Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Reduce grinding workload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lower alloy steel laser-electric arc hybrid welding method

InactiveCN103495810AImprove forming qualityImprove welding qualityMetal working apparatusWorkpiece edge portionsHeat-affected zonePetrochemical

The invention relates to a lower alloy steel laser-electric arc hybrid welding method in the technical field of metallurgy, machinery, ships, automobiles, pipelines, petrochemical industry, marine equipment, pressure vessels, war industry and the like. In order to solve the problems existing in a traditional welding method, on the basis of the effect law of laser-electric arc coupling characteristics and laser-electric arc hybrid welding parameters, the welding parameters and the groove sizes of all welding joints of multilayer welding are optimized with the orthogonal design test method, and the researched and developed lower alloy steel laser-electric arc hybrid welding method has the advantages of being small in heat input amount, large in fusion depth, small in deformation and high in welding speed, capable of reducing the area of the welding joints, the width of the heat affected zone and the exhaust amount of harmful gas and smoke and favorable for improving welding quality and welding efficiency, lowering production cost, improving the quality of products and relieving environmental pollution. The method includes the processing steps that welding grooves are machined, the optimized welding parameters are adopted for all the welding joints of the multilayer welding, and lower alloy steel laser-electric arc hybrid welding is performed.

Owner:JILIN UNIV

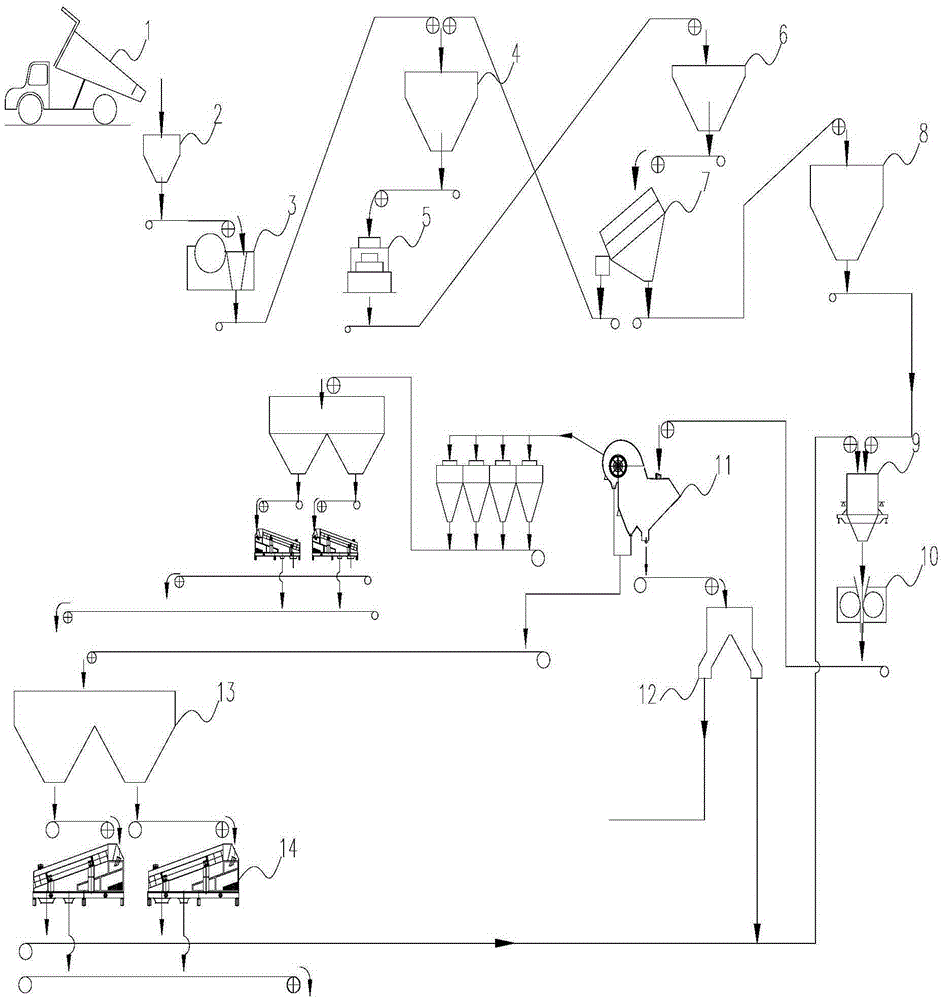

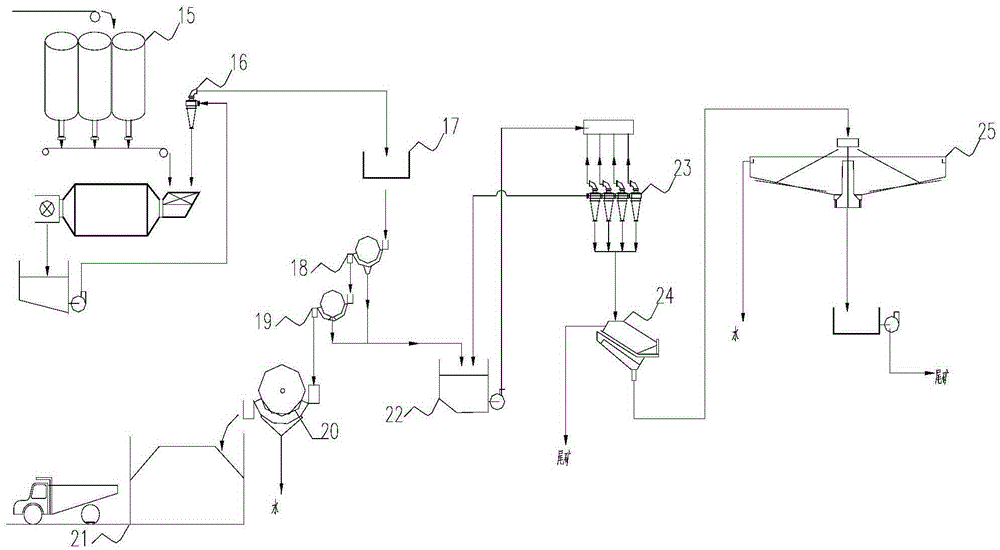

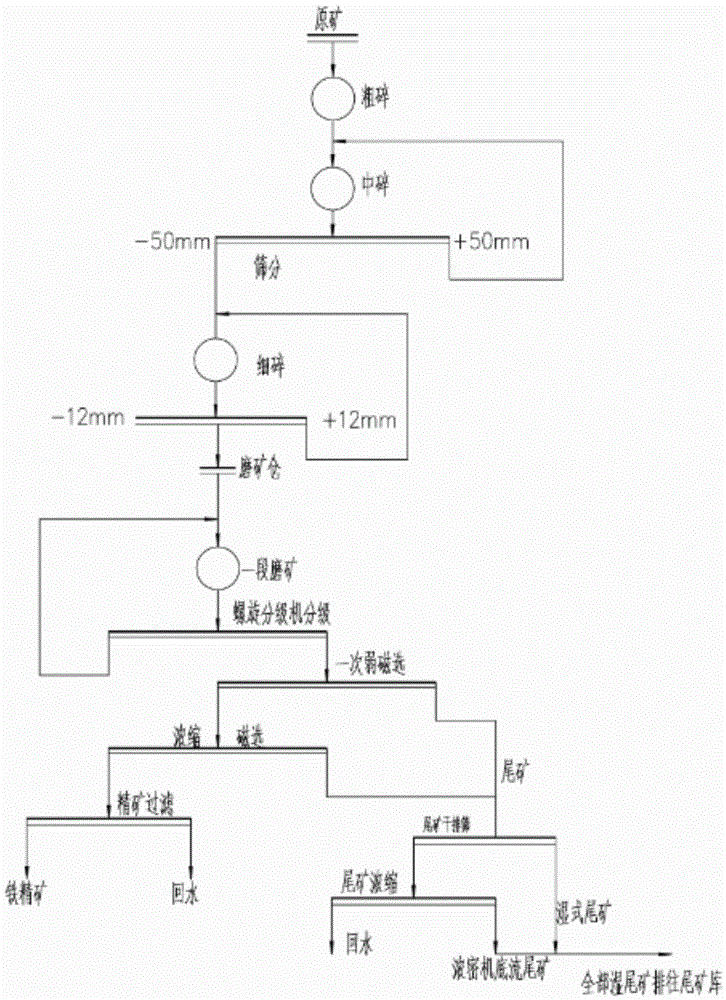

Mineral separation process and system for ultra-lean magnetite ore

ActiveCN105413842AReduce the cost of beneficiationReduce total beneficiation costMagnetic separationGrain treatmentsMagnetiteWet grinding

The invention provides a mineral separation process and system for an ultra-lean magnetite ore. The mineral separation process for the ultra-lean magnetite ore comprises the following steps of sequentially carrying out coarse crushing, intermediate crushing and fine crushing on a raw magnetite ore to obtain a fine-particle ore; carrying out dry magnetic separation on the fine-particle ore, and throwing tailings to obtain a dry concentrate; and carrying out wet grinding and separation on the dry concentrate. The dry pre-separation step is additionally arranged in the mineral separation process, so that the technical problems of high ore grinding and magnetic separation energy consumption, high cost, high mineral separation water consumption, tailing pond construction and the like are solved.

Owner:中冶沈勘工程技术有限公司

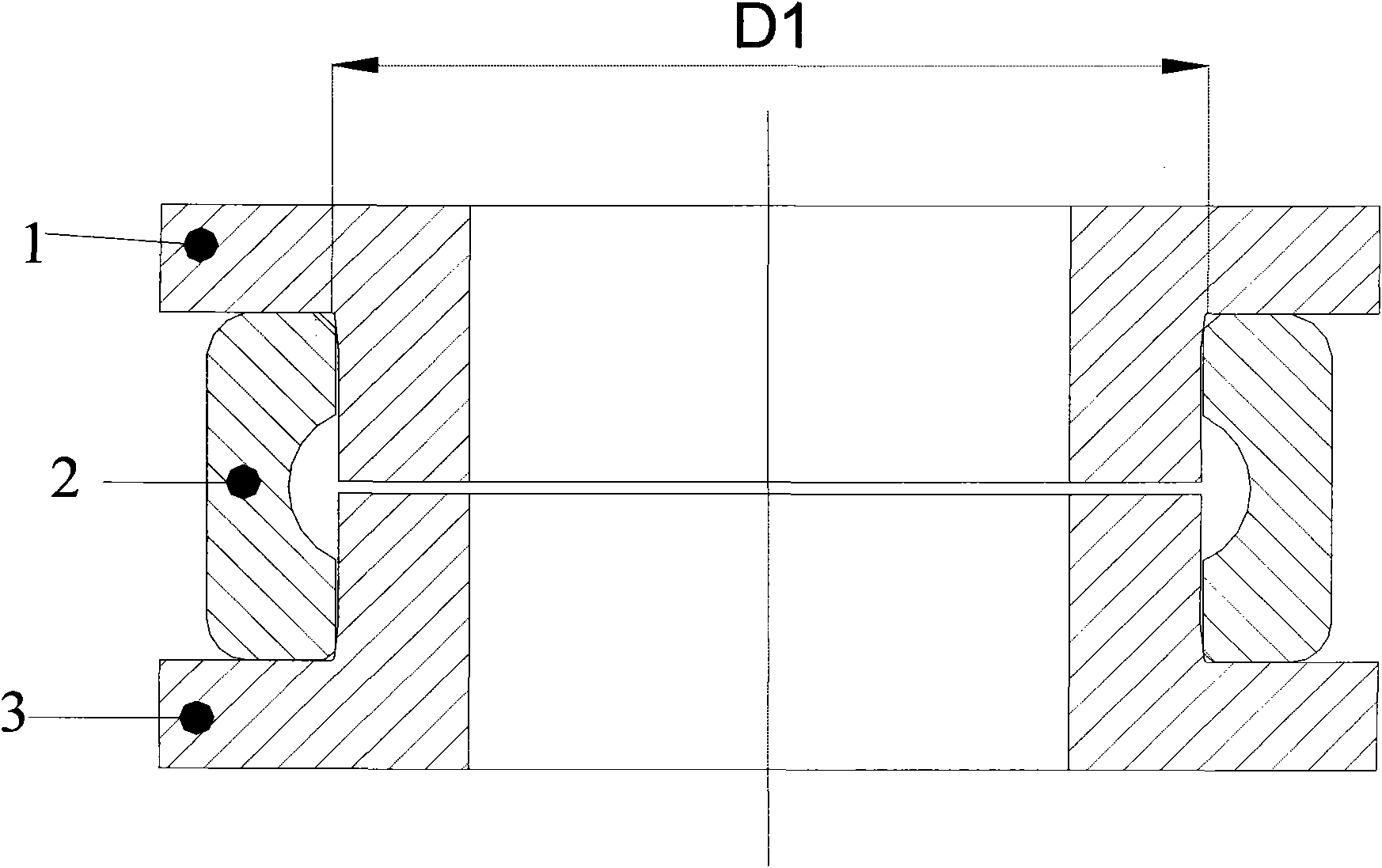

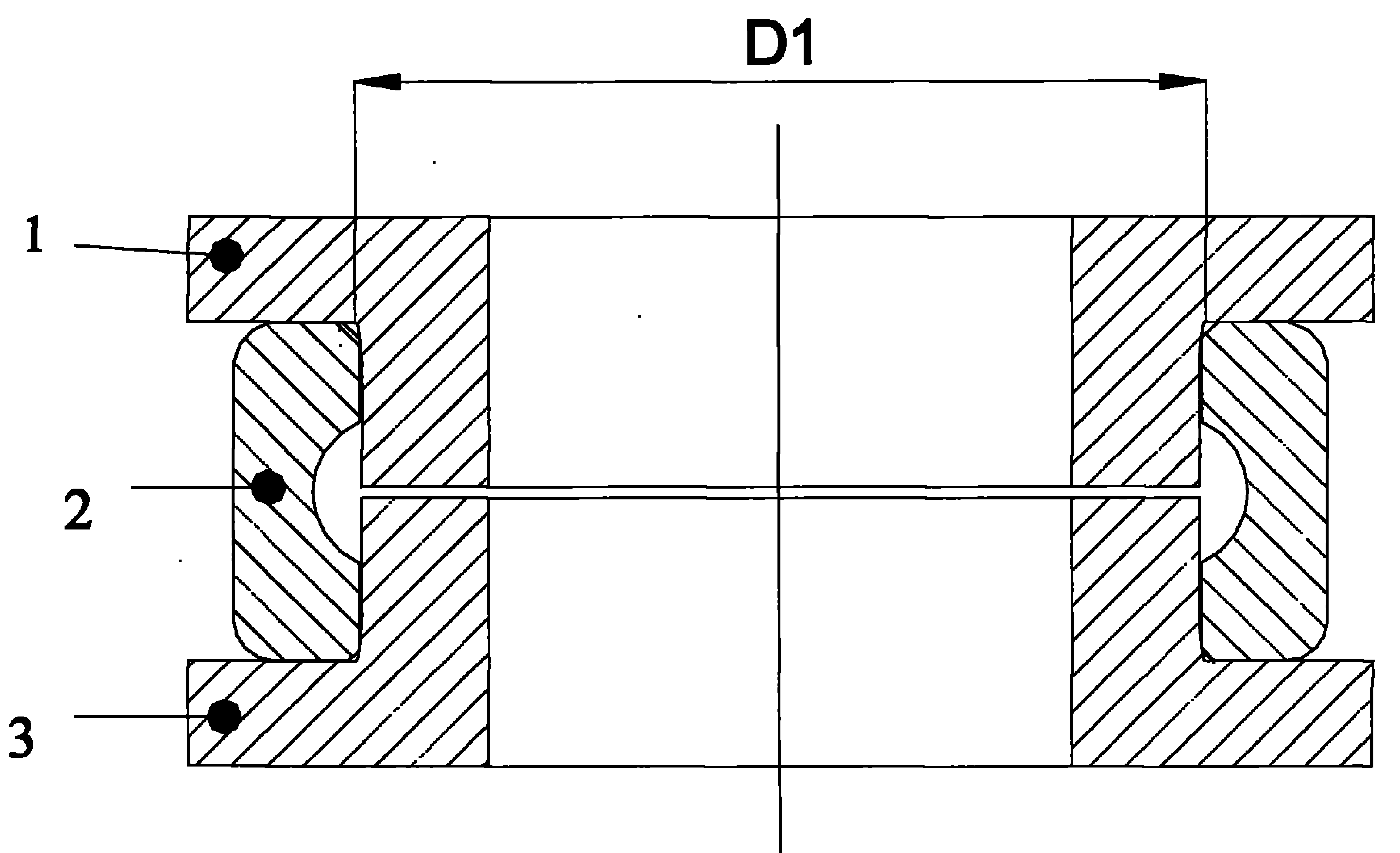

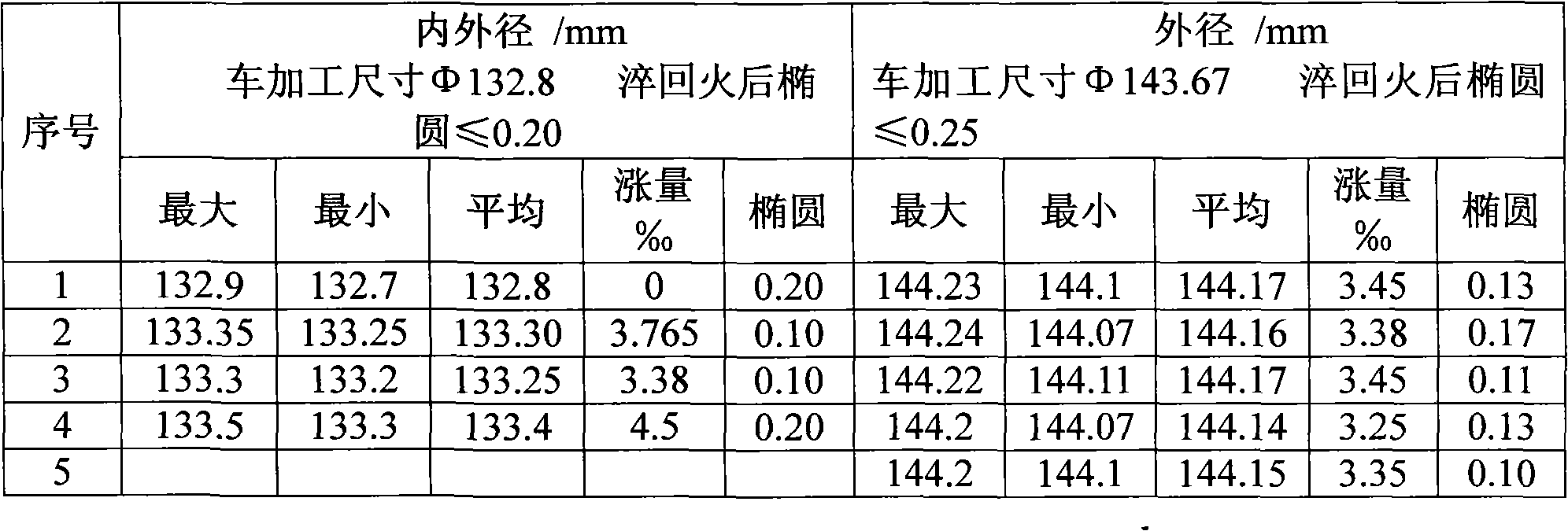

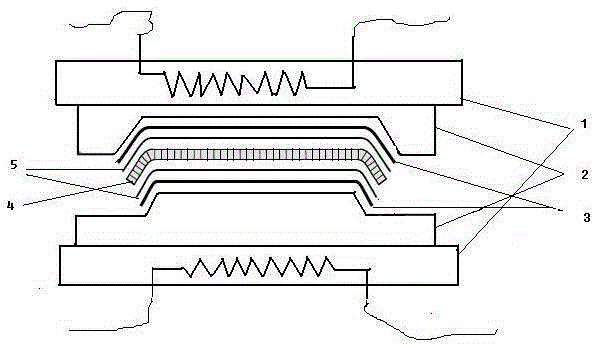

Control method for preventing deformation in quenching process of 9Cr18 thin-wall bearing ring

ActiveCN101775480AAvoid quenching deformationImprove ergonomicsFurnace typesHeat treatment furnacesEconomic benefitsHeating furnace

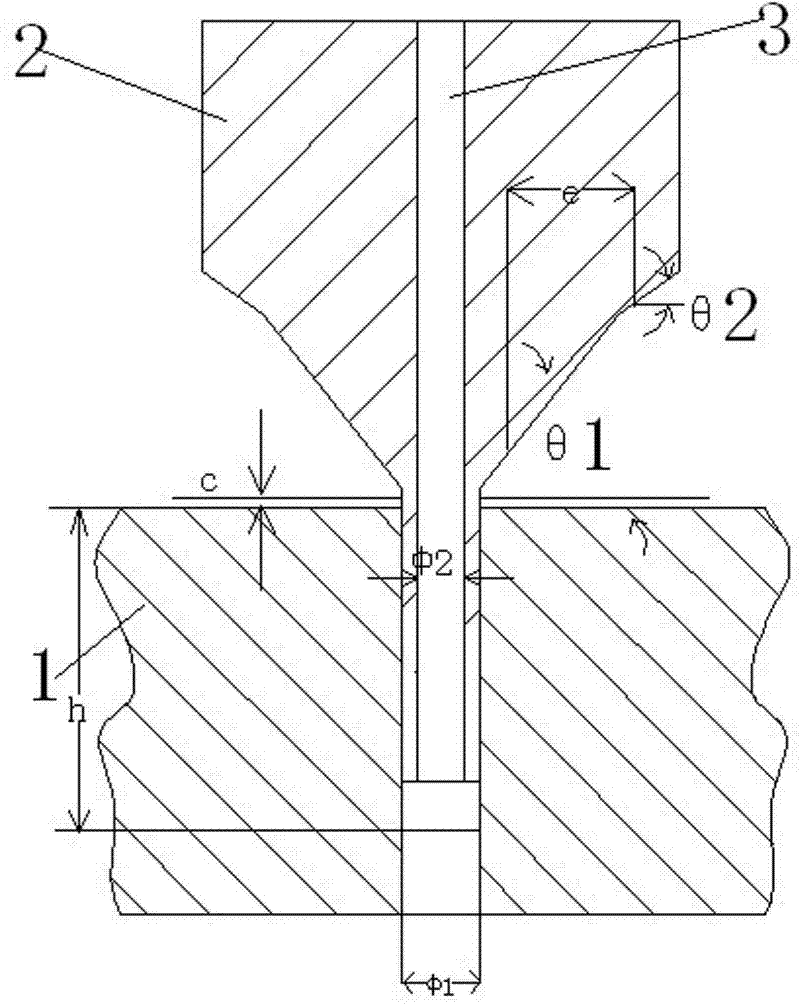

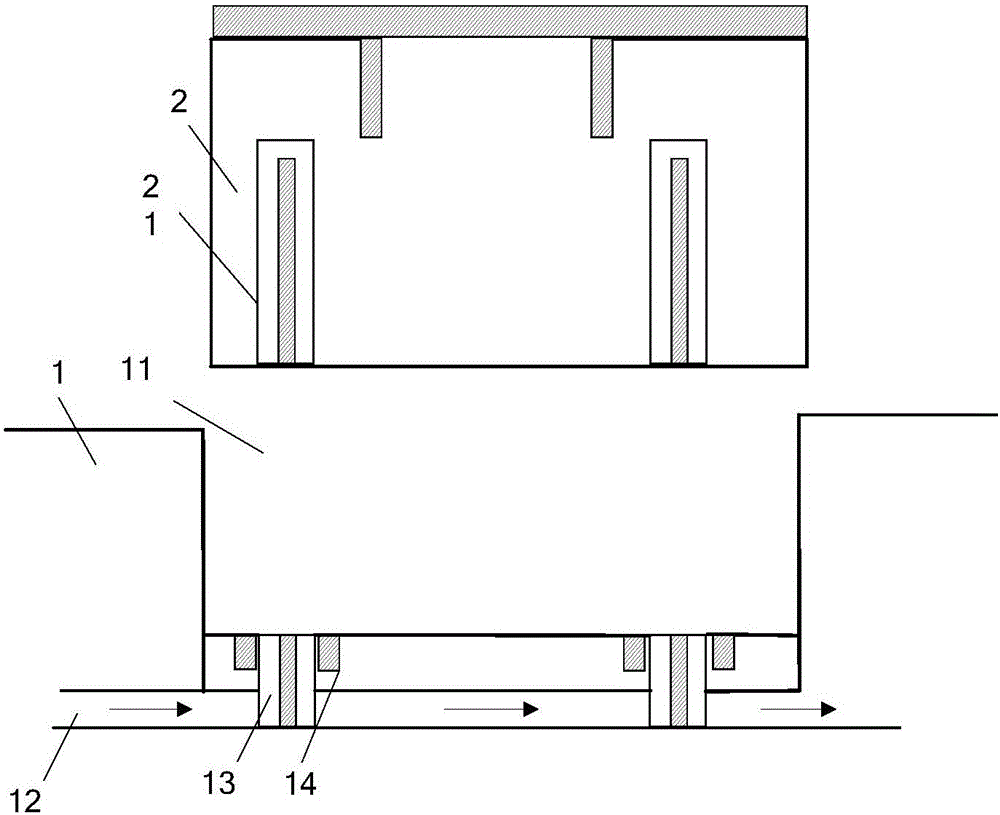

The invention relates to a control method for preventing deformation in the quenching process of a 9Cr18 thin-wall bearing ring. The method comprises the following steps of: firstly designing an upper die (1) and a lower die (3) which have symmetrical structures; before quenching, loading the 9Cr18 thin-wall bearing ring (2) into a 45KW box-type heating furnace for preheating, wherein the preheating temperature is 850 DEG C, and the preheating time is 30 min; shifting the 9Cr18 thin-wall bearing ring into a 50KW high-temperature box-type heating furnace for heating, wherein the heating temperature is 1070 DEG C, and the time for keeping the temperature is 5 min; taking the 9Cr18 thin-wall bearing ring out, and placing the 9Cr18 thin-wall bearing ring on the lower die of the quenching die; covering the upper die of the quenching die, and fixing the upper die, the 9Cr18 thin-wall bearing ring and the lower die as a whole to be placed in quenching oil for quenching; separating the upper die and the lower die 3 min after quenching, and taking out the 9Cr18 thin-wall bearing ring. The qualification rate of the bearing ring quenched by adopting the invention reaches 98 percent, and the economic benefit is remarkable.

Owner:LUOYANG BEARING RES INST CO LTD

Casting technology of wear-resistant and low-porosity steel casting

InactiveCN104325073AStrong ability to resist sand inclusionImprove thermal stabilityFoundry mouldsFoundry coresWear resistanceHot blast

The invention discloses a casting technology of a wear-resistant and low-porosity steel casting. The casting technology takes silica sand, bentonite, an additive and water as molding materials, and comprises the steps of preparing a casting mould by mixing the molding materials; drying the prepared casting mould with hot air at the temperature of 130-140 DEG C; injecting the dissolved metallic solution into the casting mould, and pouring a semi-finished product; carrying out heat treatment on the semi-finished product, polishing and machining to obtain the finished product; checking and putting into a storage. After the casting technology is adopted, the wear resistance and the toughness of the casting are greatly improved, the pores in the casting are reduced, and the service life of the casting is prolonged; furthermore, the casting technology is simple in operation and low in cost.

Owner:DAFENG HONGLIAN CAST STEEL

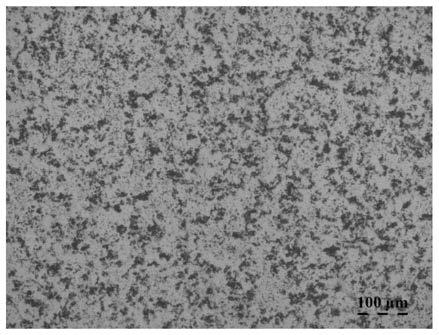

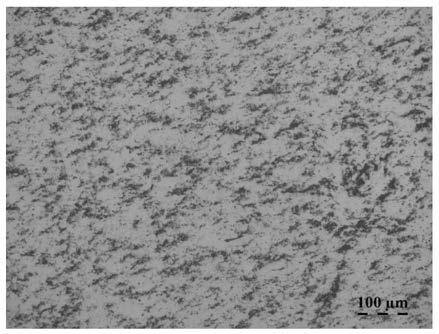

Method of processing chromium-nickel austenite stainless steel continuous casting slab

The invention relates to a method of processing chromium-nickel austenite stainless steel continuous casting billet, comprising the following steps in sequence: (1) placing cut chromium-nickel austenite stainless steel continuous casting slab into a circulating water tank and removing the slag crusts adhered to the surface of the chromium-nickel austenite stainless steel continuous casting slab; (2) lifting the chromium-nickel austenite stainless steel continuous casting slab out of the circulating water tank and cooling the same; and (3) visually detecting the chromium-nickel austenite stainless steel continuous casting slab to decide whether the chromium-nickel austenite stainless steel continuous casting slab needs to be polished. If having smaller and less oscillation marks on the surface, the chromium-nickel austenite stainless steel continuous casting slab does not need to be polished; if having obvious oscillation marks on the surface, the defected chromium-nickel austenite stainless steel continuous casting slab needs to be artificially polished; and if having deep oscillation marks, scabs on the surface or the like on the surface, the defected chromium-nickel austenite stainless steel continuous casting slab needs to be integrally polished with a polishing machine until the oscillation marks, the scabs or the like on the surface can not be seen visually. The method of processing chromium-nickel austenite stainless steel continuous casting billet uses water to remove all the protective slag crusts adhered to the surface of the chromium-nickel austenite stainless steel continuous casting slab, thus the visual detection of chromium-nickel austenite stainless steel continuous casting slab can be detected, the polishing workload can be greatly reduced, the yield can be increased and the processing efficiency can be improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

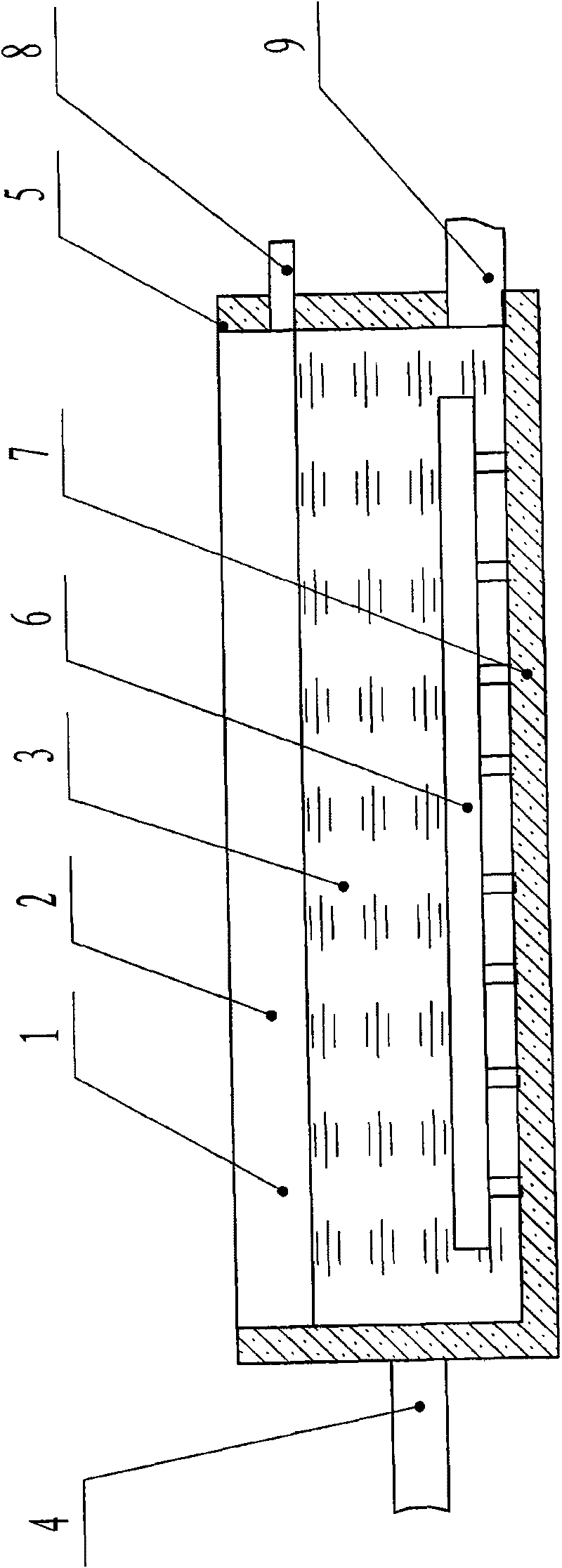

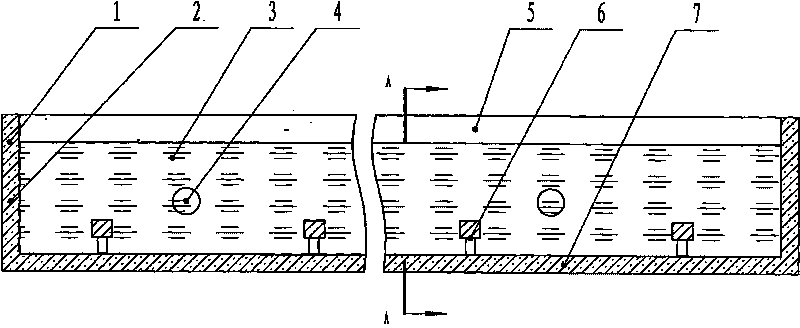

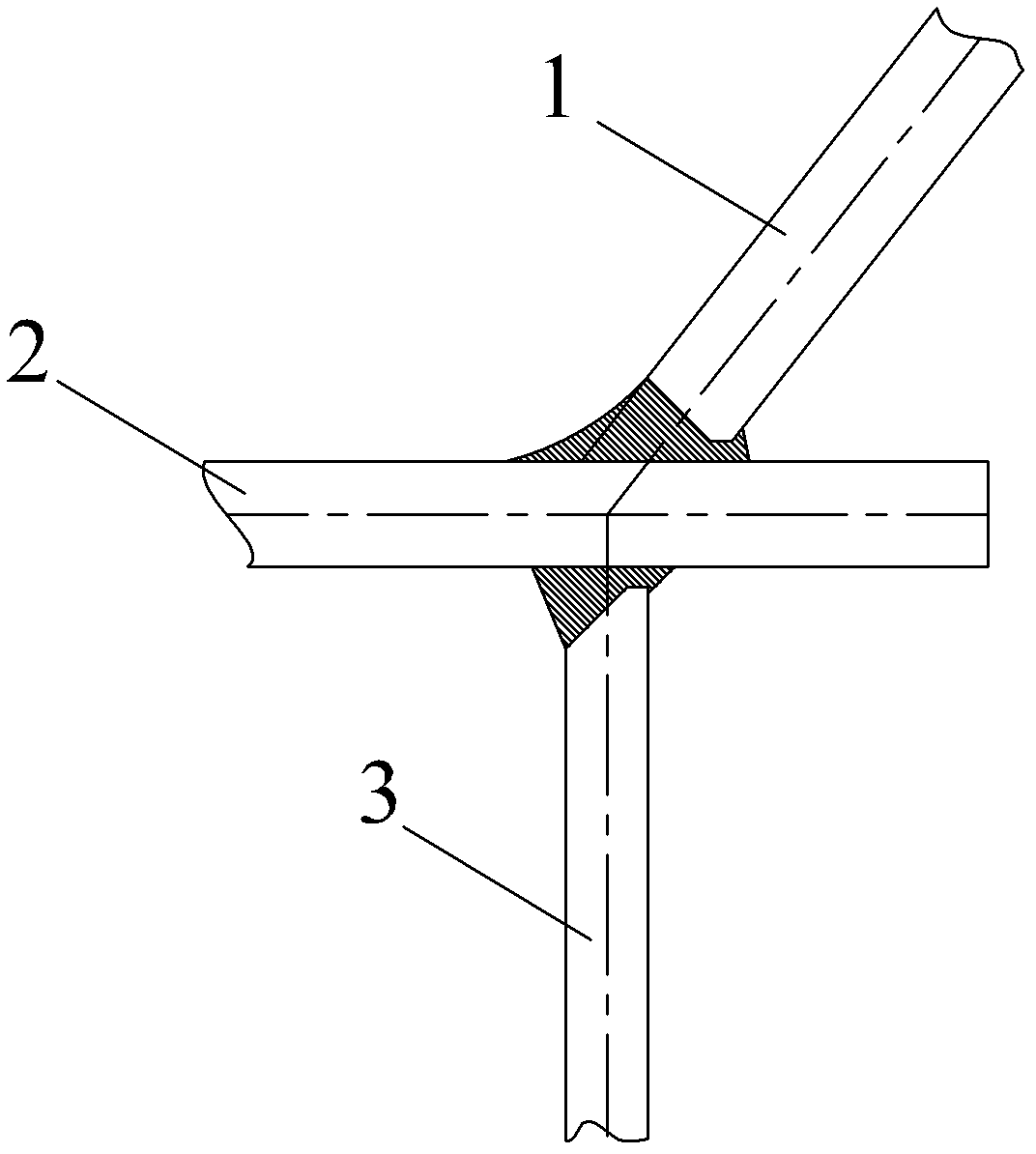

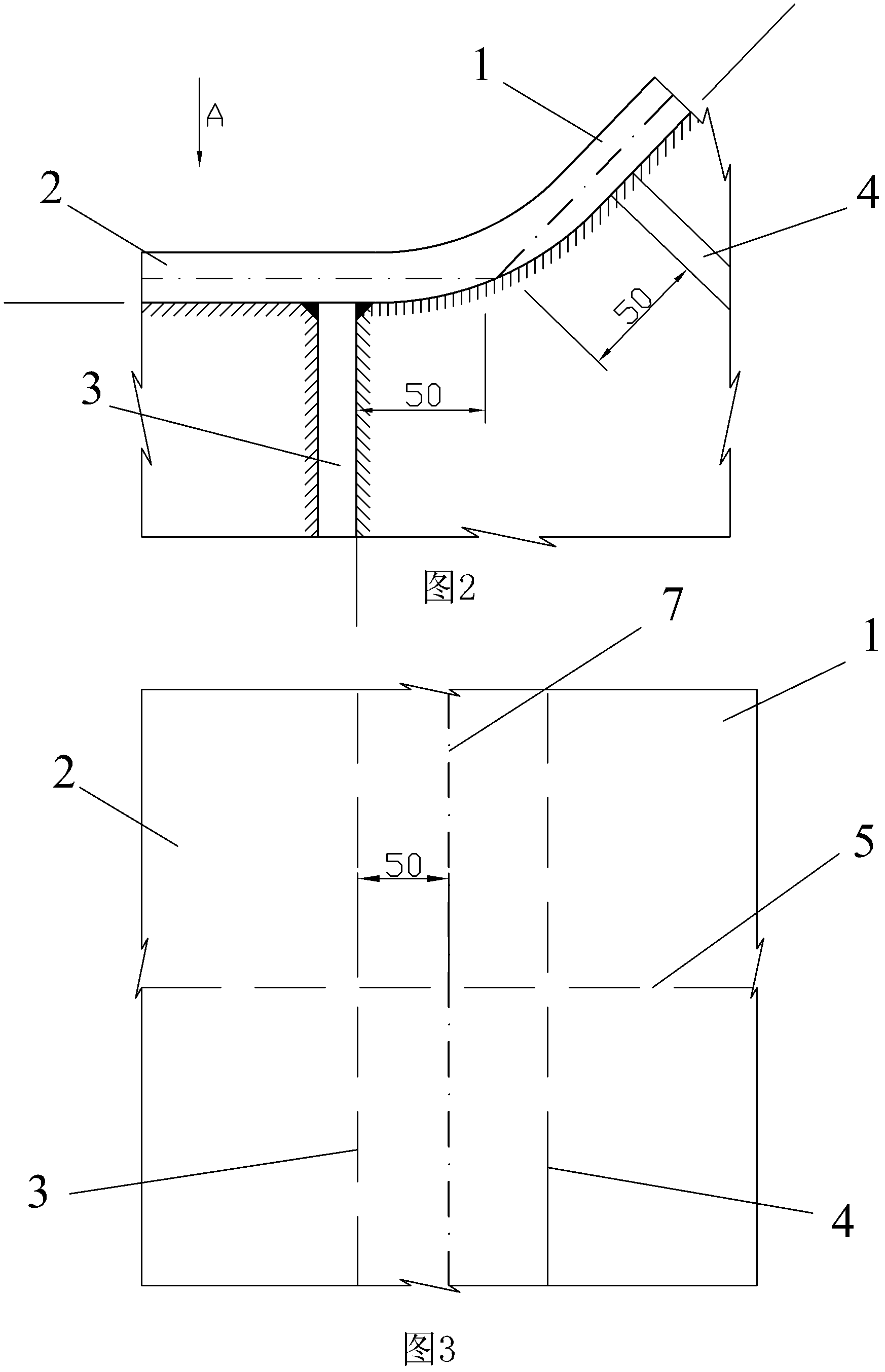

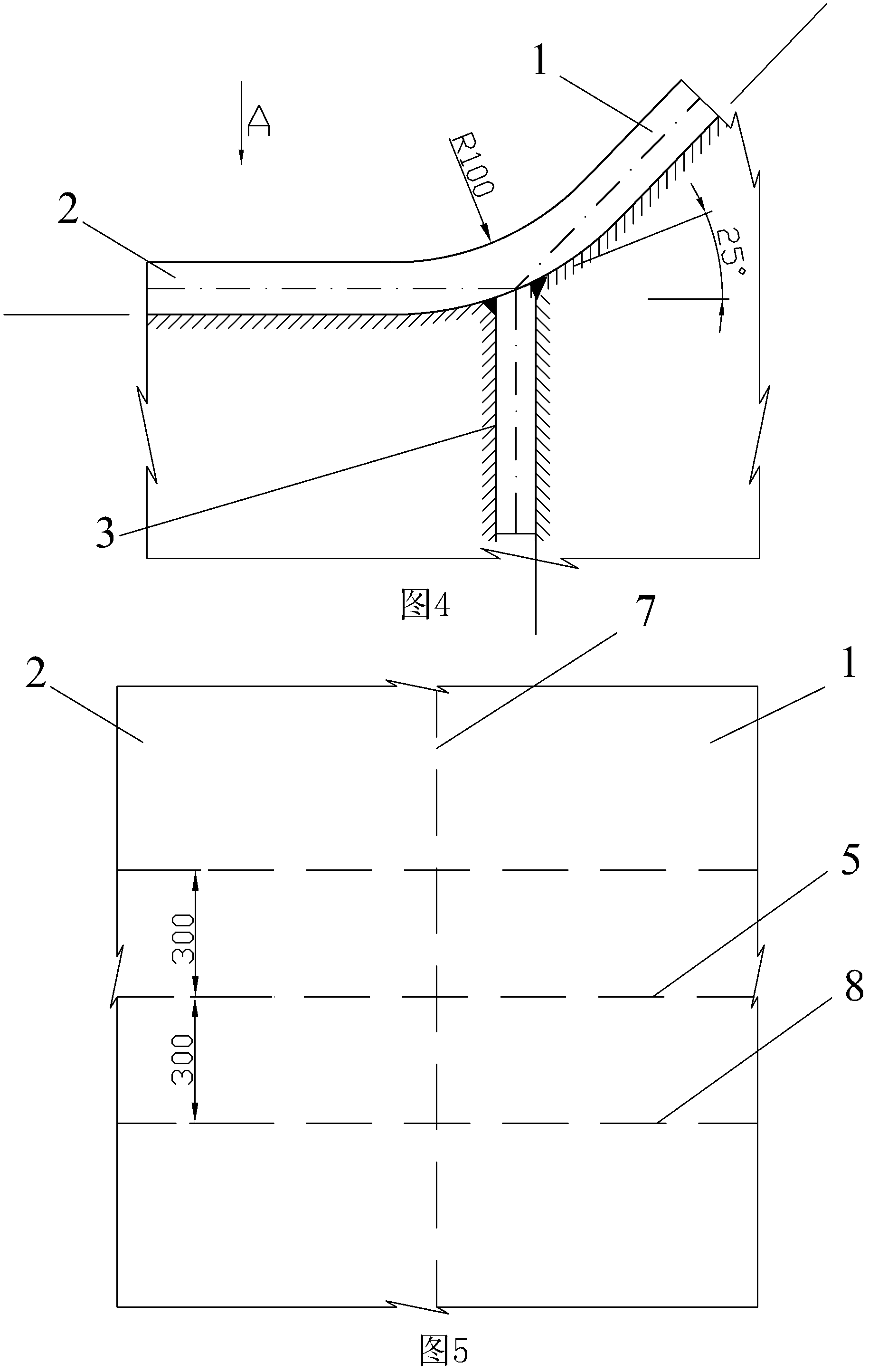

Automatic tungsten argon arc welding method for completely penetrated fillet weld of nuclear power main pipeline and branch pipe

ActiveCN102500878AQuality improvementReduce welding distortionArc welding apparatusNuclear powerNuclear engineering

The invention provides an automatic tungsten argon arc welding method for a completely penetrated fillet weld of a nuclear power main pipeline and a branch pipe. In the invention, automatic pipeline welding equipment provided with an AVC (Arc Voltage Control) function, a freedom welding function and an offline programming function is matched with reasonable welding norms, trajectories and sequences as well as forms of a bevel and dimension of a connector to realize the automatic tungsten argon arc welding for a saddle weld of a completely penetrated connector of the nuclear power main pipeline and the branch pipe, so that the shortcomings of high welding deformation, high consumption of welding materials, complex intermediate processes, severe working environment for labors and the like of the conventional welding process (manual TIG (Tungsten Inert Gas) or manual TIG + SMAW (Shielded Metal Arc Welding)) for the completely penetrated fillet weld of the nuclear power main pipeline and the branch pipe are overcome; and product quality is further stabilized.

Owner:中国船舶集团渤海造船有限公司

C276 Hastelloy alloy flange and production technology thereof

ActiveCN104791564AFirmly connectedEasy to assemble and disassembleFlanged jointsTemperature control deviceAssembly disassemblyMaterials science

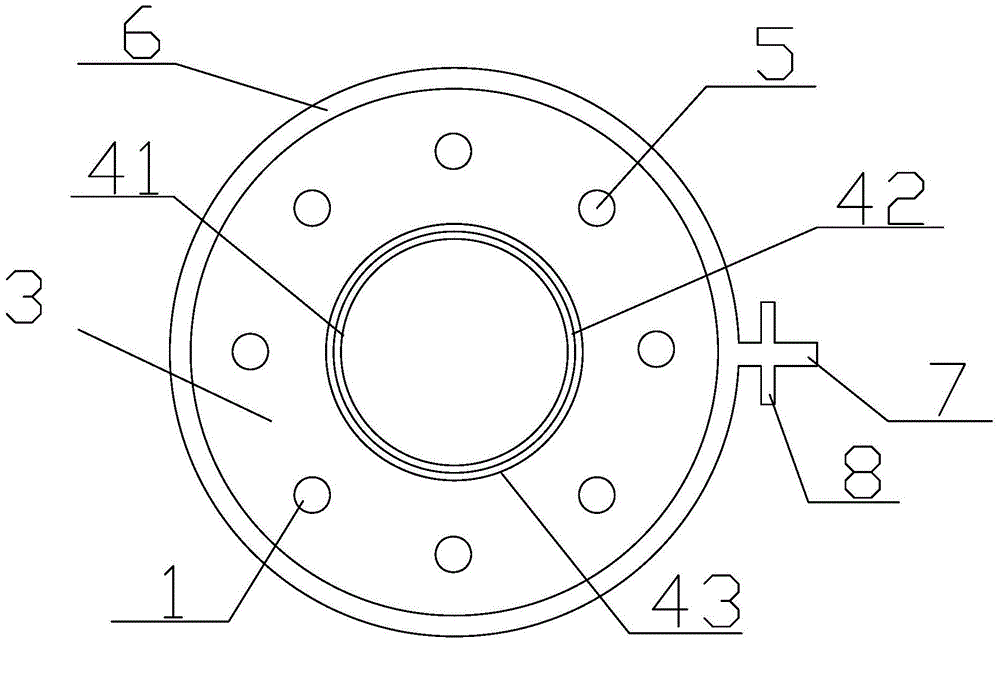

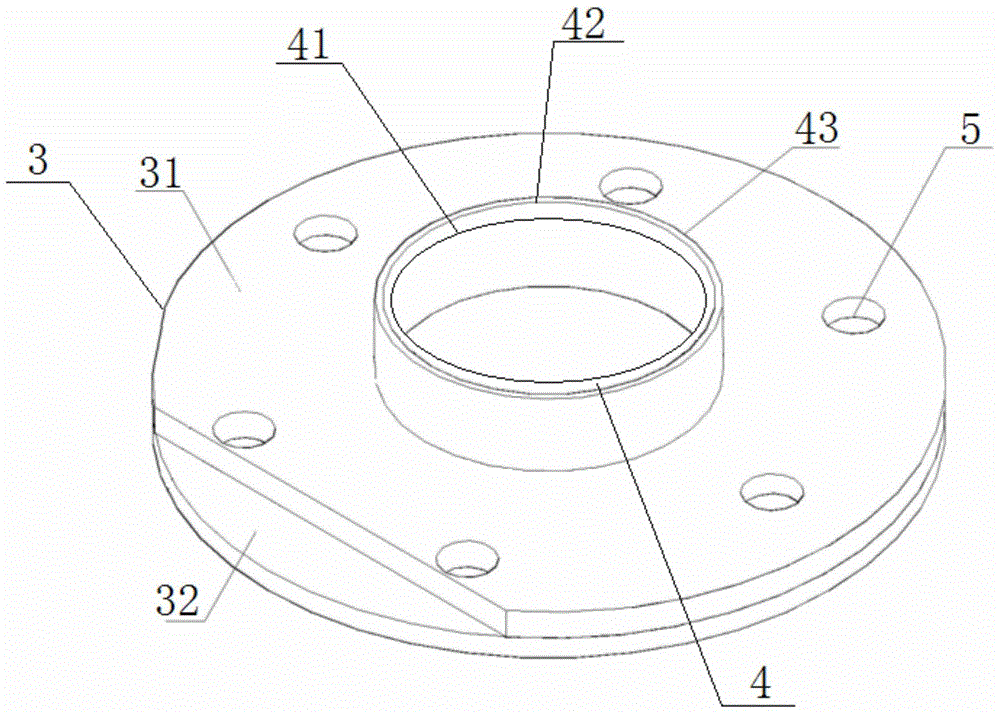

The invention discloses a C276 Hastelloy alloy flange. The C276 Hastelloy alloy flange comprises an upper flange body and a lower flange body which are of the same structure, wherein the upper flange body and the lower flange body are fixedly connected through a fixing device, the upper flange body is composed of a flange main body and a sleeve, the flange main body is of a two-layer structure and comprises an alloy layer and an abrasion-resistant layer which are coaxially arranged, the flange main body is further evenly provided with bolt holes, the sleeve comprises an inner pipe, an outer pipe and a middle pipe which are all coaxially arranged in a sleeving mode, the fixing device comprises a fixing groove containing the upper flange body and the lower flange body, a fixing edge and a fixing pin, holes are formed in the annular periphery of the fixing groove, and a fixing hole is formed in the fixing edge. The invention further relates to a production technology of the C276 Hastelloy alloy flange. The production technology is simple and easy to perform, low in production cost, small in pollution in the production process, and good in safety, the produced C276 Hastelloy alloy flange has good corrosion resistance and abrasion resistance, seal welding performance of the C276 Hastelloy alloy flange and a pipeline is excellent, assembly and disassembly are convenient, and installing efficiency is improved.

Owner:WUXI HUAERTAI MACHINERY MFG

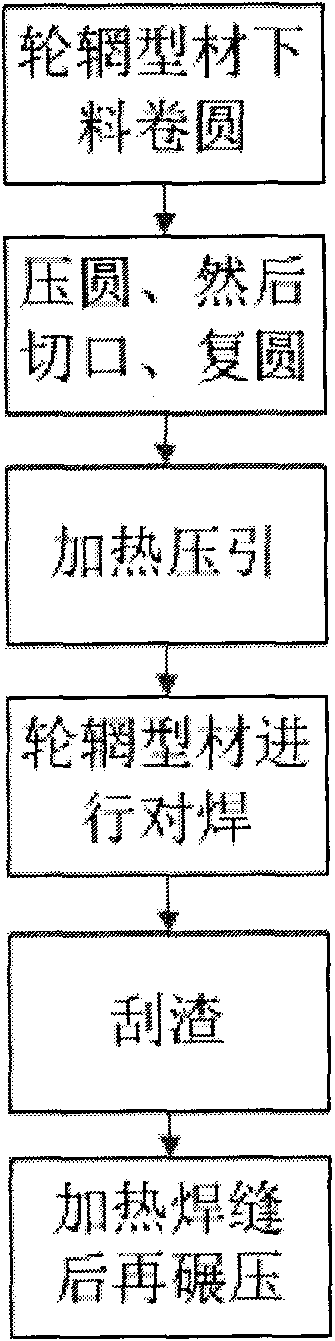

Method for manufacturing rim of inner tire-free wheel

InactiveCN102990284ASolve the problem of welding misalignmentImprove yieldWelding/cutting auxillary devicesAuxillary welding devicesButt weldingSlag

The invention discloses a method for manufacturing the rim of an inner tire-free wheel. The method comprises the following steps of (1) coiling a prefabricated rim profile into a circle according to the diameter of the rim; (2) sequentially performing circle pressing, cutting and re-circling on the coiled rim profile; (3) after heating the two ends of the rim profile which is re-circled at the temperature of 350 to 450 DEG C, pressing and stretching the rim profile until the radian of a welding part of the rim is consistent; (4) performing butt welding on the rim profile of which the radian of the welding part is consistent to obtain a rim crude blank; (5) scrapping slag of the rim crude blank; and (6) after heating the rim of which the slag is scraped at the temperature of 350 to 450 DEG C to weld seam of the hub, grinding the rim. The problem of false welding is solved by the method, the yield is high, and the workload of grinding the welding part is low.

Owner:李昕远

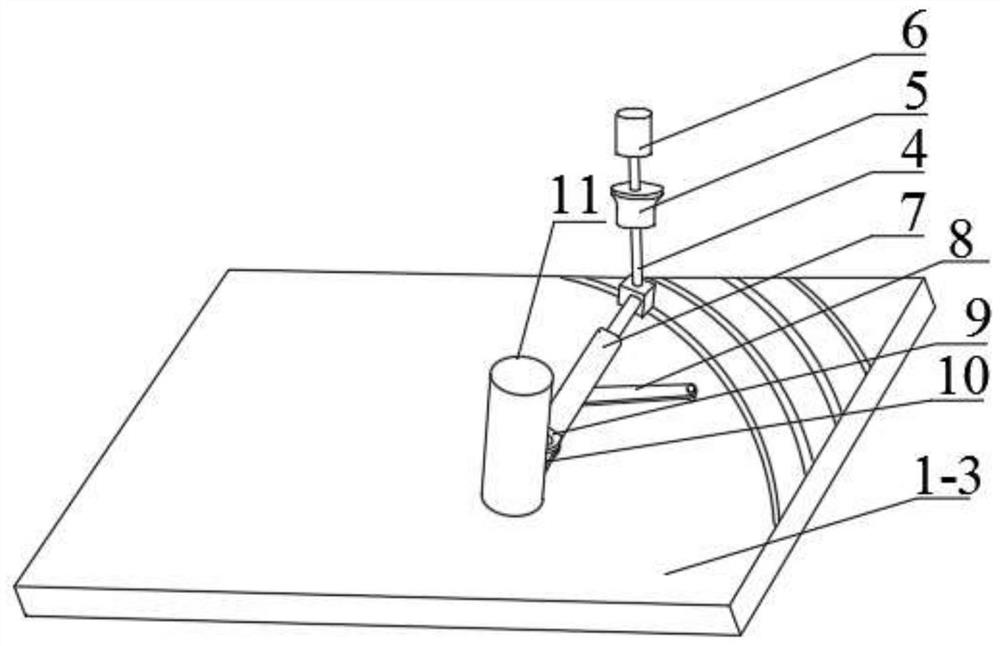

Friction stir welding stirring head material and stirring head preparation method

ActiveCN108677075AHigh strengthImprove wear resistanceNon-electric welding apparatusFree coolingTitanium carbide

The invention discloses a friction stir welding stirring head material and a stirring head preparation method and belongs to the technical field of preparation of stirring head for welding. The friction stir welding stirring head material comprises the following components in percentage by weight: 75%-85% of tungsten powder and 15%-25% of carbon alloyed powder. The carbon alloyed powder is one andor combination of two selected from titanium carbide powder and zirconium carbide powder. The stirring head preparation method comprises the following steps: 1, according to the matching, mixing tungsten powder with carbon alloyed powder to form a mixture, and placing the mixture in a stirring head die for preforming treatment to prepare a preform body; and 2, placing the preform body in a furnace, rising the temperature to 2000-2200 DEG C along with the furnace, adjusting the pressure in the furnace to be 20-25 MPa, keeping the temperature for 1-1.5 hours, and naturally cooling along with the furnace to obtain the stirring head. The stirring head has high strength and wear resistance, the service life of the stirring head can be remarkably prolonged, the adopted alloy powder can be obtained easily, and the raw material cost is greatly reduced.

Owner:SOUTHWEST JIAOTONG UNIV

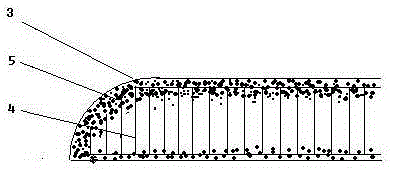

Motor train unit aramid fiber honeycomb in-built part forming process

The invention discloses a motor train unit aramid fiber honeycomb in-built part forming process. A panel is prepared from phenolic resin or cyanic acid prepreg; a middle core material is prepared from aramid fiber honeycomb; phenolic resin glass fiber foam felt is placed between the honeycomb and prepreg at corners; two layers of the prepreg are respectively paved on the upper and lower surfaces of the honeycomb; phenolic resin glass fibre foam felt is placed between the honeycomb and prepreg; blank combined by the materials is wrapped by an isolating membrane and then the wrapped blank is put onto a mould for press forming. The in-built part is light in quality, small in density and convenient to dismount, exchange and repair; the fireproofing and smoke prevention performance can reach the M1F1 grade of France NF16101, and accords with UIC564-2 standard; the production efficiency is improved greatly and the part size is accurate.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

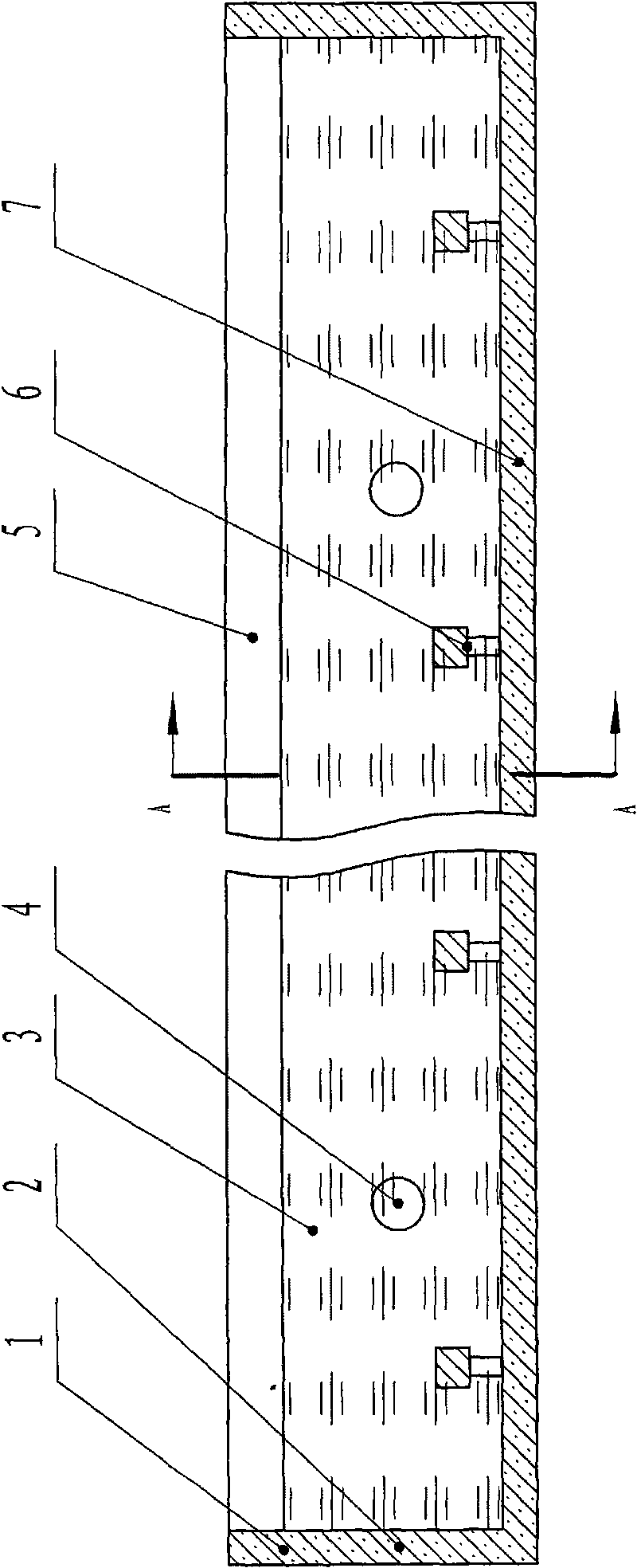

Cargo hold structure

ActiveCN103129699AImprove stress concentrationReduce welding workloadHull bulkheadsMachining processOil tanker

The invention discloses a cargo hold structure which comprises a bottom side tank inclined bottom plate (1), an inner bottom plate (2) and an inner bottom side stringer (3), wherein the lower portion of the inner bottom side stringer (3) is vertically supported. The inclined bottom plate (1) and the inner bottom plate (2) are connected through a board and by utilizing of a bent arc transition mode. The inner bottom side stringer (3) is supported below a knuckle line (7) formed by intersecting of extension planes of the inclined bottom plate (1) and the inner bottom plate (2). The cargo hold structure is especially suitable for an oil tanker cargo hold. A three-line centering and arc transition type connection structure of the bottom side tank inclined bottom plate and the inner bottom plate is mainly designed. According to the cargo hold structure, welding and polishing work load is effectively reduced. Fatigue resistance is effectively improved, at the same time, constructing and machining processes are simplified, work efficiency is improved, and the cargo hold structure has the advantages of being low in cost and high in strength.

Owner:DALIAN SHIPBUILDING IND

Balance beam intelligent welding method based on robot welding production line

ActiveCN109885007AImprove welding efficiencyReduce types of workTotal factory controlWelding apparatusProduction lineScheduling instructions

The invention discloses a balance beam intelligent welding method based on a robot welding production line. An MES issues a production line production scheduling instruction; a balance beam is manually hung and conveyed to a feeding and blanking station; manual code scanning confirmation is performed; an RGV automatically conveys the balance beam to an MES specified welding station; a welding robot performs welding seam welding in the balance beam according to offline program; after the welding is completed, the balance beam is conveyed to the feeding and blanking station by the RGV; the balance beam is manually hung and conveyed to a repair welding station for repair welding; a support pipe and an upper wing plate are installed; the balance beam is manually hung and conveyed to the feeding and blanking station again; the manual code scanning confirmation is performed again; the RGV automatically conveys the balance beam to the MES specified welding station; the robot performs weldingseam welding outside the balance beam according to the offline program; after the welding is completed, the RGV conveys the balance beam to the feeding and blanking station; the balance beam is manually hung and conveyed to the repair welding station; sealing plates at two sides of the box body, an electric pipe and an anti-shearing block are installed; the balance beam is conveyed off the line; and the manual inspection is completed. The method has the advantages that the work intensity of workers is reduced; the welding quality of the balance beam and the management level in the production process are improved; and the construction environment is improved.

Owner:SHANGHAI ZHENHUA PORT MACHINARY HEAVY IND CO LTD

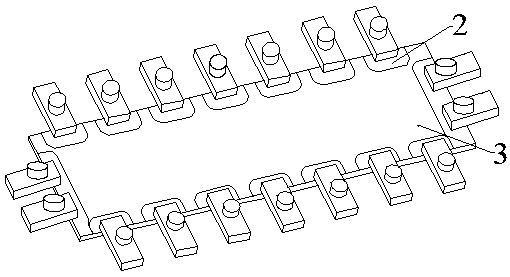

Connecting member for mounting of spring supports and hangers and manufacturing method of connecting member

ActiveCN104879572AReduce porosityReduce tensionPipe supportsFoundry mouldsRare-earth elementUltimate tensile strength

The invention discloses a connecting member for mounting of spring supports and hangers. The connecting member comprises a base and supporting frames, the supporting frames are symmetrically arranged on the base, the supporting frames and the base form a U-shaped groove, a threaded hole is formed in each supporting frame, the base is of a cuboid structure, a fixing hole is formed in each of four corners of the base, a zinc layer is plated on the surface of each supporting frame, the base and the supporting frames are made by a same material, and the material is composed of Cr, Mo, C, Co, Mn, P, S, Ni, Ti, W, V, Cu, Si, Nb, Ta, N, Mg, rare earth element and the rest Fe and unavoidable impurities. The invention further discloses a manufacturing method of the connecting member. The manufacturing method is simple and easy to implement, pollution-free in manufacturing process and low in manufacturing cost, and the connecting member manufactured by the method is resistant to corrosion and wear, high in strength and tenacity and long in service life.

Owner:BEIDELI ENERGY EQUIP JIANGSU CO LTD

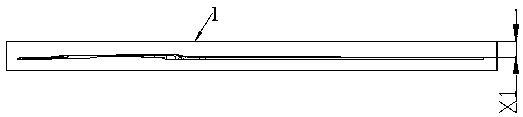

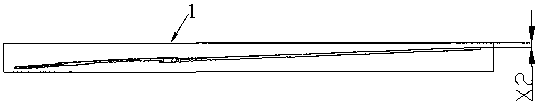

Machining method for controlling thickness of stainless steel sheet part

The invention discloses a machining method for controlling the thickness of a stainless steel sheet part. The method comprises the following steps: firstly tightly pressing a blank of a sheet part toform all pressure plate grooves, wherein the pressure plate grooves are more than 0.2mm lower than a reference surface to be corrected; then tightly pressing the blank, carrying out rough machining and fine machining on a first surface, and when a web plate after fine machining is in place, correcting the reference surface under the situations of the same working step, the same tight pressing state and the same tool so as to reduce the the error between the actual distance and the theoretical distance between the sheet part and the reference surface; and during machining of a second surface, it is guaranteed that the reference surface and a positioning surface are tightly attached so as to effectively control the thickness of the sheet part. According to the machining method for controlling the thickness of the stainless steel sheet part, the machining errors of the stainless steel sheet part can be effectively reduced, the ultrathin phenomenon of the stainless steel sheet part is avoided, the machining efficiency of the sheet part is improved, and the machining quality and stability of the sheet part are ensured.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

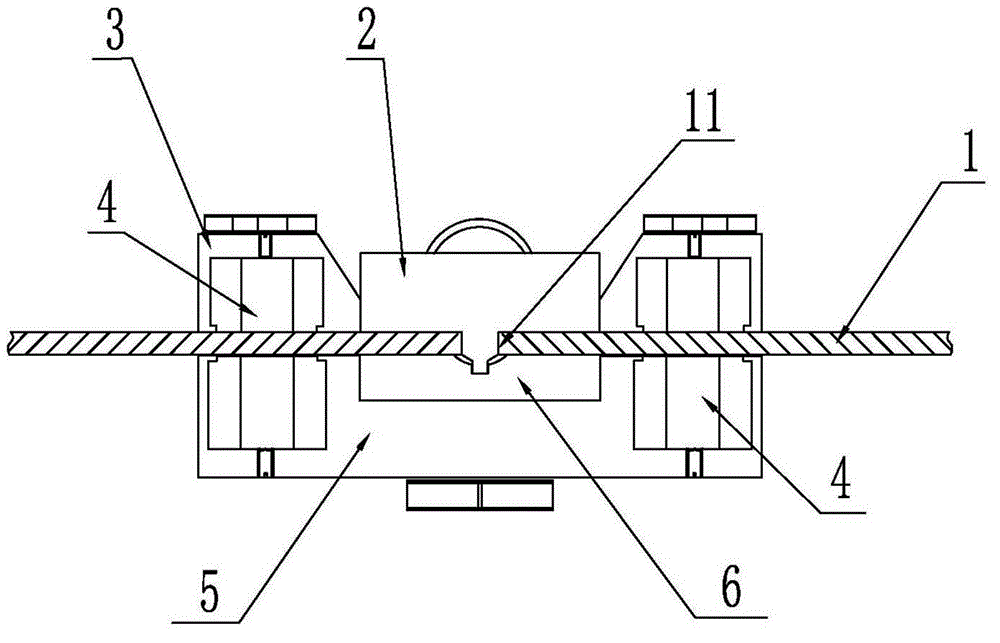

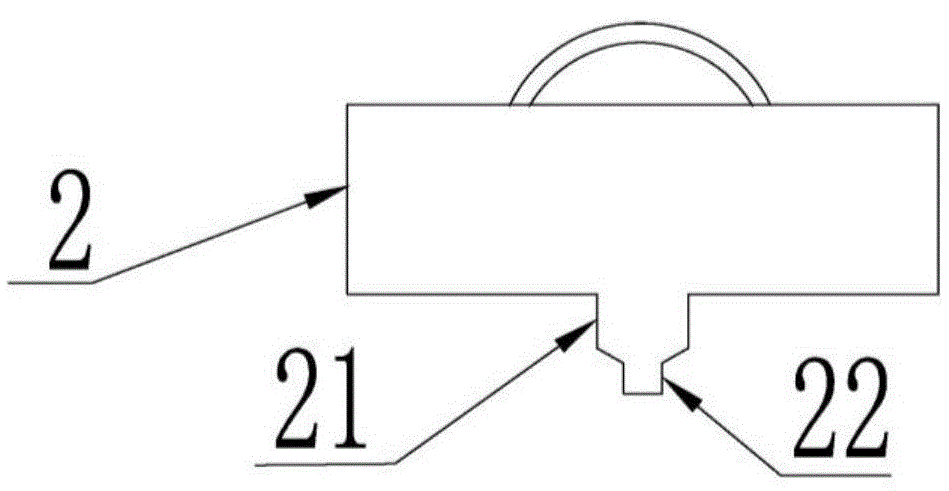

Device and method for controlling suspension welding seam root gap and welding deformation in self-supporting mode

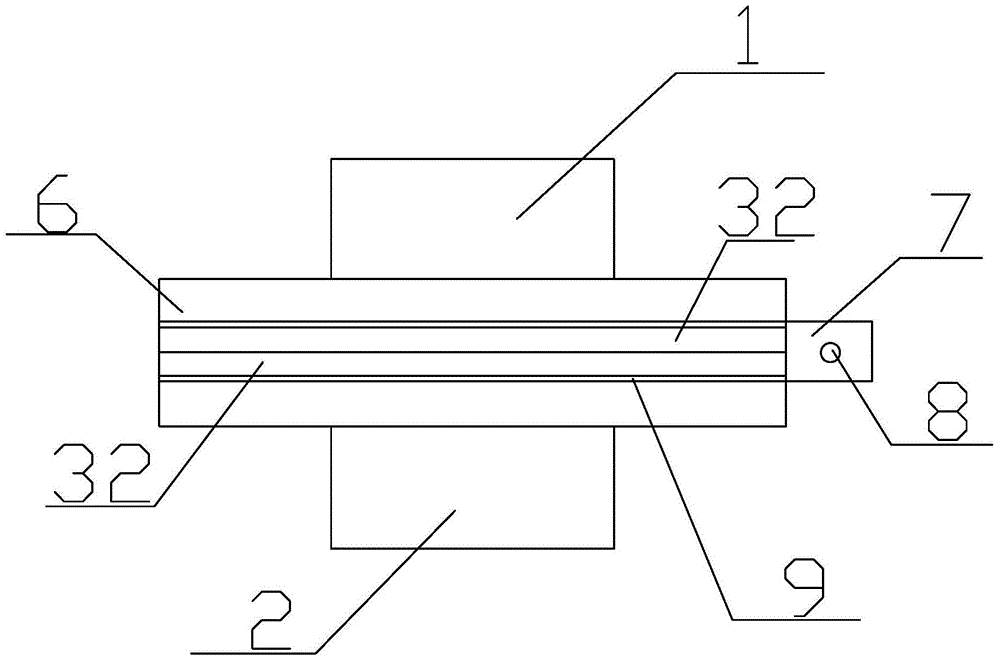

ActiveCN104625318AWell formedEasy to useWelding/cutting auxillary devicesArc welding apparatusEngineeringWeld seam

The invention discloses a device and method for controlling a suspension welding seam root gap and welding deformation in a self-supporting mode. The device comprises a positioning block, upper rigid press blocks, a lower rigid press block and a forming groove. The positioning block comprises a positioning block body and a positioning part, wherein the positioning part penetrates through the seam root gap and is embedded in the forming groove. The upper rigid press blocks are symmetrically installed on the two sides of the positioning block body, the lower rigid press block is provided with provided with an inward-concave part matched with the forming groove, and the forming groove is formed in the inward-concave part. Magnets are installed in the upper rigid press blocks and the lower rigid press block. The invention further discloses the method with the device for controlling the suspension welding seam root gap and the welding deformation in the self-supporting mode used. The device for controlling the suspension welding seam root gap and the welding deformation in the self-supporting mode is convenient to use, low in cost and high in adaptation, the transverse retraction and staggered edges of a welding seam can be controlled, the welding deformation can be reduced, and it can be ensured that the back face of the welding seam is good in formation.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

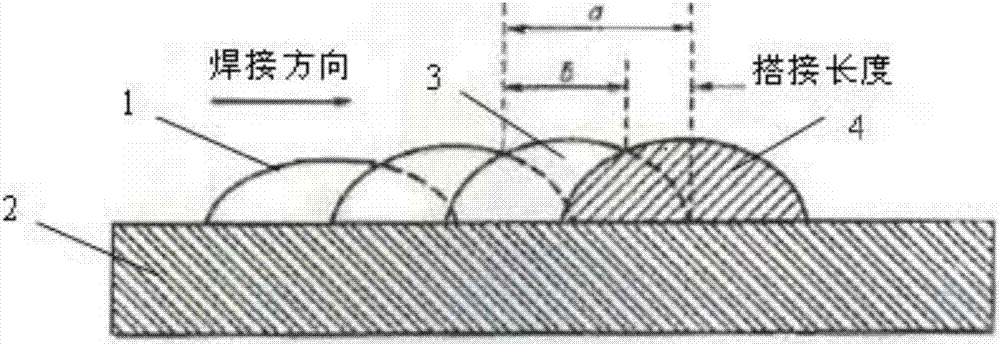

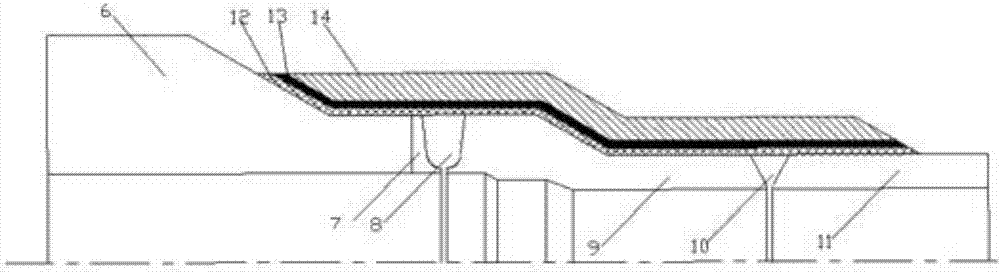

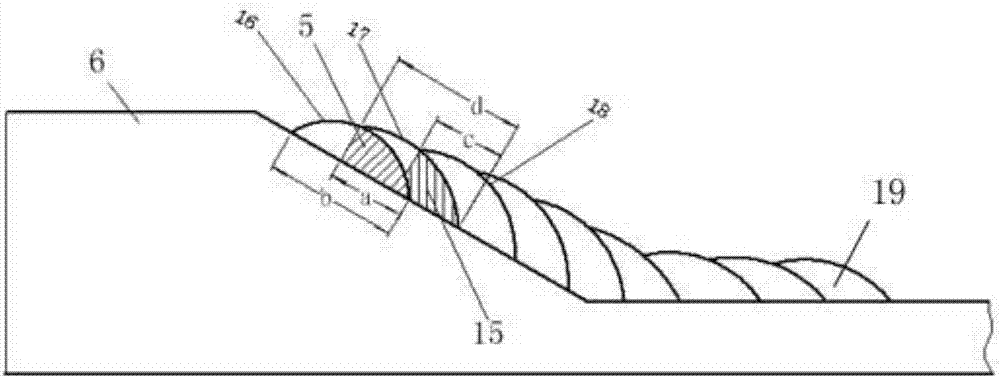

Automatic tempering surfacing welding method for pipeline maintenance

ActiveCN107186317AImprove organizationImprove performanceArc welding apparatusTubular articlesHeat-affected zoneNuclear power

The invention discloses an automatic tempering surfacing welding method for pipeline maintenance. The method comprises the steps of 1, tempering surfacing welding layer welding, wherein a tempering surfacing welding layer is welded to the ring surface of a to-be-maintained pipeline of a dissimilar metal joint, and in the tempering surfacing welding layer welding process, welding is conducted in a layer welding manner, and then a bead overlapping manner is adopted for welding; 2, transition surfacing welding layer welding, wherein a transition surfacing welding layer is welded to the tempering surfacing welding layer in a surfacing welding manner; 3, reinforcing tempering welding bead welding, wherein tempering welding is conducted on the two ends of the tempering surfacing welding layer and the two ends of the transition surfacing welding layer; and 4, polishing, wherein after welding is completed, reinforcing welding seams are polished to required sizes. On the one hand, structure and performance of a heat-affected zone on the low alloy steel side of the dissimilar metal joint of a nuclear power device can be effectively improved, and postweld heat treatment is not conducted after surfacing welding maintenance is conducted; on the other hand, according to the designed reinforcing welding seam structure form, not only can the tempering effect of the two ends of a workpiece be improved, but also the polishing working load of completed welding seams is effectively reduced.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Processing technique of end teeth

The invention discloses a processing technique of end teeth, comprising the steps of 1, preparing a material; 2, forging; 3, carrying out thermal treatment; 4, carrying out turning I; 5, roughly machining teeth; 6, drilling, and machining screw holes; 7, carrying out high-frequency thermal treatment; 8, carrying out carburization thermal treatment; 9, carrying out turning II; 10, grinding; 11, flattening by dressing, and polishing; 12, inspecting, and measuring; 13, cleaning; 14, oiling, and packaging. Modifications are made herein in order to solve the problems that, for instance, end teeth processed by means of existing end tooth processing techniques are low in hardness, poor in wear resistance, prone to rusting, low in surface flatness, prone to causing noise during operating and shortin service life. The processing technique herein has the advantages that, for instance, end tooth hardness is improved, end tooth wear resistance is improved, corrosion resistance of end teeth is improved, surface flatness of end teeth is improved, the end teeth produce less noise during operating, and the end teeth have longer lives.

Owner:雄名航空科工(芜湖)股份有限公司

Optimized technology for manufacturing water glass shell

InactiveCN105014004ALow costEliminate prone defectsFoundry mouldsFoundry coresAluminium chlorideMullite

The invention relates to the steel casting industry, in particular to an optimized technology for manufacturing a water glass shell. The Be' of water glass ranges from 39 to 41, the modulus M of the water glass ranges from 3.1 to 3.4, and the density rho of the water glass ranges from 1.33 g / cm<3> to 1.368 g / cm<3>. A first face layer is formed by a mixture comprising 85% to 92% of 200-mesh quartz powder and 8% to 15% of 70-mesh-to-140-mesh quartz sand, the powder-liquid ratio n is 1.25 to 1.40:1, the viscosity measured through a phi6 flow cup ranges from 20 S to 60 S, the thickness of a coating ranges from 0.28 mm to 0.42 mm, and 40 / 70-mesh quartz sand is scattered. A second face layer is formed by 200-mesh quartz powder, the powder-liquid ratio n is 0.8 to 1.15:1, the viscosity measured through a phi6 flow cup ranges from 20 S to 60 S, the thickness of a coating ranges from 0.22 mm to 0.26 mm, 20 / 40-mesh quartz sand is scattered, and hardening is carried out through ammonium chloride. A transition layer is formed by mullite powder, the viscosity measured through a phi8 flow cup ranges from 8 S to 25 S, and 16 / 30-mesh mullite sand is scattered. Reinforcing layers are formed by 200-mesh mullite powder, the powder-liquid ratio n is 1.10 to 1.75:1, the viscosity, measured through a phi8 flow cup, of the first layer ranges from 30 S to 40 S, the viscosity, measured through the phi8 flow cup, of the second layer ranges from 50 S to 65 S, the viscosity, measured through the phi8 flow cup, of the third layer ranges from 70 S to 85 S, the viscosity, measured through the phi8 flow cup, of the fourth layer and the other layers ranges from 90 S to 120 S, 10 / 20-mesh mullite sand is scattered, and hardening is carried out through aluminum chloride. The manufactured shell can meet the requirements for cast fine steel castings.

Owner:江苏万恒铸业有限公司

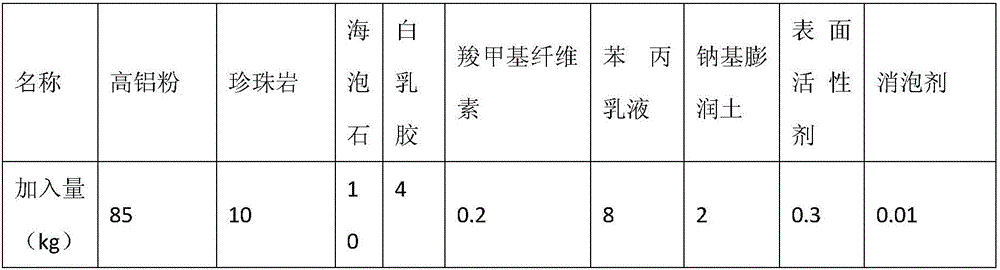

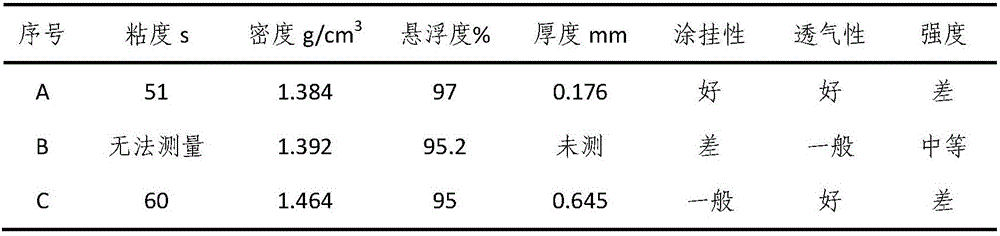

Cast-iron evaporative pattern coating and preparation method thereof

The invention provides a cast-iron evaporative pattern coating and a preparation method thereof. The cast-iron evaporative pattern coating comprises 84 to 88 parts of high aluminum powder, 8 to 12 parts of perlite, 8 to 12 parts of sepiolite, 6 to 10 parts of styrene-acrylic emulsion, 2 to 3 parts of sodium bentonite, 2 to 5 parts of white latex, 0.1 to 0.4 part of carboxymethylcellulose, 0.2 to 0.6 part of additive, and 105 to 120 parts of water. The coating of the invention has the advantages of uniformity and smoothness and good air permeability, and is easy to overcome the problems that the casting is easy to spray back and the local carbon is deficient, and the strength is high under the high temperature condition, which can eliminate the sticky sand and the collapse of the casting surface.

Owner:桃江新兴管件有限责任公司

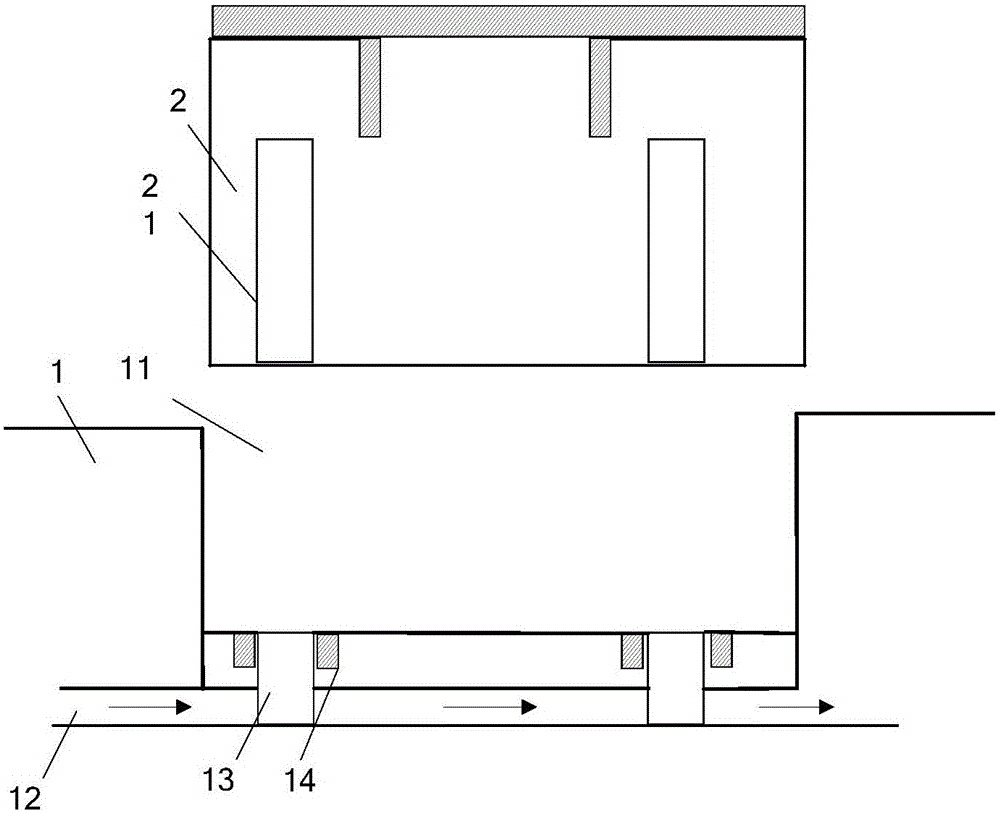

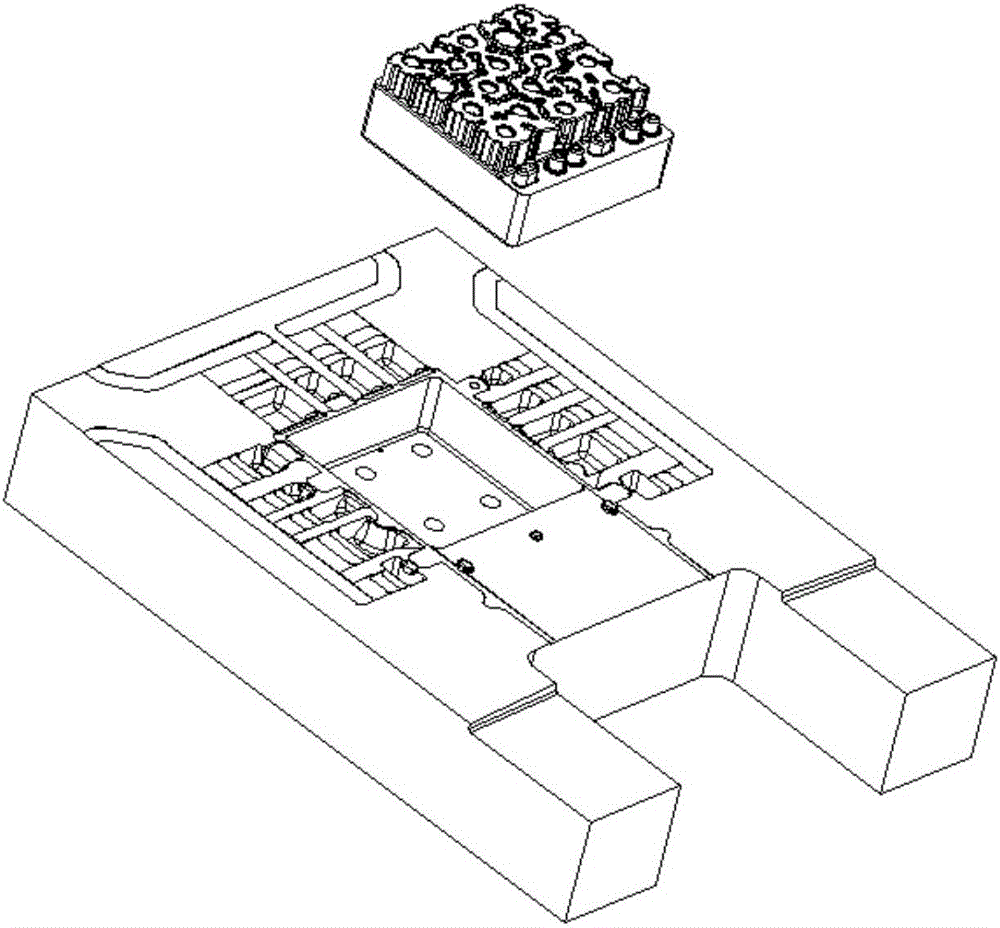

Inlaying structure for telecommunication base station filter cavity mold and production method thereof

The invention discloses an inlaying structure for a telecommunication base station filter cavity and a production method thereof. The inlaying structure comprises a mold body and an insert. A groove is formed in the middle of the mold body; a cooling water channel and at least one vertical cooling groove are formed in the mold body; the vertical cooling grooves are both located in the bottom of the groove; the shape and size of the groove are the same as those of the insert; the depth of the groove is equal to or smaller than the height of the insert; and vertical cooling grooves are formed in the insert. When the insert is mounted in the groove of the mold body, the vertical cooling grooves of the mold body and the vertical cooling grooves of the insert are matched and in correspondence in the vertical direction. During using of the inlaying device, when products are remodeled or improved or when casting points on the surface of the filter cavity are worsened and influence the grinding process to be not capable of bearing any more, the surface quality can be improved quickly only by changing an insert prepared in advance, and the grinding workload is reduced. The inlaying structure can effectively save the production cost while guaranteeing the forming quality.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL +1

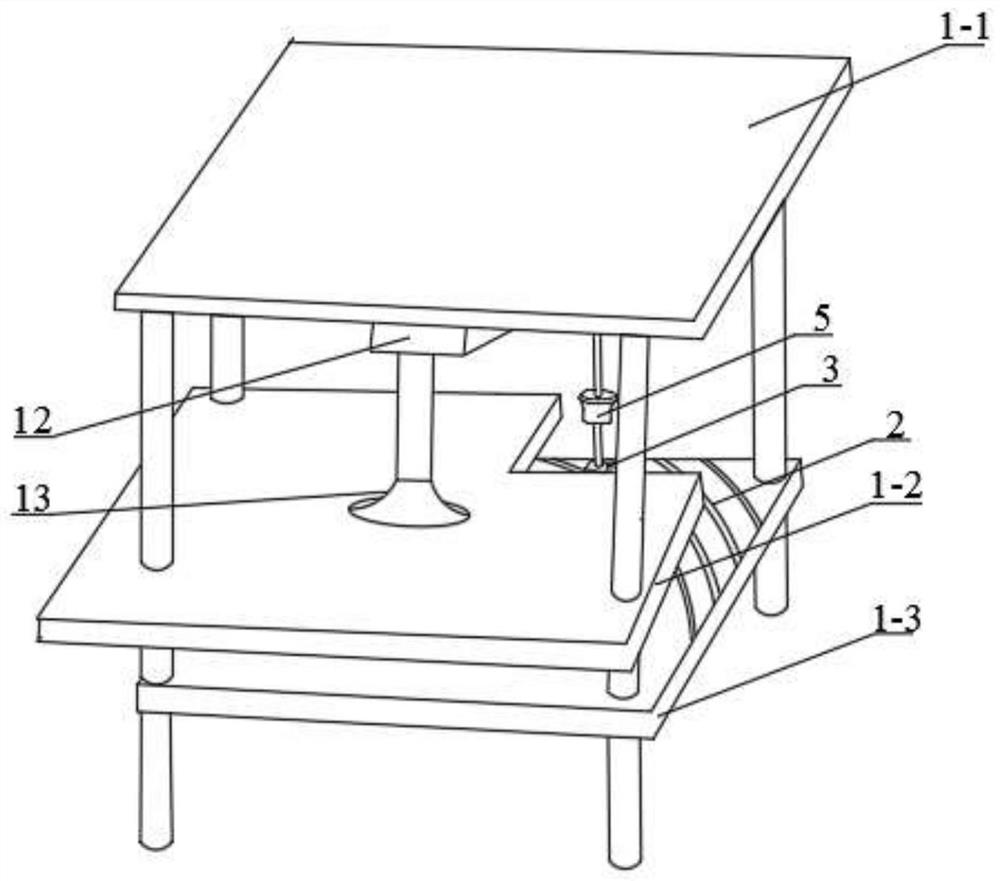

Board fillet processing method and fillet cutting equipment

PendingCN113977708AHigh strengthGuaranteed aestheticsProfiling/shaping machinesDomestic articlesStructural engineeringIndustrial engineering

The invention provides a board fillet processing method which comprises the following steps: firstly, cutting four corners of a board into fillets by using cutting equipment, bonding matched decorative films on the surfaces of the fillets, and then fixing film-coated sheet metal parts at the fillets. Cutting equipment on which the method depends comprises a rack, a lower arc-shaped track arranged on a bottom board of the rack, a cutting wheel sliding along the lower arc-shaped track, a driving mechanism for driving the cutting wheel to slide, and a fixing mechanism fixed on a top board of the rack and used for fixing the board. According to the cutting equipment, in the working process, a wood board is fixed, the cutting wheel slides along the arc-shaped track for cutting, the cutting stability and the chamfering attractiveness are guaranteed, and the later polishing workload is reduced; and the board and a sheet metal part are subjected to film pasting through a film laminating technology and then fixed, so that the strength of the fillet of the board is improved, collision damage is avoided, the service life is long, and attractiveness is achieved.

Owner:漾子家居(天津)有限公司

A kind of friction stir welding stirring head material and preparation method of stirring head

ActiveCN108677075BHigh strengthImprove wear resistanceNon-electric welding apparatusFree coolingTitanium carbide

The invention discloses a friction stir welding stirring head material and a preparation method of the stirring head, belonging to the technical field of welding stirring head preparation. The material of the friction stir welding stirring head includes: 75-85% of tungsten powder and 15-25% of carbon alloy powder in terms of weight percentage, and the carbon alloy powder is one or a combination of titanium carbide powder and zirconium carbide powder . The preparation method of the stirring head includes: (1) mixing the tungsten powder and the carbon alloy powder according to the above-mentioned ratio and placing them in the stirring head mold for preforming to obtain a preformed green body; (2) making the preformed The green body is placed in the furnace, and the temperature is raised to 2000-2200°C with the furnace, the pressure in the furnace is adjusted to 20-25MPa, and the temperature is kept for 1-1.5h, and it is produced after natural cooling with the furnace. The stirring head prepared by the invention has excellent strength and wear resistance, can significantly improve the service life of the stirring head, the alloy powder used is easy to obtain, and the cost of raw materials is greatly reduced.

Owner:SOUTHWEST JIAOTONG UNIV

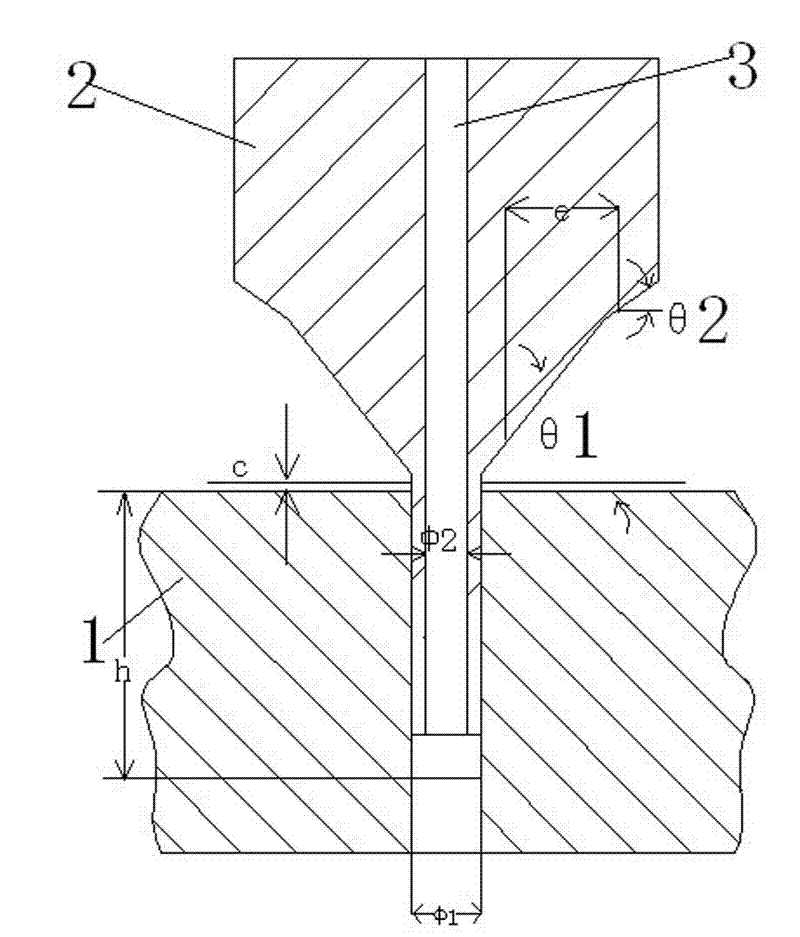

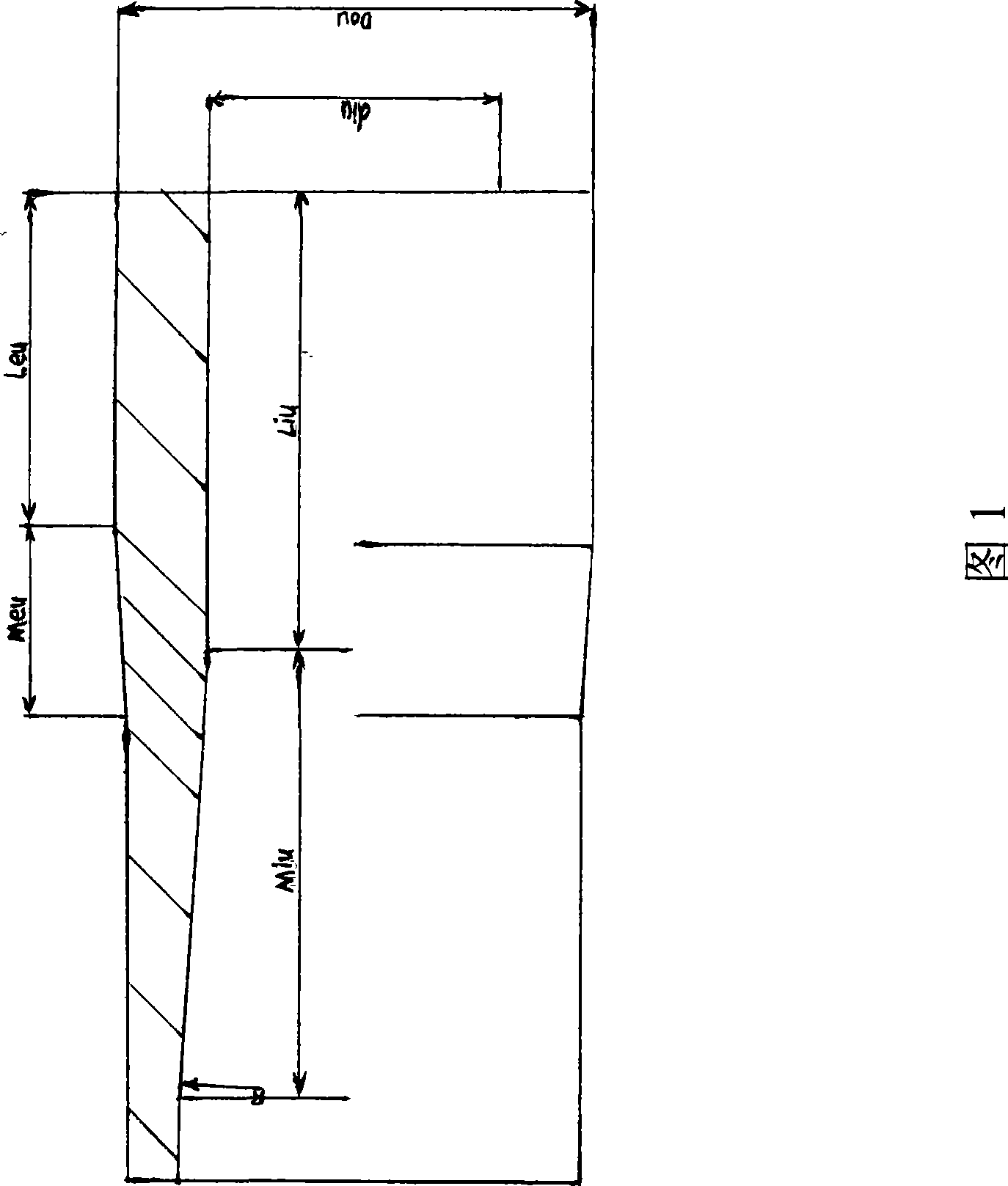

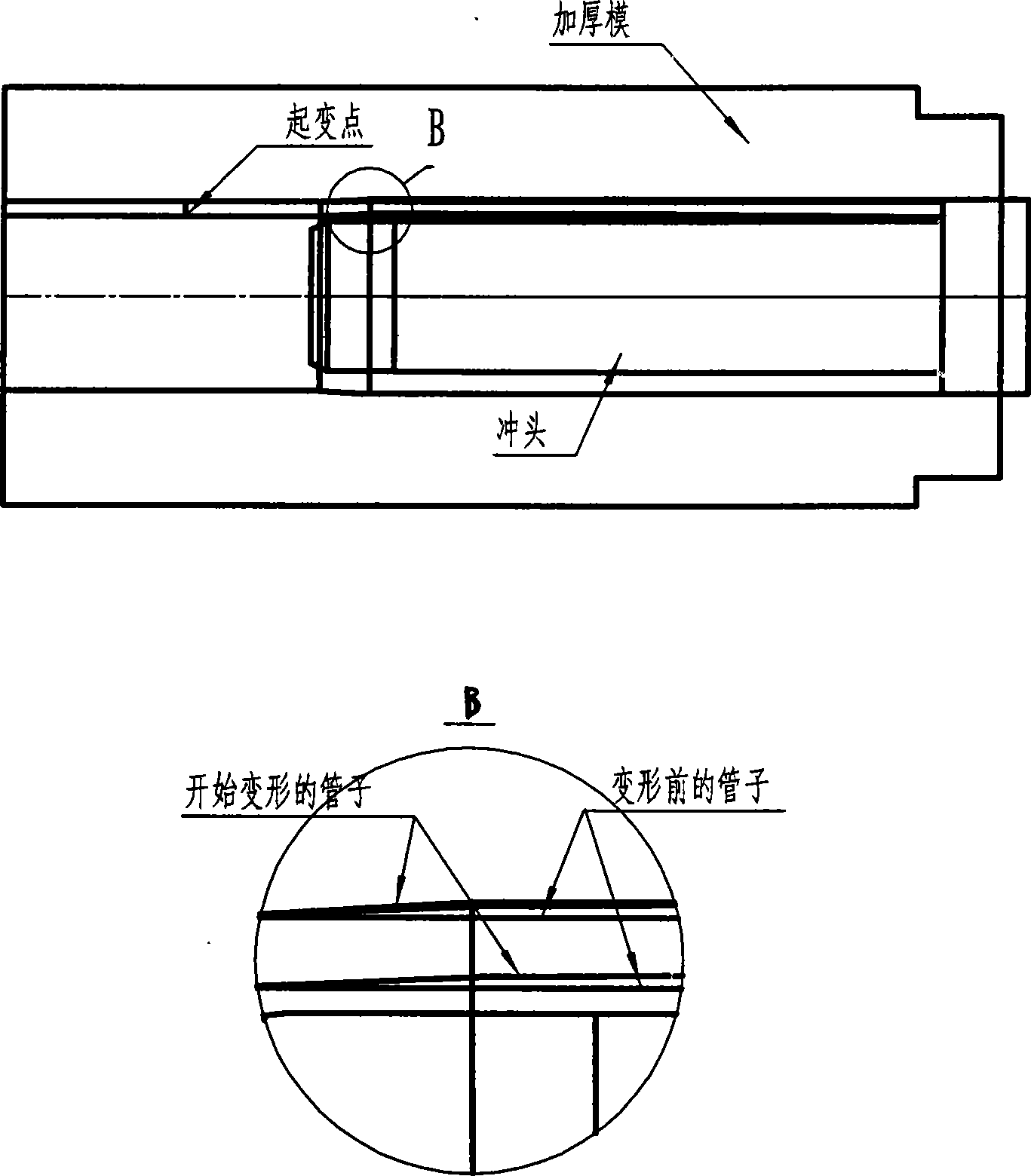

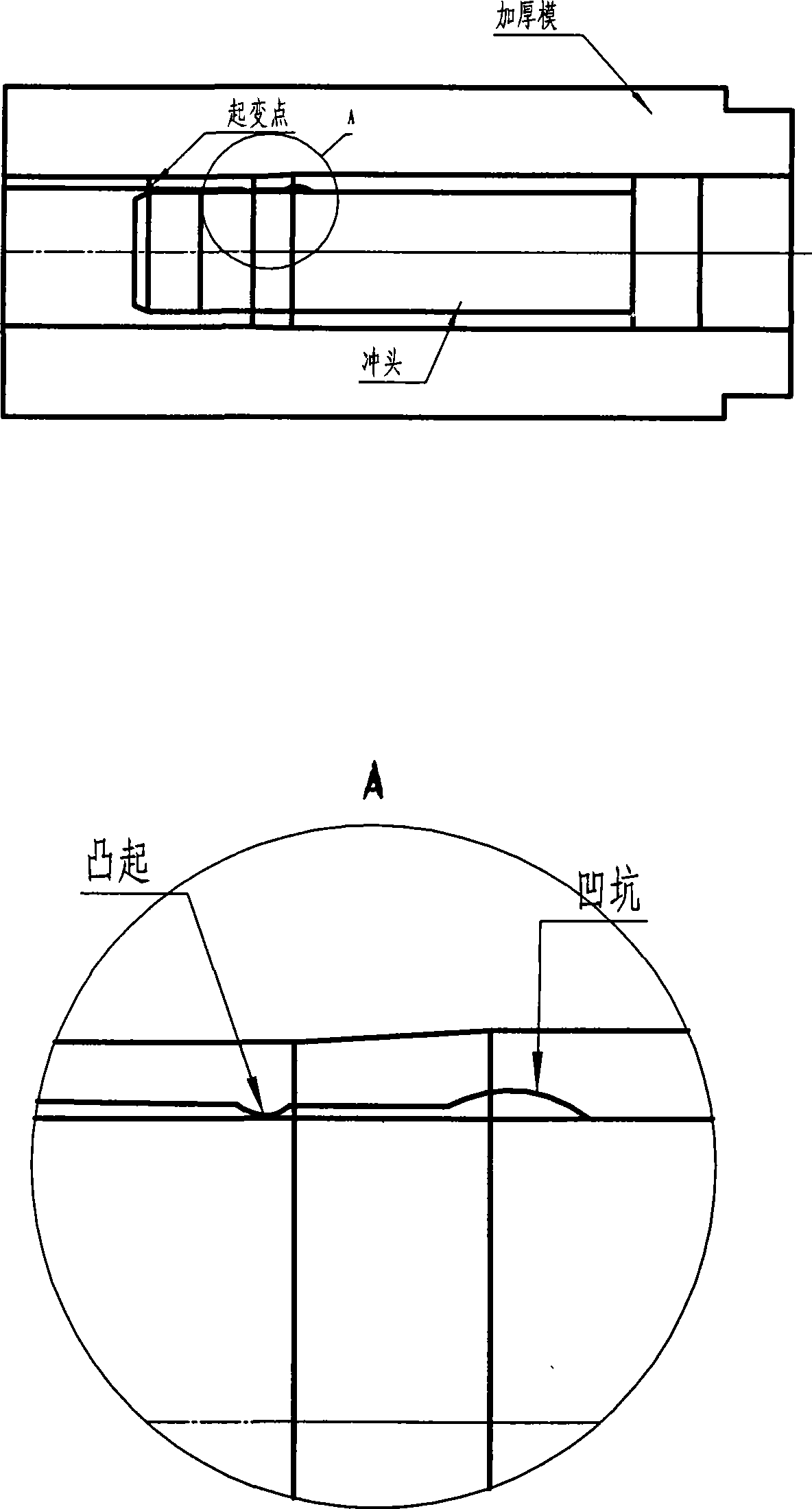

Drill rocker end upsetting method

InactiveCN101439385AImprove smooth transition shapeReduce grinding workloadMetal-working apparatusUpset forgingDrill pipe

The invention relates to a technology for thickening the pipe end of a drill pipe, an oil pipe and a sleeve used for oil and natural gas drilling, in particular to a method for thickening the pipe end of the drill pipe. The conicity and the length of a pipe end external thickening transitional section and an external thickening section are molded by mould control. The conicity and the length of an internal thickening transitional section are molded freely by the upset forging of a punching head. The technology is characterized in that each pass Meu during the process is shortened gradually, and the conicity is increased gradually. The invention mainly solves the technical problem in the multi-pass thickening technology by a drill pipe internal-external thickening method that the start point of the internal thickening transitional section of a first thickening pass always has concave pits and embossments. The invention improves the smooth transitional shape of an internal thickening transitional zone and ensures that the round angle diameter at the position of a thickening zone disappearing point is more than 300mm, and the invention reduces the workload for grinding and improves the thickening quality.

Owner:SHANGHAI HILONG DRILL PIPE MATERIALS INST

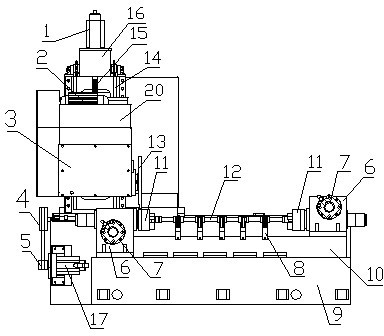

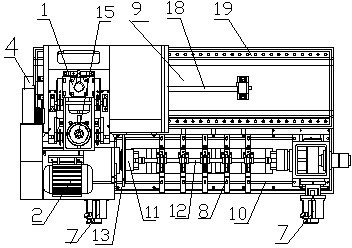

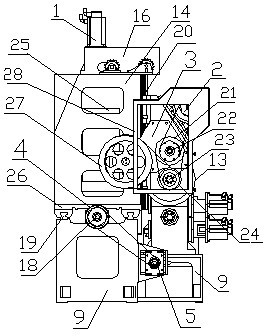

Fully CNC Camshaft Milling Machine

InactiveCN102274998AExtended service lifeUniform speedFeeding apparatusMilling equipment detailsDrive wheelMilling cutter

The invention discloses a full numerical control camshaft milling machine, which comprises a bed (9), a guide rail plate (10), a guide rail (19), a rotating power head (6), a milling power head (3) and a lifting power head (16), Rotary power heads are respectively arranged at both ends of the guide rail plate, hydraulic chucks (11) are arranged on the rotating power heads, and auxiliary supports (8) are arranged between the hydraulic chucks, and the milling power heads are arranged on the lifting platform, and the lifting platform (20) can move on the column (14). The milling power head includes the milling cutter spindle (23). The column can move left and right on the guide rail (19). An inertial balance wheel (27) or a milling cutter spindle is arranged on the milling cutter spindle. The main shaft is connected with the inertia balance wheel through the driven wheel (24) on the milling cutter main shaft. The milling cutter spindle of the present invention does not generate vibration, which not only reduces the processing noise, prolongs the service life of the milling cutter, but also improves the milling quality, reduces the reserved grinding amount, reduces the grinding workload, improves the processing efficiency, and reduces the Camshaft machining cost.

Owner:胡益萍 +2

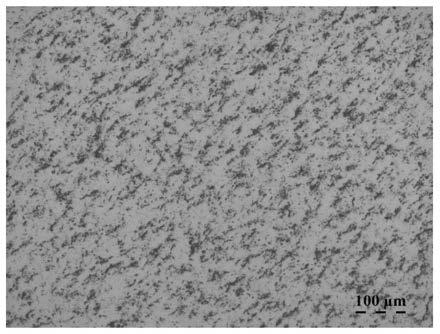

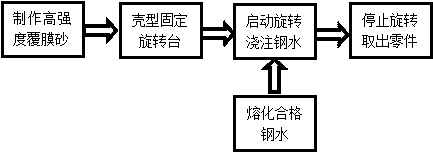

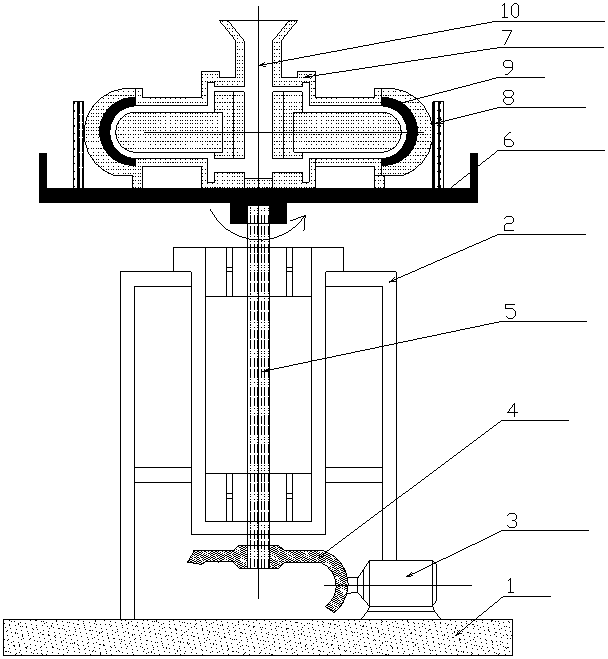

Centrifugal casting method of coated sand shell type cast steel

InactiveCN109093089AReduce dosageSave electricity consumption for smeltingFoundry mouldsFoundry coresProduction rateAlloy

The invention discloses a centrifugal casting method of coated sand shell type cast steel. The centrifugal casting method of the coated sand shell type cast steel comprises the following steps that high-strength coated sand is manufactured, coated sand raw sand is refined, silicon content of the raw sand is required to be more than or equal to 99.6%, and the raw sand is scrubbed and dried by tertiary water; shell-type is fixed to a centrifugal rotating table, and the coated sand shell type is fixed to the centrifugal rotating table; molten steel is smelted; rotating is started, molten steel pouring is carried out; the rotating is stopped, and parts are taken out. According to the centrifugal casting method of the coated sand shell type cast steel, the production rate can reach 95%, and thequalified rate of product leakage detection can reach more than 98%. Compared with an original coated sand shell type process, smelting power consumption of 52.6% can be saved, smelting alloy consumption is reduced by 30%, two welt risers can be omitted in per product, the cutting is reduced, and polishing workload can reach 80%.

Owner:JIANGSU YAWEI POUNDRY MATERIAL TECH CO LTD

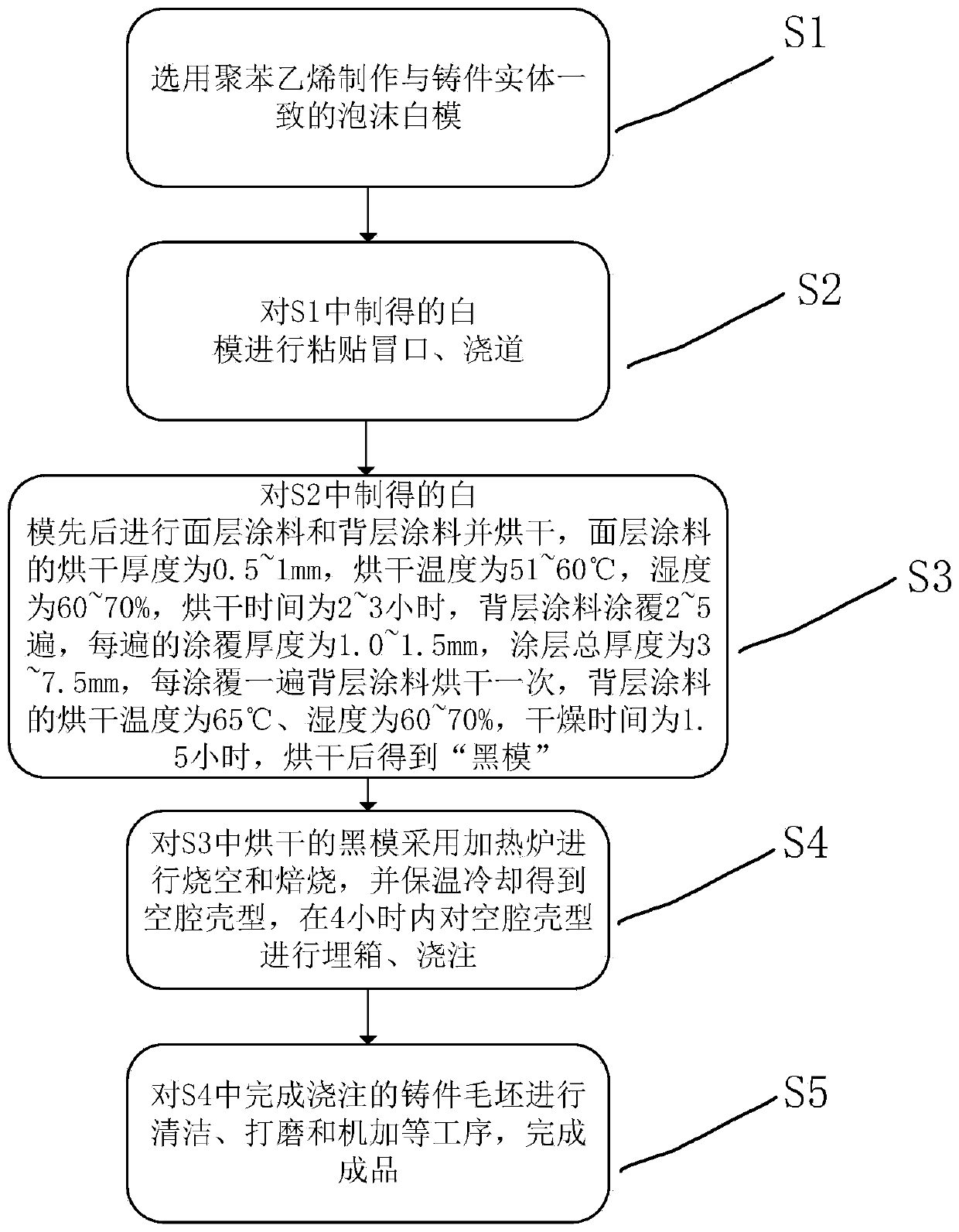

Evaporative pattern casting burned shell type casting process

InactiveCN111421112AReduce subsequent welding repairsReduce grinding workloadFoundry mouldsFoundry coresSurface finishPolishing

The invention relates to the technical field of casting forming and casting, in particular to an evaporative pattern casting burned shell type casting process. The process comprises the primary process flows of molding, riser and pouring gate adhering, coating, drying, burning, box burying, pouring, cleaning, polishing and machining. A casting produced by the casting process has the advantages ofbeing high in surface smoothness, high dimensional precision and the like, and the evaporative pattern casting burned shell type casting process not only can meet the demand on precision of the casting, but also can lower the production cost and reduce the production pollution greatly, can meet the demand on top-grade precise casting of complex structure, and is green and environment-friendly in shell manufacturing process.

Owner:JIANGSU JINGCHENG MASCH MFG CO LTD

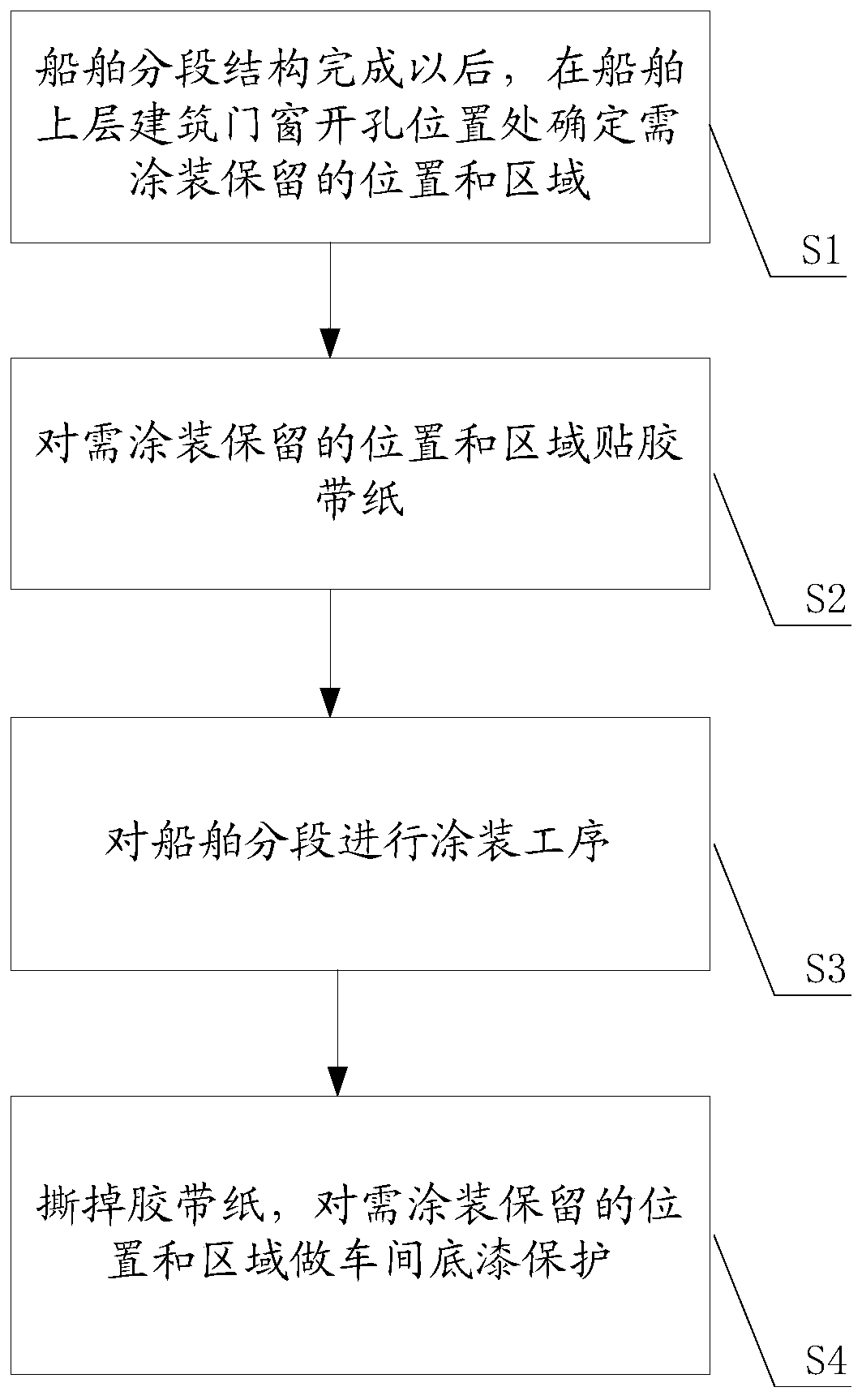

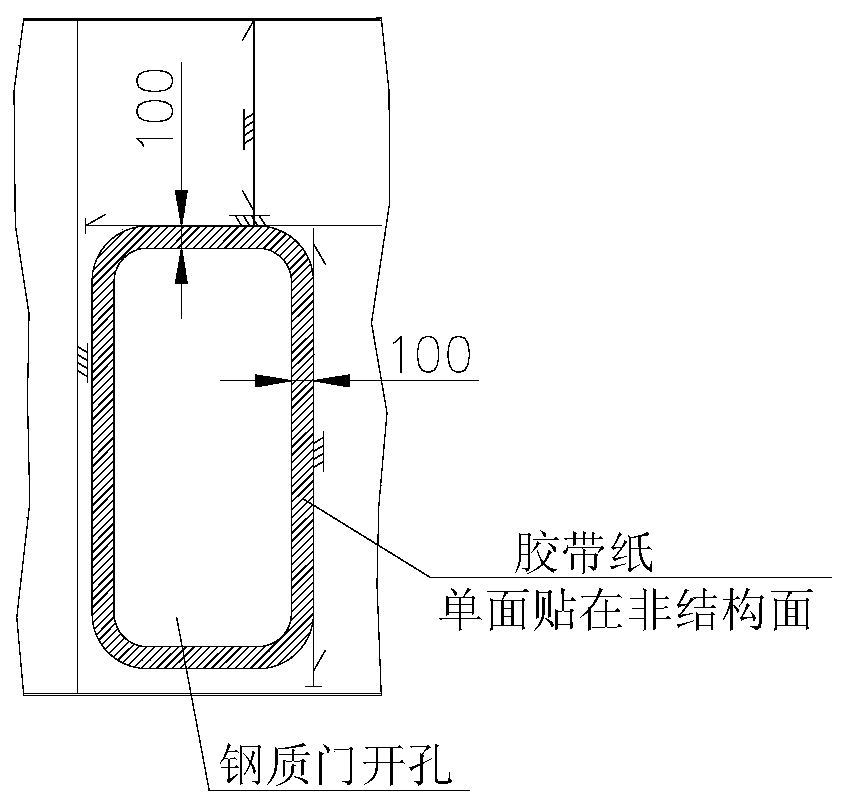

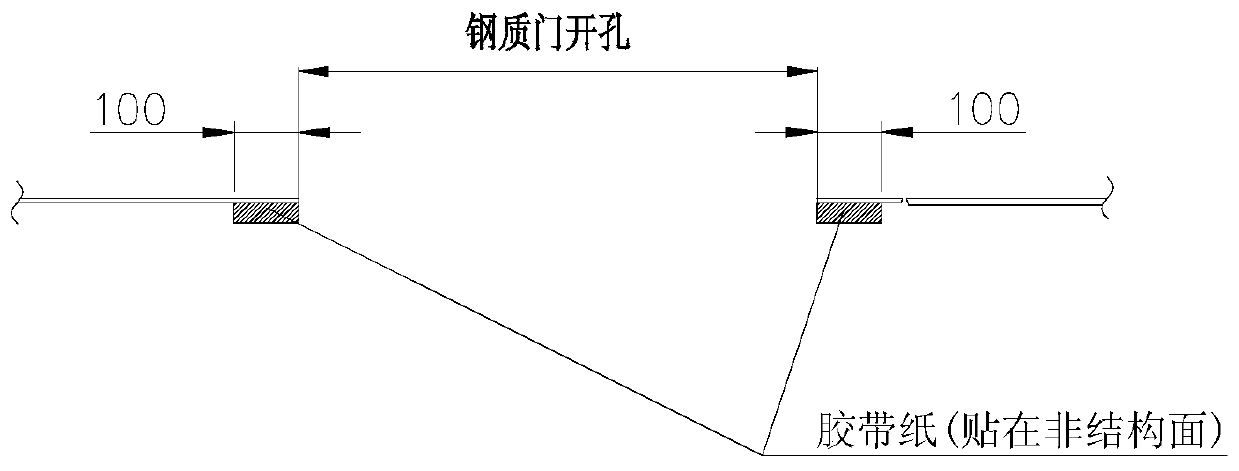

Method for coating retention around door and window open holes of large ship superstructure

InactiveCN111570219AReduce grinding workloadReduce grinding dustLiquid surface applicatorsCoatingsAdhesive beltMarine engineering

The invention discloses a method for coating retention around door and window open holes of a large ship superstructure. The method comprises the steps that after ship block structures are completed,positions and areas needing to be subjected to coating retention are determined at the door and window open holes of the ship superstructure; adhesive tape paper is pasted to the positions and areas needing to be subjected to coating retention; ship blocks are coated; and the adhesive tape paper is torn off, and the positions and areas needing to be subjected to coating retention are protected byworkshop primer. The labor cost is effectively lowered, and the construction period is shortened.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

Casting method for preventing large-scale steel casting surface from generating orange peel defects

ActiveCN107498006ASolve problems without direct contactAvoid the problem of reactive sinteringMoulding toolsFoundry mouldsMolten steelZircon

The invention relates to a casting method for preventing a large-scale steel casting surface from generating orange peel defects. The casting method includes the steps of modeling, coating spraying and mould assembling pouring. The step of coating spraying includes spraying of a first coating layer and spraying of a second coating layer, coating adopted in the first coating layer is emery powder coating, coating adopted in the second coating layer is zircon powder coating, the method for spraying the first coating layer is that the emery powder coating is sprayed to the surface of a steel casting cavity through a spraying machine, the spraying thickness is 0.2 mm to 0.3 mm, the method for spraying the second coating layer is that the zircon powder coating is sprayed to the first coating layer through the spraying machine, and the spraying thickness if 0.2 mm to 0.3 mm. The zircon powder coating layer and sand mould chromite sand are isolated through the emery powder coating layer, the zircon powder coating layer is not in direct contact with the chromite sand, and therefore the aim that the emery powder coating and molten steel are not in direct contact is achieved, and the problem of reactive sintering of the zircon powder coating and the chromite sand is avoided.

Owner:KOCEL STEEL

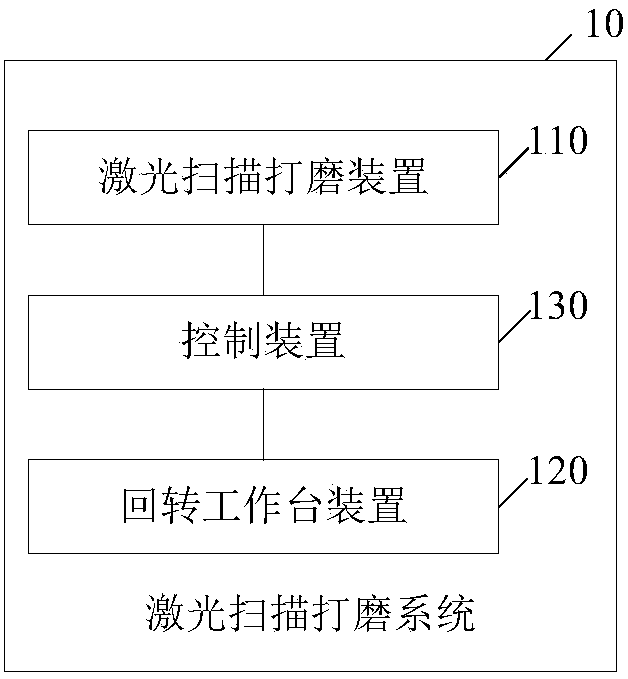

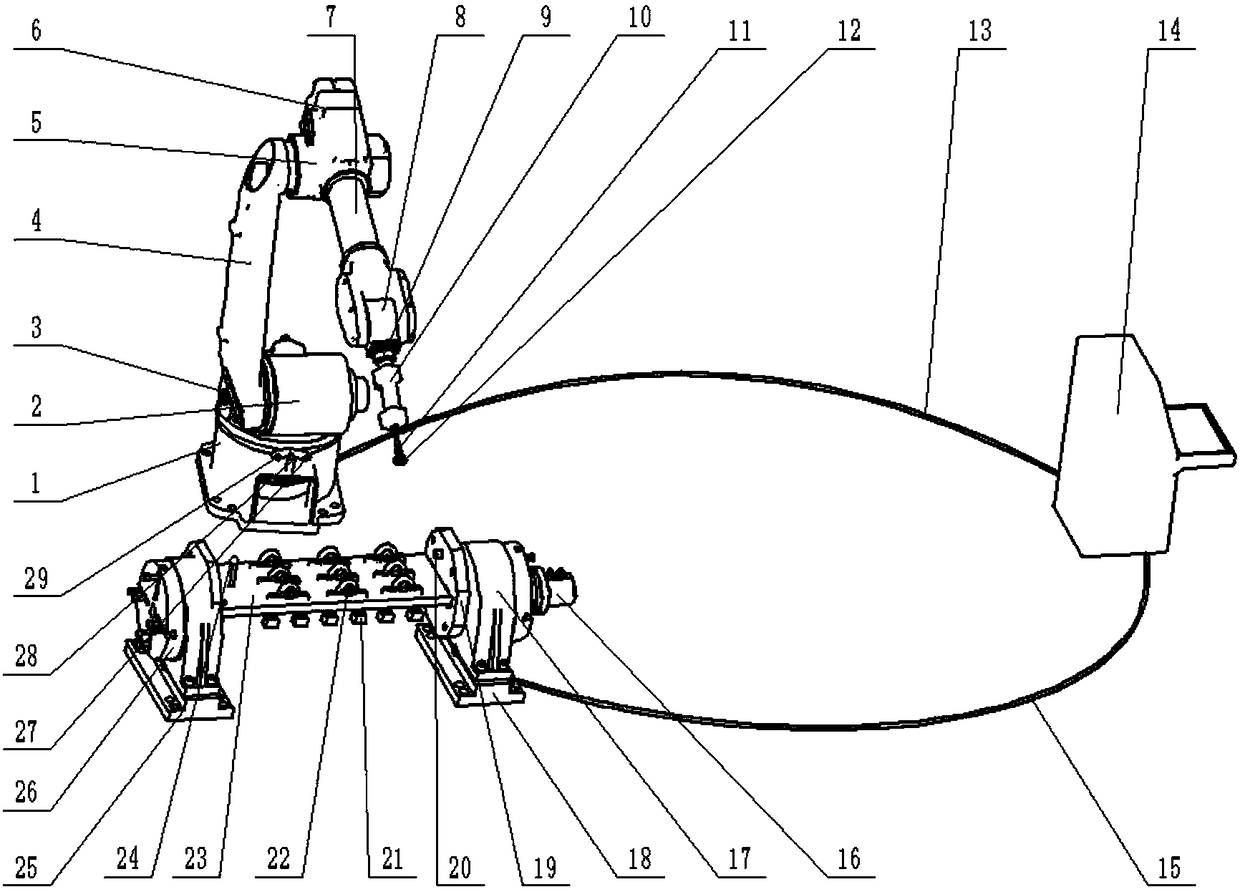

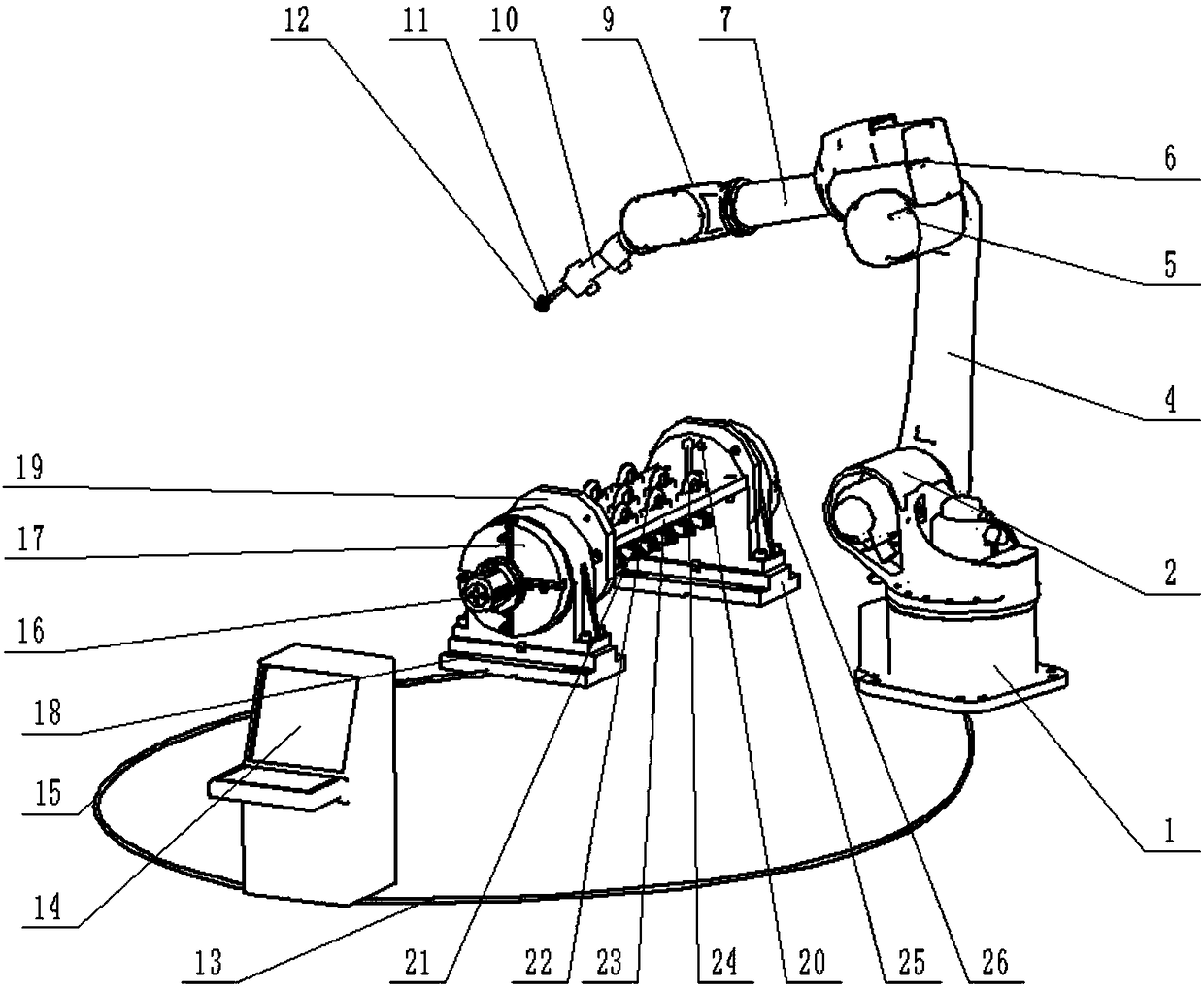

Laser scanning grinding system and method

ActiveCN108161664AHigh precisionImprove securityGrinding feed controlGrinding machinesLaser scanningEngineering

The invention relates to the technical field of grinding and polishing, and particularly discloses a laser scanning grinding system. The laser scanning grinding system comprises a laser scanning grinding device, a rotary workbench device and a control device. The laser scanning grinding device and the rotary workbench device are both connected with the control device. The laser scanning grinding device comprises a robot rotary base and a grinding mechanism arranged on the robot rotary base. A first laser scanning transmitting device, a second laser scanning transmitting device and a laser receiving device are arranged on the side, facing the rotary workbench device, of the robot rotary base. The laser receiving device is located between the first laser scanning transmitting device and thesecond laser scanning transmitting device. The rotary workbench device comprises a rotary workbench. The rotary workbench is used for fixing multiple to-be-ground parts and is provided with a third laser scanning transmitting device. The invention further discloses a laser scanning grinding method. The laser scanning grinding system has the advantage of precise grinding.

Owner:鹰普航空科技有限公司

Anti-sulfurizing coating

InactiveCN106734873AReduce manufacturing costLow maneuverabilityFoundry mouldsFoundry coresDefoaming AgentsSurface-active agents

The invention discloses anti-sulfurizing coating and belongs to the technical field of coating design. The anti-sulfurizing coating is composed of following components of, by mass, 100% of zircon powder, 0.2% of vegetable glue, 1% of modified clay, 1.6% of bakelite, 26% of water, 0.1% of a dispersing agent, 0.03% of a surface active agent, 0.3% of a thickening agent, 0.3% of a penetrant, 0.08% of a defoaming agent, 0.2% of a preservative and an anti-sulfurizing agent. The anti-sulfurizing coating disclosed by the invention is low in production cost, high in operability, reliable in performance and remarkable in anti-sulfurizing effect and crack prevention effect, and the workloads of cleaning, soldering and polishing are greatly lowered.

Owner:安徽龙氏机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com