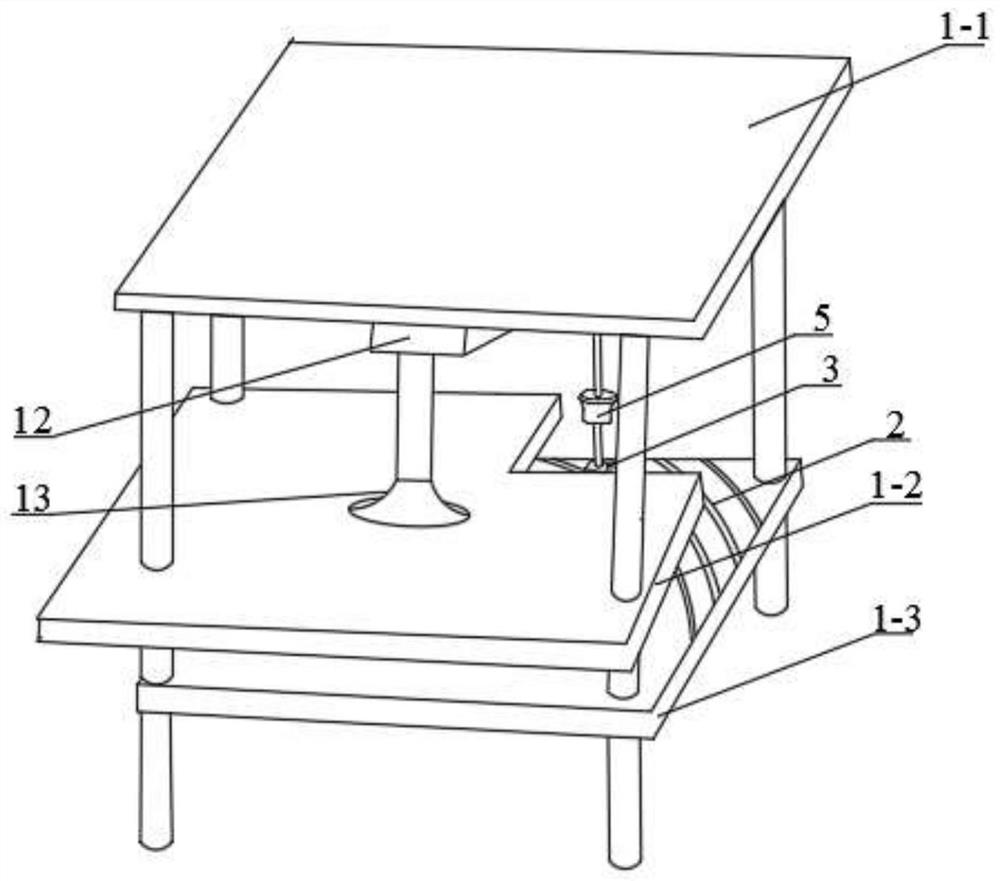

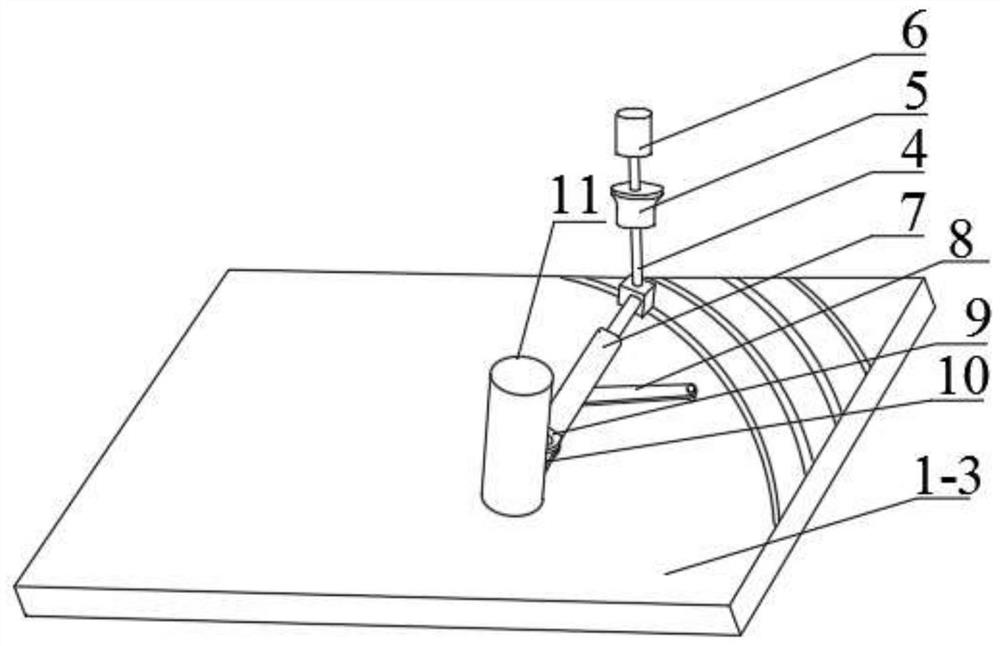

Board fillet processing method and fillet cutting equipment

A processing method and technology of cutting equipment, applied to wood processing appliances, manufacturing tools, household components, etc., can solve the problems of low strength and easy breakage of furniture corners, poor cutting stability of rounded corners, and low cutting efficiency, so as to reduce grinding Increased workload, increased strength, and beautiful service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 The present invention provides a method for processing plate rounded corners, comprising the following steps:

[0025] 1) Cut the rounded corners of the four corners of the plate with a cutting device;

[0026] 2) Bond a matching decorative film on the rounded surface of the board;

[0027] 3) Cutting and blanking the metal sheet, processing to obtain a sheet metal part with the same rounded corners as the four corners of the sheet metal, bonding a matching decorative film on the surface of the sheet metal part to obtain a film-coated sheet metal part;

[0028] 4) Fix the coated sheet metal parts at the rounded corners of the sheet. Through the setting of the film-coated sheet metal parts, the strength of the four corners of the sheet is increased, and the stress is dispersed to avoid being easily damaged by collisions. Bonding the decorative film can enhance the adhesion of the adhesive, and the decorative film can be made of PVC decorative film, which h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com