Phosphorus slag silicate building block and production process

A production process, silicate technology, which is applied in the field of construction engineering materials and its preparation process, can solve the problems of improving energy conservation and environmental protection, reducing the brand image of blocks, and flooding of inferior building blocks, so as to reduce production energy consumption and reduce The effect of using energy consumption and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] A kind of production technology of phosphorus slag silicate block of the present invention, comprises the following steps:

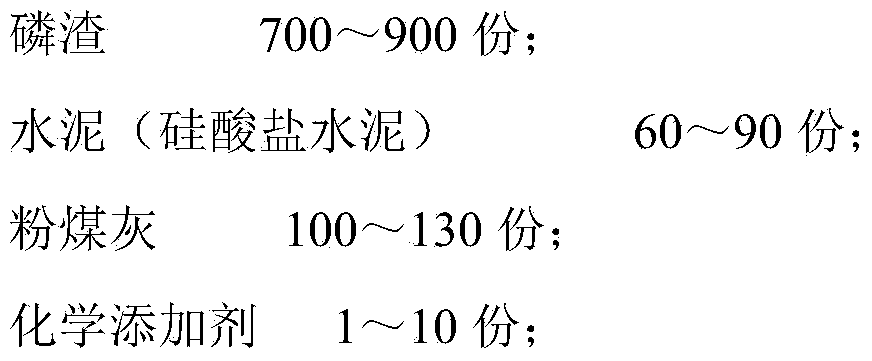

[0045] (1) Prepare main raw materials: prepare phosphorous slag, cement, fly ash and chemical additives in the following parts by mass;

[0046]

[0047] The main technical indicators of phosphorus slag used in this embodiment are: loss on ignition—0.22%, SiO 2 Content 36.97%, Fe 2 o 3 Content 0.29%, Al 2 o 3 content of 5.65%, CaO content of 45.965%, MgO content of 2.54%, and a particle size of less than 5mm, which meet the technical requirements of heavy slag aggregates, and can meet the quality standard requirements of the present invention for phosphorus slag; the safety reaches GB6566-2010 "Radioactive Nuclei of Building Materials "Supplement limit" standard requirements.

[0048] (2) Batching: Send the prepared raw materials into their respective hoppers, and use the batching system to automatically batch according to the above-mentione...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com