Sintering waste heat power generation exhaust gas recycling utilization system

A technology of waste heat power generation and hot exhaust gas, applied in waste heat treatment, lighting and heating equipment, furnaces, etc., can solve problems such as dust pollution, limited heat exchange capacity of exchangers, waste of air volume, etc., to eliminate waste of heat energy and improve the working environment of employees Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

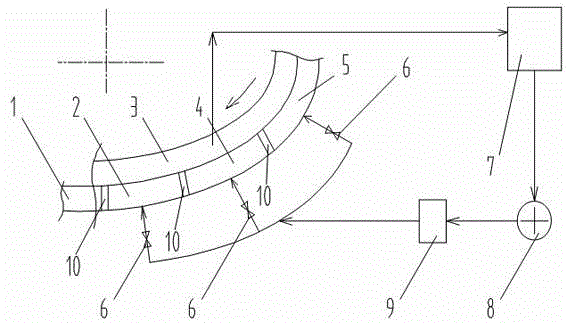

[0017] Such as figure 1 As shown, the cooling air ducts of the high-temperature section of the ring cooling are divided into sections (according to the air duct regions corresponding to the high-temperature sinter in the three temperature regions of 320~400℃, 400~500℃, and 500℃) to realize the high-temperature sintering Sectional cooling, that is, the annular cooling air duct 1 is divided into the corresponding first section cooling duct 5, the second section cooling duct 4, and the third section cooling duct 3 by the three air duct partitions 10, the first section Cooling air duct 5 corresponds to the ring-cooled high-temperature sinter layer area above 500℃, the second cooling air duct 4 of the ring-cooled high-temperature section corresponds to the 400-500℃ ring-cooled high-temperature sinter layer area, and the third cooling air duct 3 of the ring-cooled high-temperature section corresponds to 320~400℃ ring cold high temperature sinter layer area.

[0018] A heat exchanger 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com