Production technology of high quality steel slag breeze

A production process and high-quality steel technology, applied in the field of building materials, can solve the problems of restricting the popularization and application of steel slag, unreasonable particle gradation, poor wearability of steel slag, etc., and achieve low iron content, high hydration activity, and comprehensive electricity production. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: raw material: steel slag produced by Wuhan Iron and Steel Company.

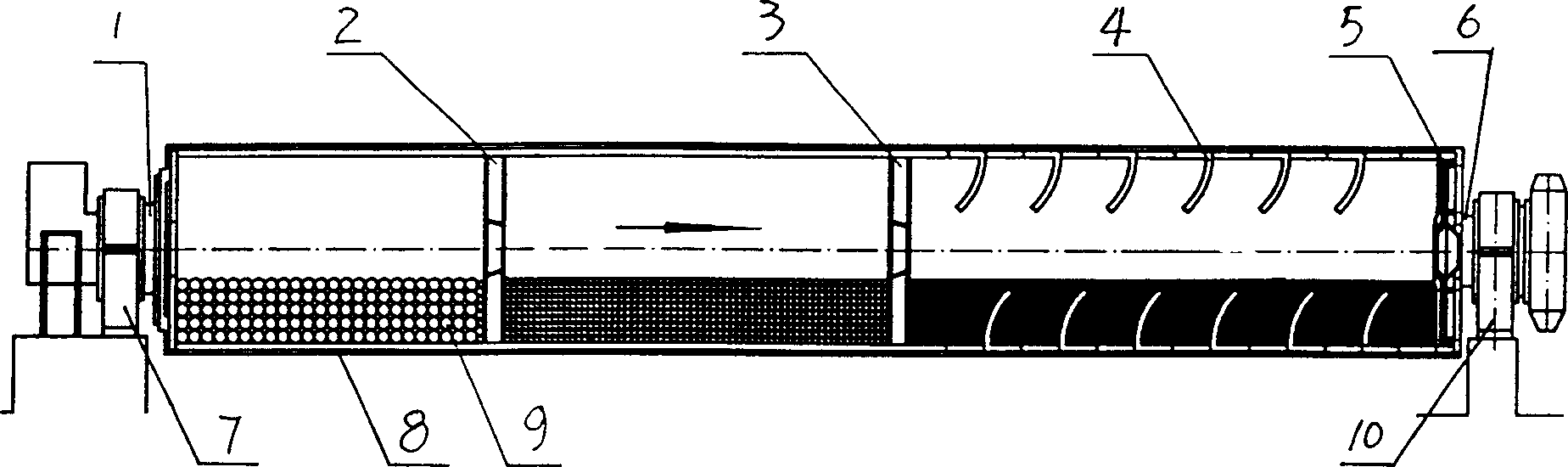

[0040] Such as figure 1 Shown, a kind of production technology of high-quality steel slag mineral powder, its steps are as follows: iron removal is carried out by electromagnetic sucker for the first time after steel slag is cooled, steel slag is crushed by jaw crusher for the first time after iron removal for the first time; The steel slag after the first crushing is subjected to the second iron removal by the first ferromagnetic iron remover, and the steel slag is crushed by the impact crusher for the second time after the second iron removal; the steel slag after the second crushing is carried out by the second The ferromagnetic iron remover performs the third iron removal, and the steel slag is crushed by the column mill for the third time after the third iron removal; the steel slag after the third crushing is carried out by the third iron electromagnetic iron remover for the fourth ...

Embodiment 2

[0065] Embodiment 2: as figure 1 As shown, it is basically the same as embodiment 1, the difference is only: as Figure 17 As shown, the iron removal system includes one set of electromagnetic iron removal equipment and one set of O-SEPA high-efficiency powder separator. The steel slag powder discharged from the steel slag tube mill enters one set of electromagnetic iron removal equipment and one set of O-SEPA efficient powder separator Iron removal is carried out to obtain iron powder raw materials and steel slag ore powder.

Embodiment 3

[0066] Embodiment 3: basically the same as Embodiment 1, the only difference is: as Figure 18 As shown, the iron removal system includes a settling chamber and a set of electromagnetic iron removal equipment. The steel slag powder discharged from the steel slag tube mill enters the settling chamber in turn, and the electromagnetic iron removal equipment removes iron to obtain iron powder raw materials and steel slag ore powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com