Nano calcium carbonate and styrene-butadiene rubber composition and preparation method thereof

A technology of nano-calcium carbonate and styrene-butadiene rubber, which is applied in the field of preparation of nano-calcium carbonate and styrene-butadiene rubber blend composition, can solve the problem of inability to realize single-particle dispersion of calcium carbonate particles, limitation of calcium carbonate particle isolation, and influence on composition Problems such as application function, to achieve good dispersion stability, improve functional enhancement, reduce energy consumption and dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

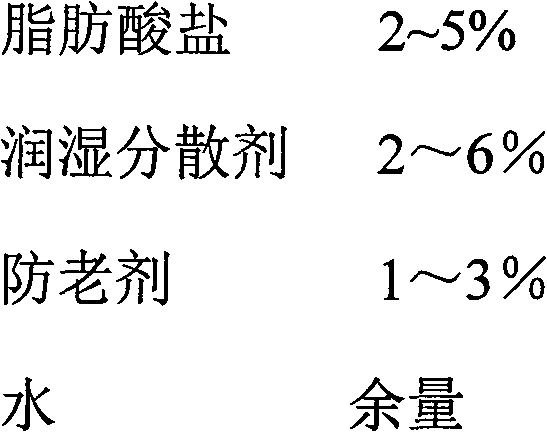

[0039] 1) Surface treatment of nano calcium carbonate

[0040] Add 10g of sodium stearate to 150ml of water at a temperature of 80°C, stir until it is completely emulsified, then add 4.5g of OP-9 and 4.5g of styrenated phenol in sequence, keep warm and continue stirring for 30 minutes to obtain the modified lotion.

[0041] The temperature prepared by the carbonization method with a solid content of 15% (wt) is 2 kilograms of nano-calcium carbonate suspension at 69°C and placed in a 5L jacketed reactor, the temperature is raised to 80°C, and the modifier prepared above is added The emulsion is kept at 80° C. and stirred for 1 hour to obtain a dispersed and stable nano-calcium carbonate suspension.

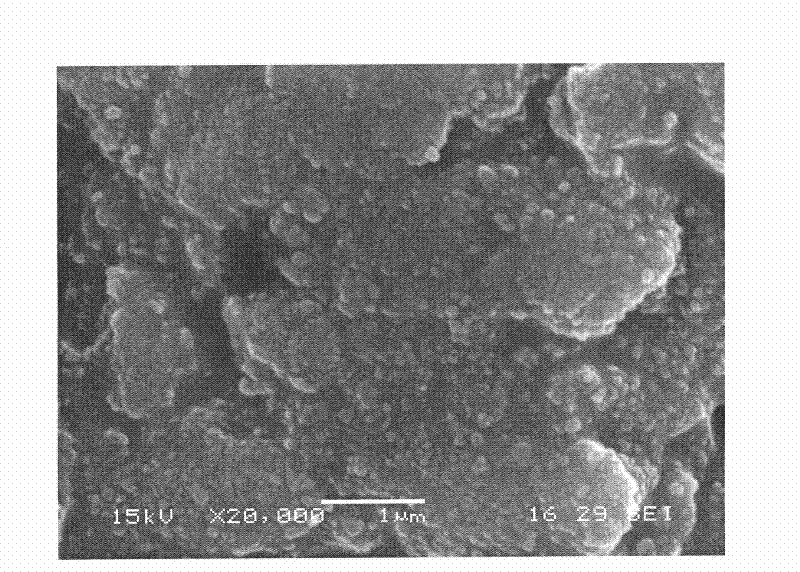

[0042] In the nano-calcium carbonate suspension, the average particle diameter of the nano-calcium carbonate is 50 nanometers.

[0043] 2) Blending and coagulation

[0044] 2.4 kilograms of styrene-butadiene latex with a solids content of 5% (wt) were added to the above-mentioned ...

Embodiment 2

[0046] 1) Surface treatment of nano calcium carbonate

[0047] Add 8.3g of sodium stearate to 150ml of water at a temperature of 90°C, stir until it is completely emulsified, then add 10g of TX-10 and 2.5g of 2,6-di-tert-butyl-p-cresol in turn, and continue to Stir for 30 minutes to obtain modifier emulsion.

[0048] The temperature prepared by the carbonization method with a solid content of 10% (wt) is 2 kilograms of nano-calcium carbonate suspensions at 46°C and placed in a 5L jacketed reactor, the temperature is controlled at 46°C, and the modifier emulsion prepared above is added , insulated and stirred for 3 hours to obtain a dispersed and stable nano-calcium carbonate suspension. In the nano-calcium carbonate suspension, the average particle diameter of the nano-calcium carbonate is 45 nanometers.

[0049] 2) Blending and coagulation

[0050] The styrene-butadiene latex that 0.4 kilogram of solids content is 10% (wt) is joined in the above-mentioned prepared nano-cal...

Embodiment 3

[0052] 1) Surface treatment of nano calcium carbonate

[0053] Add 3.4kg of sodium stearate to 150kg of water at a temperature of 85°C, stir until it is completely emulsified, then add 6.7kg of AEO1500 and 4.8kg of nickel dibutyldithiocarbamate in turn, keep warm and continue stirring for 30 minutes , to obtain modifier emulsion.

[0054] The temperature prepared by the carbonization method with a solid content of 6.5% (wt) is 2000 kilograms of 55 ℃ nano-calcium carbonate suspension placed in a 5m 3 A jacketed reactor was used to control the temperature to 90°C, and the modifier emulsion prepared above was added, and kept stirring for 1.5 hours to obtain a dispersed and stable nano-calcium carbonate suspension. In the nano-calcium carbonate suspension, the average particle diameter of the nano-calcium carbonate is 80 nanometers.

[0055] 2) Blending and coagulation

[0056] The styrene-butadiene latex that 300kg solid content is 10% (wt) joins in the above-mentioned prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com