A kind of unfired magnesia alumina spinel brick

A technology of magnesia-alumina-spinel brick and magnesium-rich-alumina-magnesia spinel, which is applied in the field of refractory materials, can solve the problems of poor corrosion resistance and low service life, and achieve high-temperature strength, erosion resistance, and good thermal shock performance , Good anti-slag erosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

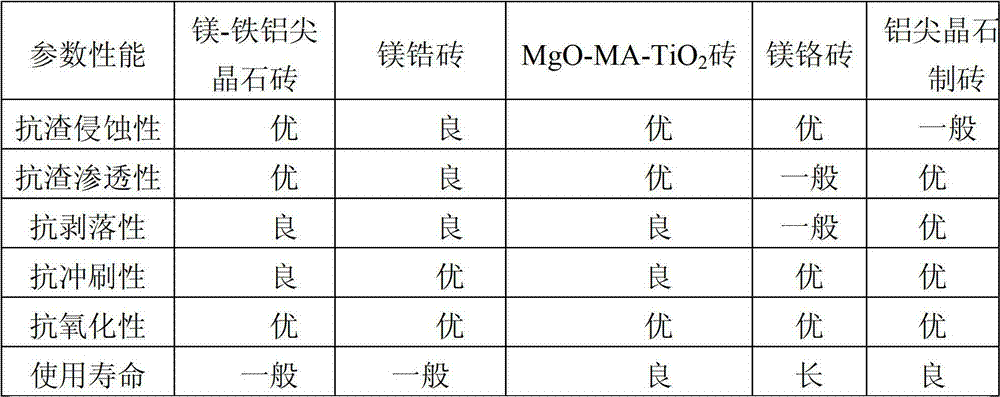

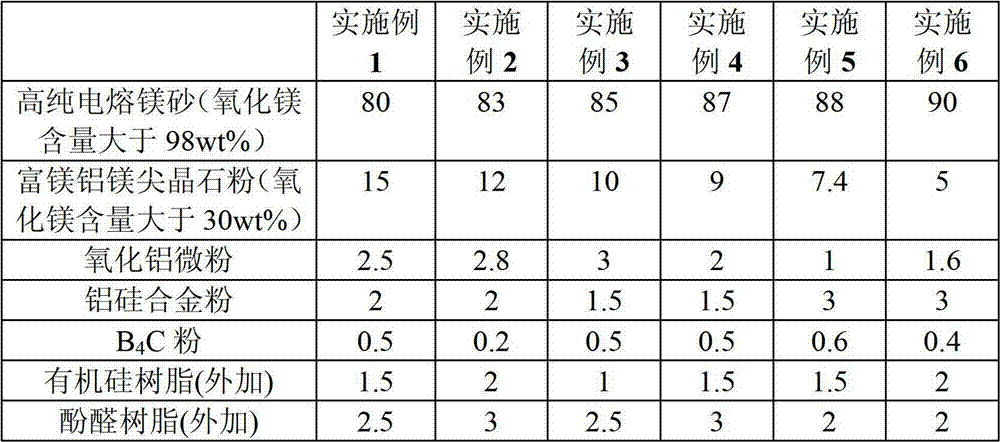

[0027] Table 2 shows the ratio of each chemical component in the embodiment 1-6 of the technical solution.

[0028] Table 2 (wt%)

[0029]

[0030] In each of the specific examples above, the high-purity fused magnesia material with a particle size of 8-10mm, magnesium-rich aluminum-magnesium spinel powder, alumina micropowder, aluminum-silicon alloy powder and B 4 C, using a binder silicone resin and phenolic resin to combine together, followed by kneading, molding and drying to make the non-fired magnesium aluminum spinel brick of the present invention.

[0031] Table 3 shows the properties of the non-burned magnesia spinel bricks in Examples 1-6.

[0032] table 3.

[0033]

[0034] *Note: High temperature flexural strength test temperature is 1400°C, non-oxidizing atmosphere, heat preservation for 1 hour.

[0035] It can be seen from Table 3 that the unfired magnesia-aluminum spinel brick described in this technical solution has an apparent porosity of 3-5%, a comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com