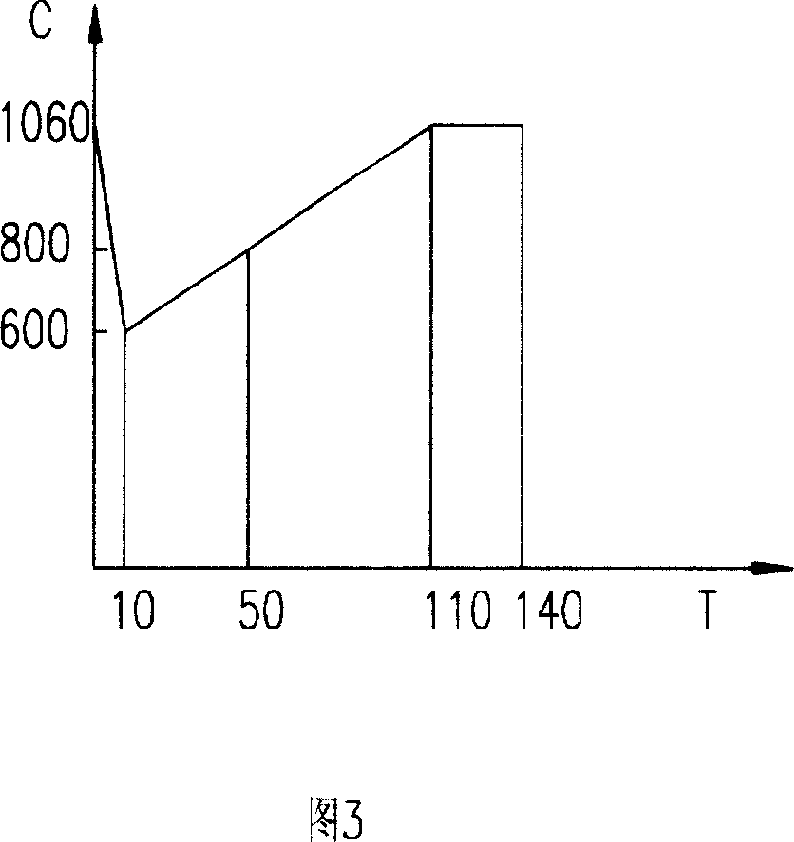

Heat treatment device of scissors products and its method

InactiveCN1948518ANo oxidationNo decarbonizationFurnace typesHeat treatment process controlElectricityControl system

The invention discloses a method and devices of vacuum heat treatment for shear productions. A furnace of heat treatment with three-cell vacuum, a standard closed loop control system and intelligent controlling are adopted to guarantee high craft accuracy. The method can efficiently solve problems of deficient finish and hardness to meet the requirements including sharp cutting edge, non-wearing and non-tipping. Processed by vacuum heat treatment, shears have much strongpoint including non-oxidation, non-decarburizing, good surface craft, minute deforming, excellent integrated mechanical property of heat treatment and long operating life. The method guarantees finish and hardness of shears and meets the requirements of sharp cutting edge, non-wearing and non-tipping. Compared with existing techniques, the method can reduce the power consumption of production, revive partial contradiction of using electricity, reduce cost of productions, advance performance and lifespan of productions, save energy sources and improve efficiency of productions.

Owner:李积回

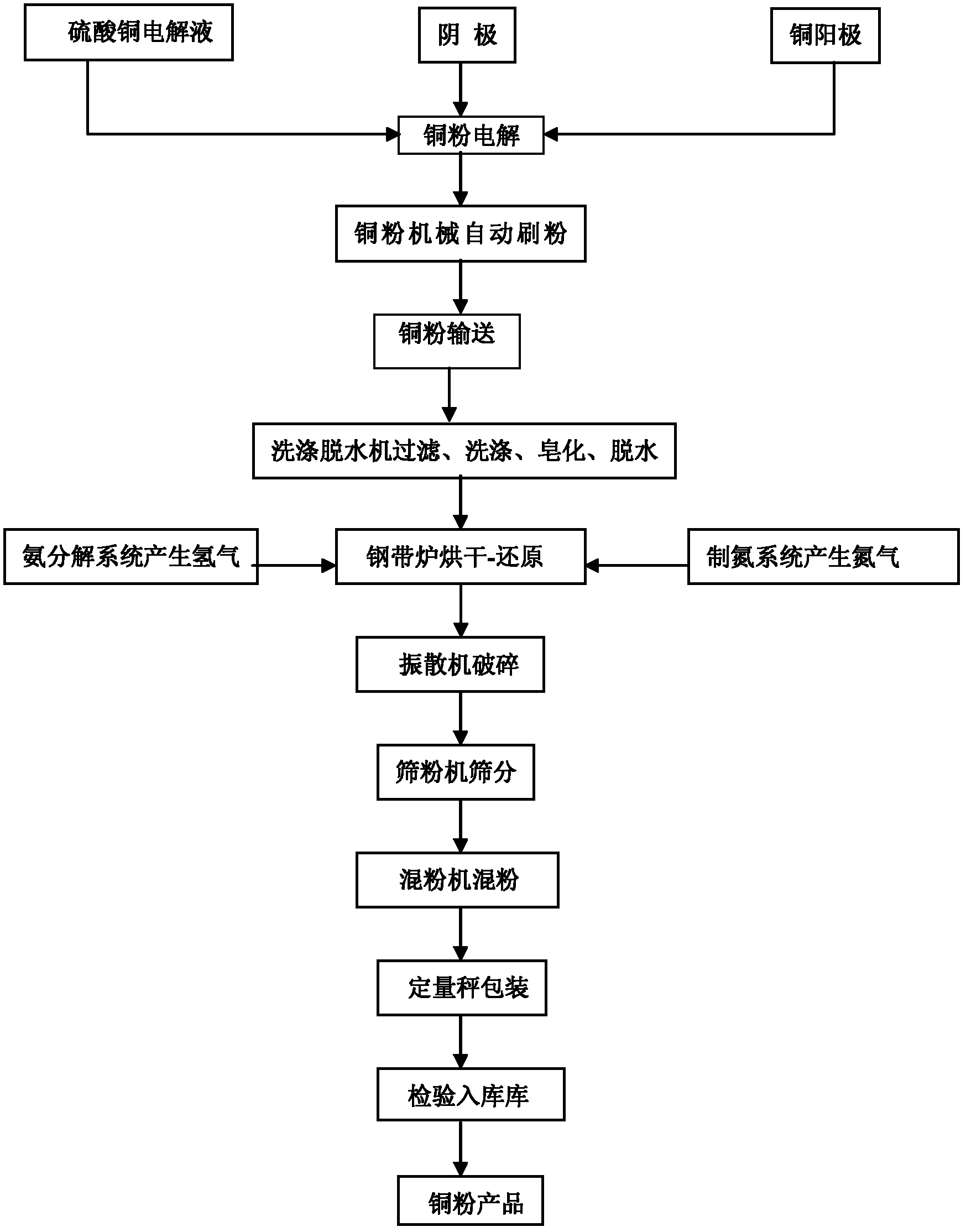

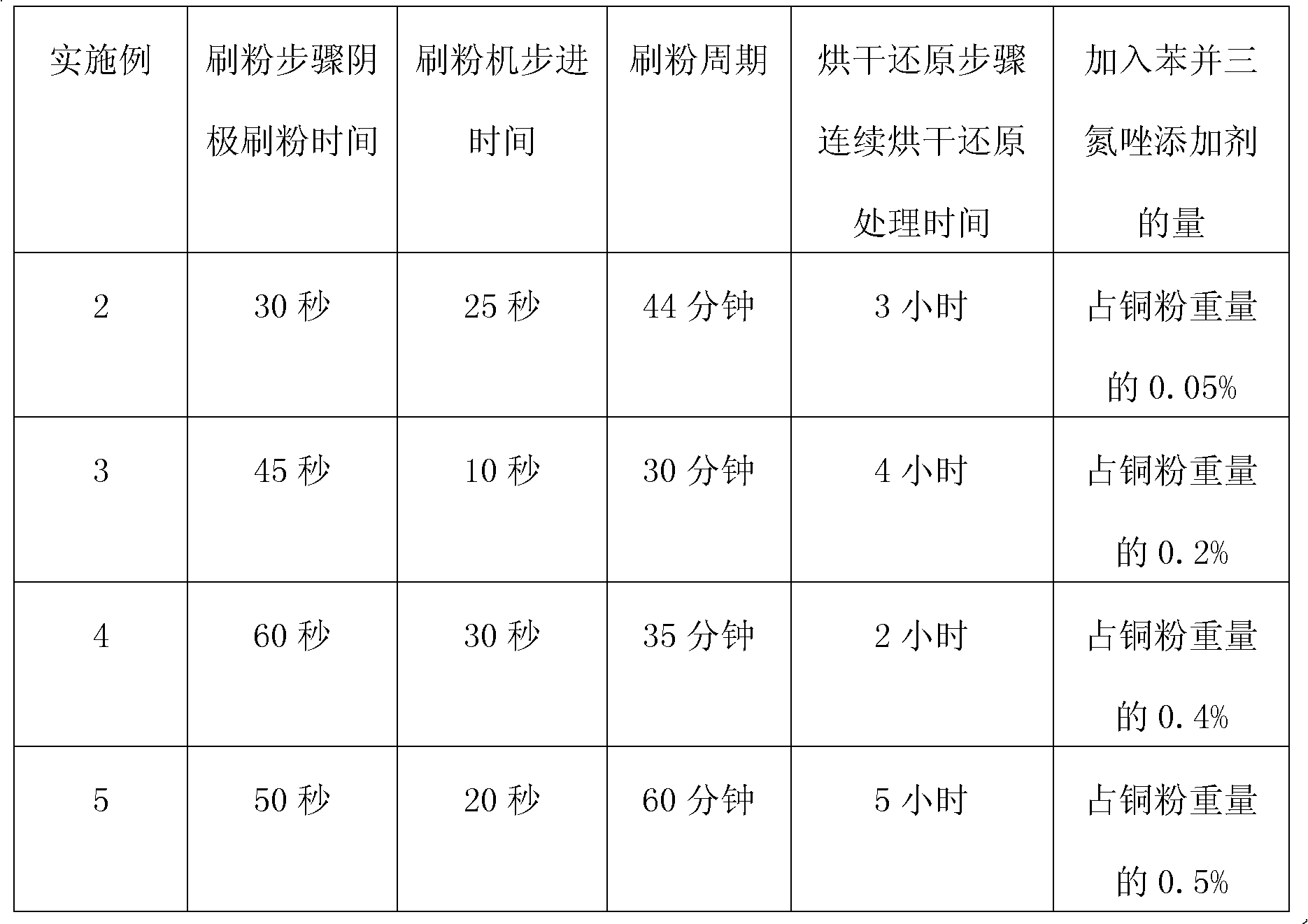

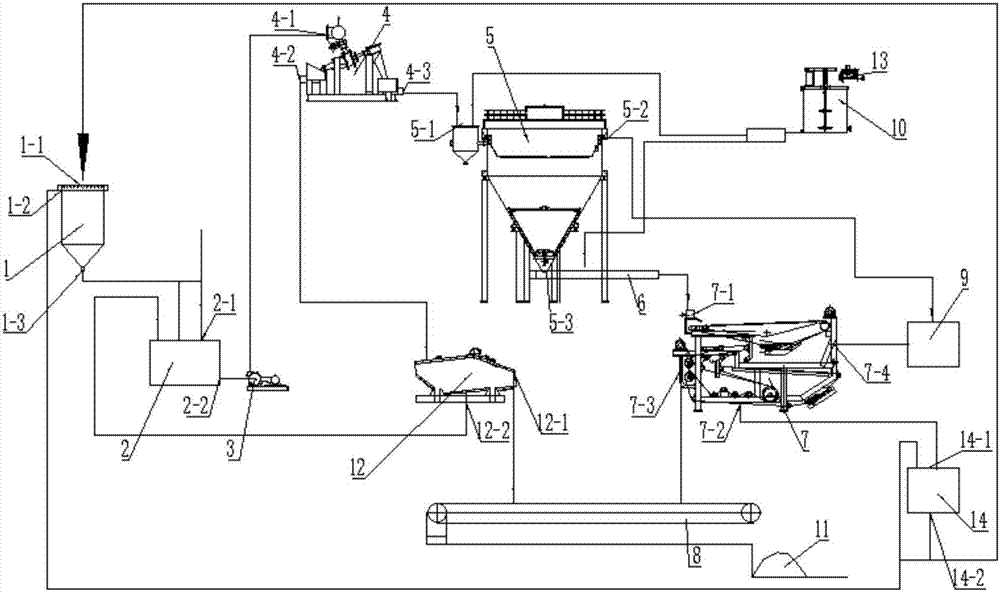

Electrolytic copper-powder-processing technique

An electrolytic copper-powder-processing technique includes electrolyzing, brushing, washing and dehydrating, roasting, restoring, grinding, sieving and other steps. An automatic brushing machine conducts brushing, negative electrode brushing format is two times up and two times down, brushing time is 20-60 seconds, brushing machine steeping time is controlled within 10-30 seconds, and brushing cycle is 30-60 minutes. Copper powder is conveyed to a washing dehydrating machine through an industrial hose pump. The washing dehydrating machine integrates filtering, washing, saponifying and dehydrating for the washing dehydrating step. The electrolytic copper-powder-processing technique achieves technique link of copper powder conveying, washing, dehydrating, roasting, restoring, sieving, mixing and packaging, greatly shortens technique process, achieves high automation degree, and reaches international advanced level in cleaning production, environment protection, resource composite recycling and the like.

Owner:CHONGQING YOUYAN ZHONGYE NEW MATERIAL

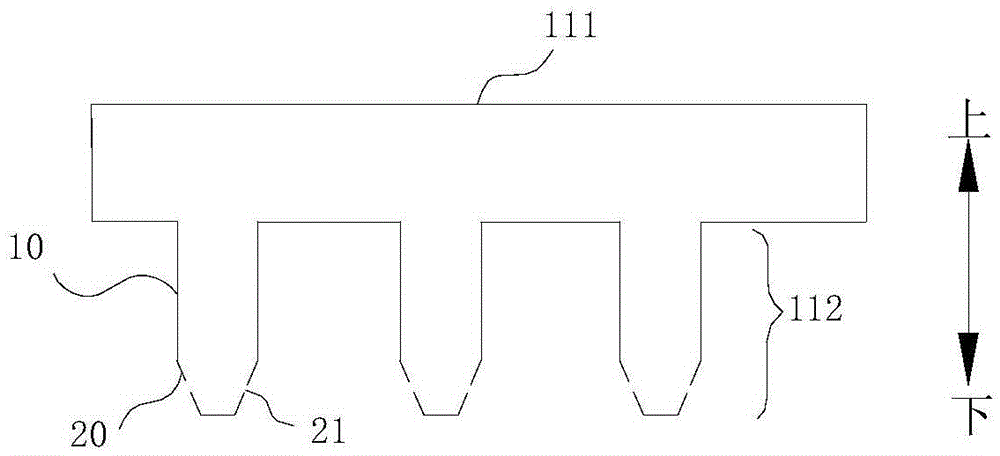

Mine tailing dry discharge system and method

PendingCN107188388AReduce production power consumptionReduce maintenance costsSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFilter cakeCyclone

The invention relates to a mine tailing dry discharge system, which includes a mine supplying apparatus, a concentration cyclone, a thickening machine, a non-power thickener, a high-frequency dewatering screen, a fine granule dewaterer and a belt conveyer. The mine supplying apparatus is connected to the concentration cyclone; an outlet of the concentration cyclone includes a concentrate outlet and a dilute liquid outlet, wherein the concentrate outlet is connected to an inlet of the dewatering screen, and the dilute liquid outlet is connected to an inlet of the thickening machine; an outlet of the dewatering screen includes a dry discharge outlet and a filtrate outlet, wherein the belt conveyer is arranged below the dry discharge outlet, and the filtrate outlet is connected to an inlet of the mine supplying apparatus; an outlet of the thickening machine comprises an upper outlet and a lower outlet, wherein the lower outlet is connected to an inlet of the fine granule dewaterer, and the upper outlet is connected to a water recycling tank of the thickening machine; and the outlet of the fine granule dewaterer includes a filter cake outlet and a press filtration flushing mixed water outlet, wherein the belt conveyer is located below the filter cake outlet and the press filtration flushing mixed water outlet is connected to a water recycling tank of the dewaterer.

Owner:烟台禹顺环保科技有限公司

Calcium carbide furnace and method for preparing calcium carbide

InactiveCN105645411AAvoid uneven heatingReduce energy consumptionChemical industryCalcium carbideCombustionReaction zone

The invention discloses a calcium carbide furnace and a method for preparing calcium carbide. The calcium carbide furnace comprises an oxygen heat reaction zone, a calcium carbide reaction zone, an oxygen-containing gas spray umbrella, a material inlet, an oxygen-containing gas inlet, a tail gas outlet, electrodes and a calcium carbide outlet. The oxygen heat reaction zone and the calcium carbide reaction zone are arranged from top to bottom; the oxygen-containing gas spray umbrella is arranged in the oxygen heat reaction zone; the material inlet is formed in the oxygen heat reaction zone and is formed in a position above the oxygen-containing spray umbrella; the oxygen-containing gas inlet is formed in the oxygen heat reaction zone and is connected with the oxygen-containing gas spray umbrella; the tail gas outlet is formed in the oxygen heat reaction zone; the electrodes are embedded into the calcium carbide reaction zone from a furnace top of the calcium carbide furnace; the calcium carbide outlet is formed in the calcium carbide reaction zone. The calcium carbide furnace and the method have the advantages that oxygen-containing gas can be in sufficient contact with mixed materials, the mixed materials can be heated under combustion effects of partial carbon-containing materials, and accordingly calcium carbide production energy consumption and the production cost can be saved.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Alga iodate evaporating crystallizer

InactiveCN105194900AImprove utilization efficiencyCompact structureEvaporator accessoriesSolution crystallizationEvaporationEngineering

The invention discloses an alga iodate evaporating crystallizer. An evaporating chamber, a heating chamber and a salt foot are connected from top to bottom to form an integrated structure; an alga iodate immersing solution enters from a feeding hole formed in the upper part of the evaporating chamber and then enters the heating chamber; the heating chamber is internally provided with a heating pipe; a steam inlet is formed in the upper part of the heating pipe and a condensed water outlet is formed in the lower part of the heating pipe; steam enters the heating pipe to heat the alga iodate immersing solution; the evaporating chamber is provided with a circulating device for circularly conveying the alga iodate immersing solution from the evaporating chamber to the heating chamber; after a certain temperature is reached, the alga iodate immersing solution is boiled and evaporated; alga iodate is concentrated to separate out the salt foot sinking to the bottom. With the adoption of the alga iodate evaporating crystallizer disclosed by the invention, the evaporating chamber, the heating chamber, the circulating device and the salt foot, which are needed by evaporation and crystallization, are integrated into a whole; the structure is compact; the boundary dimension is reduced by a half when being compared with that of an evaporating device with the same effect, so that the manufacturing cost is greatly saved and the occupied floor area is reduced.

Owner:CHENGDU BAIWEIFANG TRADE

Sintering waste heat power generation exhaust gas recycling utilization system

Provided is a sintering waste heat power generation exhaust gas recycling utilization system. The system is characterized in that the system is provided with a heat exchanger, heat recovery is carried out on annular cooling high-temperature hot exhaust gas collected from an annular cooling high-temperature section hot air hood, at least three air duct partition boards are arranged on an annular cooling air duct, and the air duct partition boards divide the annular cooling air duct into corresponding cooling air ducts. Low-temperature hot exhaust gas produced after heat exchange carried out through the heat exchanger is respectively or simultaneously sent into the cooling air ducts to form a sealed air circulation which collects and sends the low-temperature hot exhaust gas which is obtained through heat exchange and cooling of the annular cooling high-temperature hot exhaust gas into the cooling air ducts. The system has the advantages that the low-temperature hot exhaust gas generated by sintering annular cooling waste heat power generation is recycled, heat energy waste and environment pollution phenomena caused by the exhausted low-temperature hot exhaust gas are eliminated, working environment of workers is substantially improved, sintering annular cooling waste heat power generation amount can be improved by 30% through collection and recycling of the exhaust gas in power generation, investment cost is significantly reduced, and electricity consumption in production is reduced by 26,880 thousand kw.h per day.

Owner:LIUZHOU IRON & STEEL

Method for producing slag portland cement by basalt in ingredients of cement

The invention discloses a method for producing slag portland cement by basalt in ingredients of cement, and aims to solve the problems of low early strength, low admixing amount of mixed material in cement and high dosage of clinker in the conventional portland cement. The method comprises the following steps: A, grinding portland cement clinker, gypsum and basalt to produce clinker powder by a large roll squeezer and a ball grinder; B, grinding and pelletizing blast furnace slag and gypsum to produce fine slag powder by a slag vertical grinding machine; C, mixing and agitating the clinker powder of which the weight percentage is 35% and the fine slag powder of which the weight percentage is 65% to obtain the slag portland cement through a mixing homogenizer, wherein the weight percentage of each material in the slag portland cement is 5-7% of basalt, 26-28% of portland cement clinker powder, 6% of gypsum and 61% of pelletized blast furnace slag. According to the method disclosed by the invention, the early strength of the slag portland cement is improved; the admixing amount of mixed material in the cement is increased and the dosage of the clinker is reduced.

Owner:嘉峪关祁连山水泥有限公司

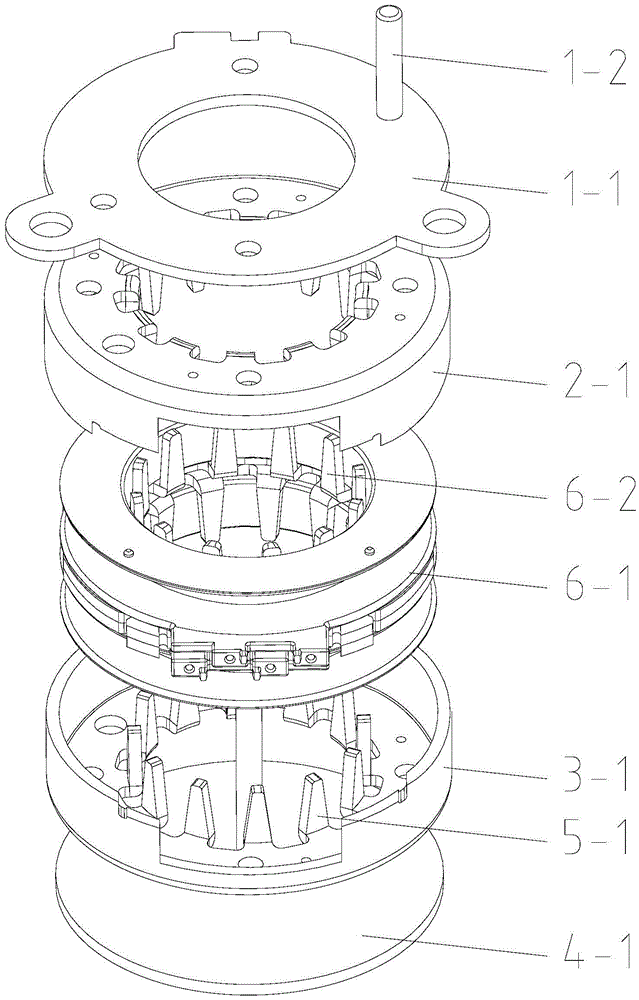

Energy-saving and efficient motor housing with high positioning accuracy

InactiveCN105553164ALess componentsReduce positioning deviationSupports/enclosures/casingsEngineeringMechanical engineering

The invention discloses an energy-saving and efficient motor housing with high positioning accuracy. The motor housing comprises an upper shell and a lower shell, wherein positioning marks are arranged on the upper shell and / or the lower shell; pawls are arranged at the inner sides of the side wall surfaces of the upper shell and the lower shell and are punched from outer circular rings on the side wall surfaces; and the inner circumferences of the outer circular rings are taken as turnover connection edges. The energy-saving and efficient motor housing has the advantages that (1) individual positioning plate and cover board are not needed; component parts of the motor housing are reduced; and the positioning marks are directly arranged on the shell, so that the positioning accuracy of assembly is directly improved; the assembly welding procedure is removed; and the production efficiency is greatly improved; (2) the pawls are directly punched from the outer circular rings on the side wall surfaces of the shells, so that scattered scraps are not generated; and reserved middle disc areas of the side wall surfaces can be taken as fixed points of a motor shaft and can also be integrally removed for other purposes; and (3) compared with an existing product, the material consumption is reduced by 30%-40%; the power consumption for production is reduced by about 60%; and the manufacturing cost is significantly reduced.

Owner:JIANGSU KIND ELECTRIC CO LTD

Calcium carbide furnace

PendingCN106966394AIncrease raw material temperatureReduce power consumption in calcium carbide productionCalcium carbideMagnesiaExhaust gasMagnesium

The invention discloses a calcium carbide furnace which comprises a furnace body, an electrode, a feeding pipe, a tail gas outlet and an oxygen-containing gas inlet. The electrode and the feeding pipe are embedded at the top of the furnace body and extend into a cavity of the furnace body, the cavity of the furnace body is divided into a material layer area, a heat layer area and a reaction area sequentially from top to bottom, and temperature of the heat layer area is 1400-1600 DEG C when the calcium carbide furnace works; the tail gas outlet is arranged on the side wall of the heat layer area of the furnace body, and the oxygen-containing gas inlet is arranged on the side wall of the furnace body and positioned below the tail gas outlet. By arranging the tail gas outlet in the heat layer area, magnesium steam in tail gas is ensured not to be in oxidizing reaction with CO; by arranging the oxygen-containing gas inlet below the tail gas outlet, part of carbon in raw materials is combusted, so that energy consumption during calcium carbide production is lowered.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

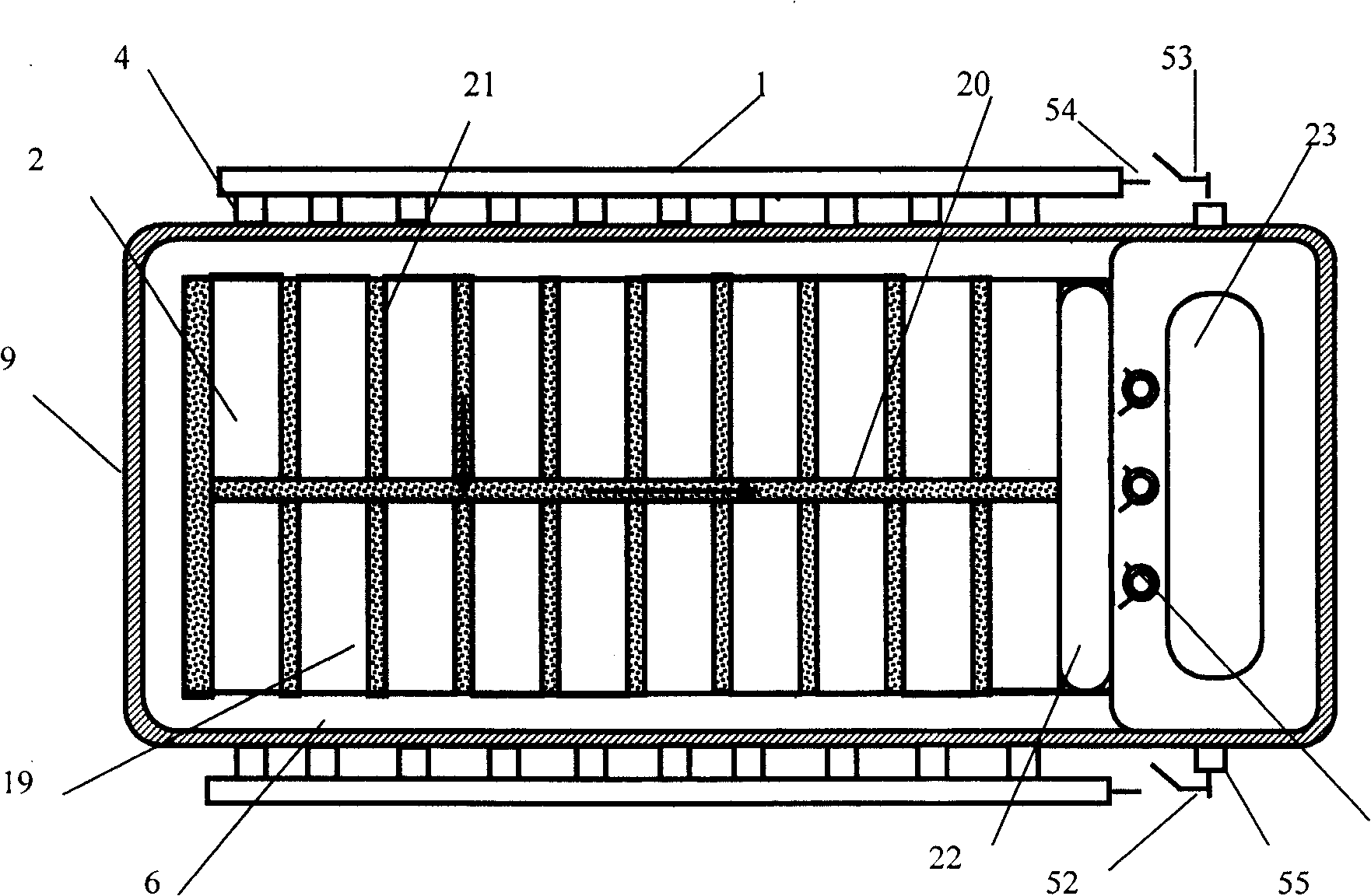

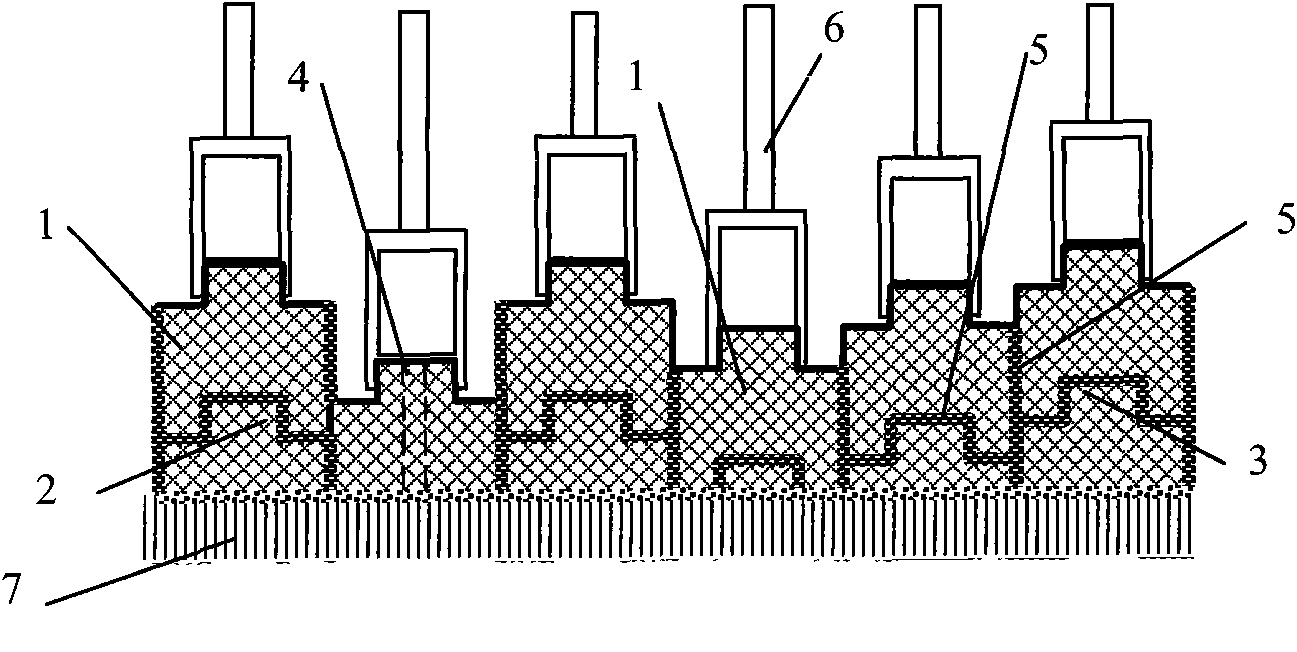

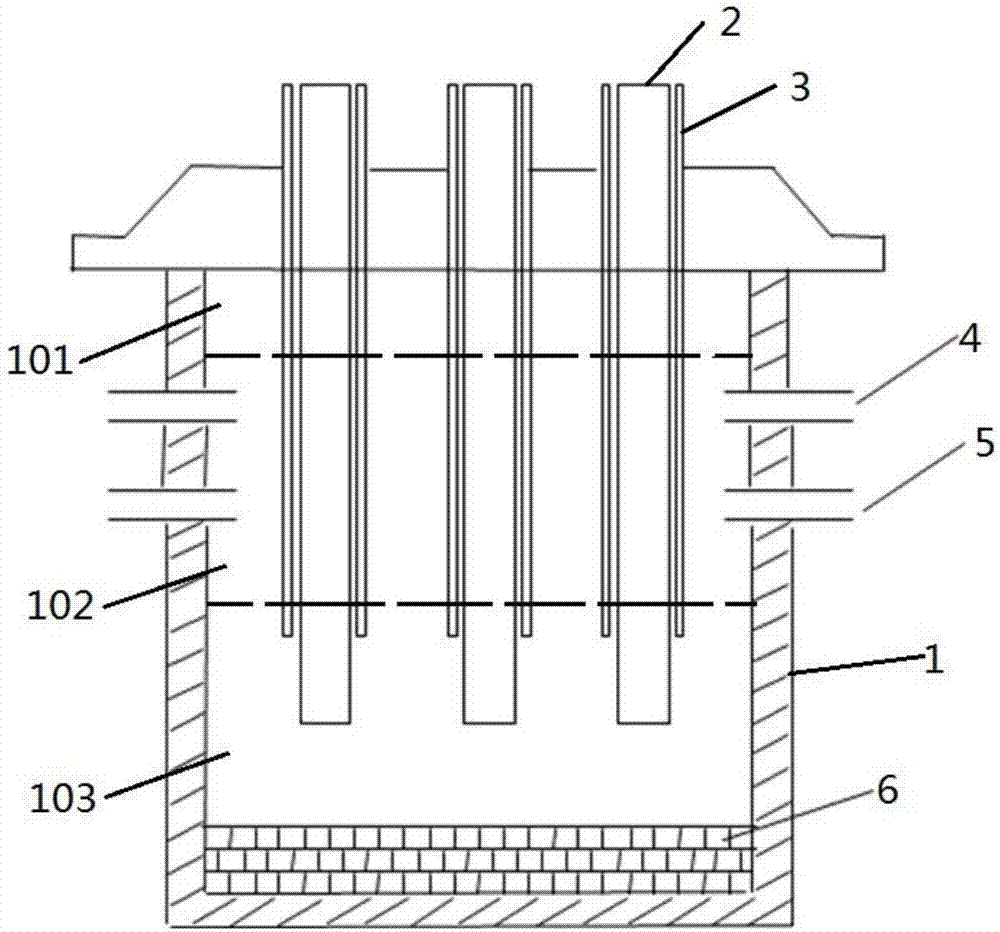

Novel cathode lining structure for aluminum electrolysis cell

The invention relates to a novel cathode lining structure for an aluminum electrolysis cell, which is characterized in that: a cathode block support boss is arranged on an impermeable layer; the bottoms of cathode blocks are arranged on the cathode block support boss; gaps through which aluminum liquid can pass up and down are reserved among lateral parts of the adjacent cathode blocks; and aluminum liquid circulating grooves are formed among the upper part of the impermeable layer and the bottoms of the cathode blocks. The peripheries of the cathode blocks can be heated by the aluminum liquid in an electrolytic cell bath during aluminum electrolysis production, so that the electrical resistivity of the cathode blocks is reduced, the contact surface areas for conducting current of the cathode blocks and the aluminum liquid are enlarged, and the density of the current conducted by the aluminum liquid is improved; magnetic vortexes of the aluminum liquid, generated on the bottom of the electrolytic cell bath, play a role in clearing and washing away sediments, and simultaneously the cathode blocks can also play a role in blocking the magnetic vortexes of the aluminum liquid above the bottoms of the cathode blocks, so that horizontal fluctuation between the aluminum liquid and an electrolyte interface is reduced, the effects of reducing electrolytic polar distance and setting low voltage are achieved, and the aim of reducing the power consumption in the production of electrolytic aluminum is fulfilled.

Owner:高德金

Carbon deoxidizer and preparation method thereof

ActiveCN103007880AReduce procurement costsContinuous and stable supplyOther chemical processesElectricityReaction temperature

The invention discloses a carbon deoxidizer and a preparation method thereof. The carbon deoxidizer is prepared from the following raw materials in parts by weight: 91-93 parts of C, 2.5-4.5 parts of KOH, 1.5-3.5 parts of NaOH and 1-3 parts of H2O. The method for preparing the carbon deoxidizer comprises the following steps of: 1) mixing; 2) activation; 3) dipping; 4) dehydration; 5) roasting treatment; and 6) packing after the product sample test is approved, thereby obtaining the carbon deoxidizer. The carbon deoxidizer has superstrong overtemperature resurrection property and is improved in deoxidization capacity; simultaneously, the deoxidizer is low in requirement for the starting point of the reaction temperature, so that the production electricity consumption of an enterprise can be reduced to a large extent and the production cost of the product can be saved; and besides, the carbon deoxidizer further has the characteristics of low cost, stable supply, use safety, simplicity in operation and non-pollution emission.

Owner:深圳市海格金谷工业科技有限公司

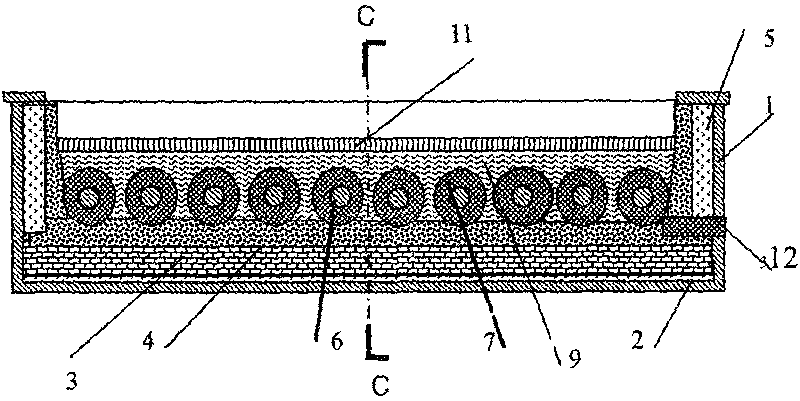

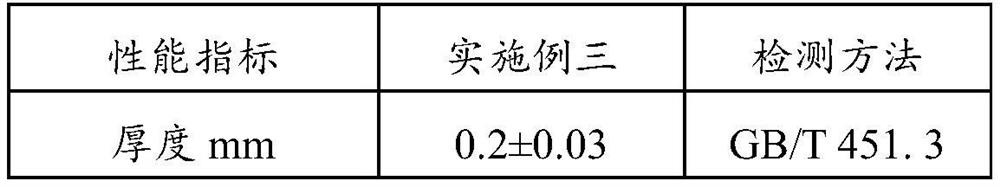

Water-blocking expansion type semi-conductive nylon tape for ultrahigh-voltage cable and preparation method thereof

PendingCN113338048AImprove electrical uniformityReduce surface resistanceClimate change adaptationInsulated cablesFiberElectrical resistance and conductance

The invention discloses a water-blocking expansion type semi-conductive nylon tape for an ultrahigh-voltage cable and a preparation method thereof. The preparation method comprises the following steps that S1, mixed weaving is carried out on metal wires and cellosilk to obtain base cloth; S2, an alcohol diluent, a dispersant, water-absorbent resin, conductive carbon black and an emulsion are uniformly mixed to prepare a water-blocking conductive liquid; and S3, the base cloth obtained in the step S1 is uniformly coated with the water-blocking conductive liquid obtained in the step S2, and then drying is carried out to obtain the water-blocking expansion type semi-conductive nylon tape. The base cloth is formed by blending the metal wires and the cellosilk, the metal wires effectively reduce the surface resistance and the volume resistance of the base cloth, and the semi-conductive performance is improved; and the water-blocking and conductive liquid is prepared by synchronously and uniformly mixing a water-absorbing material and a conductive material with the alcohol diluent, the alcohol diluent and the water-absorbing resin do not absorb, expand and react, so that the serious defects caused when water is used as the diluent in the traditional process are overcome, the prepared water-blocking and conductive liquid can endow the base cloth with semi-conductive performance and water-blocking performance at one time, working procedures are effectively reduced, production power consumption is reduced, and energy conservation and environmental protection are achieved.

Owner:YANG ZHOU TENGFEI ELECTRIC CABLE & APPLIANCE MATERIALS CO LTD

Slag-iron separation promoter as well as preparation method and use method thereof

InactiveCN111593168AIncrease surface tensionOptimizationRecycling and recovery technologiesProcess efficiency improvementIron powderSmelting process

The invention belongs to the technical field of titanium slag smelting, and particularly relates to a slag-iron separation promoter as well as a preparation method and a use method of the slag-iron separation promoter. The slag-iron separation promoter is prepared from the following components in percentage by mass: 70-90 % of iron powder, 5-15 % of coke powder, 2-8 % of magnesium oxide powder, 1-5 % of a binder, and 1-5 % of water. The slag-iron separation promoter is used for slag-iron separation in the titanium slag smelting process, the slag-iron separation time can be effectively shortened, the iron inclusion proportion in slag can be reduced, and the tapping temperature can be reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Low-energy-consumption enamelling process

InactiveCN107025962AAchieve double outputImprove flammabilityApparatus for feeding conductors/cablesInsulating conductors/cablesOrganic solventExhaust gas emissions

The invention discloses a low energy consumption enamelling process, which comprises the following steps: (1) unwinding, using two unwinding devices to unwind the wires to be enamelled on two bobbins; (2) annealing, through annealing The furnace anneals the wires to be enamelled; (3) paints, paints the two wires to be enamelled after annealing through two sets of painting modules; (4) dries, paints The obtained enameled wire is dried through a drying device; (5) cooling, cooling the enameled wire through an air cooling device; (6) lubricating, coating a layer of lubricant on the surface of the enameled wire; (7) winding, winding the enameled wire Winding on the reel appliance; (8) Packaging, weighing and packaging, pasting the product information label, packing into the warehouse and recording; the invention adopts the double-input and double-out enamelling process of wire rods to achieve double output of enameled wire , Improve production efficiency, reduce production power consumption, reduce emissions of organic solvent waste gas, energy saving and environmental protection.

Owner:阿斯塔导线有限公司

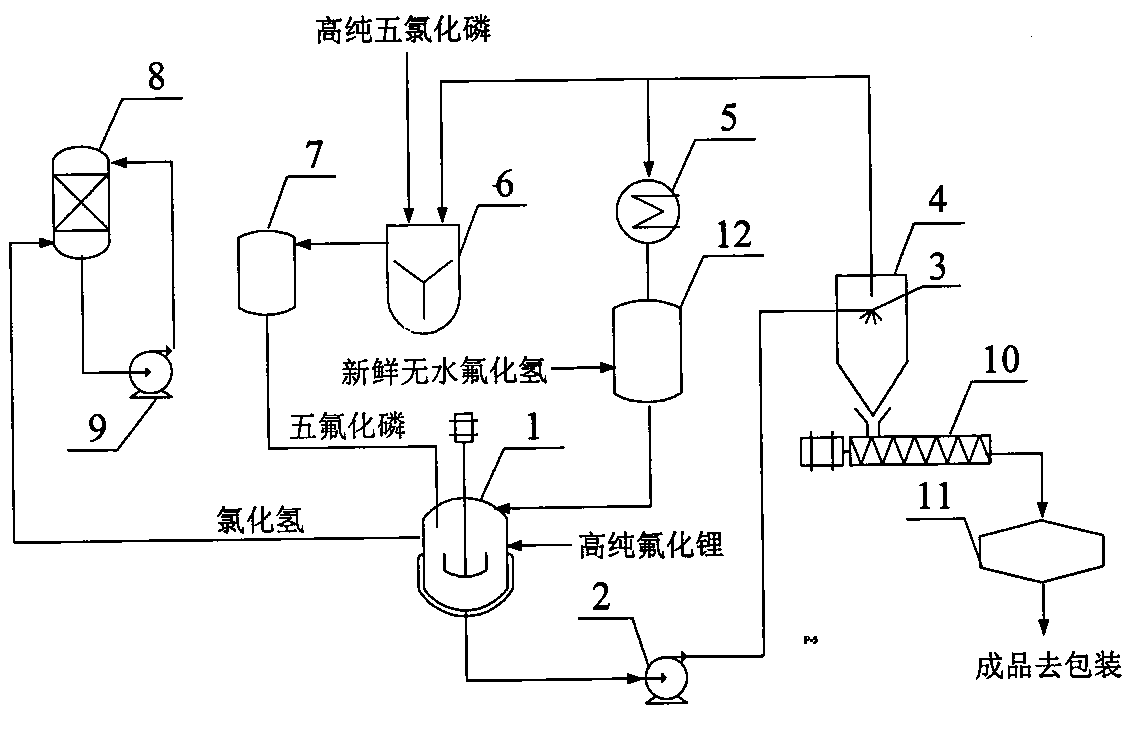

Lithium hexafluorophosphate production plant

ActiveCN106698384BReduce production power consumptionEfficient separationLithium hexafluorophosphatePhosphorus compoundsWork PerformancesMaterial transfer

Owner:JIANGSU JIUJIUJIU TECH

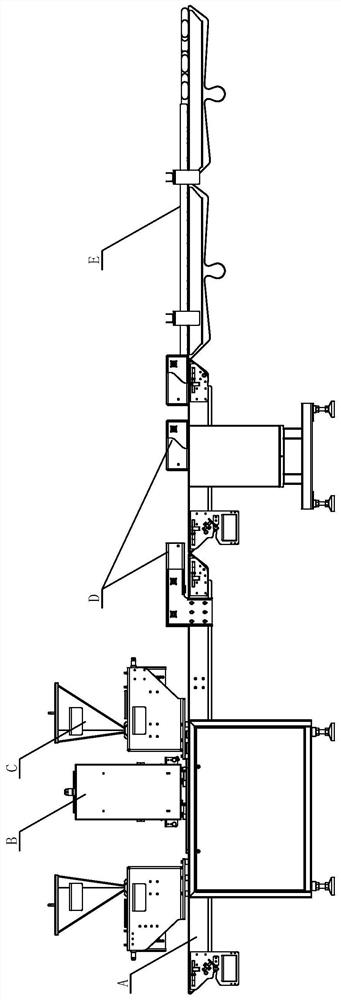

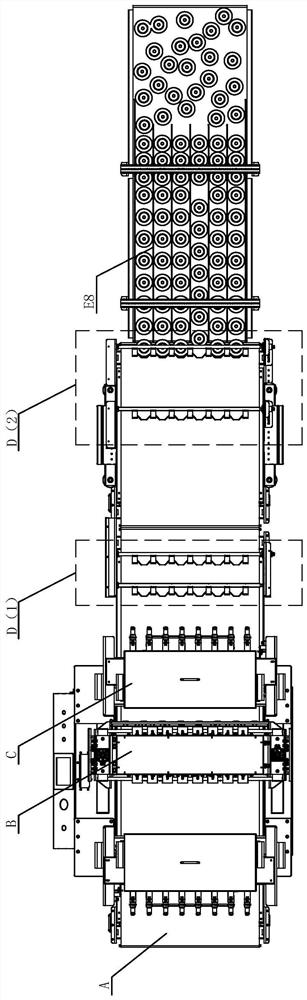

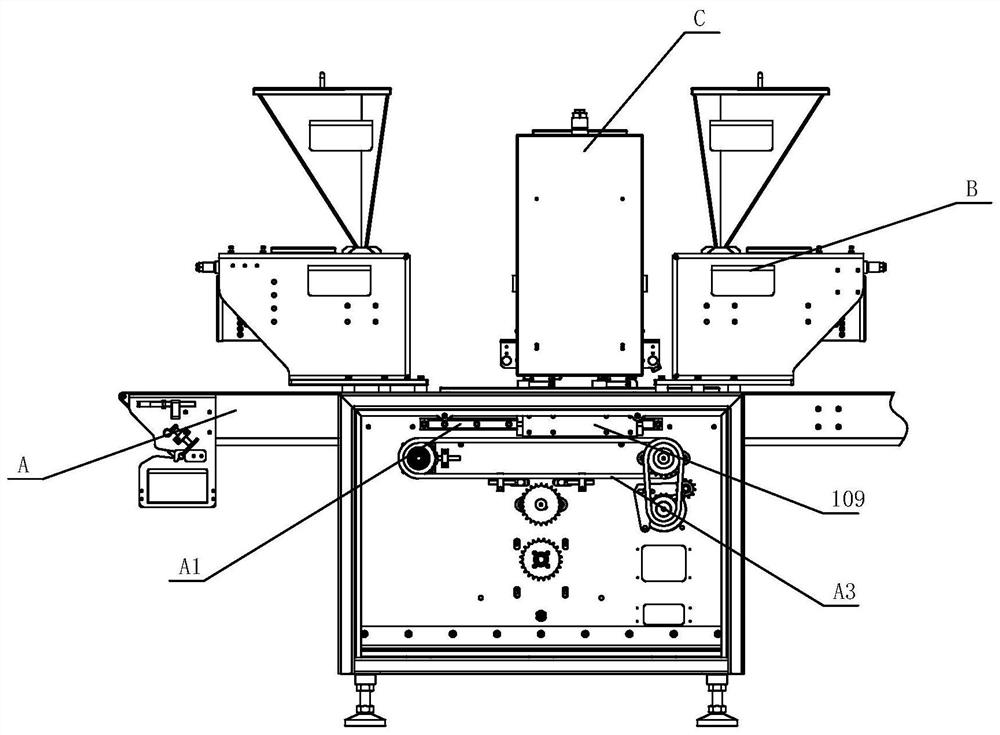

Fully automatic multiple adjustable fluid filler injecting production equipment and filler injecting technology

InactiveCN111670924AImprove machining accuracyHigh degree of automationFood coatingProgramme control in sequence/logic controllersProcess engineeringMechanical engineering

The invention discloses fully automatic multiple adjustable fluid filler injecting production equipment and a filler injecting technology. The filler injecting production equipment comprises a longitudinal queue material adjusting device, a horizontal queue material adjusting device and a filler injecting machine from an input end to an output end, wherein the longitudinal queue material adjustingdevice comprises a dividing device for dividing fed foods into longitudinal queues to be conveyed, the horizontal queue material adjusting device comprises a dividing device for dividing the foods ineach longitudinal queue to enable the foods to be aligned horizontally with the foods in the adjacent longitudinal queues, the filler injecting machine comprises a conveying table of the filler injecting machine, a food filler pumping device, and a food filler injecting device, the conveying table is used for conveying foods to be processed, the food filler pumping device pumps out a filler in the hopper and supplies the filler to the food filler injecting device, and the food filler injecting device is arranged on the conveying table for filler injection on the foods; and the food filler injecting device is provided with a movable driving device for driving the food filler injecting device to simultaneously move along with the conveyer belt of the conveying table while performing fillerinjecting. Full automation is adopted for filler injection on the conveyed foods, so that the working precision and the working efficiency can be improved.

Owner:嘉兴恒匠智能技术有限公司

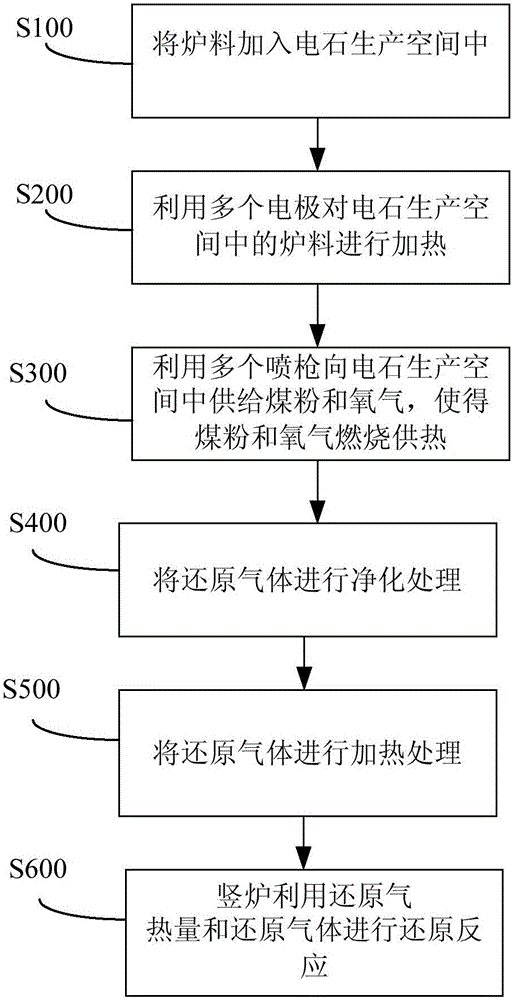

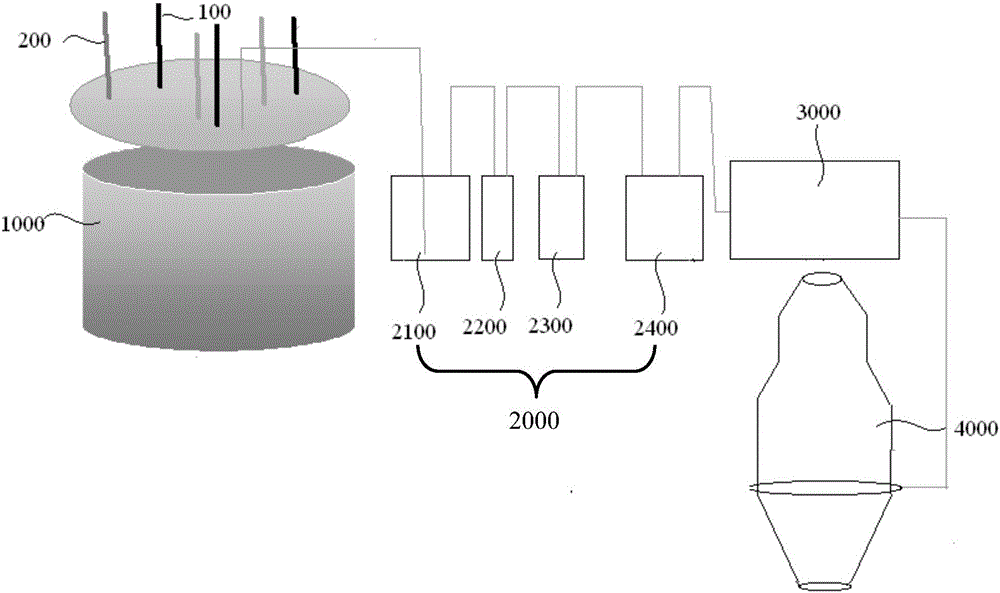

Technology and system for combined use of calcium carbide furnace and vertical furnace

ActiveCN105036133AReduce production power consumptionReduce manufacturing costCalcium carbideShaft furnaceCombined useShaft furnace

The invention discloses a technology and system for combined use of a calcium carbide furnace and a vertical furnace. The system for combined use of the calcium carbide furnace and the vertical furnace comprises the calcium carbide furnace used for preparing calcium carbide and obtaining reducing gas, a purifying device connected with the calcium carbide furnace and used for purifying the reducing gas for conveniently obtaining the clean reducing gas, a heating furnace connected with the purifying device and used for heating the clean reducing gas for conveniently obtaining the high-temperature reducing gas, and the vertical furnace connected with the heating furnace and used for conducting a reducing reaction through the high-temperature reducing gas. Smoke which is high in reducing gas content and generated in the process of preparing the calcium carbide through the calcium carbide furnace can provide heat and a reducing agent for the vertical furnace after being purified and heated, waste is utilized, system investment for preparing the reducing gas is reduced, and the production cost of vertical furnace products is reduced.

Owner:SHENWU TECH GRP CO LTD

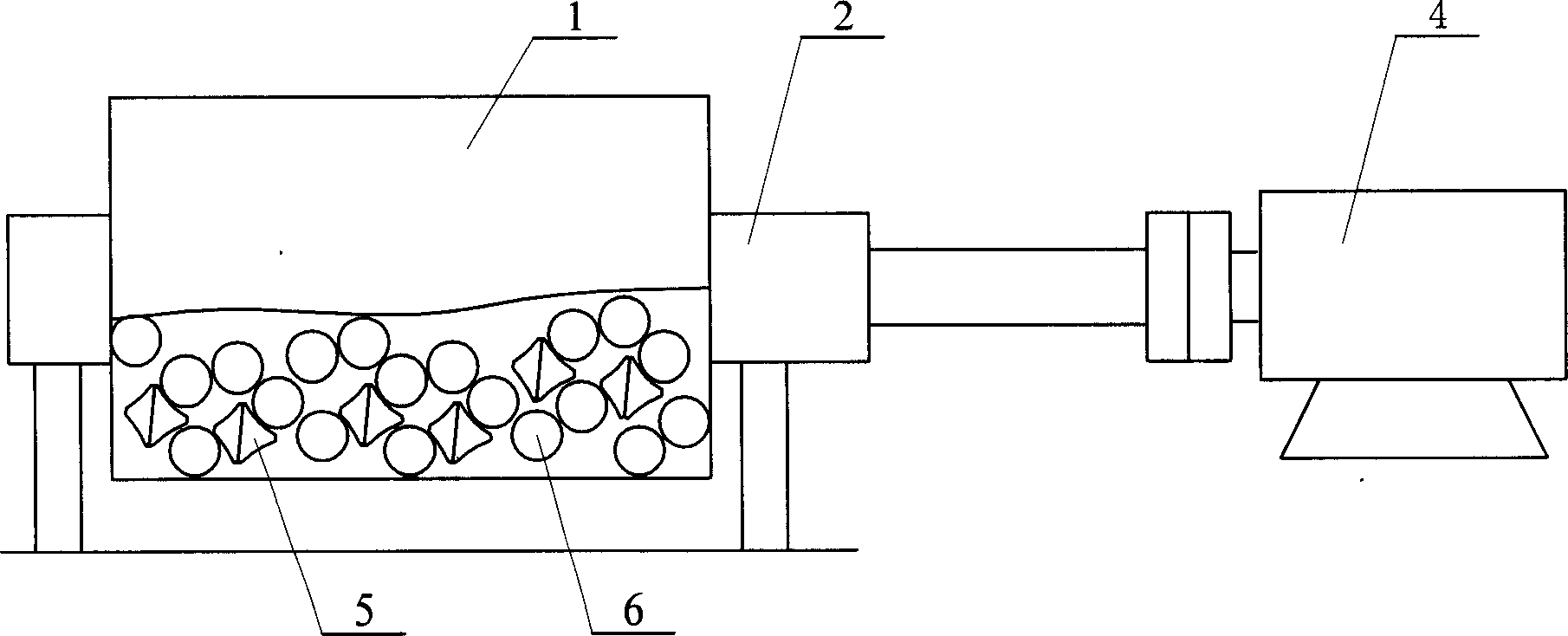

Ball mill with four-face pyramid grinding body

InactiveCN1644240AImprove grinding efficiencyImprove throughput per hourGrain treatmentsSteel ballBall mill

A ball grinder using the conic tetrahedals as grinding body is composed of cylinder, axle, motor, and the conic tetrahedals and circular balls in the ratio of (1-2):(1-10). Its advantages are high productivity, low loss of steel balls, and high specific surface area of powder body.

Owner:宋延秋

High-effective composite slagging agent used for converter and preparation method thereof

InactiveCN105950820AGood slag removal effect in the whole processFast slag meltingManufacturing convertersProcess efficiency improvementSodium BentoniteLeucite

The invention discloses a high-effective composite slagging agent used for a converter. The slagging agent is prepared from the raw materials including, by weight, 14-22 parts of refining slag, 18-26 parts of leucite, 10-15 parts of broken material of fireproof bricks, 4-9 parts of magnesia, 12-19 parts of cancrinite, 32-46 parts of bentonite, 5-10 parts of chalk powder, 15-20 parts of steel slag, 8-14 parts of sillimanite, 5-10 parts of sanidine and 9-18 parts of micro powder of white corundum. In the invention, the wastes, such as the refining slag, the broken material of fireproof brick and the steel slag are compounded with the leucite, the cancrinite, the bentonite and the like minerals, so that the slagging agent has good full-course slagging effect and short slagging time, and is high in desulfurization and dephosphorization efficiency. The industrial wastes, such as the refining slag, the broken material of fireproof brick and the steel slag, are recycled, so that not only is comprehensive utilization of secondary resources achieved but also the metallurgic effect in the converter is improved. The slagging agent is reduced in production consumption, is improved in production efficiency and has excellent promoting prospect.

Owner:ANHUI YUNTIAN METALLURGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com