Drill rocker end upsetting method

A drill pipe and pipe end technology, applied in the field of pipe end thickening, can solve problems such as pits, protrusions, and reduce grinding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

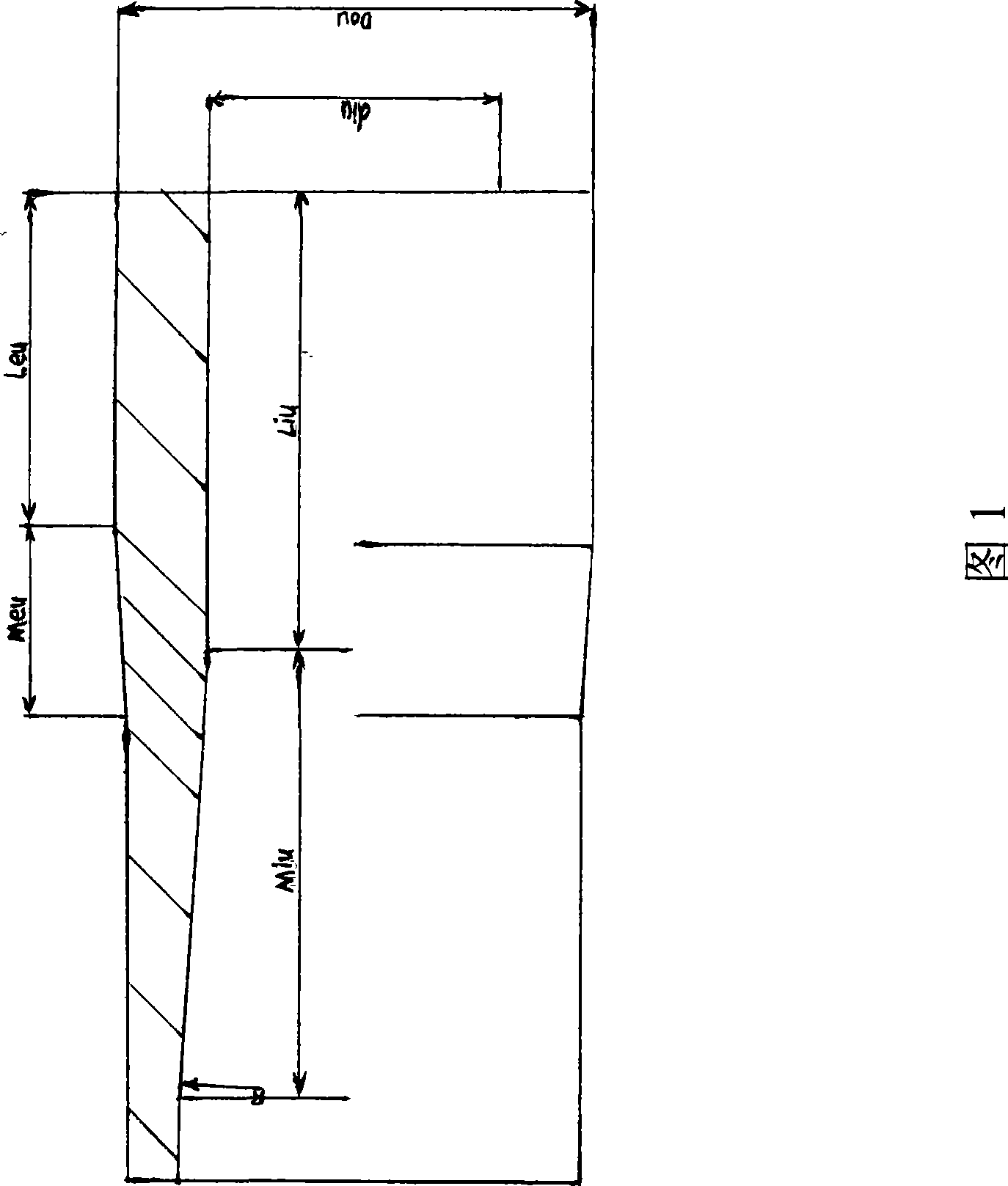

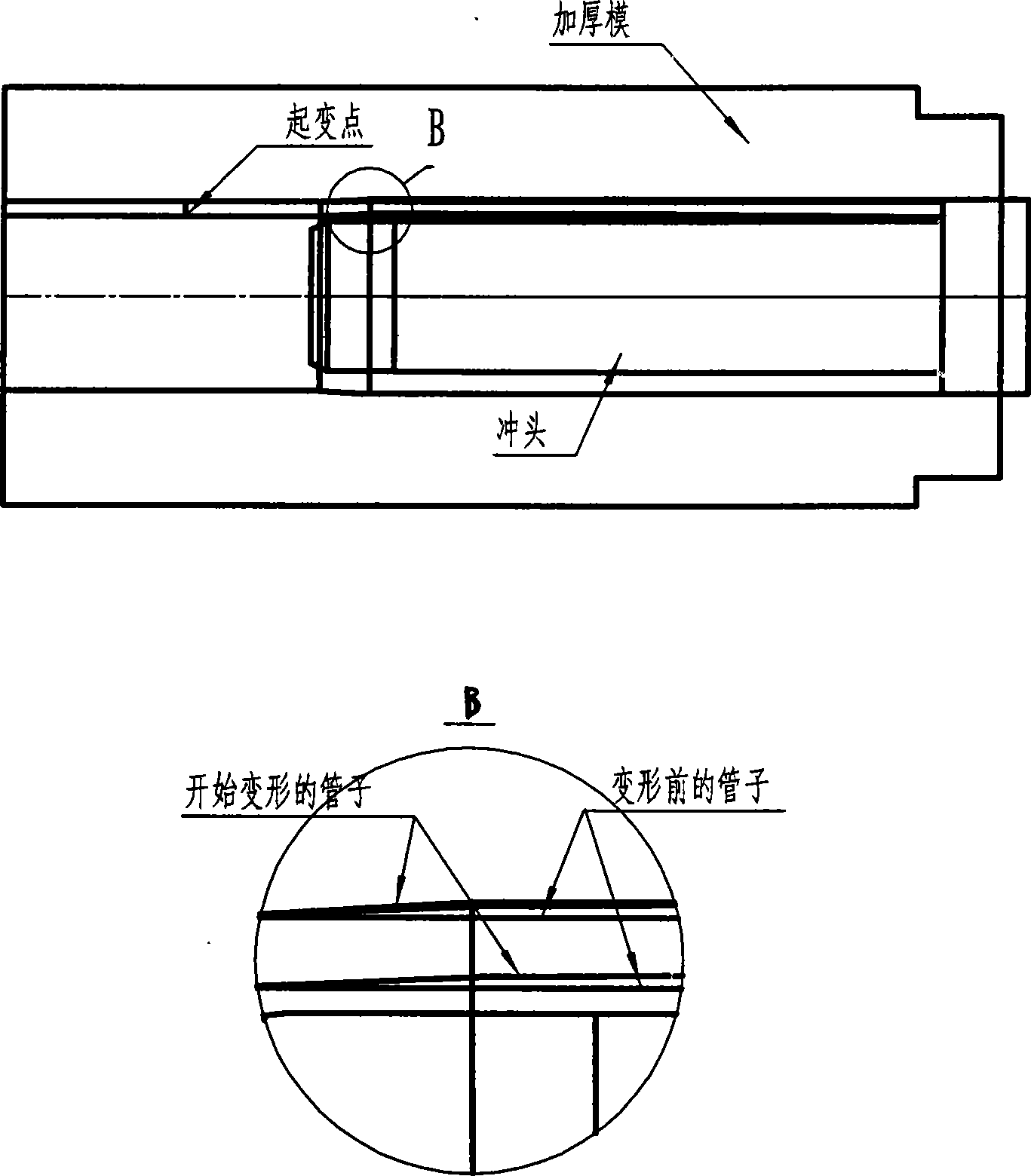

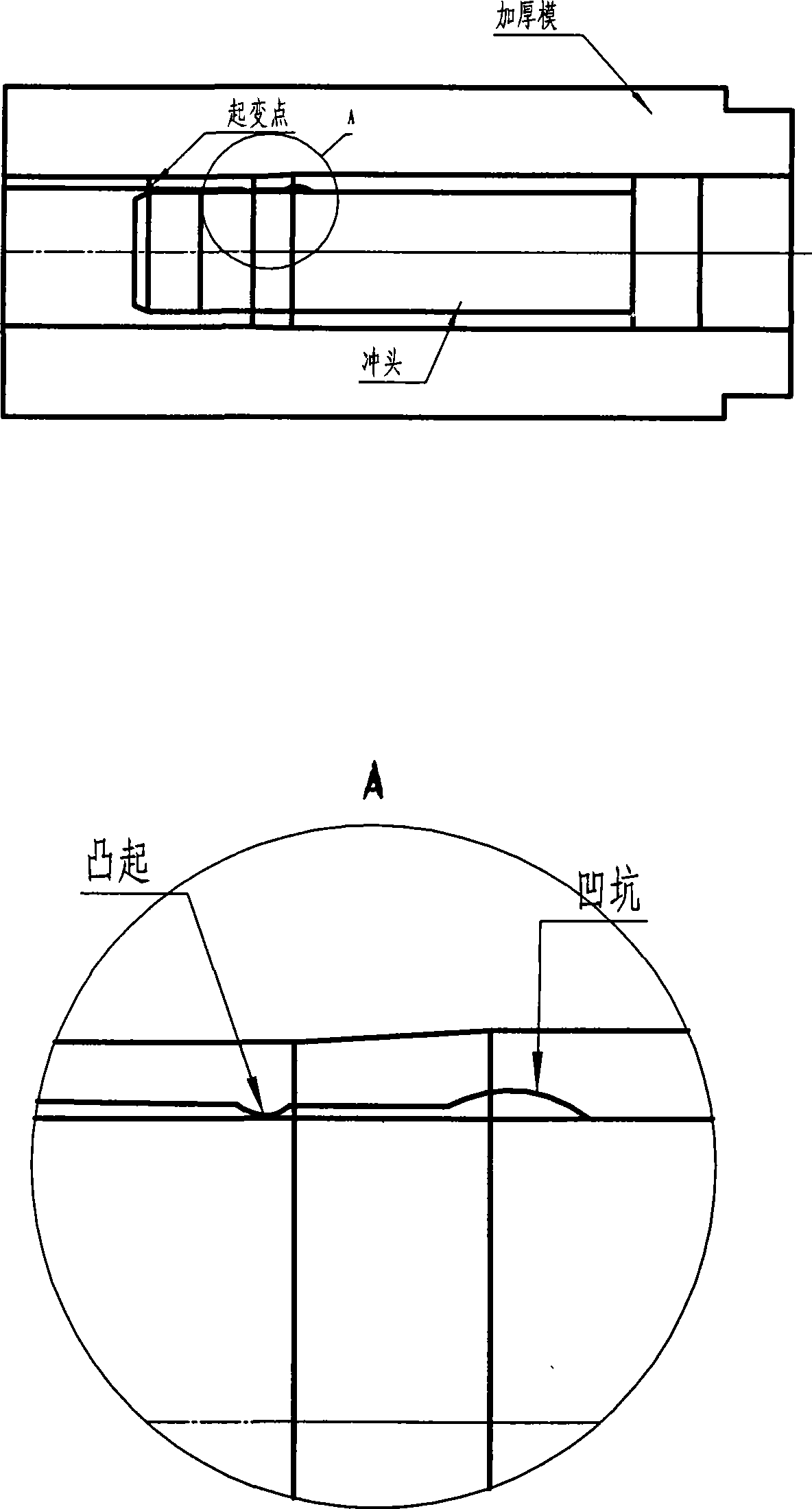

[0016] The invention provides a method for thickening the pipe end of a drill pipe. The outer thickening transition section of the pipe end, the taper and the length of the outer thickening section are formed by mold control, and the taper and length of the inner thickening transition section are formed by punching The upsetting of the head is free-formed. The first thickening pass Meu1 takes 100-110mm, the second pass Meu2 takes 70-80mm, and the third thickening pass Meu3 takes 50-60mm; the three passes Meu gradually shortens, and the taper gradually increases, so as to overcome In the traditional process, the short Meu and large taper of the first thickening pass cause the material to bend, and then defects such as protrusions and pits appear, reduce the internal grinding workload in the thickening process, and improve the thickening quality at the same time .

[0017] Taking the thickening of the Φ127*9.19 pipe body as an example, the calculated thickening passes are three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com