Method of processing chromium-nickel austenite stainless steel continuous casting slab

A technology of austenitic stainless steel and treatment method, which is applied in the field of chrome-nickel austenitic stainless steel continuous casting slab processing, can solve the problems of difficult to accurately detect surface defects, prolong the slab processing cycle, and store large slabs, etc. Achieve the effect of convenient visual inspection, reduce grinding workload, and reduce site space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The casting speed of the continuous casting machine in this embodiment is 0.75m / min, the length of the slab is 8.0m, and a continuous casting slab is produced every 10.9min. The steel grade of the continuous casting slab is 0Cr18Ni9, and the section specification of the continuous casting slab is 1240×180mm.

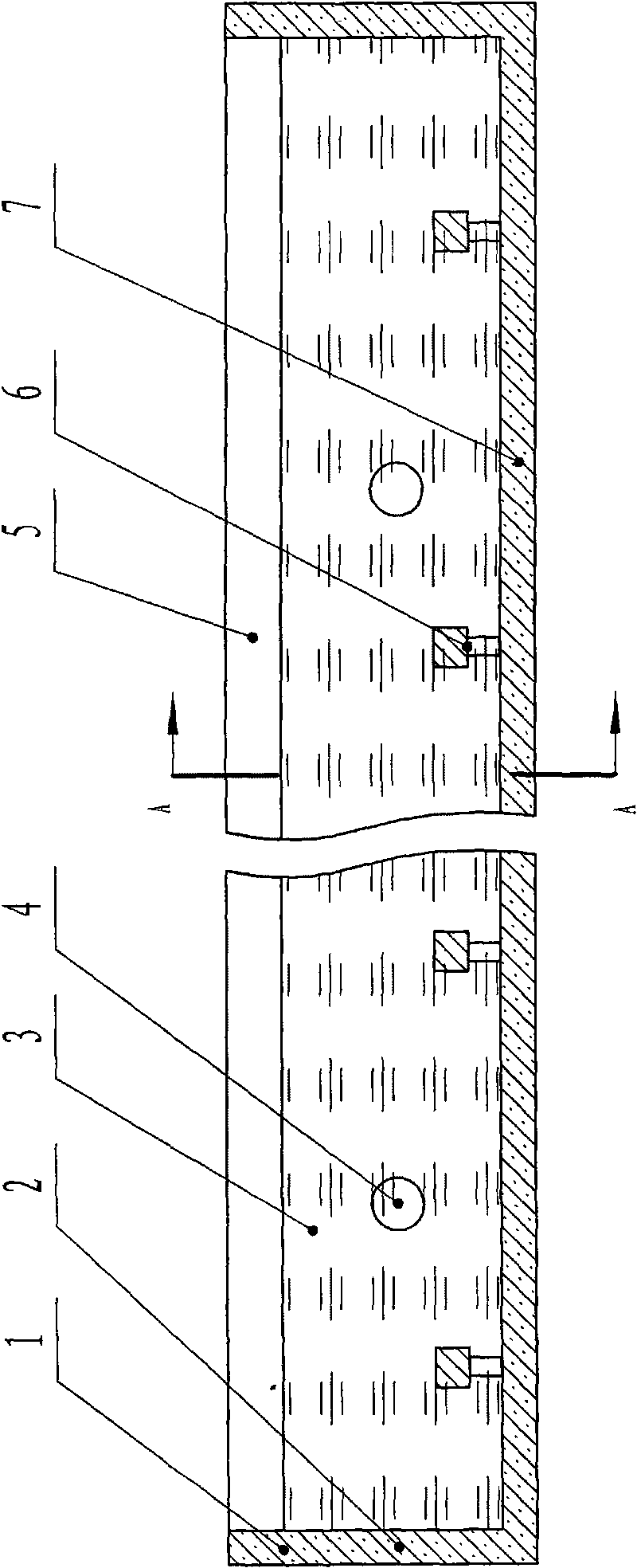

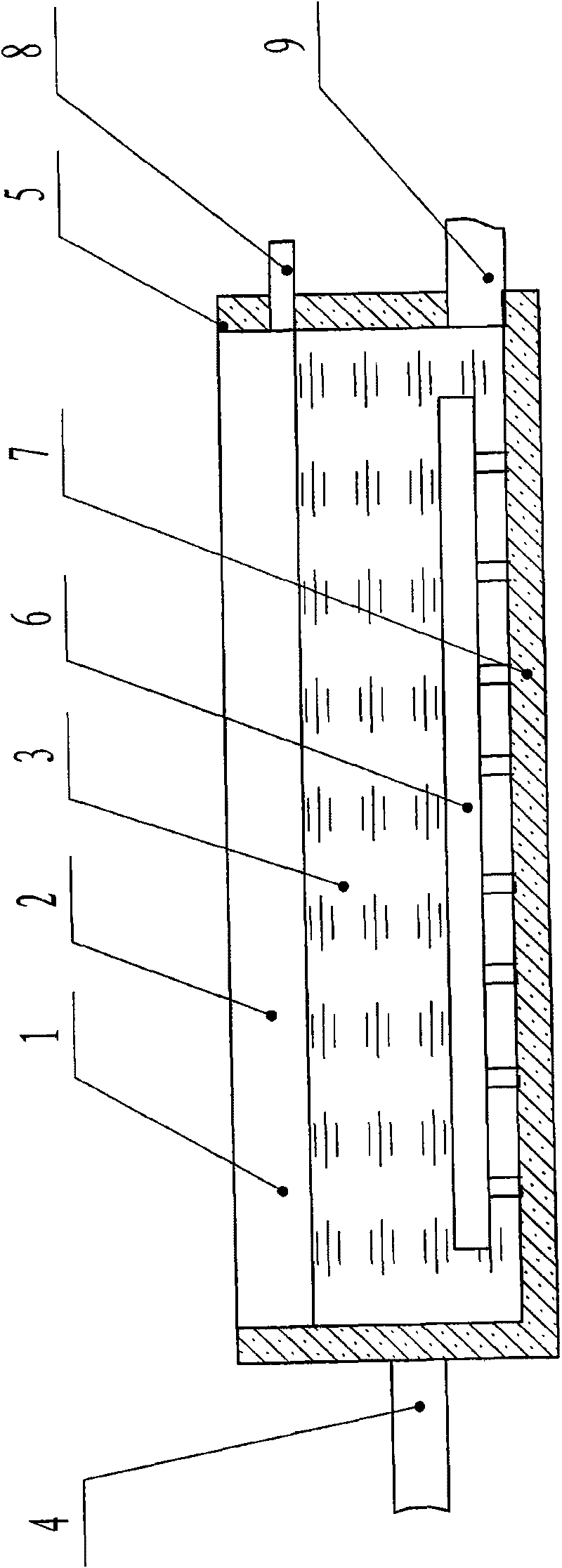

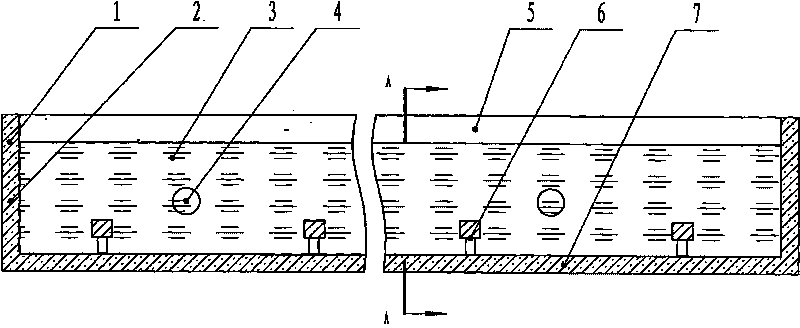

[0025] The inner size of the circulating water pool is 9200×2000×1000mm, and the water depth of the pool is 700mm after water storage, and one continuous casting slab can be put in each time. Circulating water flow rate is 1.0~2.0m 3 / min, this embodiment is 1.5m 3 / min. The structure of the pool with circulating water see figure 1 and figure 2 , it is a cement pool 1, the bottom 7 of the cement pool 1 is horizontally provided with steel beams 6 supporting the slab, one side wall 5 has three water inlets 4, and the other side wall has an overflow port 8 and an outlet Shuikou 9.

[0026] (1) During the continuous casting production process, after the continu...

Embodiment 2

[0030] The casting speed of the continuous casting machine in this embodiment is 1.0m / min, and the slab is 11.5m, that is, a continuous casting slab is produced every 11.5min. The steel grade of the continuous casting slab is 00Cr19Ni10, and the section specification of the continuous casting slab is 1240×200mm.

[0031] The structure of the pool of circulating water of the present embodiment sees figure 1 and figure 2 . The size of the cement pool 1 is 12000×3500×1000mm, and the water depth after the pool is stored is 800mm. Two continuous casting slabs can be placed side by side each time. Circulating water flow rate is 1.5~3.5m 3 / min, this embodiment is 2.8m 3 / min.

[0032] (1) During the continuous casting production process, after the continuous casting slab is cut into slabs, the surface temperature before the slabs are hoisted into the cement pool 1 of circulating water is in the range of 600-750°C. The two slabs that have been cut are discharged side by side in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com