Automatic tungsten argon arc welding method for completely penetrated fillet weld of nuclear power main pipeline and branch pipe

A technology of argon tungsten arc welding and welding method, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problem that the internal quality welding stress and welding deformation are difficult to control, the surface quality and size of the weld seam are difficult to meet the technical requirements, Welders require high operating skills to achieve the effect of reducing labor intensity of workers, improving construction conditions and improving joint quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

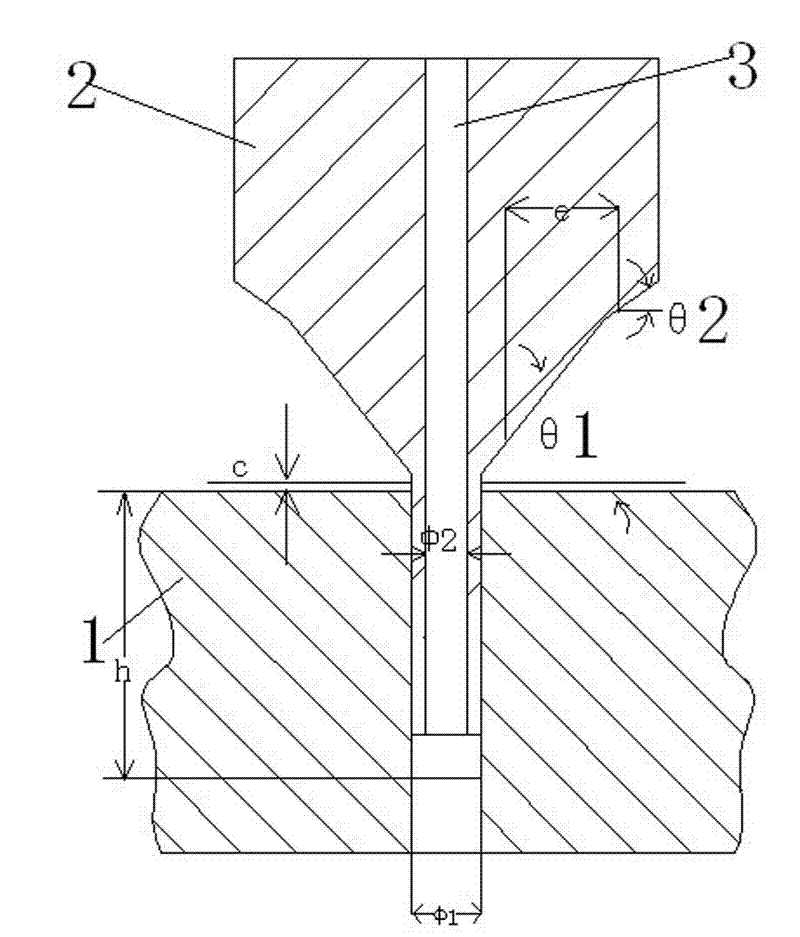

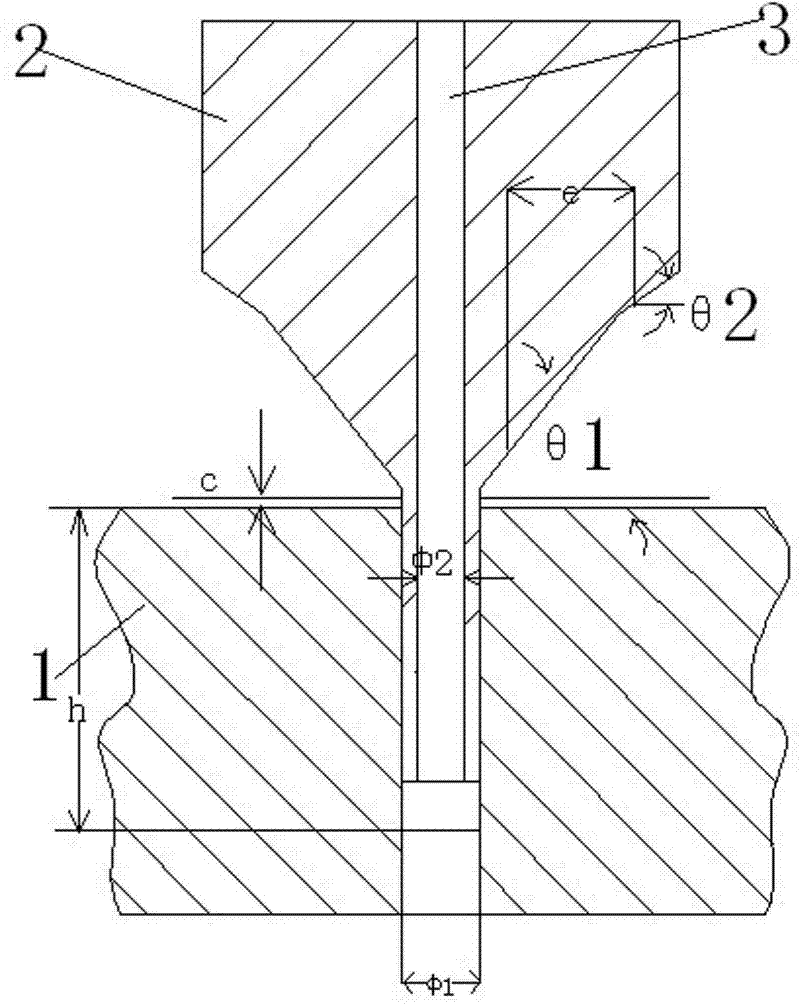

[0030] The automatic tungsten argon arc welding method for full-penetration fillet welds of nuclear power main pipes and branch pipes includes the following process steps:

[0031] The following describes the specific implementation of the present invention in the downward welding position of the AP1000 nuclear power Φ960×82.6 mm316LN main pipe joint and Φ50.8 mm316LN branch pipe joint in conjunction with the technical solution. The implementation steps are as follows:

[0032] (1) Processing the positioning hole of the main pipe 1, the diameter of the positioning hole Φ1 is 6.35 +0.05 , the depth h of the positioning hole is 31 mm; the welding groove of the branch pipe 2 is processed, and the inner groove angle θ1 is 30° +1 , the outer groove angle θ2 is 45° +1 , the inner groove depth e is 15.98, the length of the positioning column 3 is 27 mm, and the diameter of the positioning column Φ2 is 6.35 -0.05 .

[0033] (2) Clear the oil, water and other dirt within the range o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com