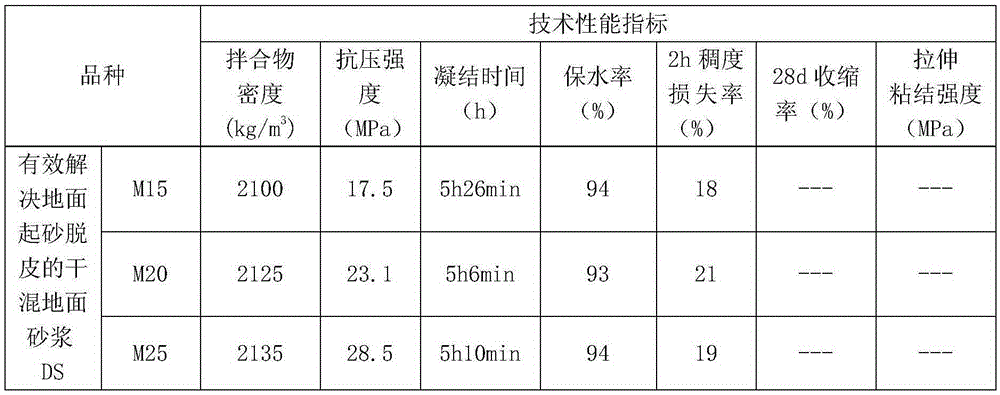

Dry mixed ground mortar for effectively solving dusting and peeling of ground and preparation method for dry mixed ground mortar

A ground and mortar technology, applied in the field of ready-mixed mortar, can solve problems such as failure to protect soil, achieve good compressive strength, good work performance, and meet construction requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention relates to a dry-mixed ground mortar that effectively solves sanding and peeling on the ground, and consists of the following components in terms of mass percentage:

[0020] Limestone rock machine-made sand 40%-60%

[0021] Yellow sand 20%-30%

[0022] Fly ash 3%-7%

[0023] Cement 15%-21%

[0024] and the remainder of the admixture;

[0025] Wherein, the admixture is a modifier and a thickener; the modifier is one or more mixtures of cellulose ether, air-entraining agent or water reducer; the thickener is made of lithium slag, raw gypsum, zeolite powder, lignosulfonate water reducer, polyacrylamide, sodium dodecylsulfonate, white sugar, and triterpene saponins. The mass parts of each raw material are: lithium slag 35- 45 parts, 5-8 parts of raw gypsum, 4-6 parts of zeolite powder, 0.5-1.4 parts of lignosulfonate superplasticizer, 0.03-0.05 parts of polyacrylamide, 1.20-2.80 parts of sodium dodecylsulfonate, white sugar 0.04-0.09 parts, 0.006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com