Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Production process energy saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

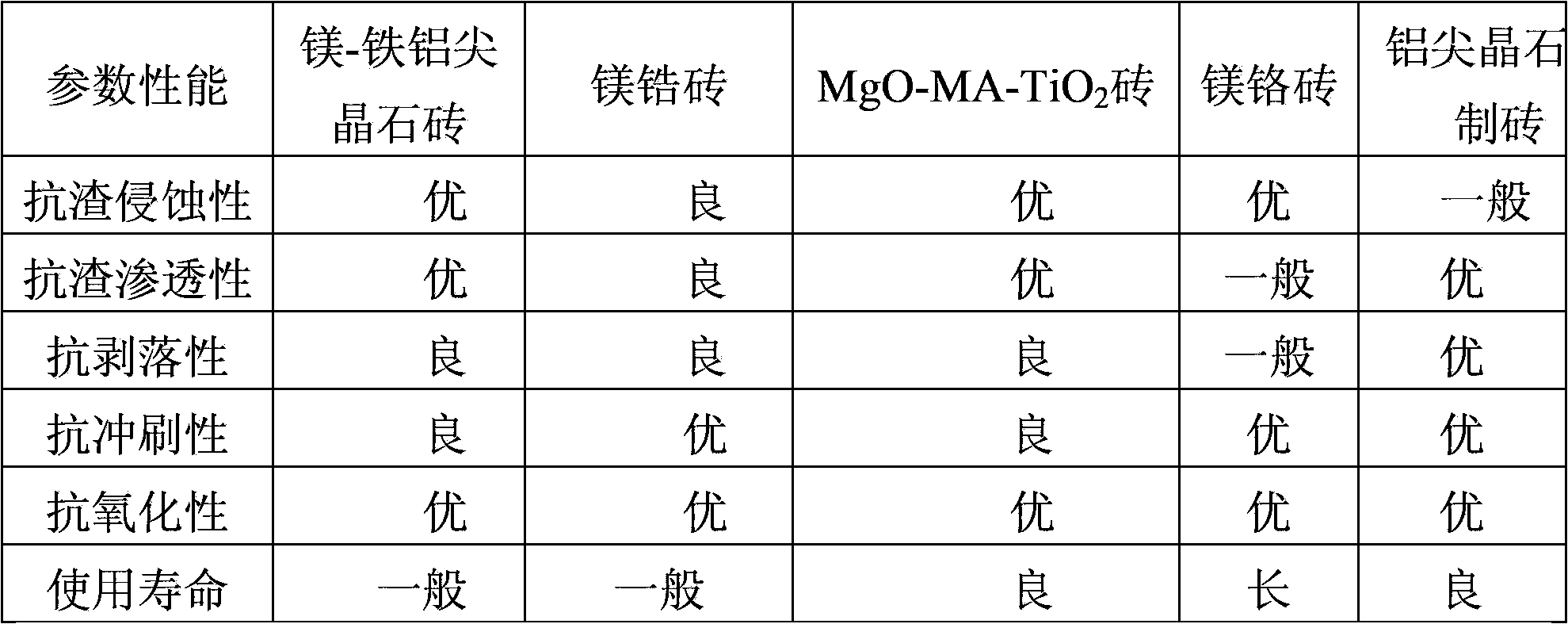

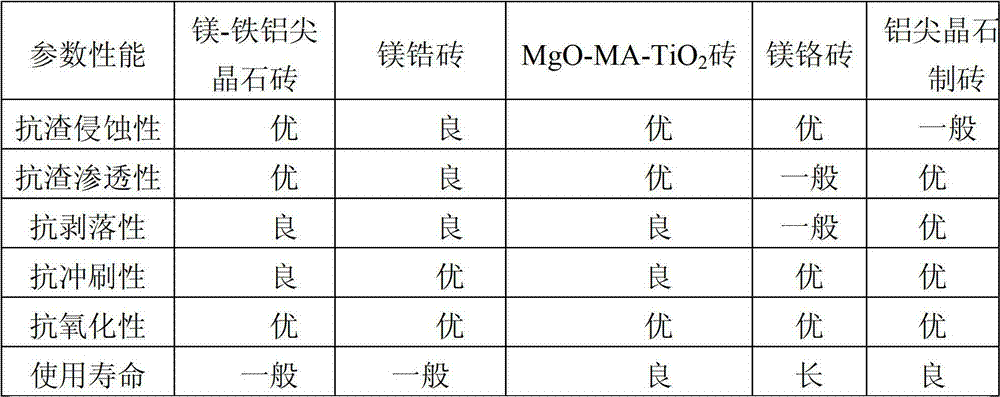

Unburned magnesium-aluminum spinel brick

The invention discloses an unburned magnesium-aluminum spinel brick, which comprises the following components by mass: 50-80% of corundum, 5-30% of magnesia-alumina spinels, 2-5% of magnesia powder, 3-10% of alumina powder, and the balance at least one of elemental silicon powder, metallic aluminum powder and boron carbide powder. All the components of the unburned magnesium-aluminum spinel brick are combined through an additionally added binder. The unburned magnesium-aluminum spinel brick causes no pollution to the environment, has excellent molten steel erosion resistance, slag penetration resistance and scouring resistance, and has a long service life additionally.

Owner:BAOSHAN IRON & STEEL CO LTD

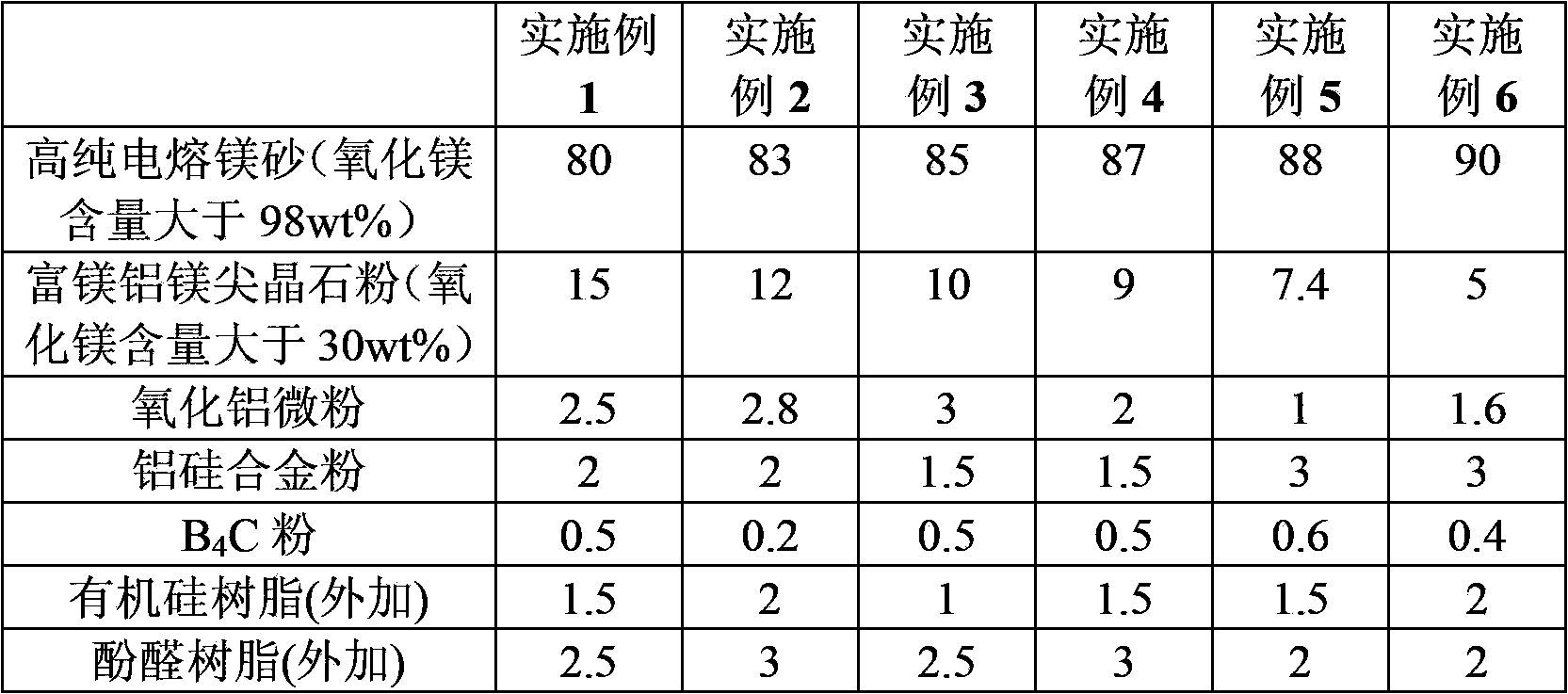

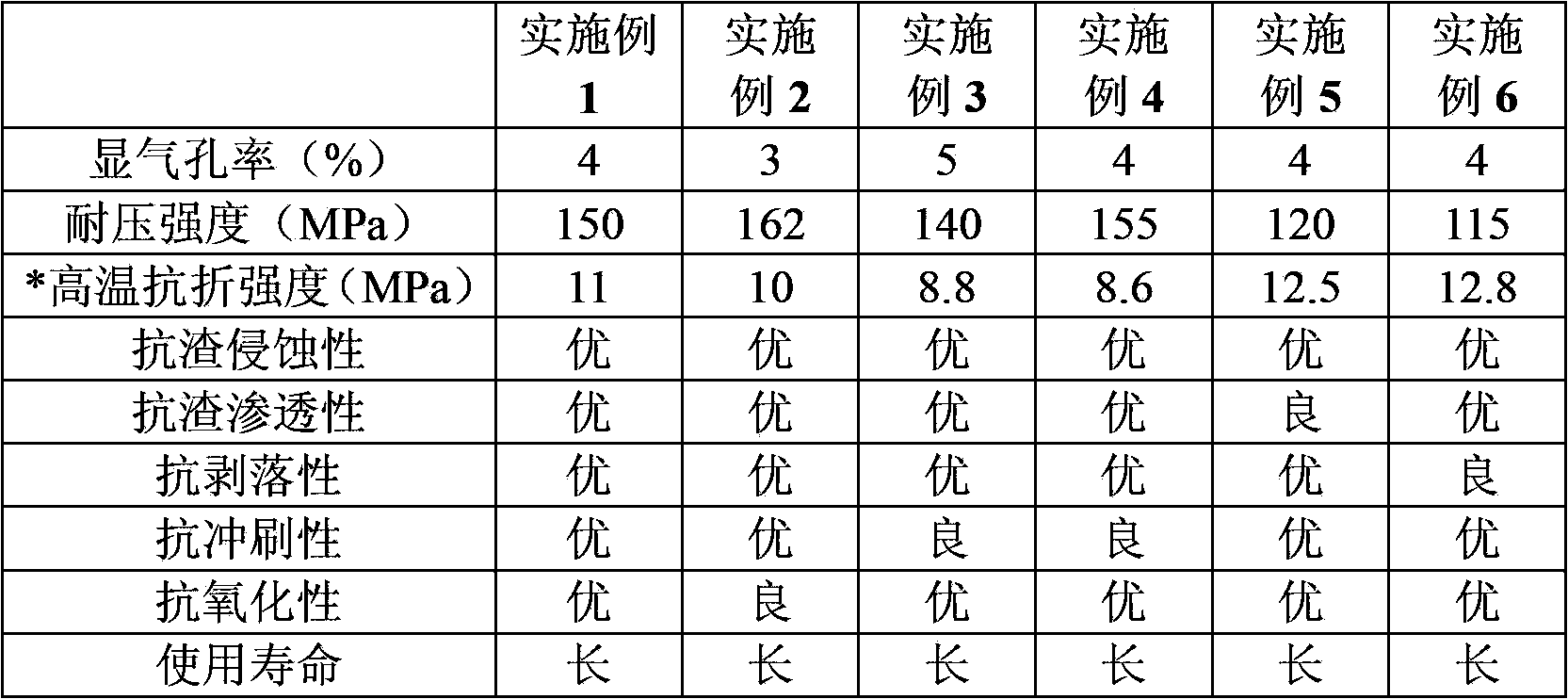

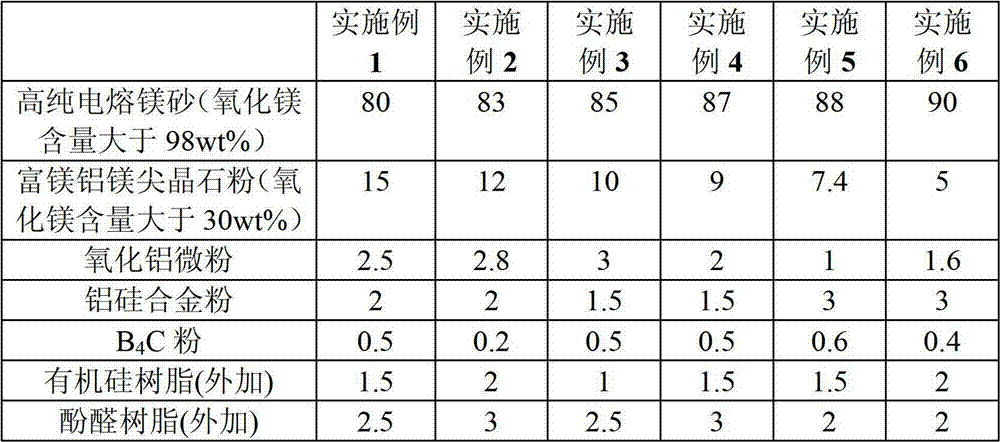

Unfired magnesia-alumina spinel brick

The invention discloses an unfired magnesia-alumina spinel brick. The unfired magnesia-alumina spinel brick comprises the following chemical components by mass: 80 to 90% of fused magnesia, 5 to 15% of magnesium-rich magnesia-alumina spinel, 1 to 3% of micro alumina powder, 1 to 3% of aluminum-silicon alloy powder and 0.2 to 0.6% of B4C. The chemical components are bonded together by using 3.5 to 5 wt% of an added binder. The content of magnesium oxide in the fused magnesia is greater than 98 wt%, and the content of magnesium oxide in the magnesium-rich magnesia-alumina spinel is greater than 30 wt%. The unfired magnesia-alumina spinel brick provided by the invention has excellent slag reaction resistance, slag penetration resistance, anti-stripping performance, anti-scouring performance, resistance to oxidation and a long service life, does not include the harmful element--chromium, avoids pollution and harm to human beings and the environment, needs low production cost and has a wide application scope.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing reagent grade sodium sulfate by using white carbon black mother solution

InactiveCN102320629ALow impurity contentImprove qualityAlkali metal sulfite/sulfate purificationCelluloseEvaporation

The invention discloses a method for producing reagent grade sodium sulfate by using a white carbon black mother solution. The method comprises the following steps of: 1) removing a little amount of solid residue such as white carbon black and the like in the white carbon black mother solution by using a mixed cellulose micropore filtration membrane with thickness phi of less than or equal to 0.15 micron, and preliminarily purifying the white carbon black mother solution into a sodium sulfate solution; 2) treating the sodium sulfate solution obtained in the step 1) by using chelating resin toobtain a 5 to 6 percent pure sodium sulfate solution; 3) performing electrodialytic concentration on the 5 to 6 percent pure sodium sulfate solution obtained in the step 2) to obtain a 15 to 25 percent pure sodium sulfate solution; and 4) performing multi-effect evaporation on the 15 to 25 percent pure sodium sulfate solution obtained in the step 3) to obtain crystal, separating the crystal by using a centrifuge, drying the separated crystal at the temperature of 120 DEG C, and thus obtaining a finished product. The sodium sulfate product prepared by the method has the characteristics of low impurity content, high quality, low moisture content and the like, and is a high reagent grade sodium sulfate product.

Owner:福建海能新材料有限公司

Nano calcium carbonate and styrene-butadiene rubber composition and preparation method thereof

The invention discloses a nano calcium carbonate and styrene-butadiene rubber composition and a preparation method thereof. The weight of styrene-butadiene rubber is 20 to 40 percent of that of calcium carbonate. The product provided by the invention is the nano calcium carbonate and styrene-butadiene rubber composition with small particle sizes and uniformly distributed granularity; and the composition can remarkably improve the dispersibility of the nano calcium carbonate in the rubber, realize the nano-scale dispersion of the nano calcium carbonate in the rubber system, enhance the functional reinforcement function of the nano calcium carbonate, simultaneously further simplify a process flow, save the steps of drying, crushing and the like in a nano calcium carbonate powder preparation process, and avoid energy consumption and dust pollutions caused by the steps of drying, crushing and the like.

Owner:建德华明科技有限公司

Method for producing active peptide from peanut cake and meal by immobilized enzyme

InactiveCN102676624AIncrease enzyme activityStability is not affectedChemical industryOn/in organic carrierBiotechnologyNeutral protease

The invention belongs to the technical field of deep processing for peanut protein, and specifically relates to a method for producing active peptide from peanut cake and meal by immobilized enzyme. The method comprises the steps of: immobilizing two proteases, i.e. alkaline and neutral proteases, by adopting chemically-modified magnetic chitosan micro-particles so as to implement enzymatic hydrolysis, and then centrifuging, decolorizing, desalting by nano-filtration, grading by ultrafiltration and spray-drying to obtain peanut active peptide. Compared with the traditional preparation method,the method has the characteristics of low production cost, short production period, high product yield, high product purity, mild, green and energy-saving production process and the like. In additionto excellent dissolubility, the peanut functional peptide produced by the method provided by the invention has the functions of lowering blood pressure and resisting oxidation, so the active peptide has high market development value.

Owner:HENAN ACAD OF AGRI SCI

Method for producing chlorfenapyr raw material pesticide

The invention discloses a method for producing a chlorfenapyr raw material pesticide. The method comprises the following steps of: adding chlorobenzol glycine and trifluoroacetic acid which serve as raw materials and 4-dimethylamino pyridine serving as a catalyst into an acetonitrile solvent, stirring uniformly, and dripping a phosphorus trichloride solution to perform acylation reaction; after the reaction is finished, adding 2-chloro acrylonitrile serving as a raw material and dimethyl formamide (DMF) serving as a cosolvent, and stirring for dissolving; dripping a triethylamine solution to perform cyclization reaction, and dripping bromine into the reaction solution; after bromination reaction is finished, and removing the solvent and the cosolvent; adding the residual substance into an alcohol solvent for dissolving, and cooling to precipitate an intermediate; adding the intermediate and chloromethyl ethyl ether into ethyl acetate serving as a solvent, stirring for dissolving, dripping triethylamine to perform condensation reaction, removing the solvent and the ethyl acetate, and hydrolyzing to obtain the chlorfenapyr raw material pesticide. In the method, the acylation reaction and the cyclization reaction are completed in one step, so a process is simplified, energy consumption is reduced, a production process is energy-saving and environment-friendly, and the purity and yield of products are improved.

Owner:山东亿嘉农化有限公司

Modified heavy calcium carbonate special for paint and preparation method and device thereof

InactiveCN105602289ALarge specific surface areaGood lipophilicityChemical industryCoatingsAntioxidantOleic Acid Triglyceride

Modified heavy calcium carbonate special for paint is prepared by mixing organic materials and inorganic materials. The oil absorption value of the modified heavy calcium carbonate is 17-20 g of oil per 100 g, and the ratio of parts by weight of the organic materials to the inorganic materials is 6-8:1000. According to parts by weight, the inorganic materials include heavy calcium carbonate, aluminum nitride, alpha-aluminum oxide, nano-silica, kaolinite and diatomite, and the organic materials include one or more of oleic acid polyoxyethylene ester, polyethylene wax, styrene and triphenyl phosphate. The materials are stirred to prepare the modified heavy calcium carbonate. The modified heavy calcium carbonate has the advantages that the adding amount of filler can be increased, the use quantity of resin adhesives can be reduced by 3-5%, 15-20% of the use amount of talcum powder, barium sulfate and titanium dioxide can be partially replaced, the use quantity of colorants, antioxidants and brighteners in the paint is reduced by about 5%, and raw material cost is lowered; meanwhile, the production process is environmentally friendly and saves energy, and construction is convenient.

Owner:HUNAN LEIXIN NEW MATERIAL TECH

Steel grating plate production process

The invention discloses a steel grating plate production process, which comprises the following steps of grooving: a plurality of longitudinal strips are fixed, and a plurality of grooves are formed on the longitudinal strips; embedding: a transverse rod is embedded into the grooves, the transverse rod is embedded into the groove of one longitudinal strip, the depth of the groove is smaller than the height of the transverse rod, and the width of the groove is greater than the thickness of the transverse rod; pressure welding: the transverse rod and the groove are welded by an electric resistance welding method, and in addition, the upper surface of the transverse rod and the upper surface of the longitudinal strips are flatly pressed when the welding position of the transverse rod and the groove is still in a high-temperature state; repeated embedding and pressure welding: the welding of the next transverse rod is completed, the many-time repeated embedding and the pressure welding are carried out until the welding between the transverse rod and the grooves is completed, and a steel grating plate is formed; cuttings: the steel grating plate is cut into steel grating plate units; end plate welding: the end surface of the transverse rod and the end surfaces of all longitudinal strips are welded with an end plate, and a steel grating plate finished product is formed; and zinc plating: the steel grating plate finished product is subjected to zinc plating treatment. The energy is saved, the production is easy, and in addition, the requirements on raw materials and processing equipment are lower.

Owner:TIANCHANG FEILONG BRAND STEEL GRID

Method for comprehensively extracting active substances from asparagus scraps based on multi-stage membrane separation

InactiveCN102532333AEasy extractionImplement extractionSugar derivativesSugar derivatives preparationUltrafiltrationSeparation technology

The invention relates to a method for comprehensively extracting active substances from asparagus scraps based on multi-stage membrane separation, which comprises the following steps that: the asparagus scraps are used as a raw material, are extracted with hot water of PH = 7-9 to obtain an extract, and then the extract is subjected to sedimentation centrifugation and 100-800-mesh bag filtering; the extract is subjected to an ultrafiltration membrane with interception molecular weight of 5000-15000Da to obtain a concentrated solution and a filtrate, the concentrated solution is precipitated with 75-95% alcohol to obtain an asparagus polysaccharide precipitate, and the asparagus polysaccharide precipitate is separated and dried to obtain asparagus polysaccharide with the content of 50%; the obtained filtrate is concentrated with a nanofiltration membrane with the molecular weight of 100-500Da to obtain a concentrated solution, the pH value of the concentrated solution is adjusted to 3-4, the concentrated solution is precipitated and dried to obtain rutin; and finally, a dialysate is pumped back to an extraction tank to be used as water for extraction. The residues are crushed to be used for feed. The process adopts an advanced membrane separation technology, improves the preparation efficiency of asparagus polysaccharide and rutin, realizes clean production and no waste water and residue emission, turns waste into wealth and realizes comprehensive utilization of resources. The method has the advantages of advanced process, stable product quality, high purity, clear target and easiness in industrial production.

Owner:FUJIAN HUIZE BIOTECH

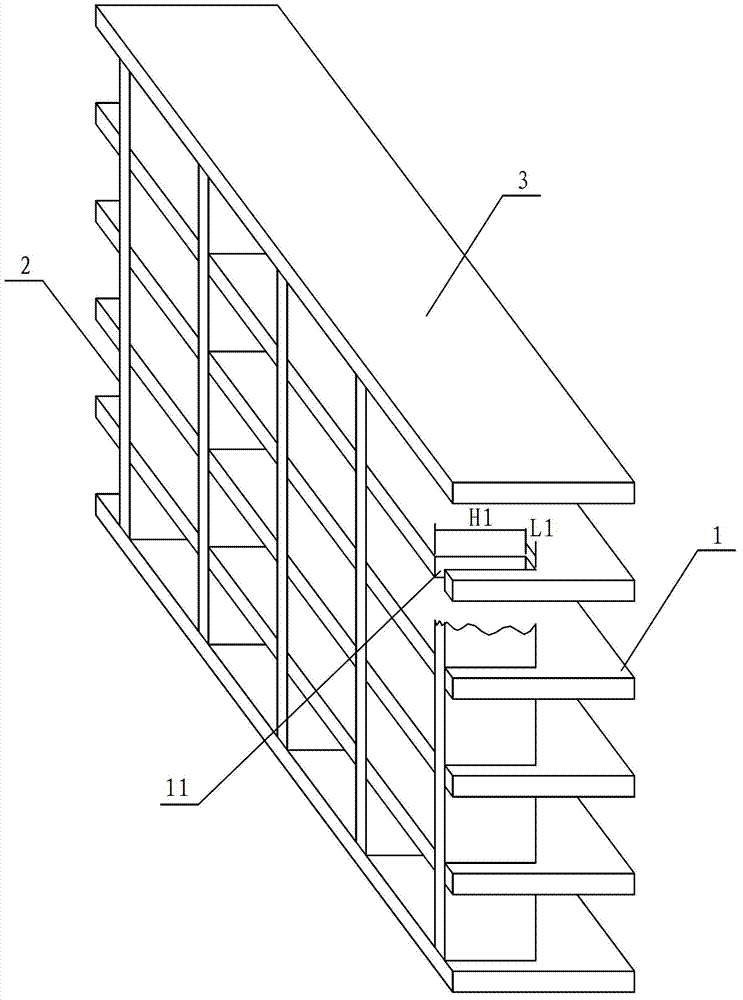

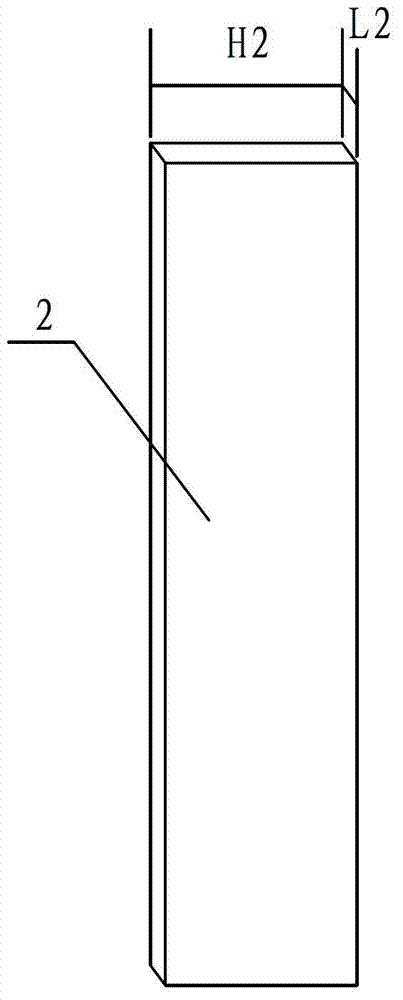

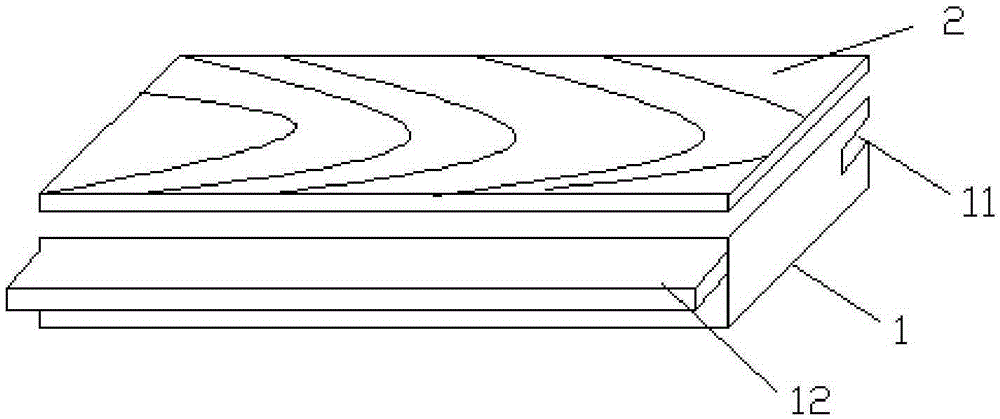

Solid wood composite floor of two-layer structure and manufacturing method

InactiveCN105256978AReduce utilizationIncrease profitLaminationLamination apparatusSolid woodFinger joint

The invention discloses a solid wood composite floor of a two-layer structure and a manufacturing method. The solid wood composite floor comprises a finger joint splicing board substrate and a decorative panel, wherein the decorative panel and the finger joint splicing board substrate are glued together and fixed into a whole; a stress groove is formed in the back of the finger joint splicing board substrate and perpendicular to the surface wood fiber direction. The manufacturing method for the solid wood composite floor comprises the following steps: step 1, putting the finger joint splicing board substrate and the decorative panel together into a balancing kiln to achieve a 6-8% water content; step 2, bonding the balanced finger joint splicing board substrate and decorative panel together; step 3, forming the stress groove in the laminated and bonded two-layer whole board blank; step 4, conducting tongue-and-groove treatment on the laminated and bonded two-layer whole board blank with the stress groove; step 5, conducting seal coating on the four surfaces of the two-layer plain board subjected to the tongue-and-groove treatment; step 6, painting the plain board subjected to the seal coating. According to the manufacturing method, less large-diameter woods are utilized, and the utilization ratio of small-diameter woods is improved; compared with the conventional laminated and multi-layer solid wood composite floor, the solid wood composite floor provided by the invention is higher in appearance grade and approaches an effect of solid woods.

Owner:ZHEJIANG DADONGWU GREENHOME WOOD CO LTD

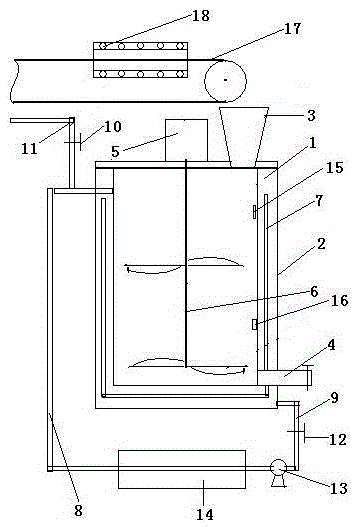

PE pipe production process

InactiveCN108016019AProduction process energy savingImprove finished product qualityTubular articlesEnergy consumptionSizing

The invention discloses a PE production process. The process comprises the steps of cleaning equipment, checking equipment, starting an extruding machine, opening a cooling water tank to discharge cooling water, carrying out vaccum sizing, carrying out cooling and shaping and carrying out pipe cutting. The process solves the problems that a traditional PE production process is large in energy consumption and low in finished product quality.

Owner:兴义市雄骏塑料管业有限公司

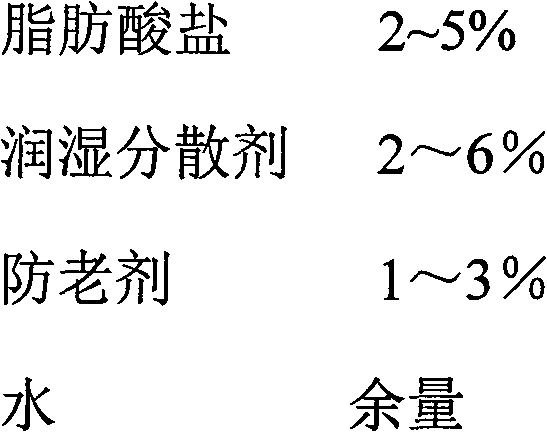

Fluorosilicic emulsion paint capable of preventing scale deposite and its production process

The invention discloses a fluorine-silicon anti-scaling latex paint, which consists of 60-80% of silicone resin emulsion, 10-30% of polytetrafluoroethylene emulsion, 10-30% of color paste, and 0.1% of defoaming agent. ~1% composition, the total amount of the above-mentioned substances is 100%, wherein the silicone resin in the silicone resin emulsion is composed of 10-50 parts by weight of methyl chlorosilane monomer, 10-45 part of phenyl chlorosilane monomer, aromatic hydrocarbon solvent 100-500, alcohol 50-200, water 100-1000; the silicone resin emulsion is composed of methyl chlorosilane monomer and phenyl chlorosilane monomer dissolved in aromatic hydrocarbon, and then mixed with the water phase composed of alcohol and water at a temperature of Hydrolyze at 25-80°C for 1-3 hours; separate the organic phase after separating the acidic water layer, polycondense at 100-170°C for 1-4 hours to obtain silicone resin, and then make the obtained silicone resin, Formulated with water, leveling agent, emulsifier and defoamer.

Owner:广州电器科学研究院有限公司

Production technology for producing pulullan by fermenting aureobasidium pullulans

InactiveCN107641634AProduction process economyEfficient production processFungiMicroorganism based processesBiotechnologyPullulan

The invention discloses a production technology for producing pulullan by fermenting aureobasidium pullulans. The production technology comprises the following steps: culturing seeds; preparing a seedculture medium; preparing a potato dextrose agar culture medium, a first-grade seed culture medium, a second-grade seed culture medium and a third-grade seed culture medium respectively; carrying outactivated culture on the seeds; inoculating an aureobasidium pullulans strain slant single bacterial colony to a first-grade seed shake flask and carrying out shake flask activation; inoculating an activated seed culture solution into a new second-grade seed culture shake flask according to the volume percent concentration of 1 percent to 20 percent and carrying out amplified culture; then inoculating the seed culture solution subjected to the amplified culture into a third-grade seed shake flask according to the volume percent concentration of 1 percent to 20 percent and culturing to obtaina seed culture solution to be fermented; inoculating the seed culture solution to be fermented into a fermentation tank filled with a fermentation culture medium and carrying out fermentation cultureto obtain the pulullan. The production technology disclosed by the invention has the advantages that the source of the raw materials is wide and the production cost is reduced, and has the effects ofeconomical efficiency, high efficiency and energy saving.

Owner:北京艾普希隆生物科技有限公司

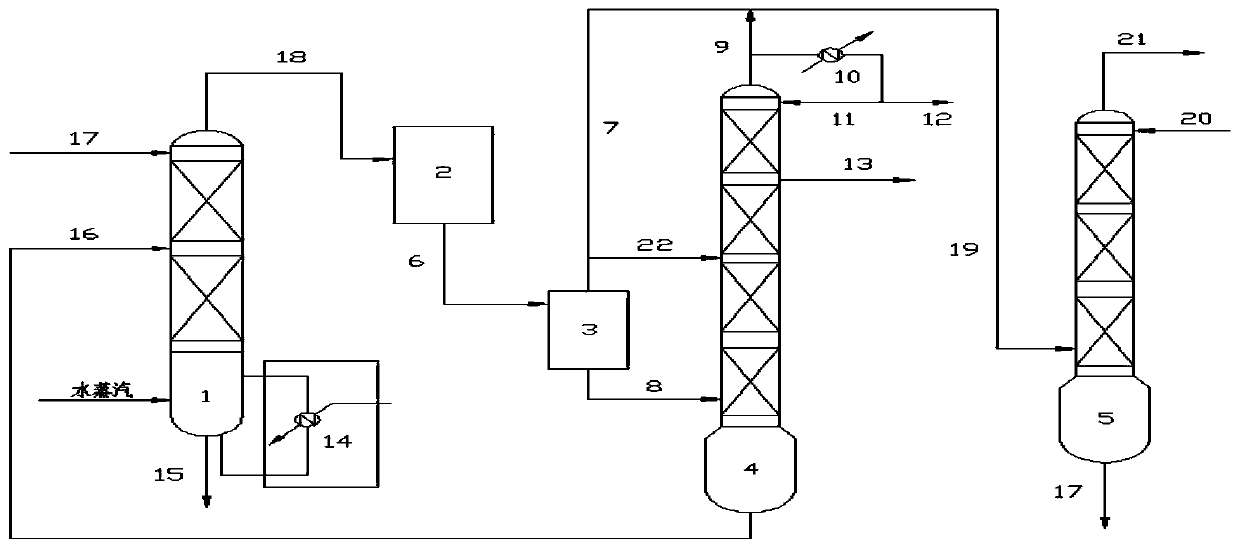

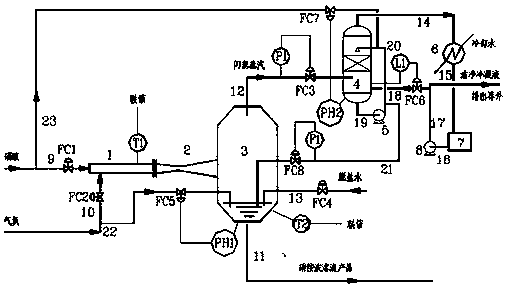

A kind of production system and production process of methanol to dimethyl ether

ActiveCN107056588BReduce energy consumptionHigh purityEther preparation by compound dehydrationAlcoholVaporization

The invention discloses a production system of dimethyl ether through methyl alcohol. The production system comprises a dimethyl ether absorption tower, a vaporization and stripping tower, a methyl alcohol dehydration system, a flash tank and a dimethyl ether rectifying tower, wherein a tower outlet of the dimethyl ether absorption tower is communicated with a tower top inlet of the vaporization and stripping tower; a tower top outlet of the vaporization and stripping tower is communicated with the methyl alcohol dehydration system; an outlet of the methyl alcohol dehydration system is communicated with the flash tank; three outlets of the flash tank are respectively communicated with the lower part of the dimethyl ether absorption tower and the middle part and the lower part of the dimethyl ether rectifying tower; a tower outlet of the dimethyl ether rectifying tower is communicated with the middle part of the vaporization and stripping tower; a tower top outlet of the dimethyl ether rectifying tower is communicated with the lower part of the dimethyl ether absorption tower through a control valve. The invention further discloses a production process of preparing a dimethyl ether product with the quality purity greater than or equal to 90 percent and less than 100 percent by using the production system; according to the process, the high-purity dimethyl ether product is prepared through the flash tank by controlling the content of dimethyl ether in absorption tower liquid; the problems of high equipment cost, complicated process and low dimethyl ether product purity in the prior art are solved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

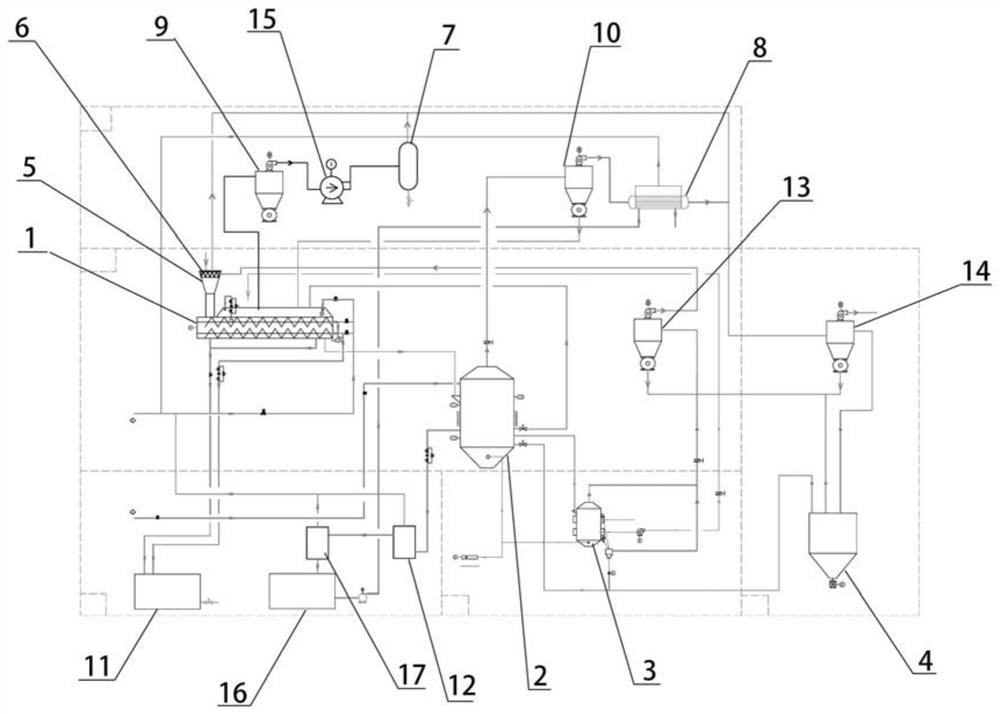

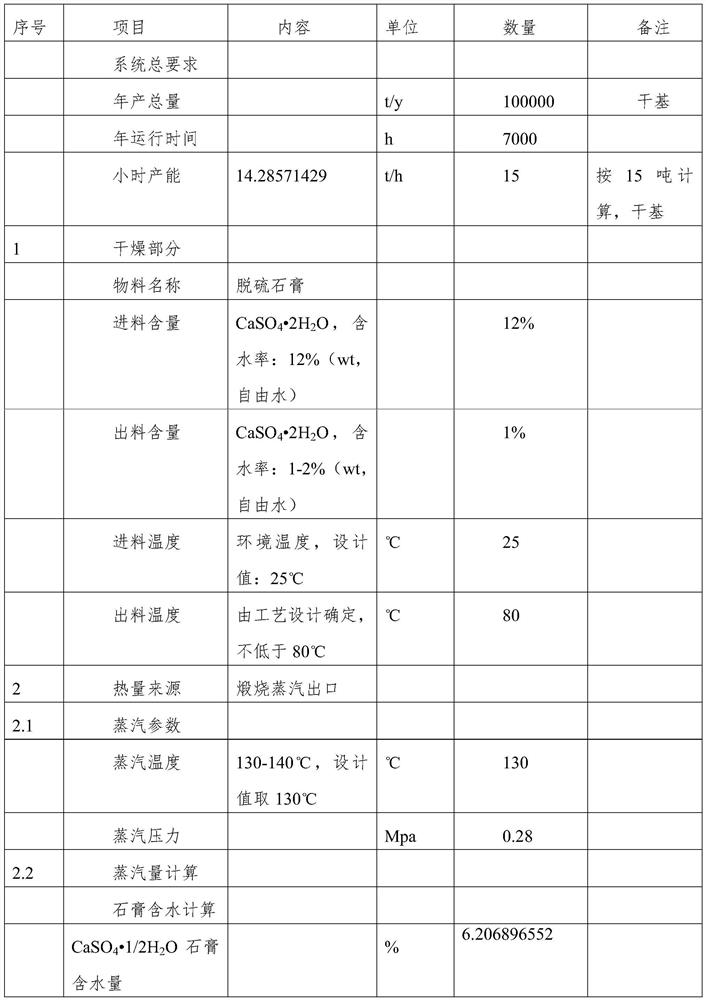

Gypsum powder production system and production process thereof

The invention discloses a gypsum powder production system and a production process thereof, and relates to the technical field of building materials. The production system comprises a paddle dryer, a fluidization calcining machine, a vertical cooler and a finished product warehouse. Gypsum is dried through the paddle dryer firstly, then enters the fluidization calcining machine to be calcined, then enters the vertical cooler to be cooled, and finally, enters the finished product bin after pressing and grinding. According to the gypsum powder production system, a grating heat exchanger is arranged in a feeding hopper before drying to preheat the gypsum, so that the problems of wall adhesion and blockage in the gypsum feeding process are solved, the risk of scaling in the drying process is effectively reduced, the maintenance rate of system operation can be reduced, the energy consumption of drying equipment can be effectively reduced, the operation cost is reduced, and the operation stability and economy of the system can be improved.

Owner:HUANENG POWER INT INC

Method for preparing concentrated ammonium nitrate solution through flash evaporation

ActiveCN106365177ATake advantage ofProduction process energy savingAmmonium nitratesHigh concentrationPressure reduction

The invention discloses a method for preparing a concentrated ammonium nitrate solution through flash evaporation. The method comprises that after nitric acid and ammonia gas undergo a pressurization reaction to produce a dilute ammonium nitrate solution (with a concentration of about 75-80wt%), the dilute ammonium nitrate solution is concentrated to a high concentration of 90-96wt% under action of reaction heat through one step in a pressure reduction flash evaporation device so that a desired concentrated ammonium nitrate solution product is obtained. The method reasonably utilizes energy and is free of ammonium nitrate solution multistage condensation of the traditional ammonium nitrate production technology so that energy is saved, a production process is simple, an investment is reduced and a production cost is reduced.

Owner:SEDIN ENG

Yeast culture preparation method

InactiveCN106987530AReduce manufacturing costGuaranteed deep fermentationFungiMicroorganism lysisWater savingBiotechnology

The invention discloses a yeast culture preparation method. The yeast culture preparation method includes strain preparation and activation, slant strain manufacturing, triangular flask liquid strain manufacturing, seed tank liquid strain manufacturing, solid fermentation, in-bag cell anaerobic autolysis, low-temperature drying and grinding to obtain a finished product. The yeast culture preparation method has unique advantages of water saving, energy saving, high saccharomycete quantity and environmental friendliness in production process and is further low in production cost.

Owner:高唐华农生物工程有限公司

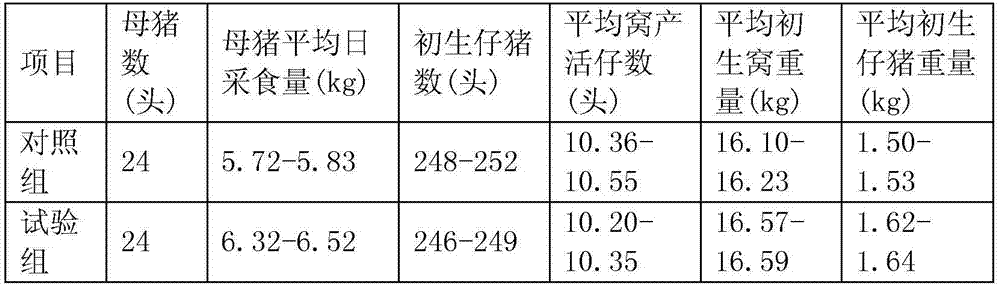

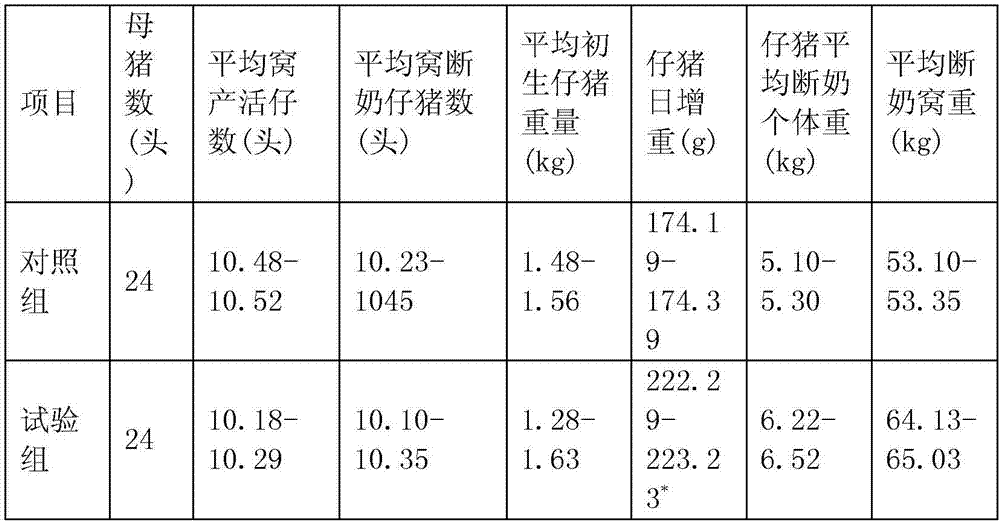

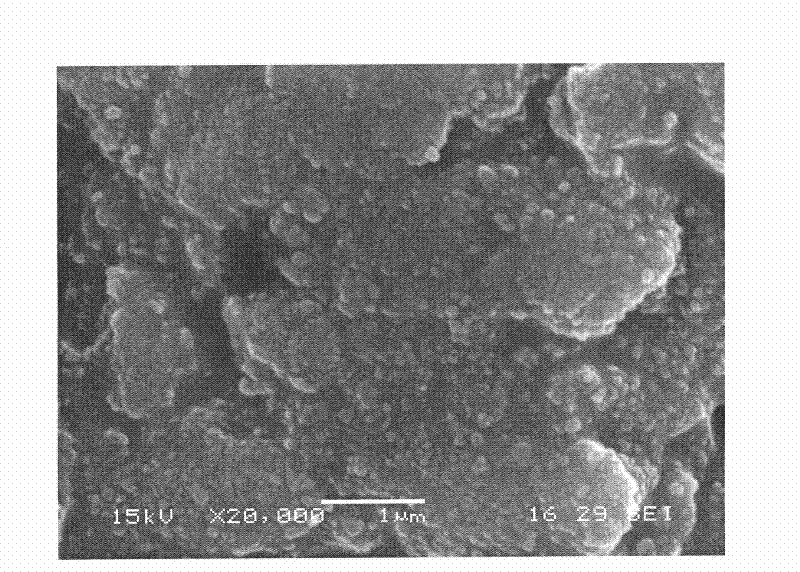

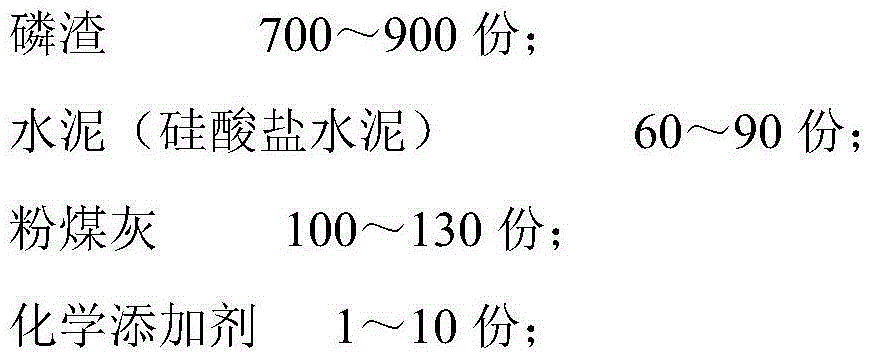

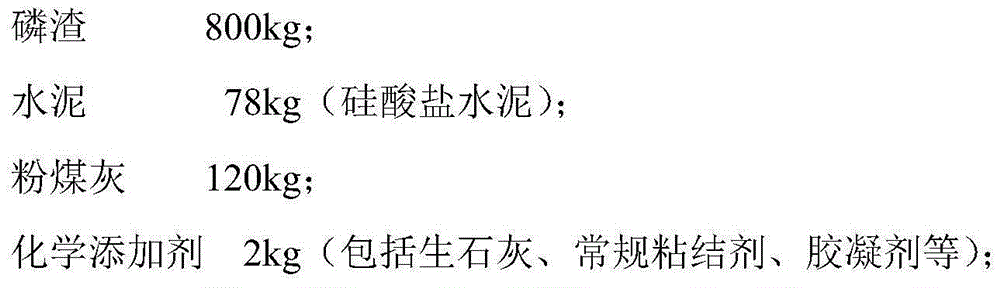

Phosphorus slag silicate building block and production process

The invention discloses a phosphorus slag silicate building block and a production process therefor. The process comprises the following steps: main raw materials are first prepared, and the main raw materials comprise 700-900 parts of phosphorus slags, 60-90 parts of cements, 100-130 parts of fly ash and 1-10 parts of chemical additives; the prepared raw materials are sent to a hopper, and automatic batching is carried out by utilization of a batching system according to the set ratio; after the batching, the raw materials are sent to a stirring system, and water is added in the stirring system and the mixture is stirred and mixed fully; then the mixture is transported to a storage bunker of a molding system, and after the mixture is subjected to pressure forming in a mold of the molding system, the formed intermediate products are subjected to truck loading by a loading transport system, and sent to a steam curing device; the intermediate products are subjected to normal pressure and temperature steam curing until the early stage intensity of the green bricks meets the requirement; after the products after curing are sent to a conveying device, and a brick pushing machine pushes the products to a package zone, and the production is finished. The production process has advantages of energy saving, environmental protection, consumption reduction, various functions of products, good quality of products and the like.

Owner:瓮安县日升新型环保建材有限责任公司

Nano calcium carbonate and styrene-butadiene rubber composition and preparation method thereof

Owner:建德华明科技有限公司

Phosphorous slag silicate block and its production process

Owner:瓮安县日升新型环保建材有限责任公司

Method for producing active peptide from peanut cake and meal by immobilized enzyme

InactiveCN102676624BIncrease enzyme activityStability is not affectedChemical industryOn/in organic carrierBiotechnologyNeutral protease

Owner:HENAN ACAD OF AGRI SCI

A kind of unfired magnesia alumina spinel brick

The invention discloses an unfired magnesia-alumina spinel brick. The unfired magnesia-alumina spinel brick comprises the following chemical components by mass: 80 to 90% of fused magnesia, 5 to 15% of magnesium-rich magnesia-alumina spinel, 1 to 3% of micro alumina powder, 1 to 3% of aluminum-silicon alloy powder and 0.2 to 0.6% of B4C. The chemical components are bonded together by using 3.5 to 5 wt% of an added binder. The content of magnesium oxide in the fused magnesia is greater than 98 wt%, and the content of magnesium oxide in the magnesium-rich magnesia-alumina spinel is greater than 30 wt%. The unfired magnesia-alumina spinel brick provided by the invention has excellent slag reaction resistance, slag penetration resistance, anti-stripping performance, anti-scouring performance, resistance to oxidation and a long service life, does not include the harmful element--chromium, avoids pollution and harm to human beings and the environment, needs low production cost and has a wide application scope.

Owner:BAOSHAN IRON & STEEL CO LTD

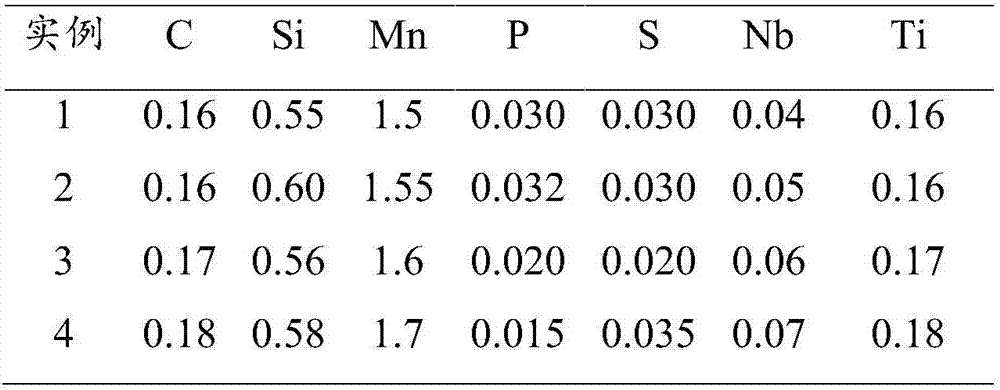

Q390KZ vibration-resistance hot-rolled H profile steel for steel structure and preparation method

The invention discloses Q390KZ vibration-resistance hot-rolled H profile steel for a steel structure. The H profile steel comprises the following chemical components in percentage by mass: 0.16-0.18% of C, 0.55-0.58% of Si, 1.5-1.7% of Mn, 0.035% or less of P, 0.035% or less of S, 0.04-0.07% of Nb, 0.16-0.18% of Ti, and the balance of Fe element. The invention further discloses a preparation method of the Q390KZ vibration-resistance hot-rolled H profile steel for the steel structure. The H profile steel enables the material to achieve excellent welding performance and low-temperature impact resistance.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Preparation method of q390kz anti-seismic hot-rolled h-shaped steel for steel structure

The invention discloses Q390KZ vibration-resistance hot-rolled H profile steel for a steel structure. The H profile steel comprises the following chemical components in percentage by mass: 0.16-0.18% of C, 0.55-0.58% of Si, 1.5-1.7% of Mn, 0.035% or less of P, 0.035% or less of S, 0.04-0.07% of Nb, 0.16-0.18% of Ti, and the balance of Fe element. The invention further discloses a preparation method of the Q390KZ vibration-resistance hot-rolled H profile steel for the steel structure. The H profile steel enables the material to achieve excellent welding performance and low-temperature impact resistance.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Method for preparing ceramic handicraft by utilizing dried sludge

PendingCN114835470AIncrease the proportionSimple ingredientsCeramic materials productionClaywaresVitrificationSludge

The invention belongs to the technical field of sludge treatment, and discloses a method for preparing ceramic artware from dried sludge. The method comprises the following steps: sequentially carrying out heat treatment and crushing on dried sludge, and then mixing with clay and water to obtain sludge strips; sequentially performing pugging, pressing and air drying on the mud strips to obtain a mud blank; and glazing the mud blank, and firing to obtain the ceramic handicraft. According to the invention, the dried sludge is subjected to heat treatment, so that organic matters are removed, and the proportion of the sludge in the formula is increased; moreover, the raw material components are simple, additional additives are not needed, and the cost of the raw materials is reduced. According to the invention, through firing after glazing, the release of heavy metals is avoided, and the obtained ceramic artware reaches the relevant standards of the ceramic industry and has a relatively high additional value; and the firing temperature is lower than the conventional ceramic glass transition temperature, and the production process is more energy-saving.

Owner:广州市净水有限公司 +1

Method for producing reagent grade sodium sulfate by using white carbon black mother solution

InactiveCN102320629BLow impurity contentImprove qualityAlkali metal sulfite/sulfate purificationCelluloseEvaporation

Owner:福建海能新材料有限公司

A kind of flash evaporation prepares the method for ammonium nitrate concentrated solution

ActiveCN106365177BTake advantage ofProduction process energy savingAmmonium nitratesHigh concentrationAmmonium nitrate

The invention discloses a method for preparing a concentrated ammonium nitrate solution through flash evaporation. The method comprises that after nitric acid and ammonia gas undergo a pressurization reaction to produce a dilute ammonium nitrate solution (with a concentration of about 75-80wt%), the dilute ammonium nitrate solution is concentrated to a high concentration of 90-96wt% under action of reaction heat through one step in a pressure reduction flash evaporation device so that a desired concentrated ammonium nitrate solution product is obtained. The method reasonably utilizes energy and is free of ammonium nitrate solution multistage condensation of the traditional ammonium nitrate production technology so that energy is saved, a production process is simple, an investment is reduced and a production cost is reduced.

Owner:SEDIN ENG

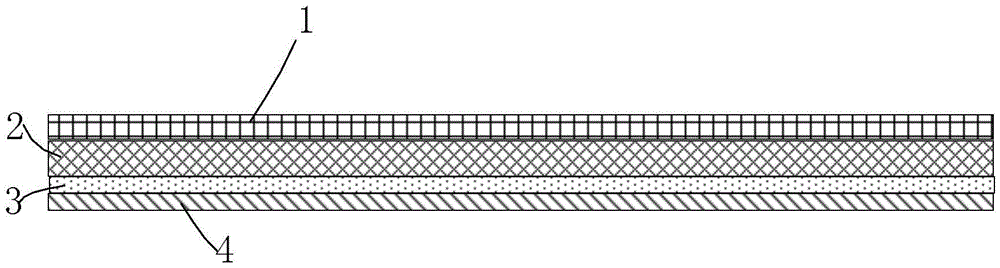

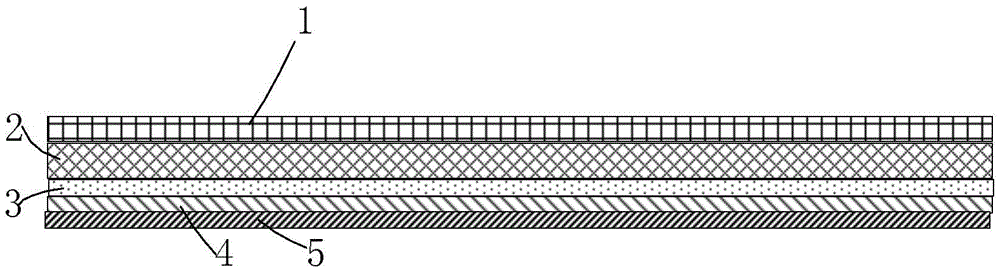

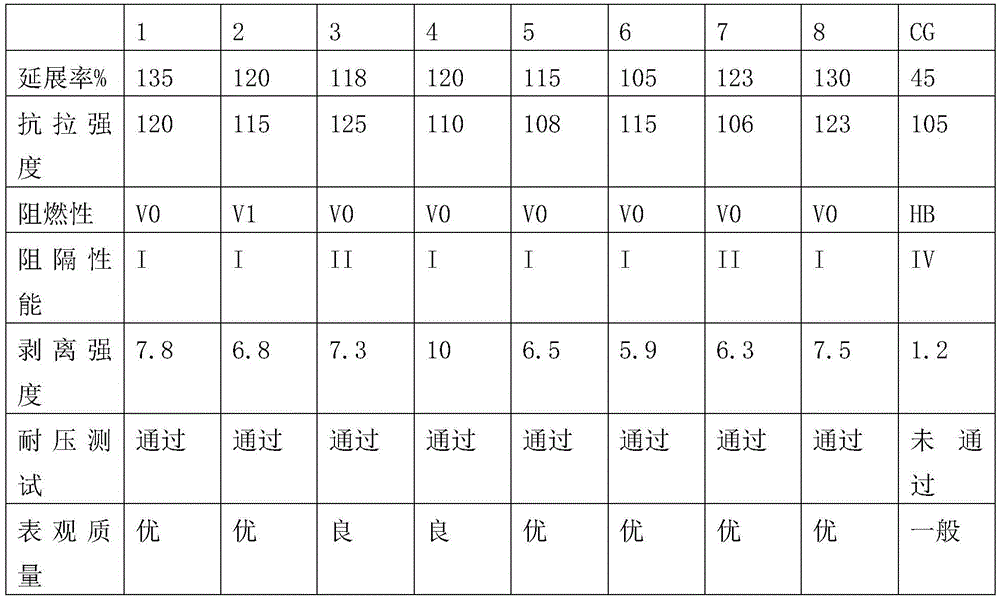

A kind of preparation method of high temperature resistant flame retardant composite material

ActiveCN103660499BHigh temperature resistant and flame retardantImprove ductilityLamination ancillary operationsSynthetic resin layered productsPolyesterPolyvinyl chloride

The invention discloses a high-temperature-resistant flame retardant composite material and a preparation method of the high-temperature-resistant flame retardant composite material. The high-temperature-resistant flame retardant composite material comprises a polyester layer, a polyvinyl chloride soft cloth layer, a non-setting adhesive layer and a paper centrifuge film layer which are sequentially compounded. The preparation method of the high-temperature-resistant flame retardant composite material comprises the following steps of printing a pattern on the polyester film according to a preset model, gumming by using a dry compound machine, carrying out heat seal and rolling on the polyester film and the polyvinyl chloride soft cloth under the certain temperature and pressure to obtain a middle product; curing the rolled middle product under the certain temperature; and cooling a rolling film, coating glue by using the compound machine, compounding the rolling film and a paper centrifuge film under certain pressure and rolling an obtained compound product, and slitting and packing according to the scheduled standard. The high-temperature-resistant flame retardant composite material and the preparation method thereof provided by the invention have the advantages that the high-temperature-resistant flame retardant composite material has the excellent ductility and flexibility, the technological monopoly of a foreign company is broken through, the technological blank and the product blank in China are filled, the high-temperature-resistant flame retardant composite material has the wide market prospect, the production technology is green, environmentally-friendly and energy-saving, the standard of the national high technology industry is met, and the high-temperature-resistant flame retardant composite material and the preparation method thereof have the very outstanding technical advantage.

Owner:江苏东浦精细陶瓷科技股份有限公司

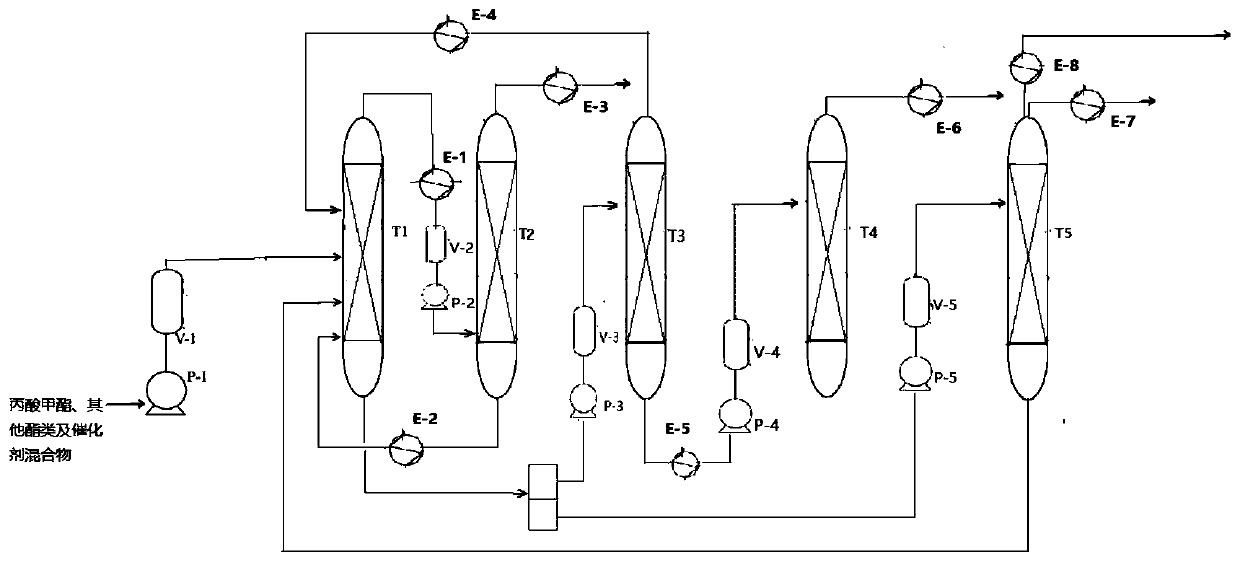

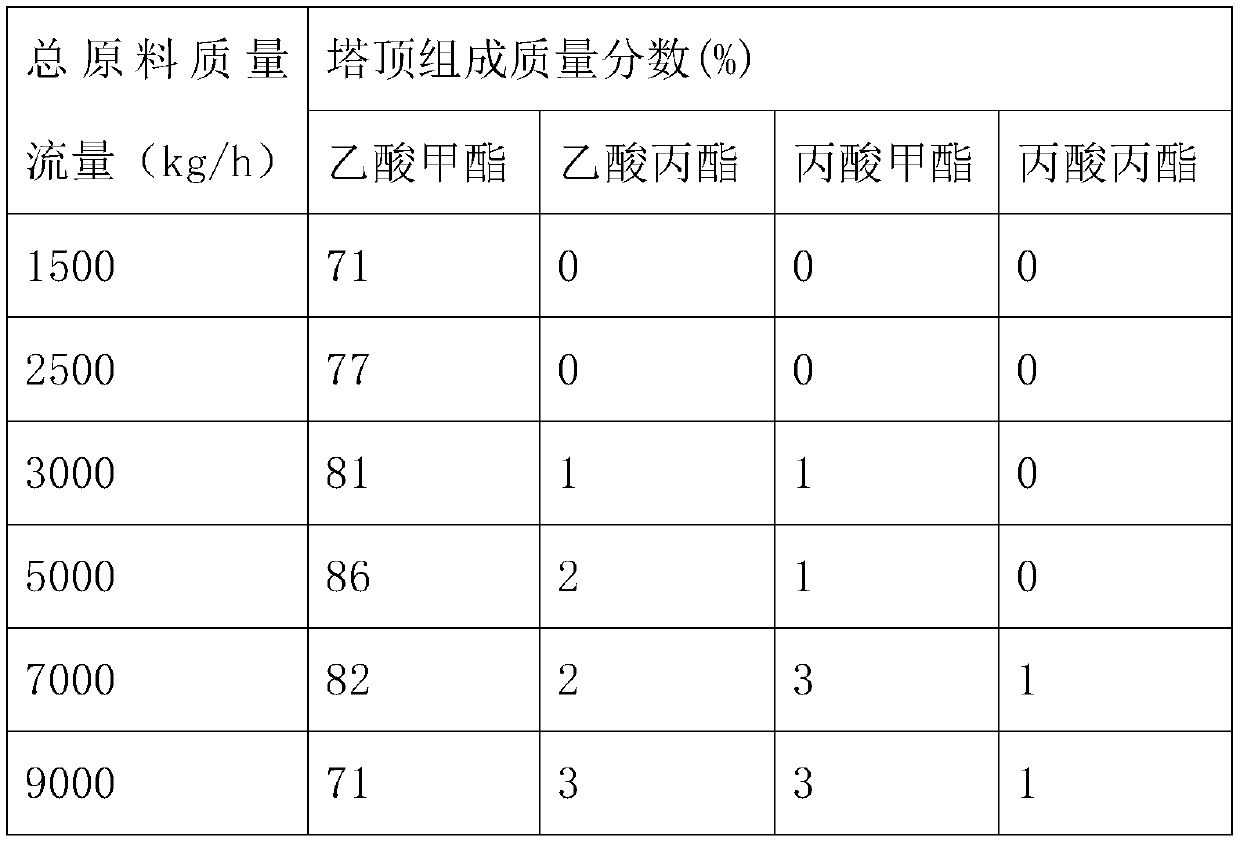

Homogeneous-phase catalytic rectification process for preparing propionic ester through ester-ester exchange

InactiveCN109776310AHigh selectivityHigh purityOrganic compound preparationChemical industryMethyl propionateHomogeneous catalysis

The invention provides a catalytic rectification process which takes homogeneous-phase soluble alkali or ionic liquid as a catalyst to catalyze methyl propionate and various esters such as ethyl formate, propyl formate, butyl formate, ethyl acetate, propyl acetate and butyl acetate to synthesize propionic ester with high added value and high purity in one step. The process has the advantages of simple reaction system and short reaction path; a product is high in selectivity and purity and generates no by-products absolutely. The reaction time is short, the activity of the catalyst is high, andthe catalyst can be repeatedly used. Azeotropy between raw material esters and a product ester does no happens generally, separation is easy, and the process has great significance in large-scale andlow-cost production of the propionic ester with high added value and high purity. The whole reaction process is environmentally friendly, capable of saving energy and efficient.

Owner:SHANDONG SHIDA SHENGHUA CHEM GROUP

Preparation method of a high-barrier fireproof and high temperature resistant composite material

ActiveCN103722810BImprove barrier propertiesImprove high temperature resistanceLaminationLamination apparatusGlass fiberPolyester

The invention discloses a high-barrier, fireproof and high temperature resistant composite material and a preparation method thereof. The high temperature resistant composite material comprises a polyester layer, a polyvinyl chloride soft cloth layer, an adhesive sticker layer and a paper centrifugal film layer which are composited sequentially. The preparation method of the composite material comprises steps as follows: patterns are printed on a polyester film in a preset mode; a dry compound machine is used for gluing, the polyester film and polyvinyl chloride soft cloth are heat-sealed and rolled at certain temperature and pressure, and an intermediate product is obtained; the rolled intermediate product is cured at a certain temperature; after a rolled film is cooled, the dry compound machine is used for gluing, and the film is composited and rolled with a paper centrifugal film at certain pressure; and slitting and packaging are performed according to preset specifications. The composite material has excellent ductility and softness, breaks the technological monopoly of foreign companies, fills the technological blank and the product blank at home and has a wide market prospect; and the production process is green, environment-friendly and energy-saving, meets requirements of the national high technology industry and has outstanding technological advantages.

Owner:江苏东浦精细陶瓷科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com