Novel cathode structured aluminum cell with longitudinal and transversal wave damping functions

A cathode structure, aluminum electrolytic cell technology, applied in the field of aluminum electrolysis, can solve problems such as large stress difference, reduced electrolytic cell life, electrolytic cell operation influence, etc., to achieve the effects of improving stability and reducing dissolution loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

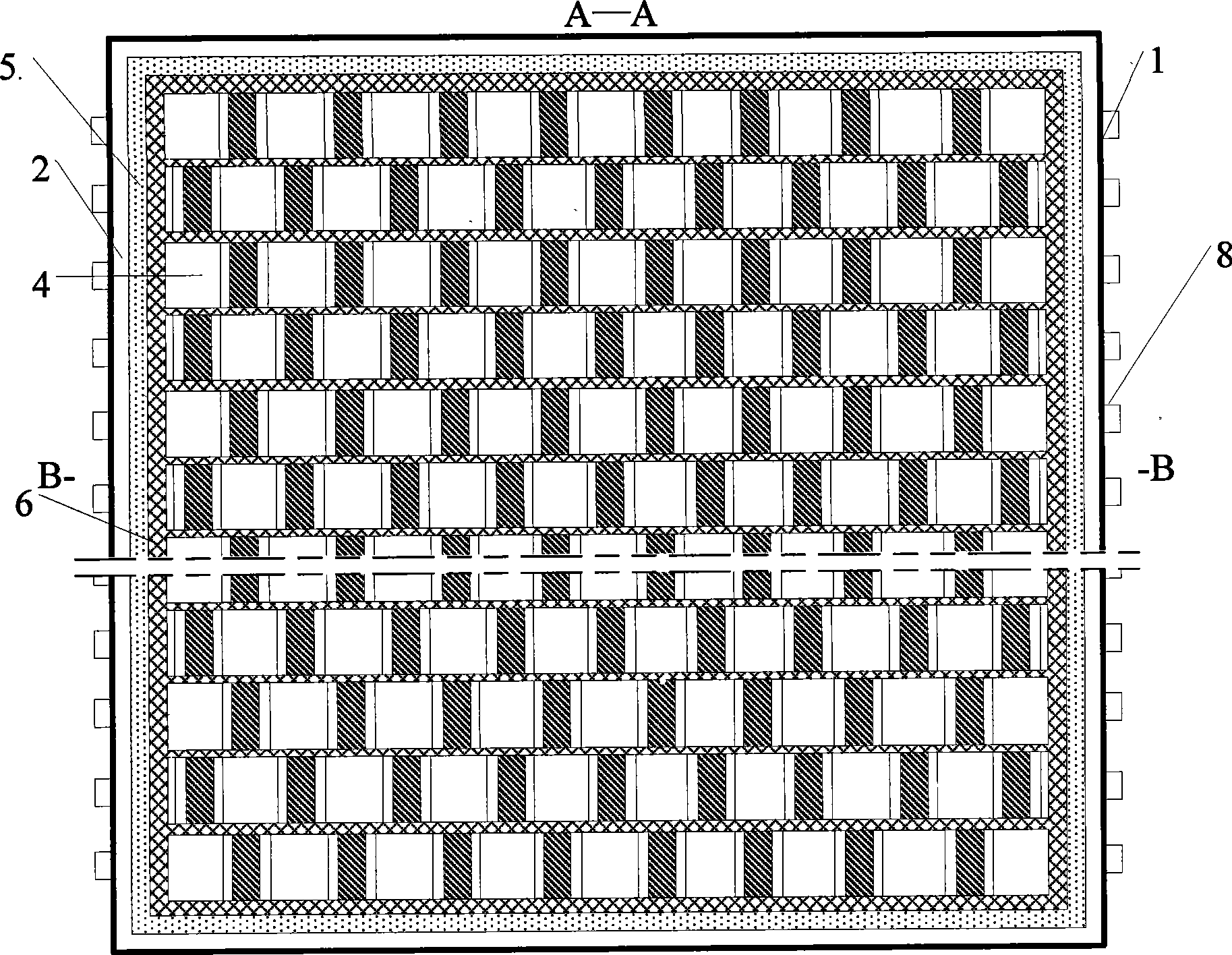

[0054] A new type of cathode structure aluminum electrolytic cell with longitudinal and transverse wave reduction functions is adopted, such as figure 1 with figure 2 As shown, the outside of the aluminum electrolytic cell is a steel electrolytic cell shell 1; the thermal insulation material 2 of the electrolytic cell shell 1 is an asbestos board, and the bottom refractory brick and thermal insulation brick are laid on the bottom asbestos board of the thermal insulation material 2 3; On the bottom refractory bricks and insulation bricks 3 are cathode carbon blocks 4 and cathode steel rods 8 with raised structures on the upper surface.

[0055] The side of the electrolytic cell is the side carbon brick 5, and the cathode lining of the cell bottom in the electrolytic cell is composed of no less than 8 cathode carbon blocks 4 with a raised structure with cathode steel rods 8 installed at the bottom, each The cathode carbon block 4 is placed horizontally in the electrolytic cell...

Embodiment 2

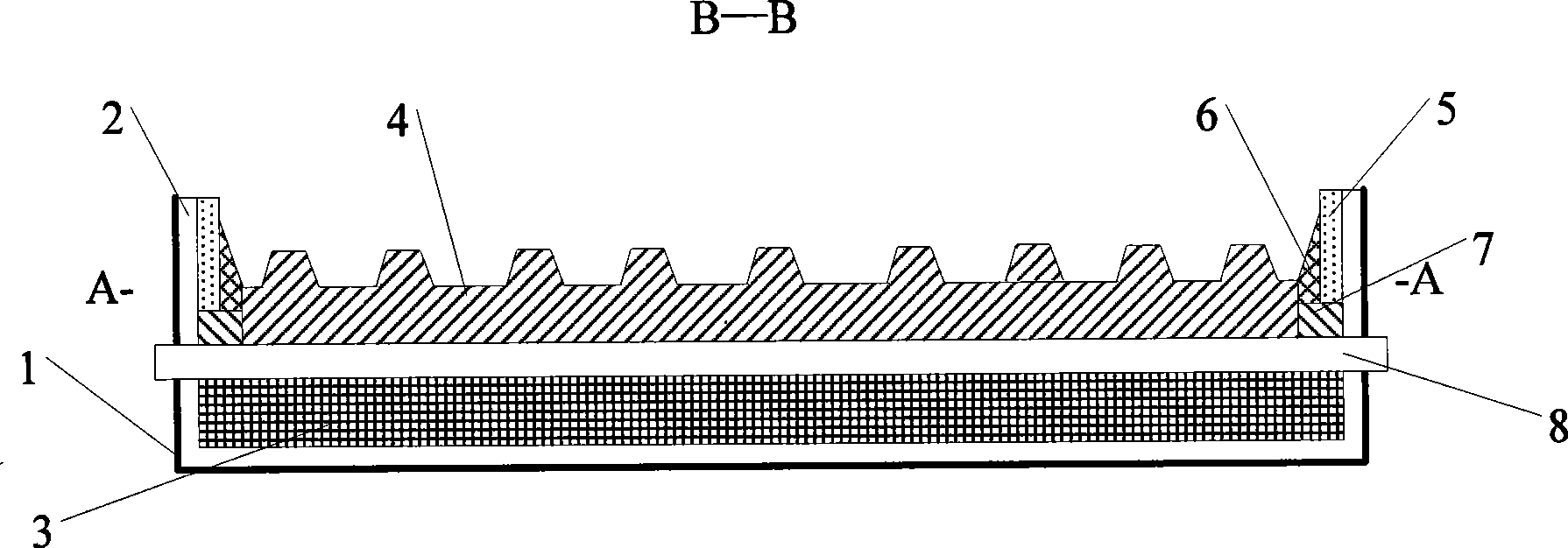

[0065] A new type of cathode structure aluminum electrolytic cell with longitudinal and transverse wave reduction functions is adopted, such as image 3 with Figure 4 As shown, the overall structure of the electrolytic cell is the same as in Example 1, the difference is that the raised structure on the cathode carbon block is a mixed arrangement of horizontal raised structure and longitudinal raised structure, and the horizontal raised structure and vertical raised structure on each cathode carbon block substrate The protruding structures are arranged in a staggered manner, of which there is one horizontal protruding structure, the length of which is the same as the width of the cathode carbon block matrix; Above, the distance between the bottom of the longitudinal protruding structure at both ends and the two ends of the cathode carbon block is 30-50 mm; the distance between the adjacent transverse protruding structures and longitudinal protruding structures on the same cath...

Embodiment 3

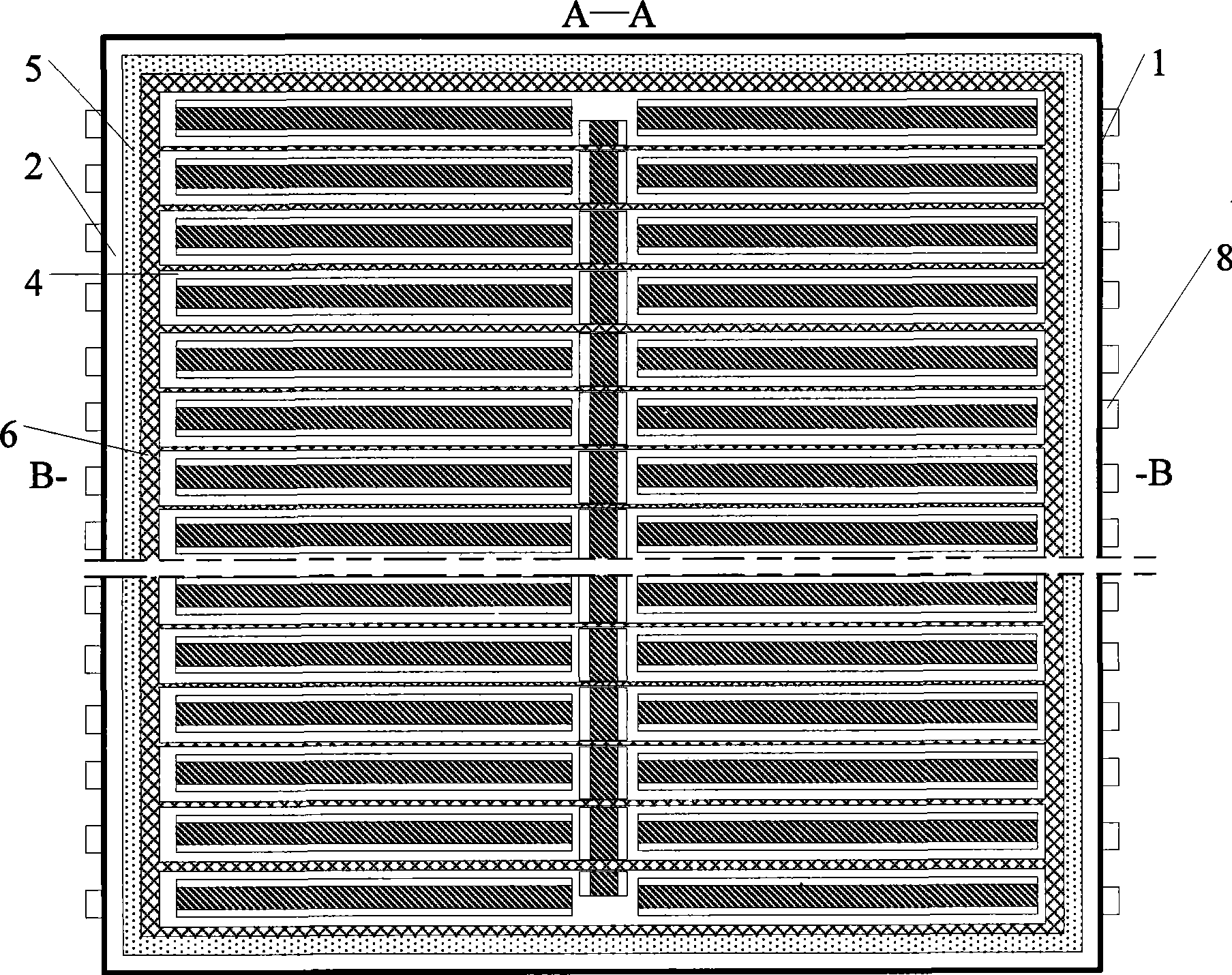

[0071] A new type of cathode structure aluminum electrolytic cell with longitudinal and transverse wave reduction functions is adopted, such as Figure 5 and Figure 6 As shown, the overall structure of the electrolytic cell is the same as in Example 1, the difference is that the protrusion structures on the cathode carbon block are arranged in a mixed manner, and the protrusion structures on the matrix of each cathode carbon block are arranged alternately according to the horizontal protrusion structure and the longitudinal protrusion structure , wherein there are 3 horizontal raised structures, the length of which is the same as the width of the cathode carbon block matrix; The distance between the bottom of the longitudinal protruding structure at the end and the two ends of the cathode carbon block is 30-50 mm; the distance between adjacent protruding structures on the same cathode carbon block is 30-100 mm.

[0072] The cross-section of the longitudinal raised structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com