A kind of production system and production process of methanol to dimethyl ether

A production process and production system technology, applied in the field of methanol-to-dimethyl ether production system, can solve problems such as gaps, increased equipment investment costs, and inability to prepare high-purity dimethyl ether products, so as to increase energy consumption and reduce equipment investment The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

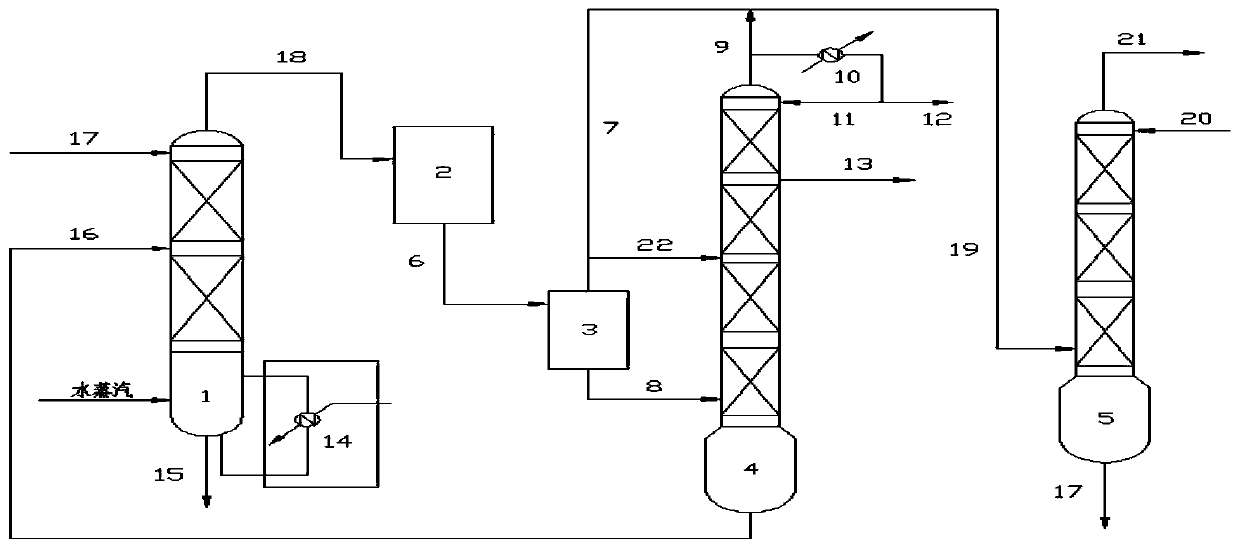

[0037] see figure 1 The technical process, the raw material methanol is fed from the top of the dimethyl ether absorption tower 5, the raw material methanol 3000kg / h, wherein methanol 2400kg / h, water 600kg / h, methanol content 80% (Wt).

[0038] Dimethyl ether absorption tower liquid composition: methanol 2400kg / h, water 600kg / h, methanol content 80% (Wt), enters from the top 17 of the vaporization stripping tower. Vaporization and stripping tower 1 has 22 theoretical plates and an operating pressure of 0.6Mpa (G). Methanol 245kg / h and water 1183.8kg / h in the mixed liquid in the 4th kettle of the dimethyl ether rectification tower, the feeding position is the 12th theoretical tray from the 1st kettle of the vaporization stripping tower, and the steam discharged from the top of the tower is fed into 18 Dehydration reaction system 2, wherein methanol 2644.9kg / h, water 212.4kg / h, methanol content 92.56% (Wt). The methanol content in the water discharged from the tower kettle is ...

Embodiment 2

[0041] see figure 1 The technical process, raw material methanol is fed from the top of dimethyl ether absorption tower 5, raw material methanol 3000kg / h, wherein methanol 2700kg / h, water 300kg / h, methanol content 90% (Wt).

[0042] Dimethyl ether absorption tower liquid composition: methanol 2700kg / h, water 300kg / h, dimethyl ether 100kg / h, methanol content 87.1% (Wt), dimethyl ether content 3.2% (Wt), dimethyl ether by dimethyl The outlet 9 at the top of the ether rectification tower 4 is partly vented and introduced, and the bottom liquid of the tower enters from the top 17 of the vaporization stripping tower. Vaporization and stripping tower 1 has 22 theoretical plates and an operating pressure of 0.6Mpa (G). Methanol 445kg / h and water 1059.4kg / h in the mixed liquid in the 4th kettle of the dimethyl ether rectification tower, the feeding position is the 12th theoretical tray from the 1st kettle of the vaporization stripping tower, and the steam discharged from the top of t...

Embodiment 3

[0045] see figure 1 The technical process, the raw material methanol is fed from the top of the dimethyl ether absorption tower 5, the raw material methanol 3000kg / h, wherein methanol 2500kg / h, water 500kg / h, methanol content 83.3% (Wt).

[0046] Dimethyl ether absorption tower 5 kettle liquid composition: methyl alcohol 2500kg / h, water 500kg / h, dimethyl ether 900kg / h, methanol content 64.1% (Wt), dimethyl ether content 23.1% (Wt), by vaporization stripper 17 on the top of the tower to enter. Vaporization and stripping tower 1 has 26 theoretical plates and an operating pressure of 0.7Mpa (G). Methanol 600kg / h and water 1203.1kg / h in the mixture liquid of dimethyl ether rectification tower bottom, the feeding position is at the 16th theoretical tray counted from the 1st bottom of the vaporization stripping tower, and the steam 18 discharged from the top of the tower is sent to dehydration Reaction system 2, wherein methanol 3099.1kg / h, water 202.5kg / h, dimethyl ether 900kg / h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com