Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Prevention and Control of Pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

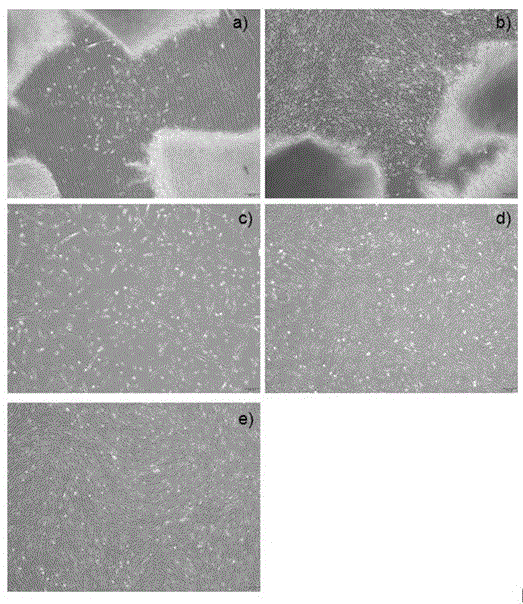

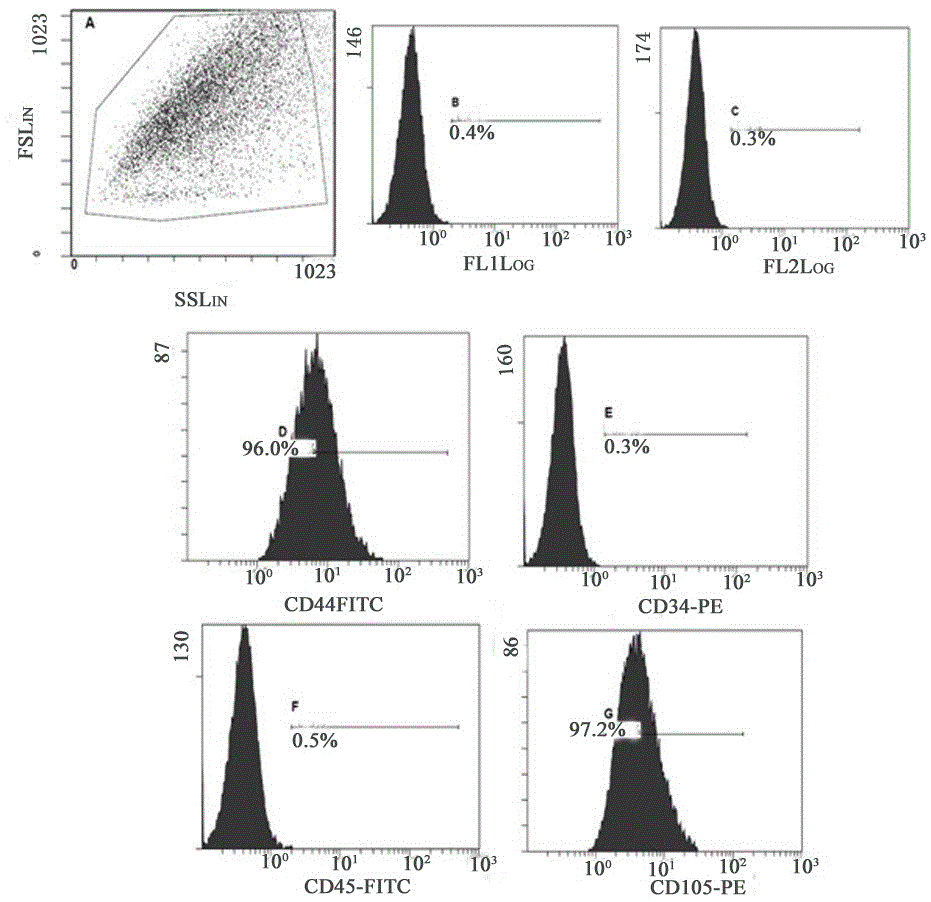

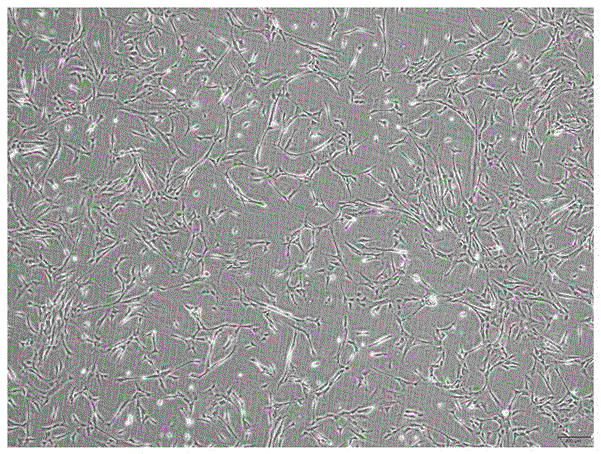

Method for acquiring safe and effective umbilical cord mesenchymal stem cell

ActiveCN105586309AHigh purityWell representedCell dissociation methodsSkeletal/connective tissue cellsMesenchymal stem cellUmbilical cord

The invention provides a method for acquiring a safe and effective umbilical cord mesenchymal stem cell. A pollution-free umbilical cord mesenchymal stem cell can be prepared by umbilical cord acquisition, umbilical cord transportation, umbilical cord preparation and methods of detecting, screening, adding antibiotics and the like in a cell culturing process, so that the safety can be guaranteed; and improved culture system and culture method are adopted in the separating and culturing processes, so that the separation efficiency is improved, the culturing cycle is shortened, and a high-purity excellent-characterization cell can be obtained. According to the method, the cost can be effectively reduced, the high-quality umbilical cord mesenchymal stem cell can be quickly acquired, injury on cells can be reduced, the culturing cycle can be shortened, pollution can be reduced, and the cell purity can be improved.

Owner:FUJIAN YINFENG STEM CELL ENG

Salmonella phage LPSE34 and application thereof in food

ActiveCN108588037AImprove the bactericidal effectOvercoming the disadvantages of isotype specificityLectin superfamilyMeat/fish preservation by coatingFood borneSalmonella Phage

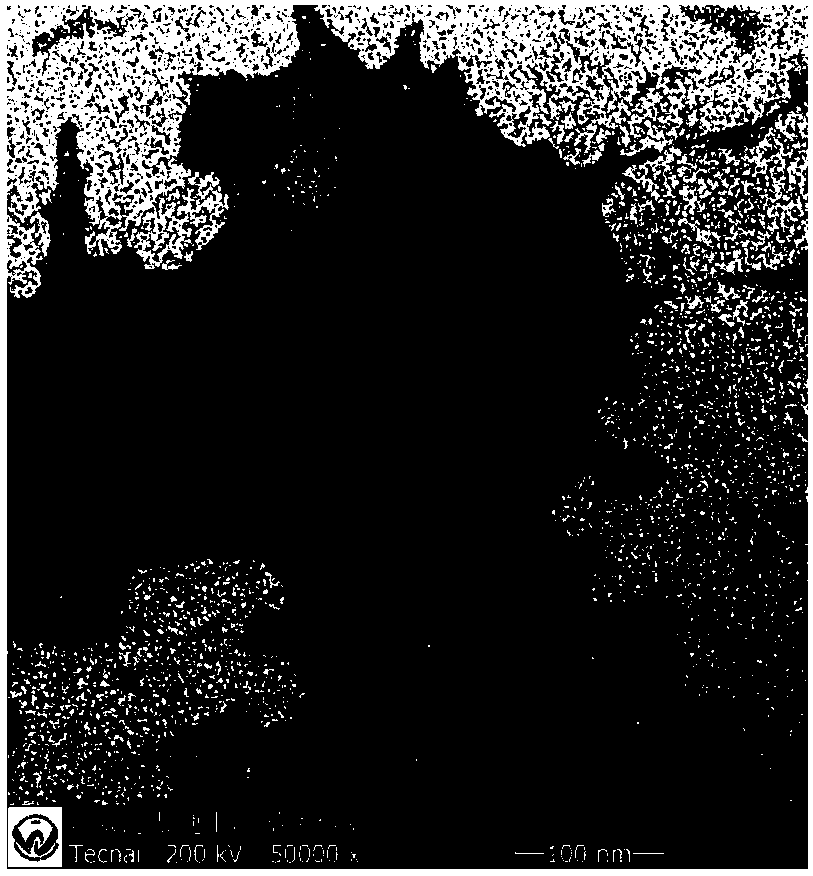

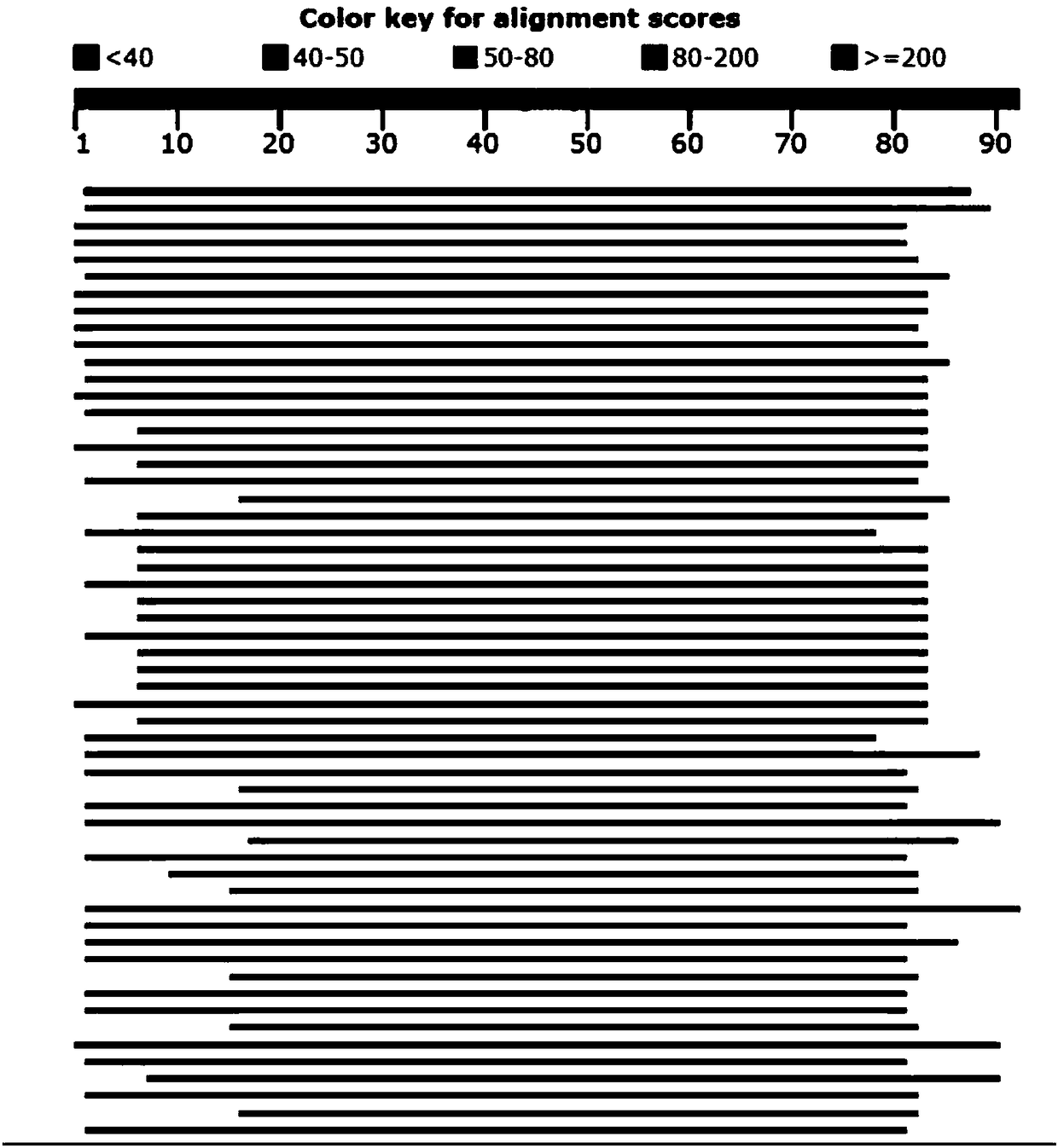

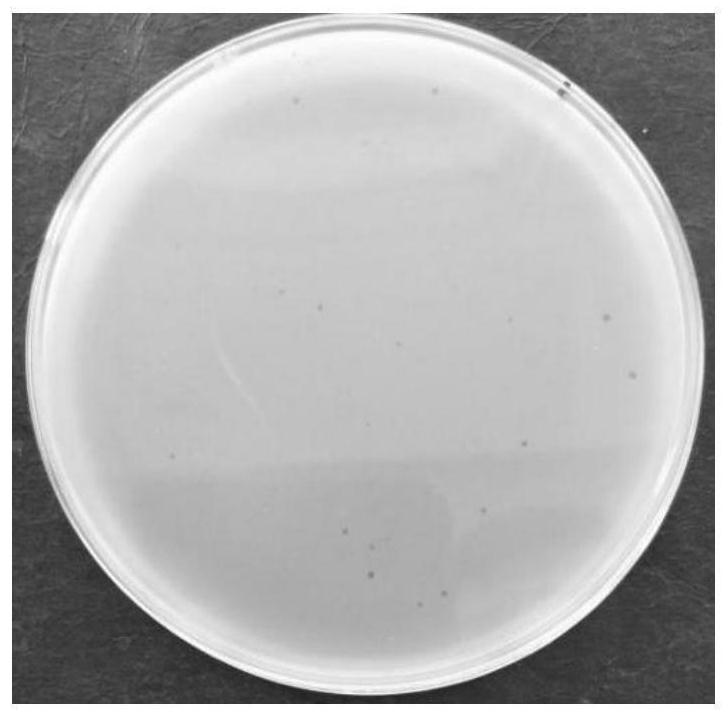

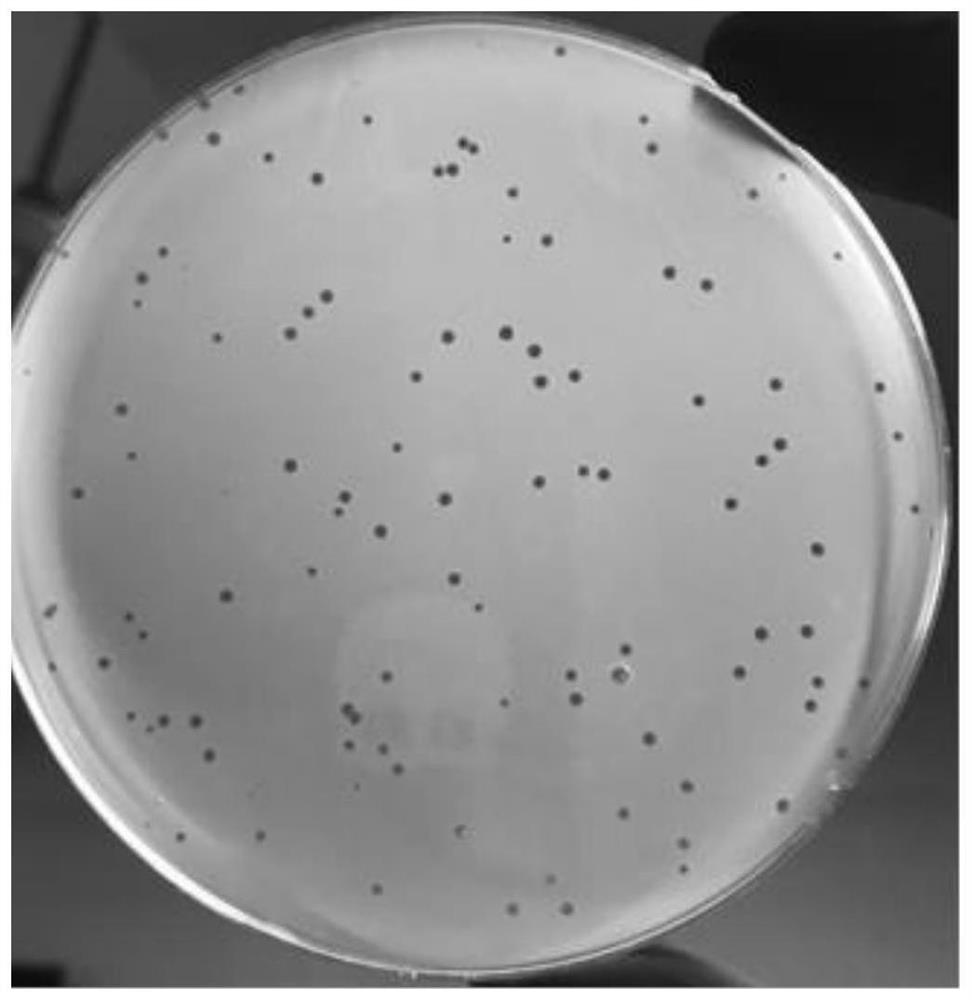

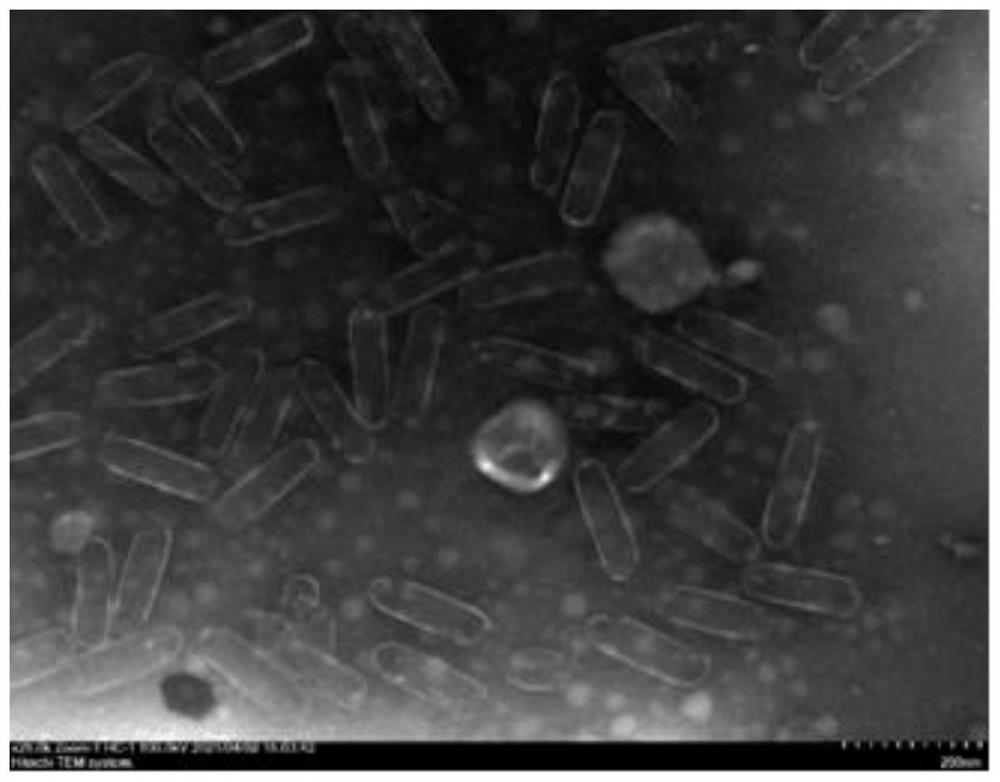

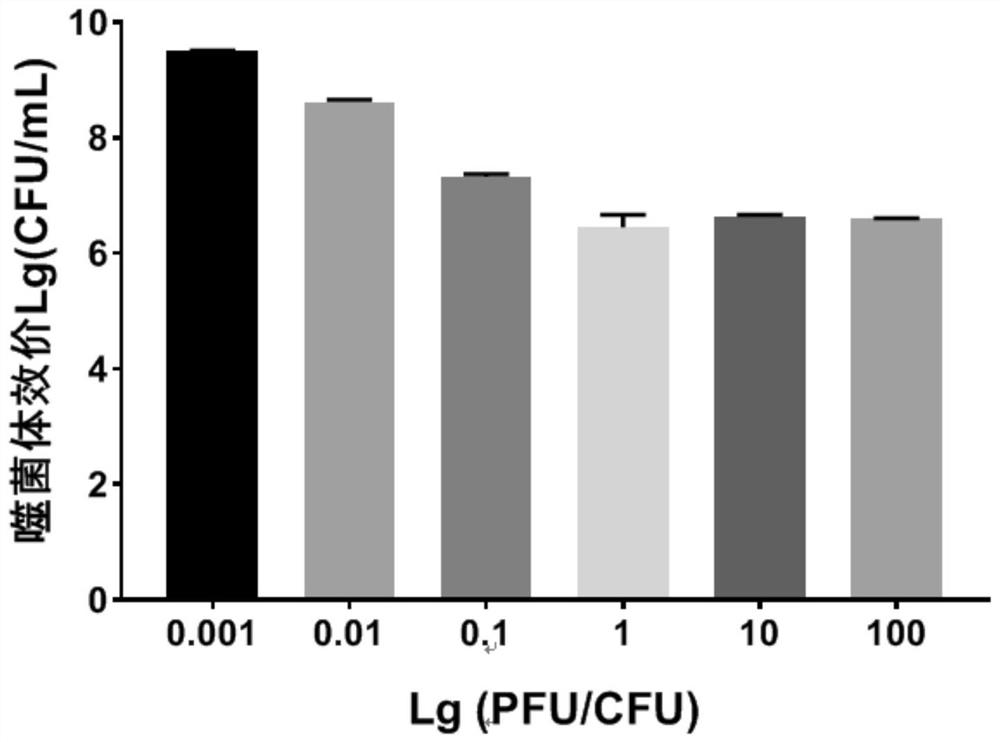

The invention discloses a salmonella phage LPSE34. The preservation number of the salmonella phage LPSE34 is CCTCC NO 2018121. The phage is a broad-spectrum salmonella phage and can crack drug-tolerant salmonellas, it is identified that the phage belongs to myoviridae, and the phage is named as LPSE34. The phage LPSE34 is stable in titer at the pH of 4-12 and the temperature of 30-60 DEG C. The invention further discloses application of the salmonella phage in food, especially in chicken and ham systems; and in addition, the invention further discloses a compound edible coating film formed bytaking the phage as an antibacterial substance to be combined with sodium alginate, and compared with antibiotics and chemical preservatives, the phage cannot affect the texture and flavor of food andhas the characteristics of high specificity, no residue and safety. The salmonella phage LPSE34 can serve as a bacteriocidal substance / the antibacterial substance to control pollution of food-borne pathogens to the food and is a very promising biological agent for guaranteeing the food safety.

Owner:HUAZHONG AGRI UNIV

Salmonella typhimurium bacteriophage T156 and application thereof

ActiveCN111944766AOvercoming the disadvantages of isotype specificityImprove the bactericidal effectBiocideMicroorganism based processesSalmonella frintropBacteriophage

The invention discloses a salmonella typhimurium bacteriophage T156 and application thereof. The bacteriophage is a broad-spectrum type, can split salmonella and a drug-resistant strain thereof, and is identified as a caudal bacteriophage long-tail bacteriophage family; and the bacteriophage T156 has stable titer with the pH of 3-12 and the temperature of 30-50 DEG C. The bacteriophage provided bythe invention can be used for effectively controlling salmonella typhimurium ATCC 13311 in a food sample, and has the characteristics of high specificity, no residue and safety compared with antibiotics and chemical preservatives.

Owner:HUAZHONG AGRI UNIV

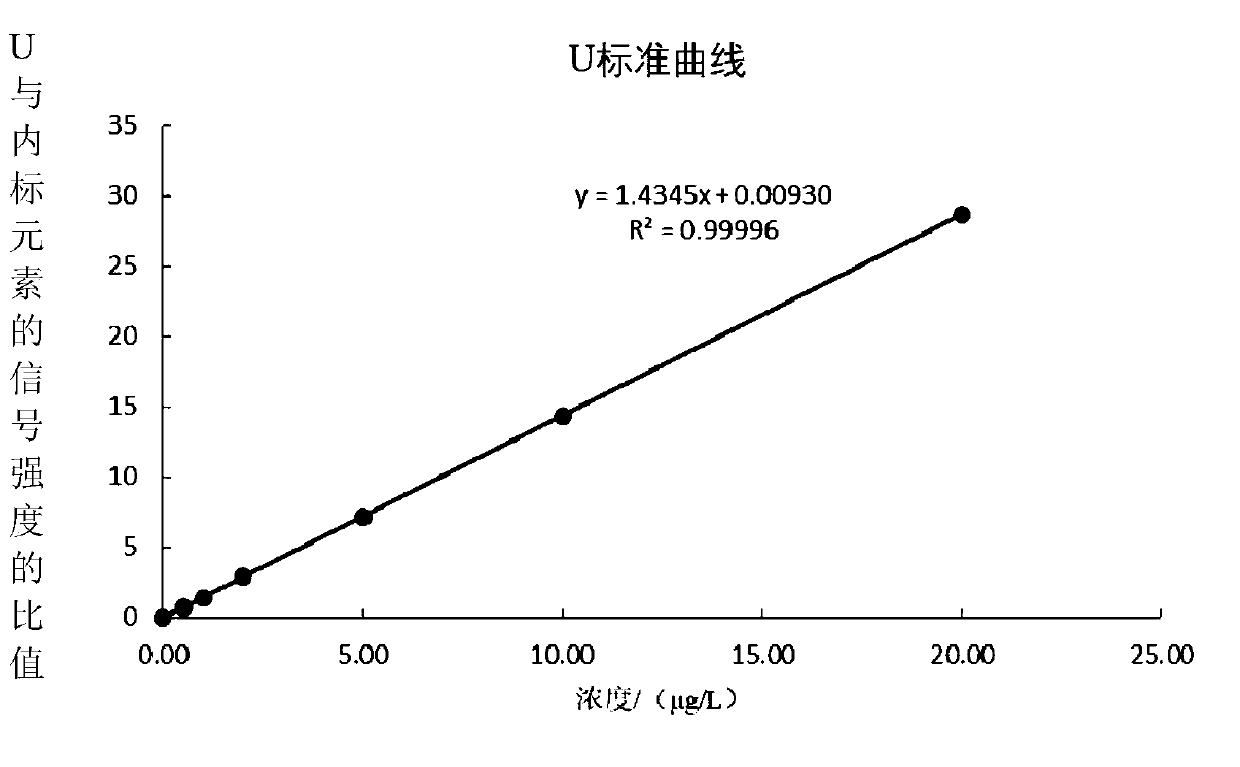

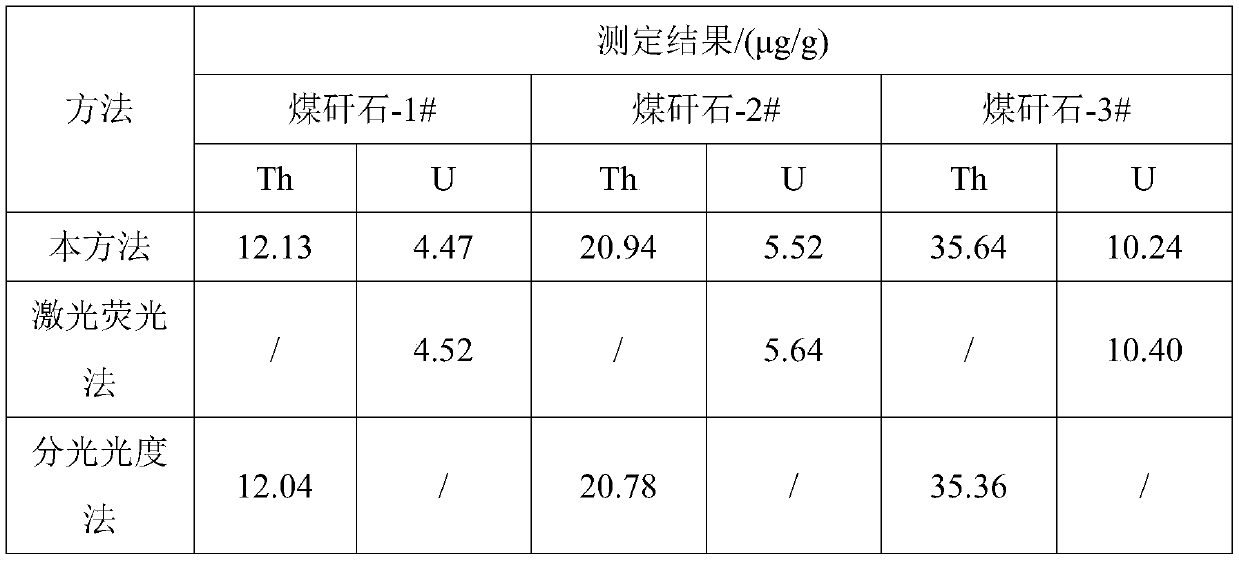

Method for measuring content of radioactive elements thorium and uranium in coal gangue

PendingCN111505106APrevention and Control of PollutionReliable test resultsPreparing sample for investigationMaterial analysis by electric/magnetic meansAcid dissolutionMass analyzer

The invention discloses a method for measuring the content of radioactive elements thorium and uranium in coal gangue. The method comprises the following steps: carrying out microwave digestion on coal gangue in a concentrated nitric acid-concentrated hydrofluoric acid-concentrated hydrogen peroxide system in a closed manner, adding concentrated perchloric acid after the digestion is completed, performing heating on an acid driving instrument to remove fluorine and silicon, heating a sample digestion solution until white smoke comes near, performing cooling, adding nitric acid to dissolve salts, and performing diluting with ultrapure water to obtain a test solution; preparing a series of standard solutions and internal standard solutions, and determining by using an inductively coupled plasma mass spectrometer. According to the invention, hydrogen peroxide is added during microwave digestion, the decomposition of fixed carbon in the sample is obviously promoted, and the dissolution effect of the to-be-detected element is improved. According to the method, the content of the natural radioactive elements thorium and uranium in the coal gangue sample can be rapidly determined, the detection limit of the method reaches 0.0028 mu g / g, the relative standard deviation ranges from 0.75% to 2.54%, and the adding standard recovery rate ranges from 98.00% to 103.60%.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

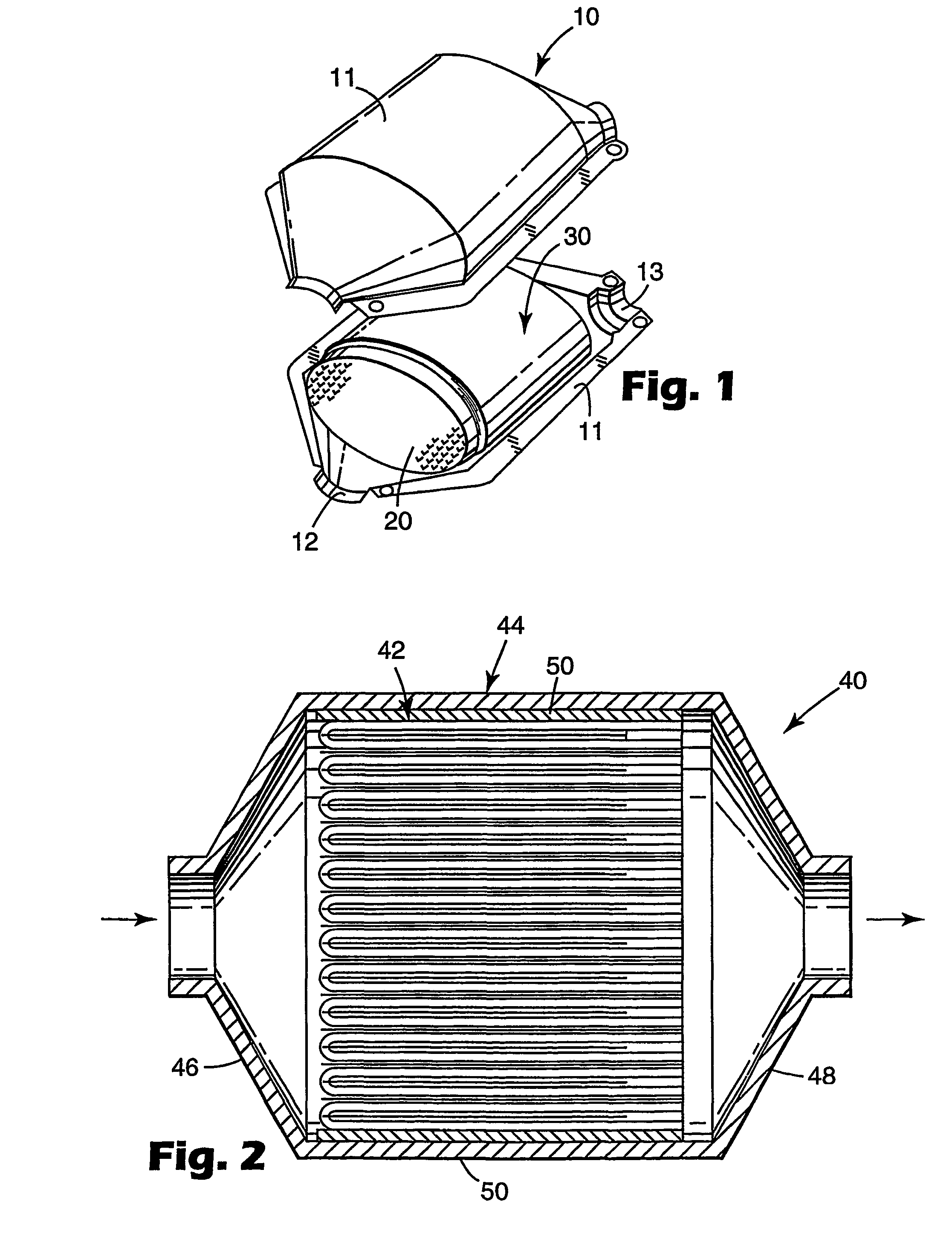

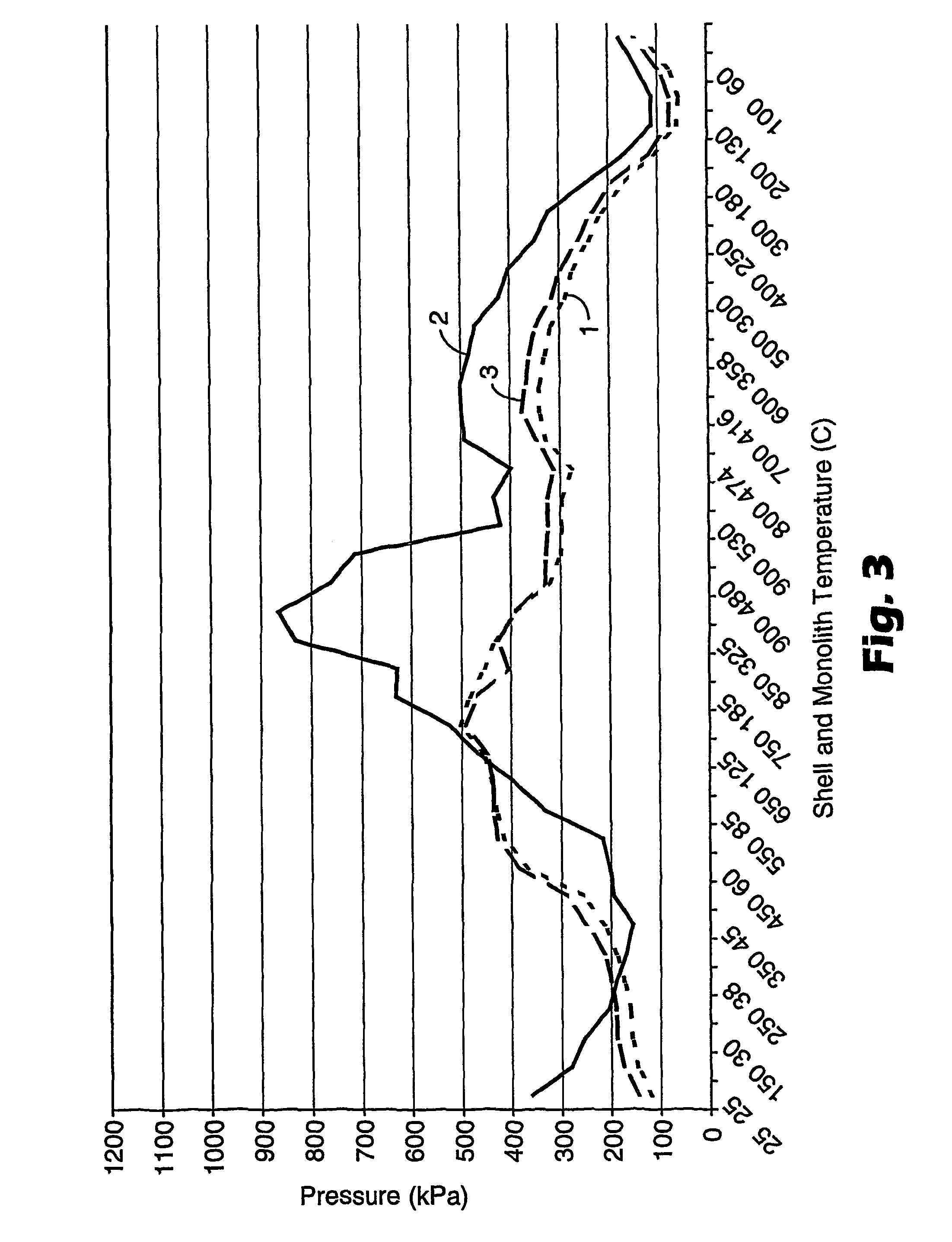

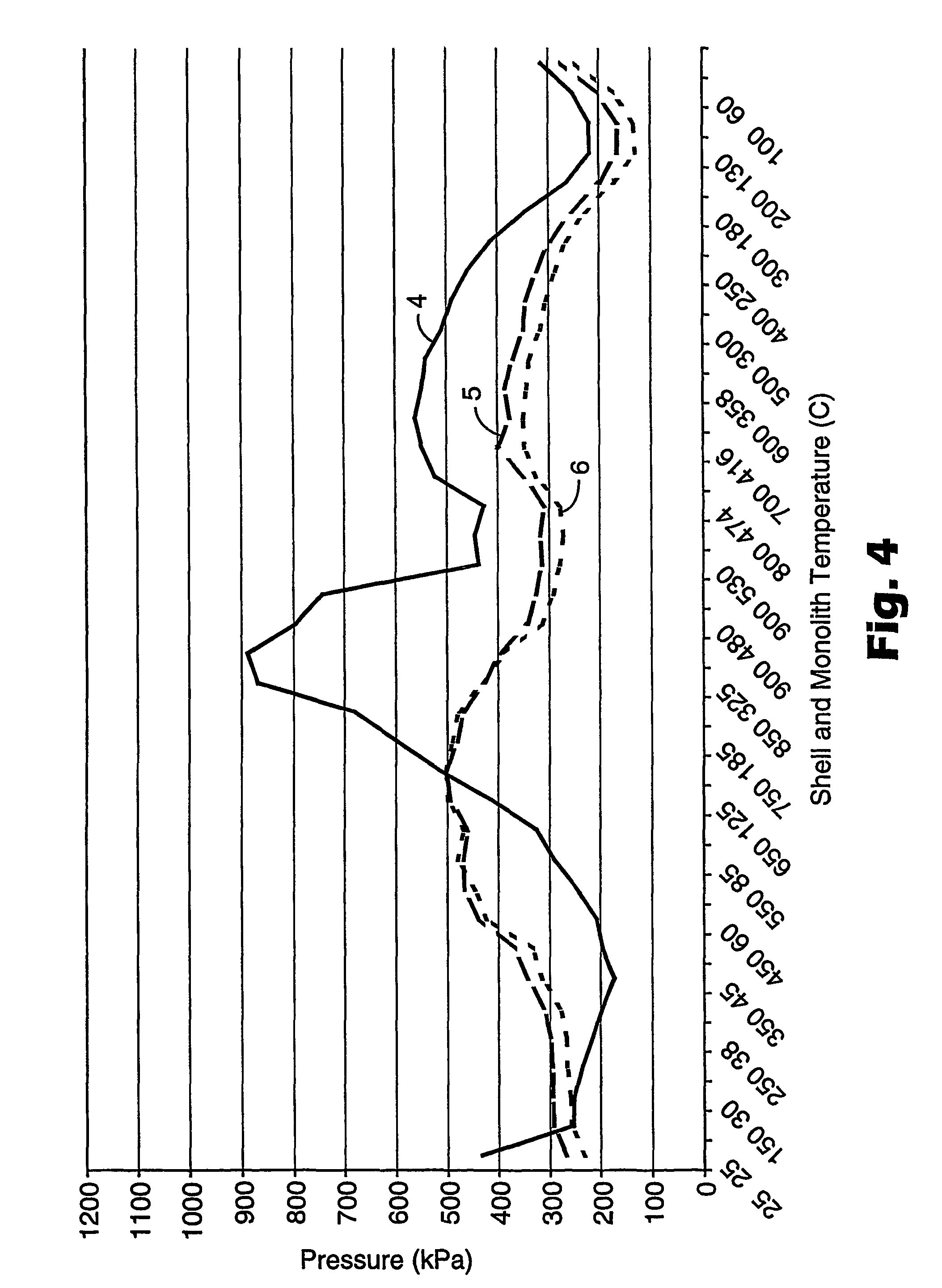

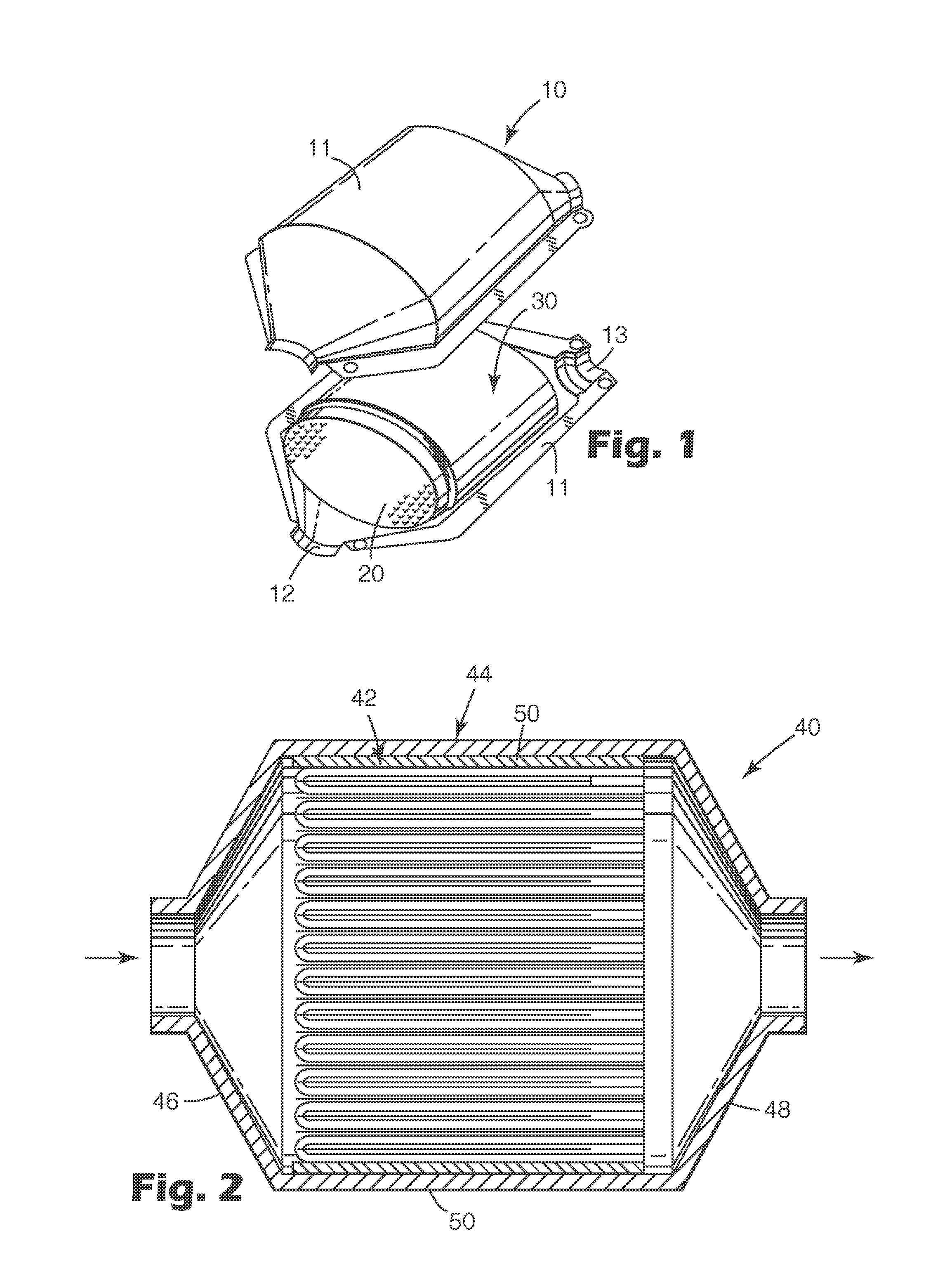

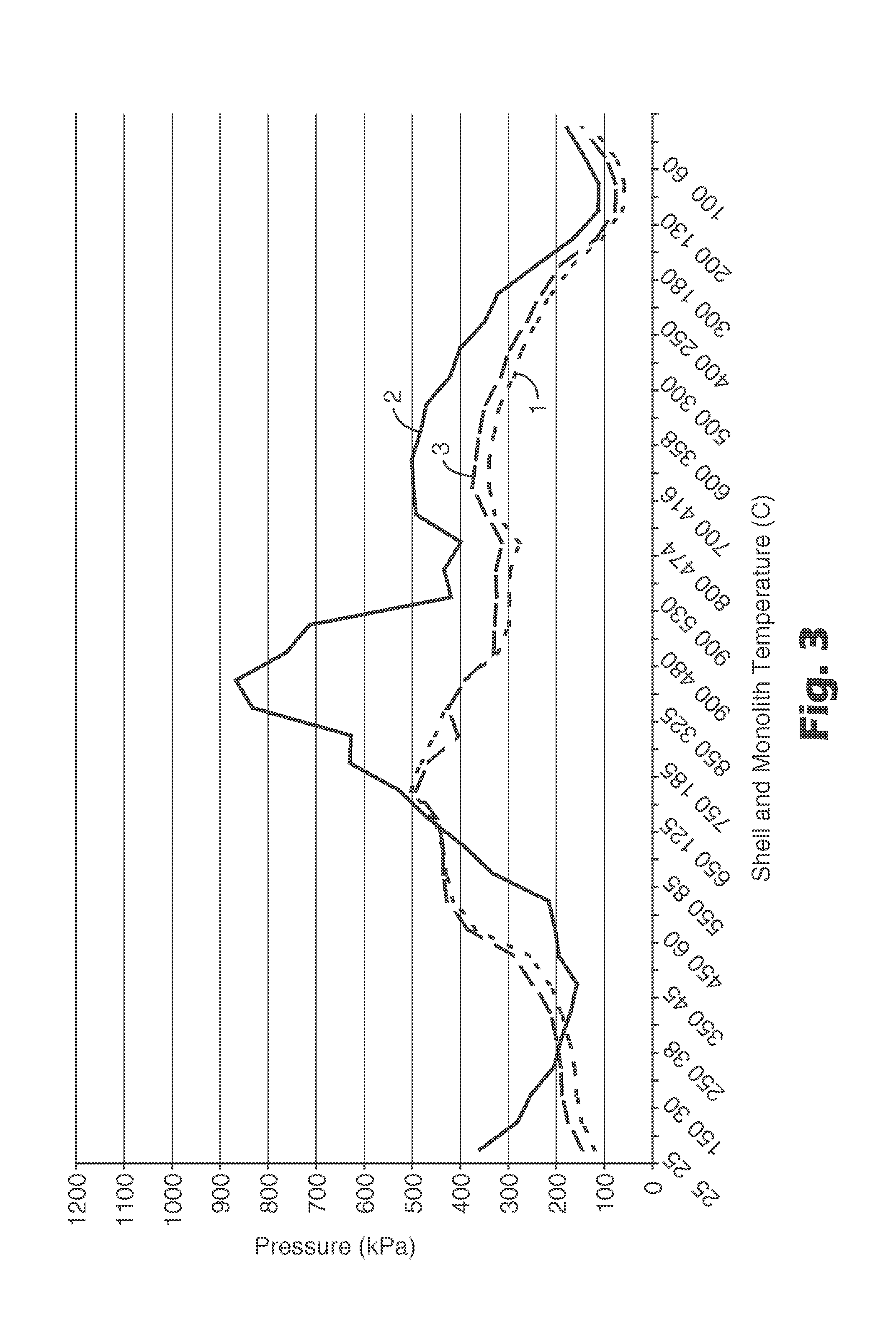

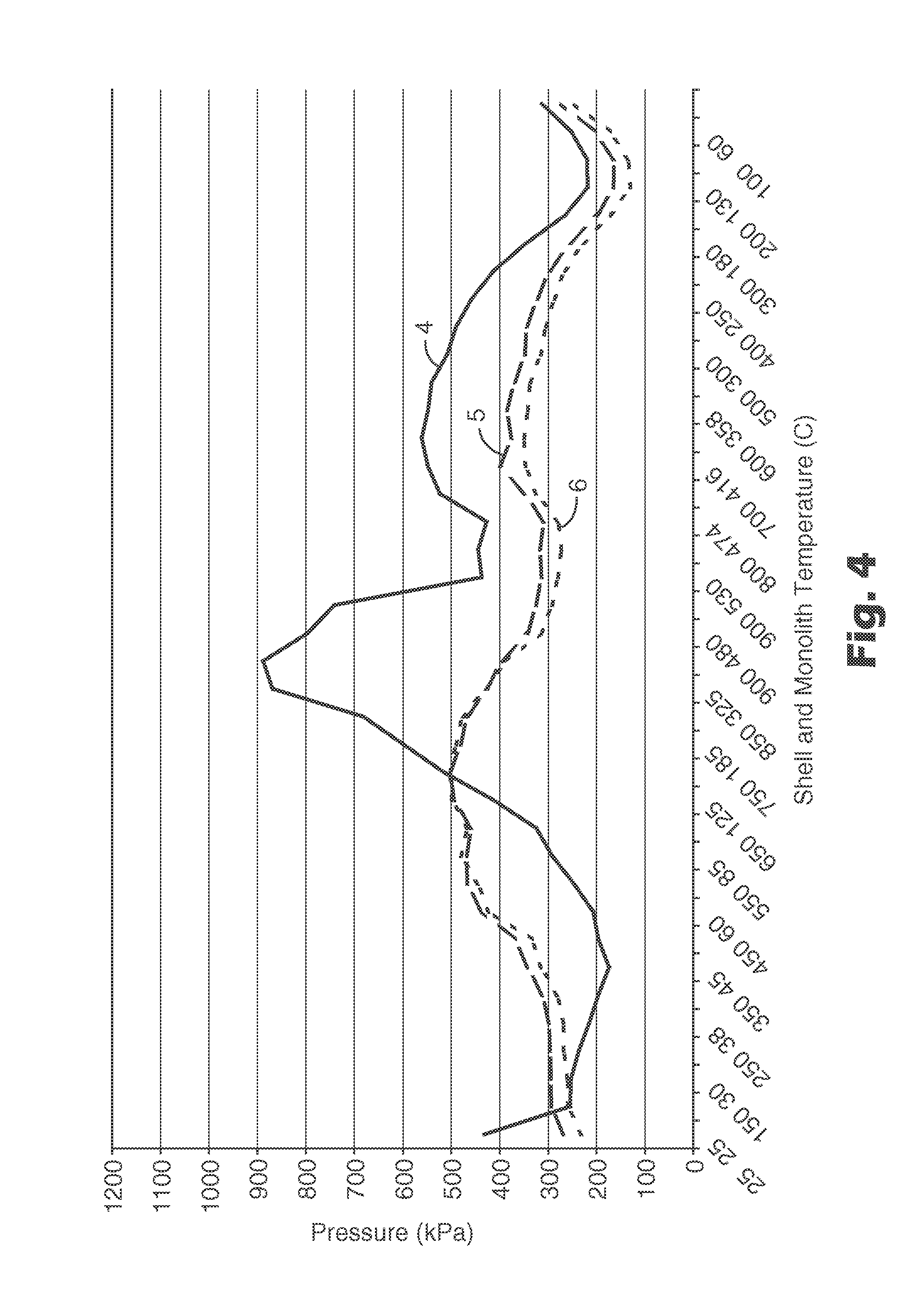

Compositions containing biosoluble inorganic fibers and micaceous binders

InactiveUS8673229B2Prevention and Control of PollutionCombination devicesPhysical/chemical process catalystsFiberPollution

Compositions that include a mixture of biosoluble inorganic fibers and a micaceous binder are described. The compositions can be prepared free of refractory ceramic fibers that are respirable but durable in a physiological medium. The compositions are typically in the form of a sheet material or a paste and can be used, for example, as a protective packing material around the pollution control element or as an insulating material in the end cone region in a pollution control device. Sheet materials formed from the compositions have an area of a X-Y plane that decrease less than about 6 percent when heated to about 900° C.

Owner:3M INNOVATIVE PROPERTIES CO

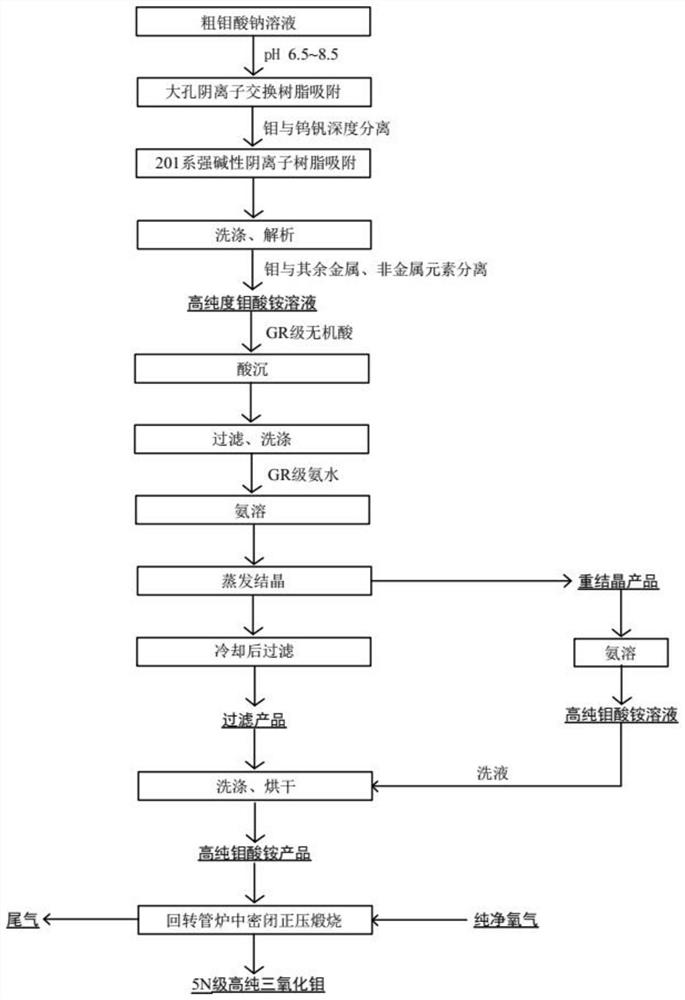

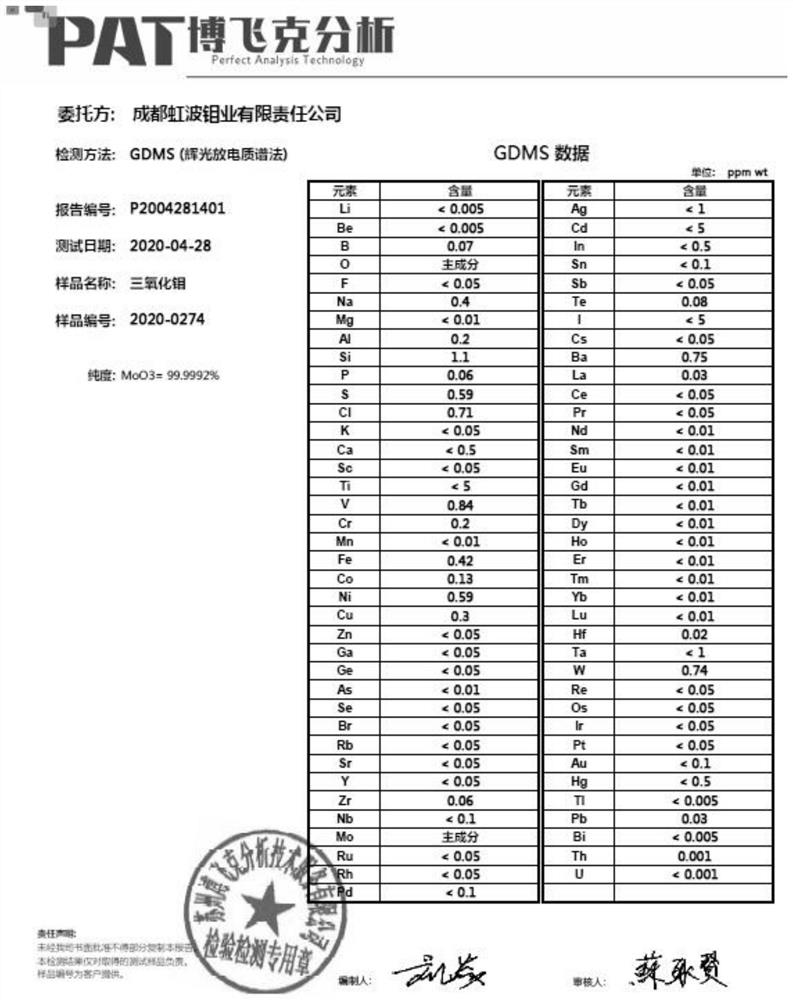

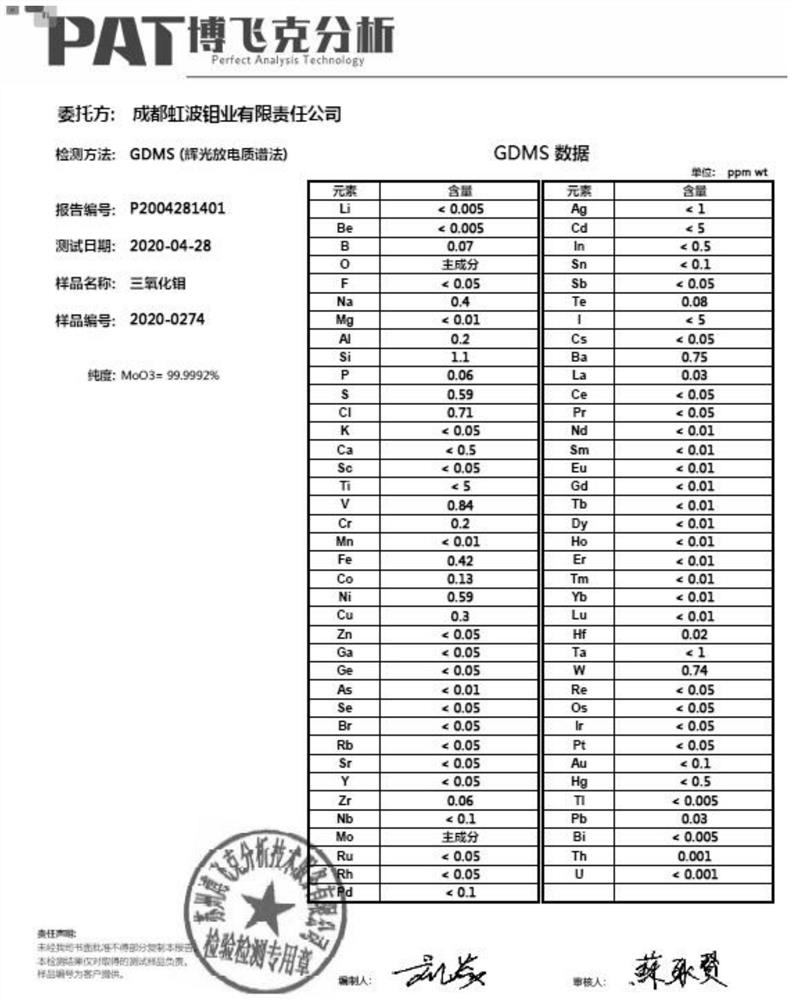

Production process of 5N-grade high-purity molybdenum trioxide

ActiveCN112744864AHigh purityProcess parameters are precisely controlledMolybdeum compounds preparationMolybdenum oxides/hydroxidesIon exchangeMolybdic acid

The invention provides a production process of 5N-grade high-purity molybdenum trioxide. The production process comprises the following steps: by taking crude sodium molybdate containing impurity elements such as tungsten, vanadium and the like as a raw material, deeply separating molybdenum from metal impurities and deeply separating molybdenum from non-metal impurities through multi-stage ion exchange, transforming the obtained high-purity sodium molybdate solution to obtain a high-purity ammonium molybdate solution, after the high-purity ammonium molybdate solution is subjected to acid precipitation to form a solid product, finally obtaining the 5N-grade high-purity molybdenum trioxide with the total impurity content smaller than or equal to 10 ppm through full-process closed conveying and operation. The technological parameters in the production process are precisely controlled, and equipment and environment pollution is strictly prevented and controlled.

Owner:成都虹波钼业有限责任公司 +1

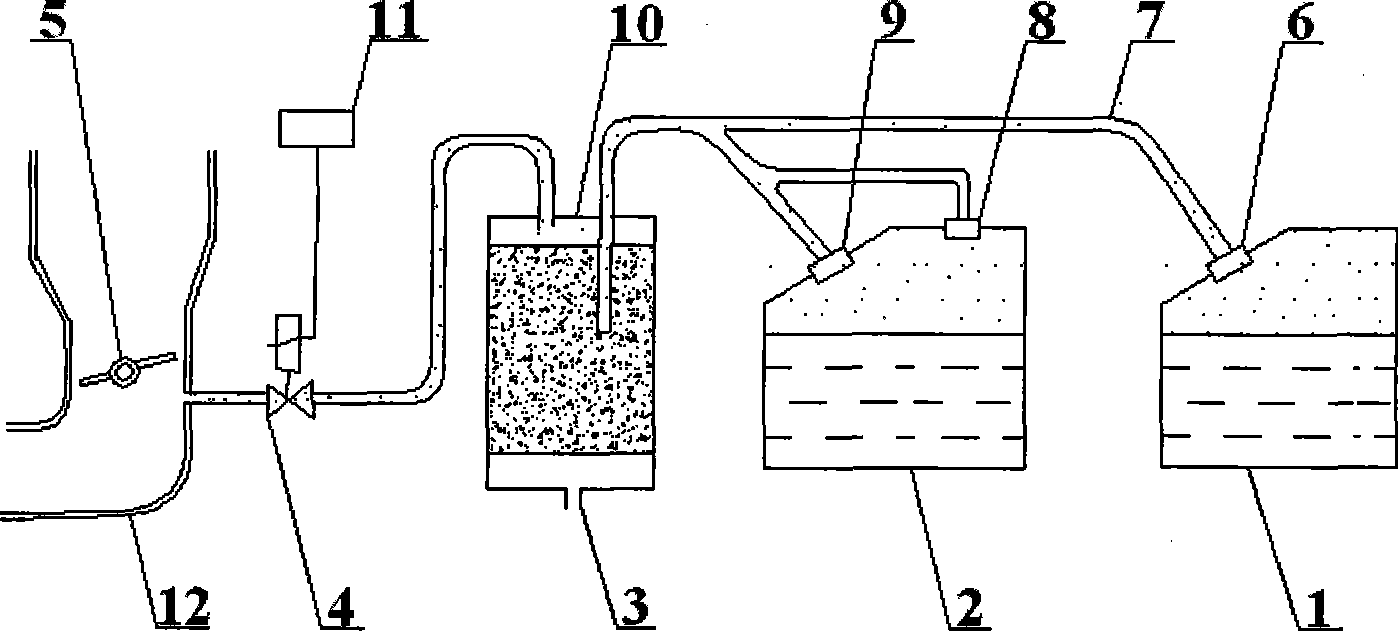

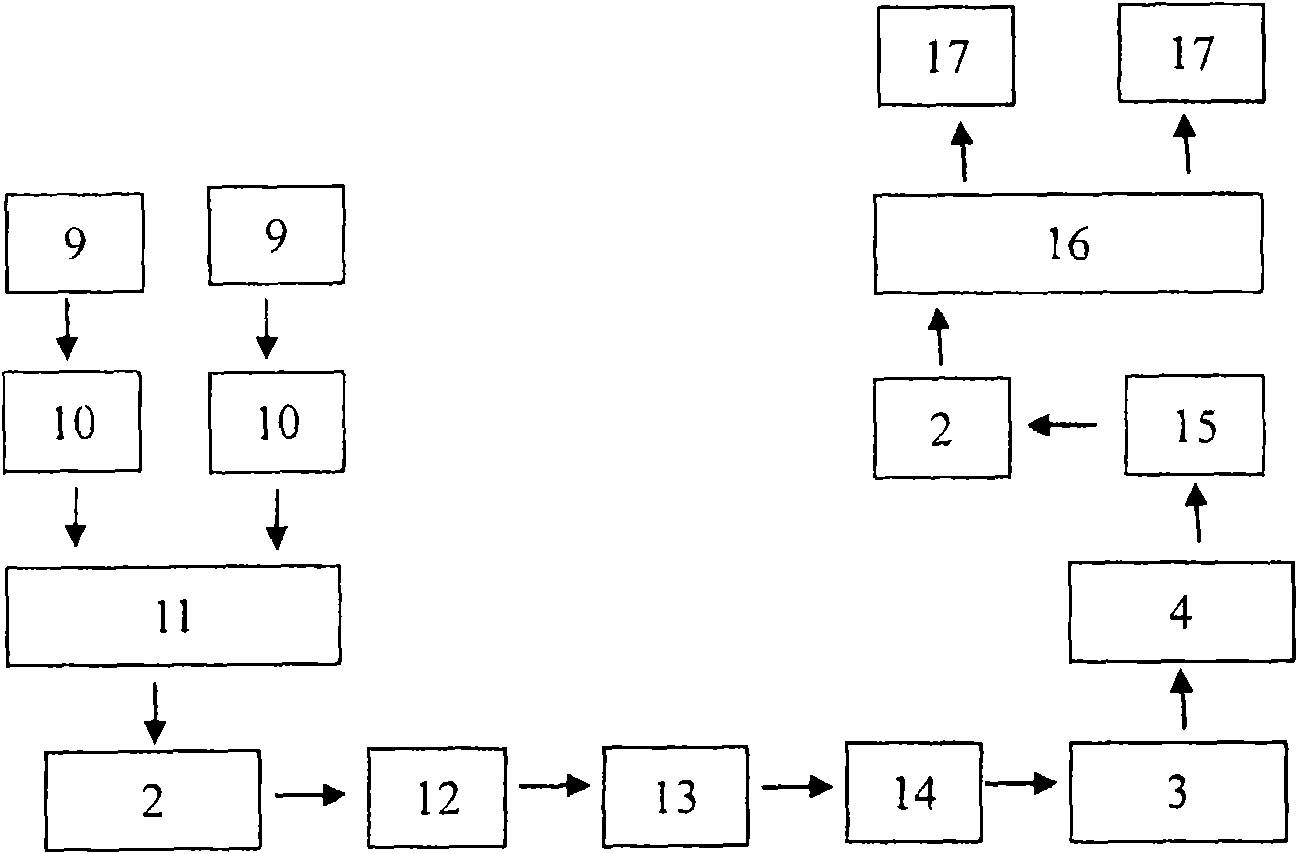

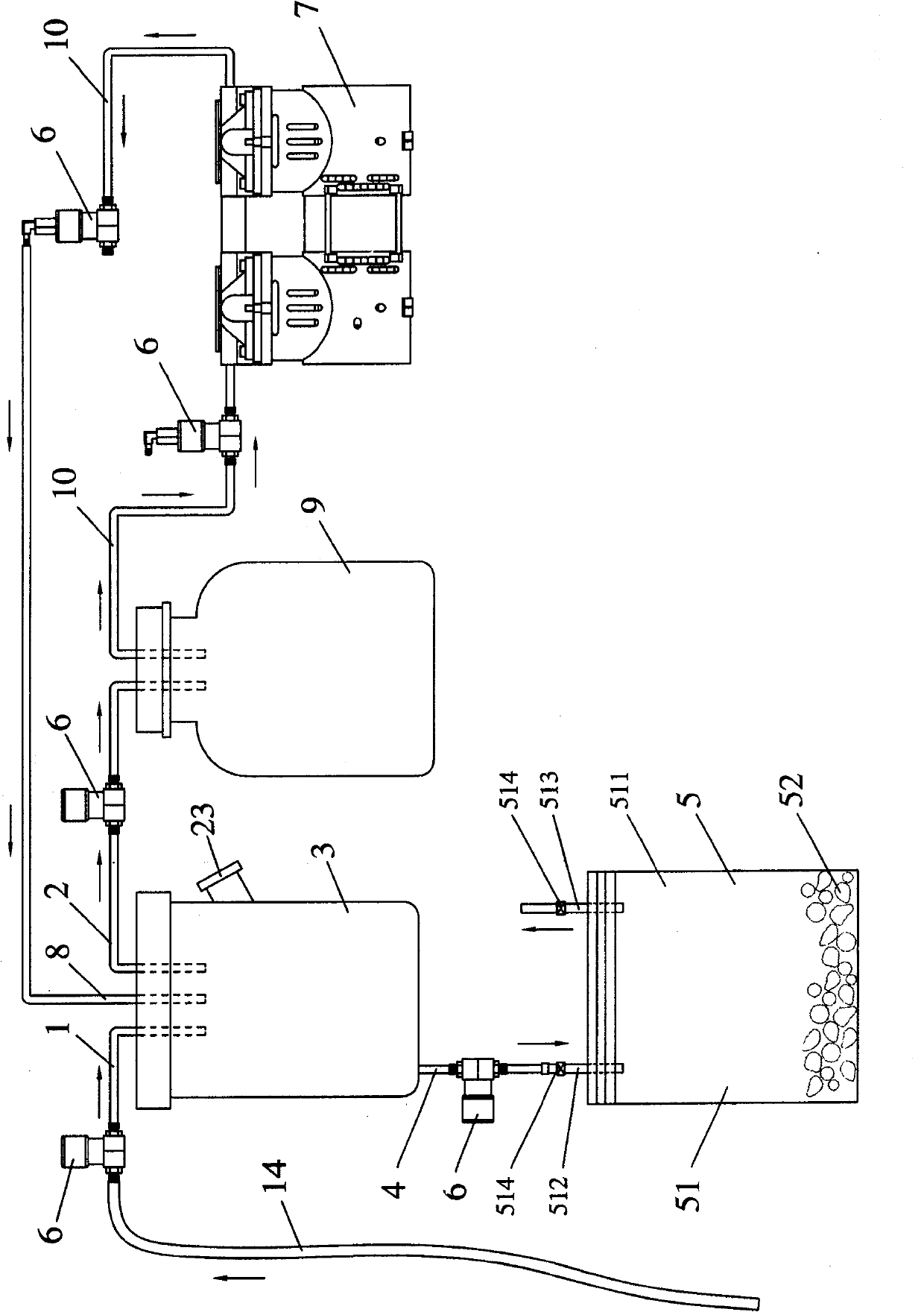

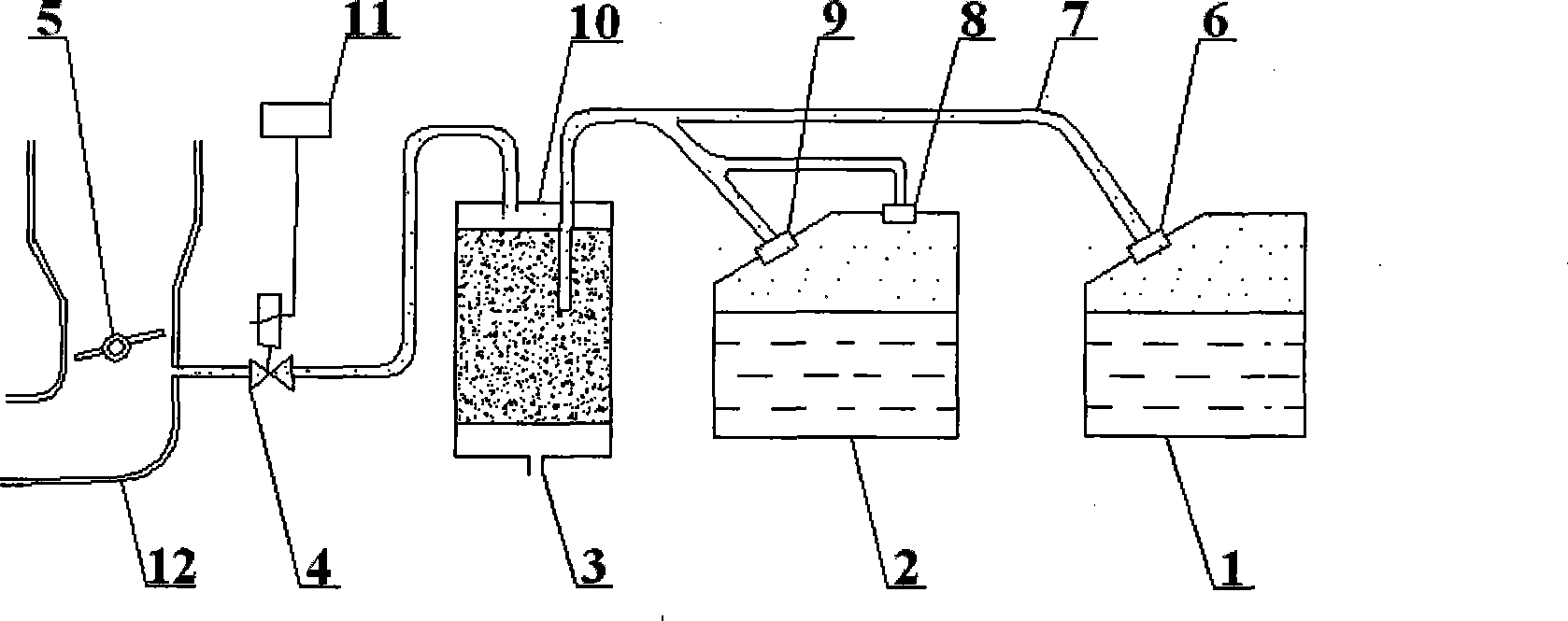

Vehicle fuel oil evaporation control system and method thereof

ActiveCN101368530APrevention and Control of PollutionReduce connectionsNon-fuel substance addition to fuelMachines/enginesGasoline fuelMethanol fuel

The invention belongs to the automobile structure field and discloses an automobile fuel evaporation control system; a gasoline fuel tank (1) and a methanol fuel tank (2) are connected with an active carbon tank (10) through a fuel vapor tube (7); the fuel vapor tube (7) is communicated with the methanol fuel tank (2) through methanol tank gravity valves (8, 9) and communicated with the gasoline fuel tank (1) through a gasoline tank gravity valve (6). The invention also provides a fuel evaporation control method adopted by the control system. When the technical proposal is adopted, the gasoline vapor and the methanol vapor are effectively avoided from polluting the environment; the oil vapor is recovered to have the oil-saving effect and reduce the oil consumption. The automobile fuel evaporation control system and the control method have the advantages of simple structure, reasonable design, less pipeline connection, low cost, convenient application, mounting and being applicable to the fuel evaporation discharge control of the flexible fuel automobiles.

Owner:CHERY AUTOMOBILE CO LTD

Compositions containing biosoluble inorganic fibers and micaceous binders

InactiveUS20140147340A1Prevention and Control of PollutionCombination devicesExhaust apparatusFiberPollution

Compositions that include a mixture of biosoluble inorganic fibers and a micaceous binder are described. The compositions can be prepared free of refractory ceramic fibers that are respirable but durable in a physiological medium. The compositions are typically in the form of a sheet material or a paste and can be used, for example, as a protective packing material around the pollution control element or as an insulating material in the end cone region in a pollution control device. Sheet materials formed from the compositions have an area of a X-Y plane that decrease less than about 6 percent when heated to about 900° C.

Owner:3M INNOVATIVE PROPERTIES CO

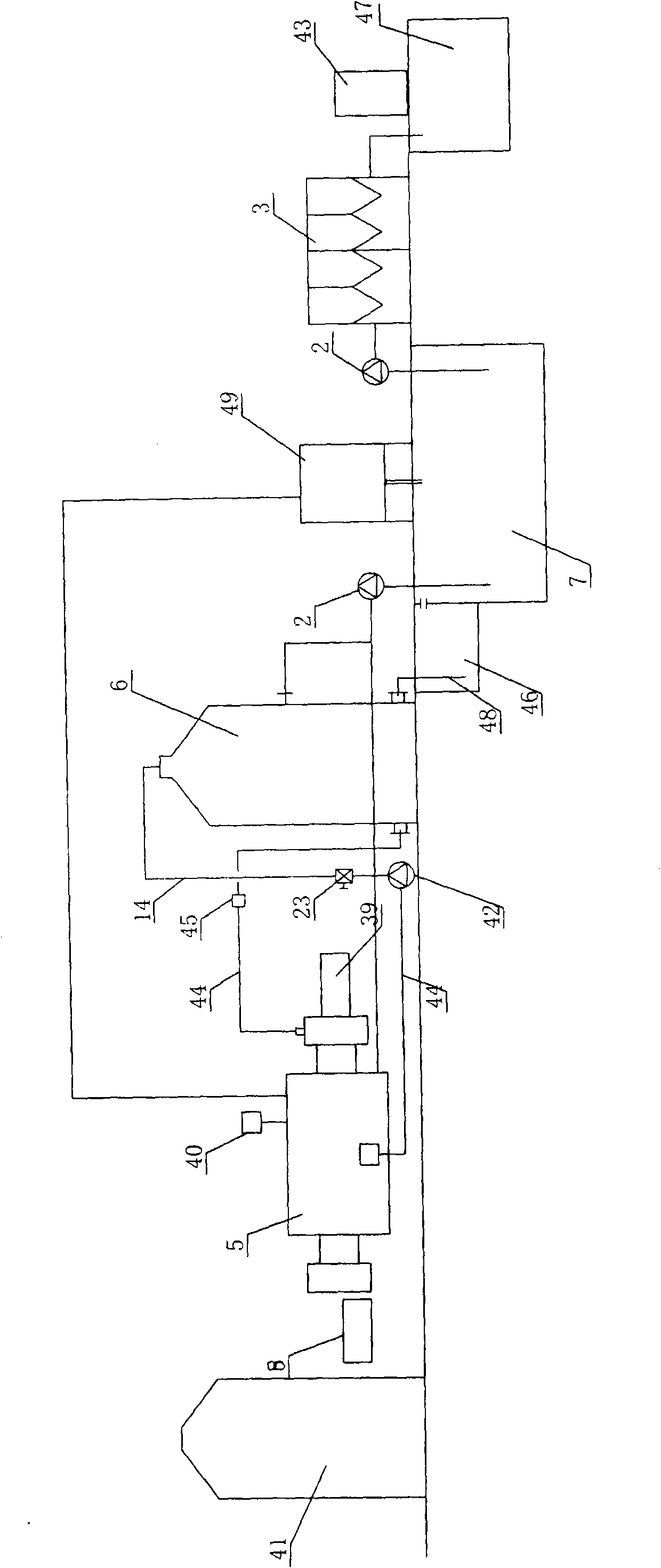

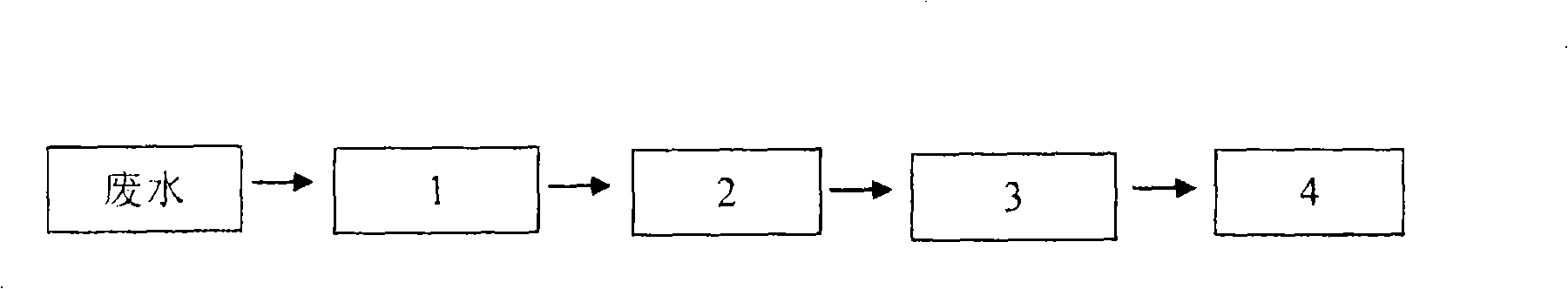

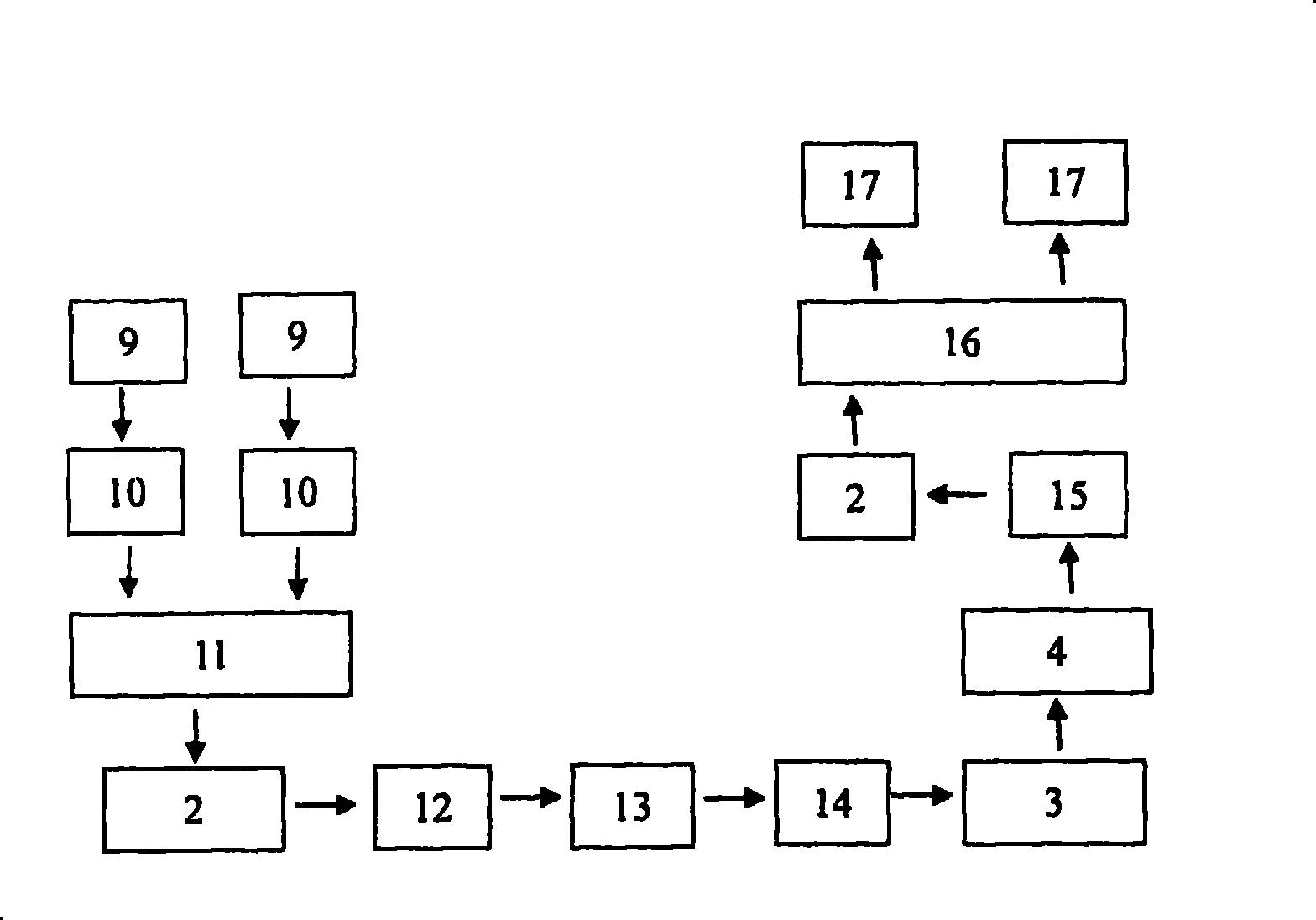

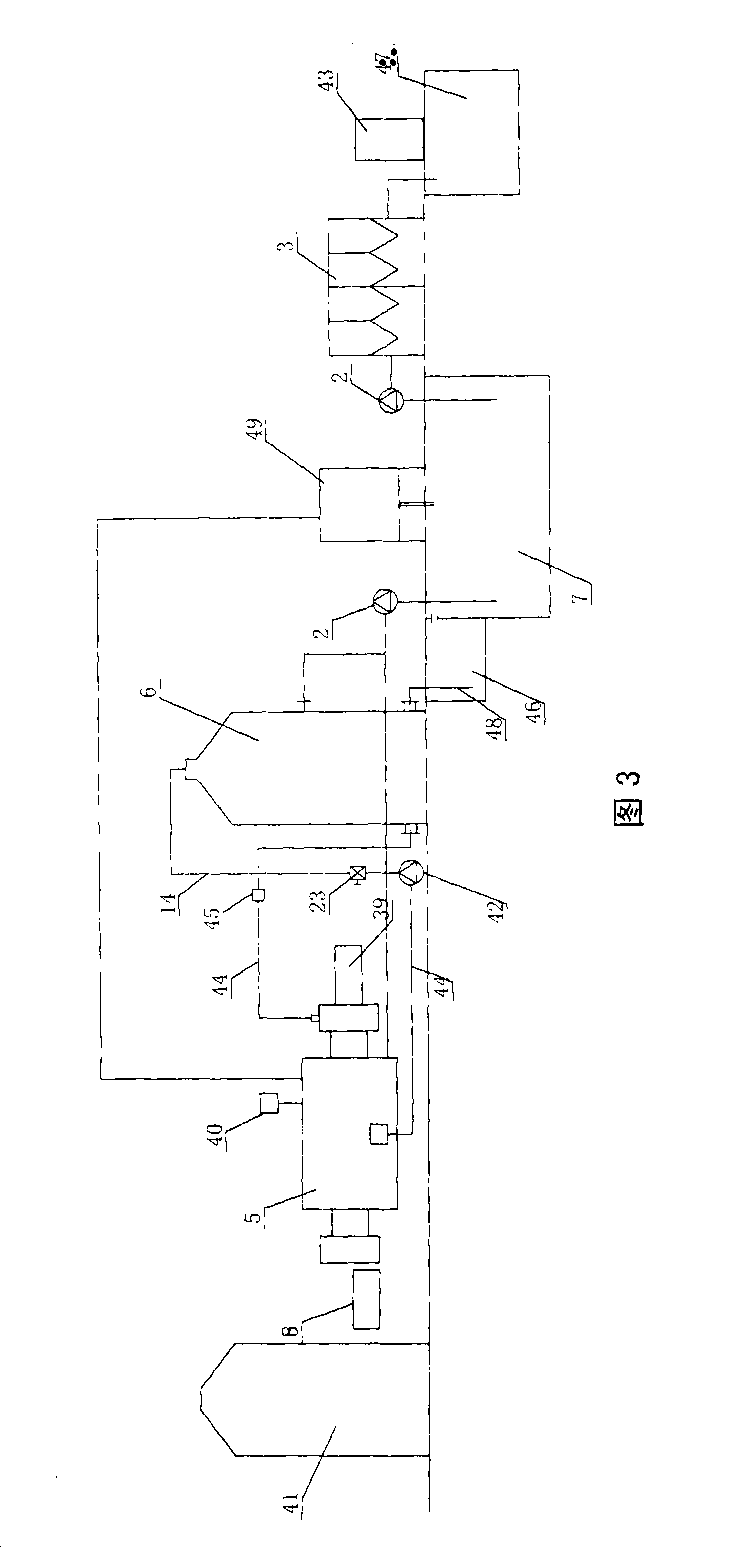

Lake water pollution prevention and control method and device

InactiveCN101774718APrevention and Control of PollutionImprove self-cleaning abilityMultistage water/sewage treatmentWater/sewage treatment by heatingEmergency treatmentWastewater

The invention relates to a lake water pollution prevention and control method and a device; the device comprises a wastewater and sewage deep treatment and reuse station, a lake water circulating purification treatment station, an organic pyrolysis treatment station and a water pollution emergency treatment station. The method comprises the following steps: the wastewater and sewage are discharged into a sedimentation tank, and then conveyed to water treatment equipment by a water pump, and the water treated by the water treatment equipment is conveyed to a clean water tank to be reused; the lake water flows into a collecting tank through a grid arranged at a water intake, and then conveyed to filter equipment by the water pump through a water pipe; the water treated by the filter equipment flows into the water treatment equipment, and the water treated by the water treatment equipment flows into the clean water tank; and the water in the clean water tank is conveyed to a spray pipe by the water pump through a water return pipe paved in a lake, and sprayed out by a sprinkler head on the spray pipe.

Owner:张大伟 +1

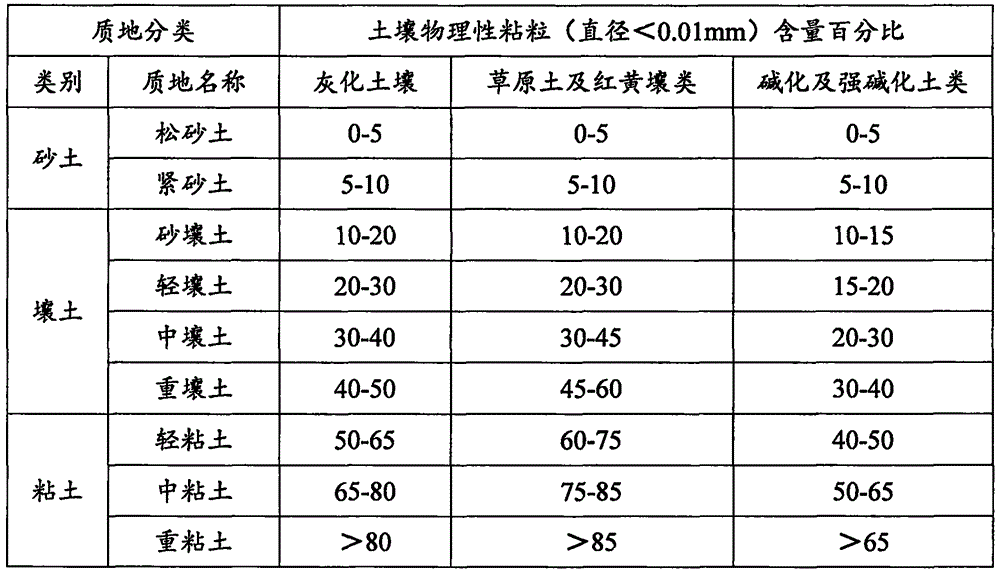

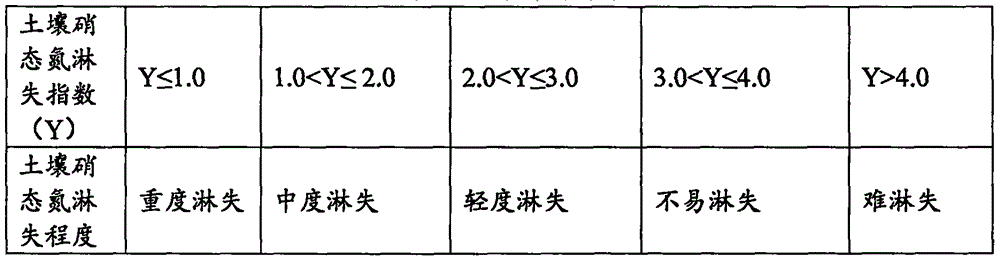

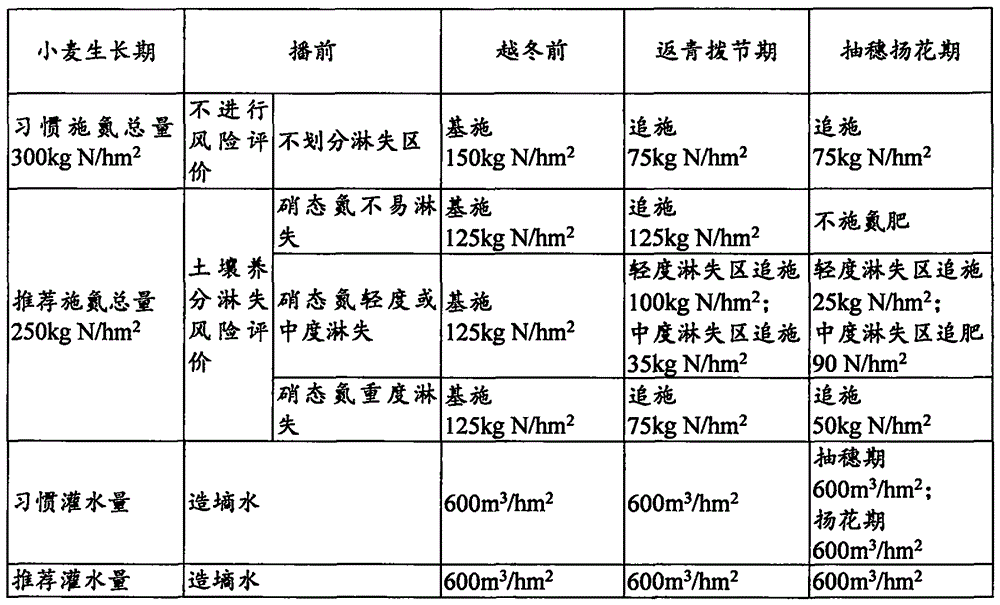

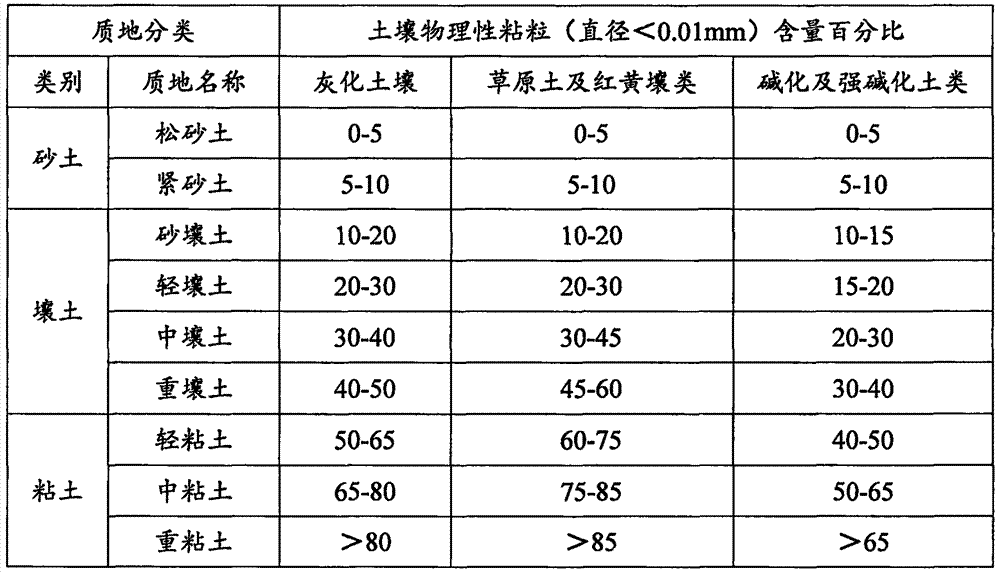

Method for evaluation of agricultural soil nitrate nitrogen leaching loss and application

ActiveCN105911250AAvoid pollutionPrevention and Control of PollutionEarth material testingFertilising methodsSoil scienceNitrate nitrogen

The invention discloses a method for evaluation of agricultural soil nitrate nitrogen leaching loss. The method is specifically implemented according to the steps of: dividing a soil profile into surface soil, middle soil and bottom soil; acquiring the respective soil physical clay content percentage of the surface soil, the middle soil and the bottom soil; acquiring a surface soil texture coefficient, a middle soil texture coefficient and a bottom soil texture coefficient; taking importance degree of agricultural soil nitrate nitrogen leaching loss as the basis, conducting weight assignment to all layers of soil to obtain a surface soil texture coefficient weight, a middle soil texture coefficient weight, and a bottom soil texture coefficient weight; calculating a soil nitrate nitrogen leaching loss index, and determining the evaluation criterion. The method provided by the invention evaluates the soil nitrate nitrogen leaching loss degree, then determines the nitrogen application amount of crops and the fertilizing method, and avoids pollution of nitrate nitrogen leaching loss caused by excessive use of nitrogen fertilizer to underground water.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT HEBEI ACADEMY OF AGRI & FORESTRY SCI

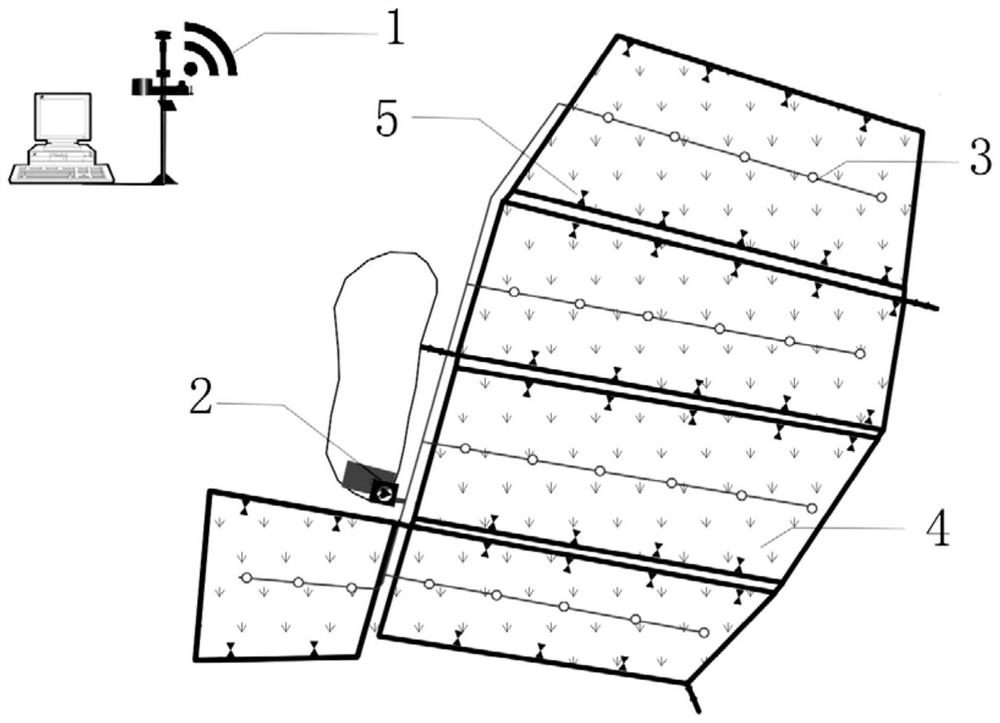

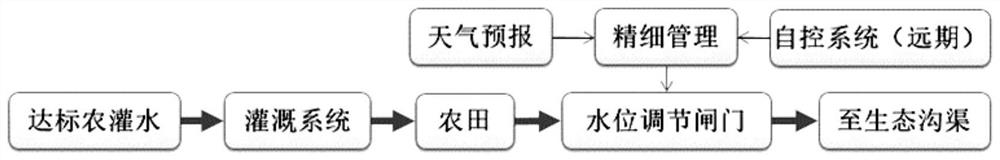

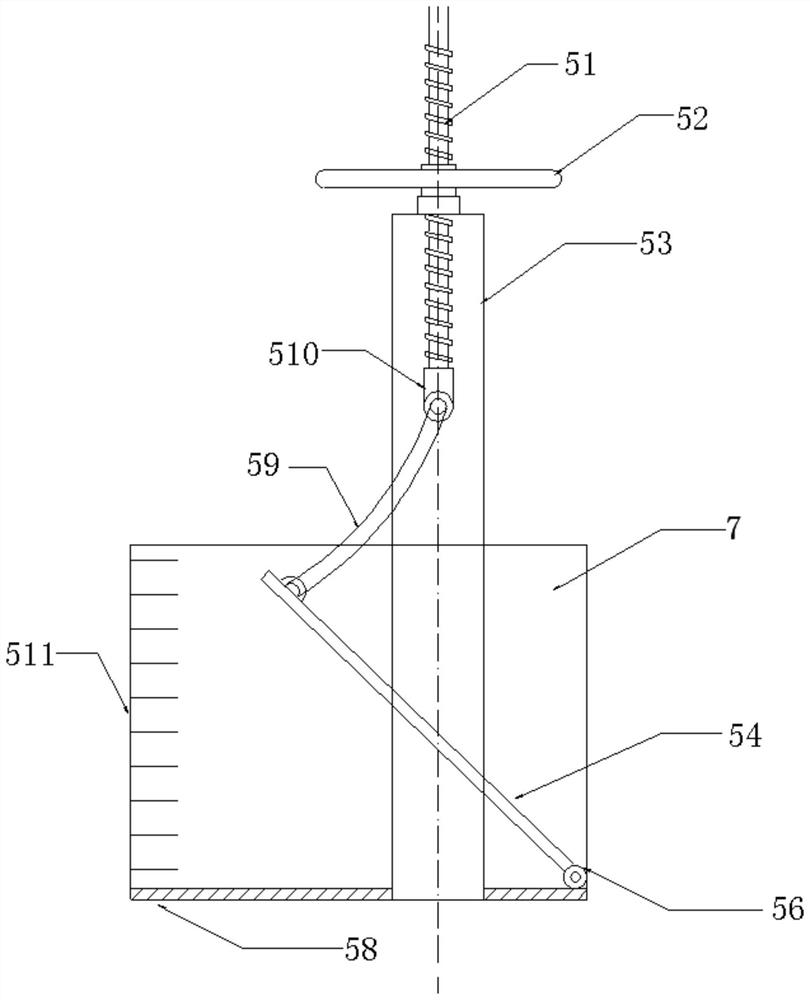

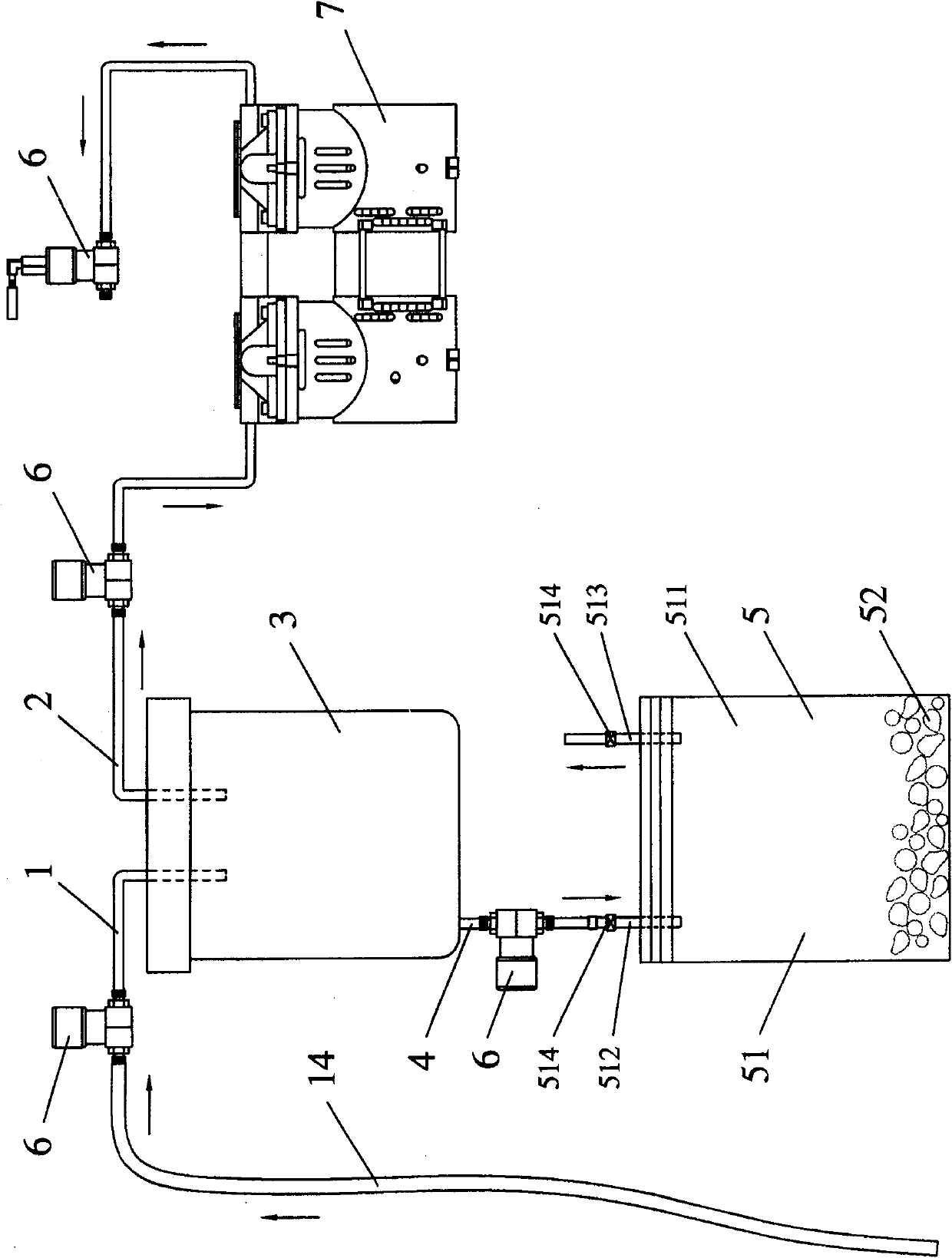

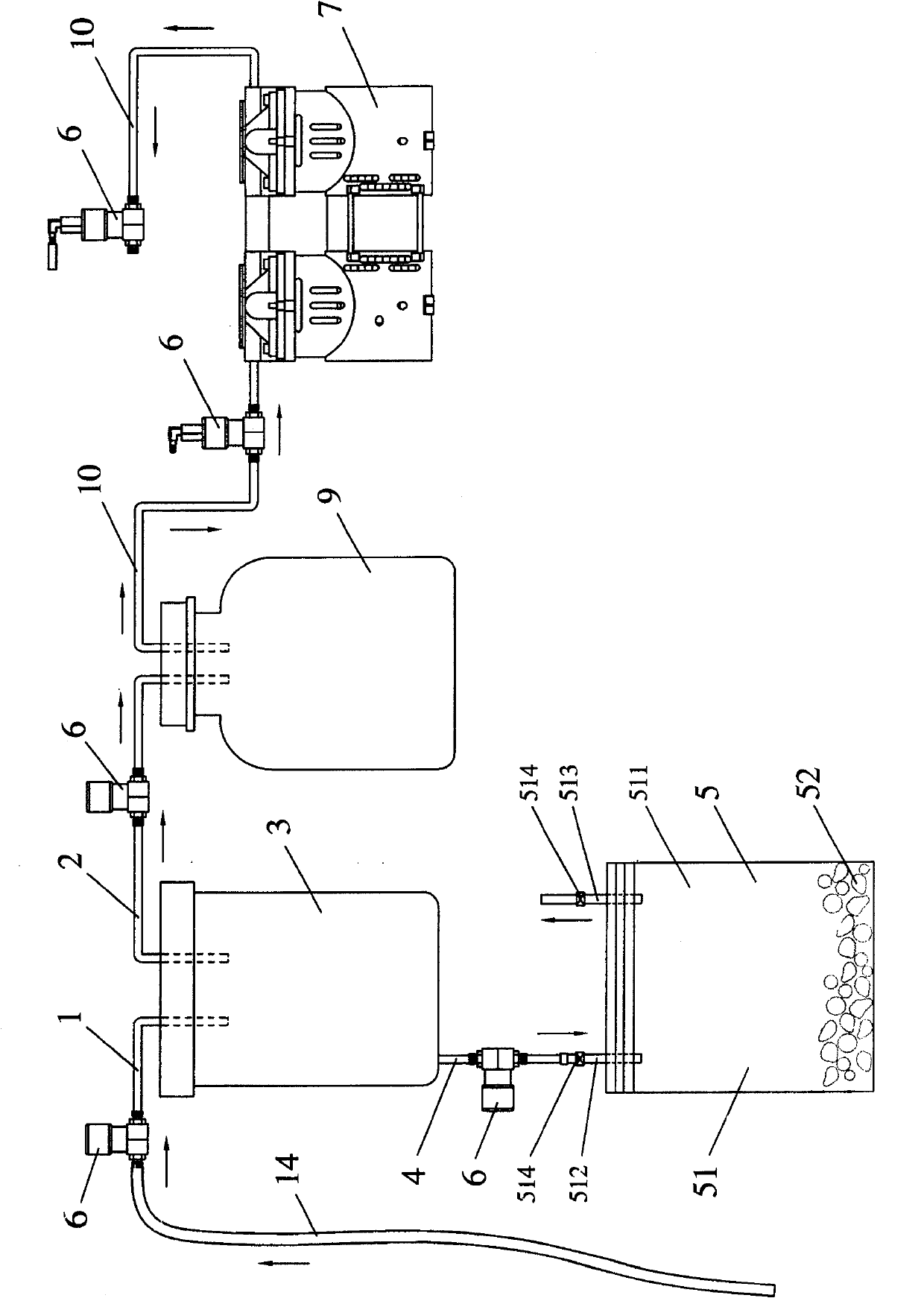

A Smart System for Prevention and Control of Nitrogen and Phosphorus Loss in Shallow Water Wetlands

ActiveCN106258814BDoes not occupy arable land resourcesSave engineering investmentConstructionsWatering devicesData acquisitionSurface water

The invention provides an intelligent paddy field surface shallow-water wetland system capable of preventing and controlling nitrogen and phosphorus loss. The system comprises a central control system, a pump station, an irrigation system, a paddy field and a water level regulating gate, wherein the central control system comprises a data acquisition and analysis module, a control base station and a signal receiver; the data acquisition and analysis module comprehensively analyzes water and fertilizer management and a growth stage of aquatic crops determines field surface water level, transmits the information to the pump station and the water level regulating gate, controls start and stop of a water pump at the pump station and regulates the water level of the water level regulating gate; the data acquisition and analysis module reduce the water level of the paddy field in advance before rainfall through combination with weather forecast, and the system produces passive drainage as little as possible; when active drainage is required, water retention time in the field is ensured not to be shorter than required time, so that flow out of a large amount of tail water containing high-concentration nitrogen and phosphorus can be avoided. By means of absorption and purification of nitrogen and phosphorus by the field, agricultural non-point pollutants are discharged out of the area to the smallest extent on the premise that stable and high yield of crops is guaranteed.

Owner:SHANGHAI JIAO TONG UNIV

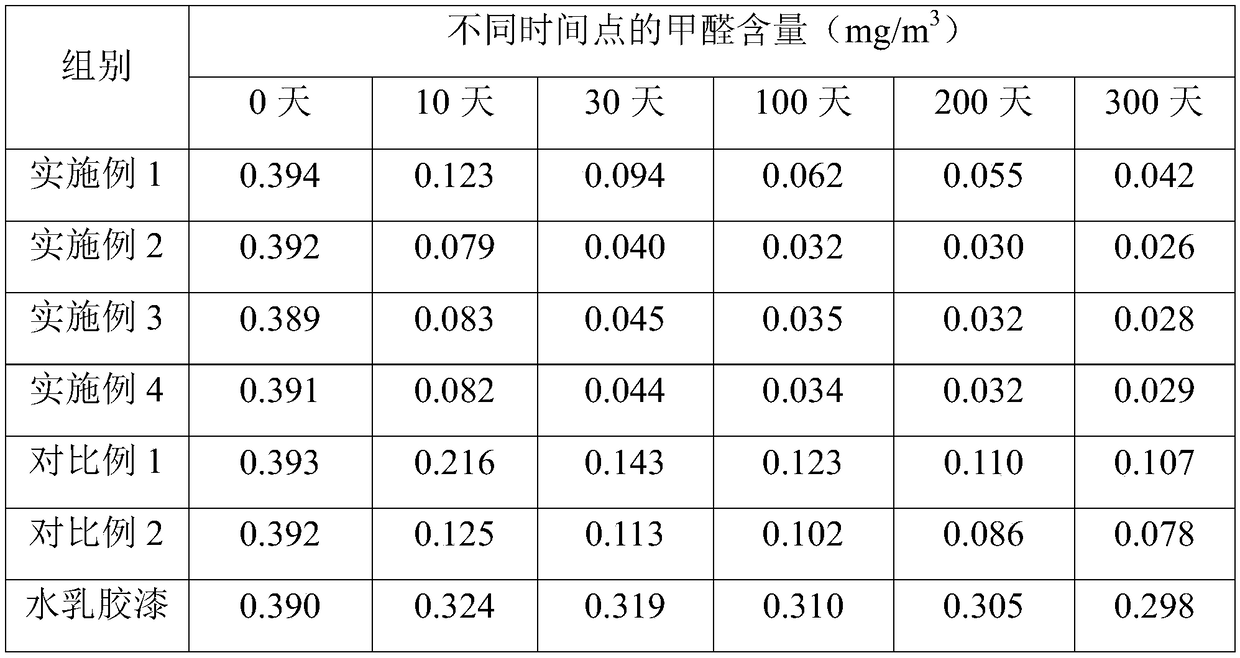

Energy composition with function of improving decoration product performance and preparation method of energy composition

InactiveCN109337426AImprove performanceStay away from infringementAntifouling/underwater paintsPaints with biocidesOxygen ionsFar infrared

The invention relates to energy composition with a function of improving decoration product performance and a preparation method of the energy composition. The energy composition is prepared from rawmaterials in parts by weight as follows: 1.5-3.0 parts of potassium sorbate, 2.0-4.0 parts of sodium dehydroacetate, 20-40 parts of nanometer negative ion powder, 22.5-45 parts of nanometer tourmalinepowder, 13-26 parts of nanometer white bamboo charcoal powder, 22.5-45 parts of nanometer medical stone powder, 18.5-37 parts of nanometer titanium dioxide powder and 5.0-10 parts of nanometer silverions. The energy composition has the function of improving decoration product performance and can effectively inhibit bacteria, fungi and mould in added decoration products and prevent mildew, and service performance of the added decoration products is not affected; the energy composition further has a function of releasing negative oxygen ions and far infrared rays.

Owner:西安金海礁建筑节能科技有限公司

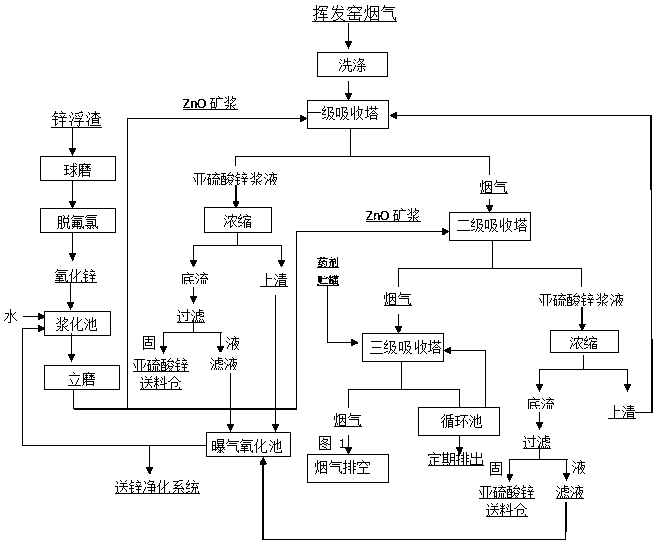

Flue gas desulfurization system for zinc smelting process

InactiveCN109954380AHigh removal ratePrevention and Control of PollutionDispersed particle separationFiltrationSlurry

The invention relates to a flue gas desulfurization system for a zinc smelting process. The system comprises a zinc oxide ore pulp manufacturing part, a primary desulfurization part, a secondary desulfurization part and a tertiary desulfurization part. The zinc oxide ore pulp manufacturing part: zinc scum after casting is subjected to ball milling, the metal zinc in the zinc scum is separated, thezinc scum is subjected to a fluorine and chlorine removal process until the fluorine content is not more than 0.1% and the chlorine content is not more than 0.3% in the zinc scum, slurrying is performed in a slurry tank, and then zinc oxide is further refined through a vertical grinding process to form a zinc oxide ore pulp. The primary desulfurization part: the prepared zinc oxide ore pulp is sprayed into a primary absorption tower and reacts with sulfur dioxide in the washed flue gas of the zinc smelting system, the formed zinc sulfite pulp liquid after reaction is concentrated, the supernatant is discharged into an aerated oxidation tank, the bottom flow is subjected to filtration and the filtrate is discharged into the aerated oxidation tank, the solution after oxidation by the aerated oxidation tank is returned to the slurry tank of the zinc oxide ore pulp manufacturing part for cyclic utilization, when the concentration of zinc ion in the solution reaches to be 150 g / L, the solution is fed to a zinc purification system for further treatment, and the filter residue is sent to a zinc sulfite material bin and is subjected to the comprehensive recovery of zinc after the collocation treatment with other zinc-containing materials. The process does not produce harmful waste gas, waste residue and waste water.

Owner:ZHUZHOU SMELTER GRP +1

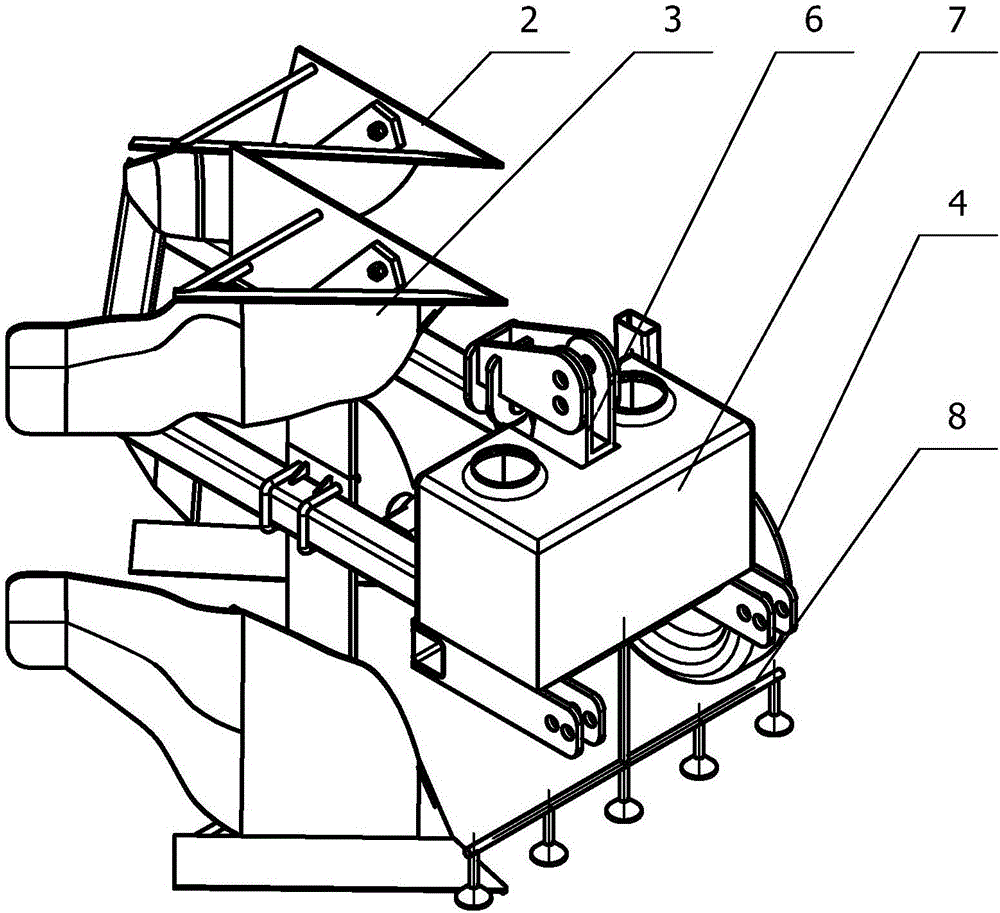

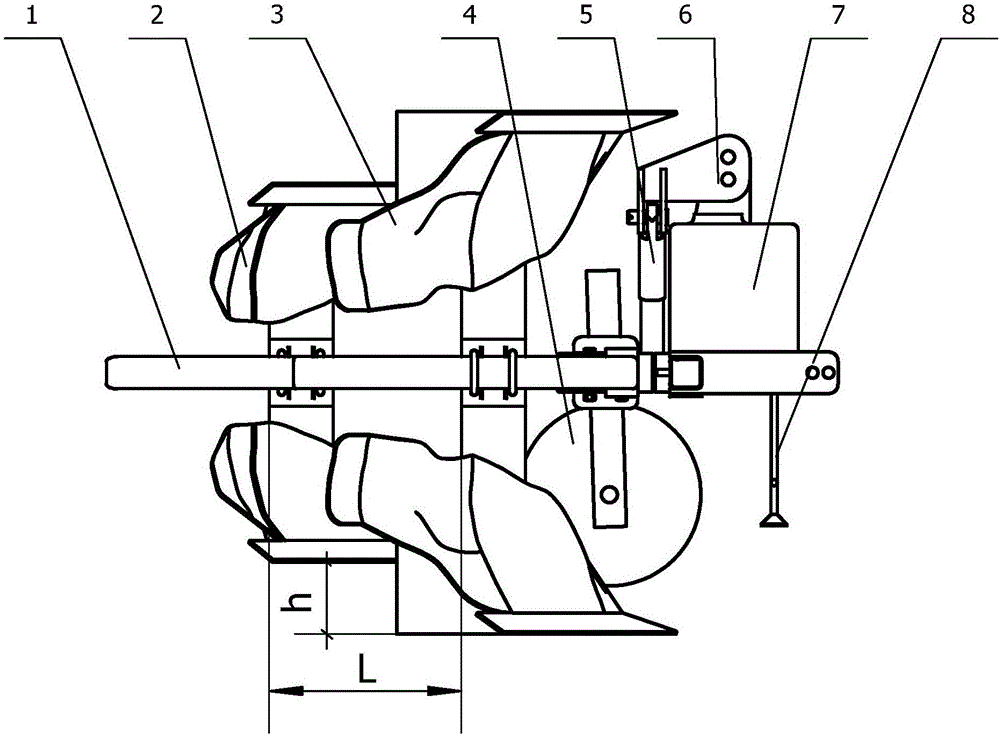

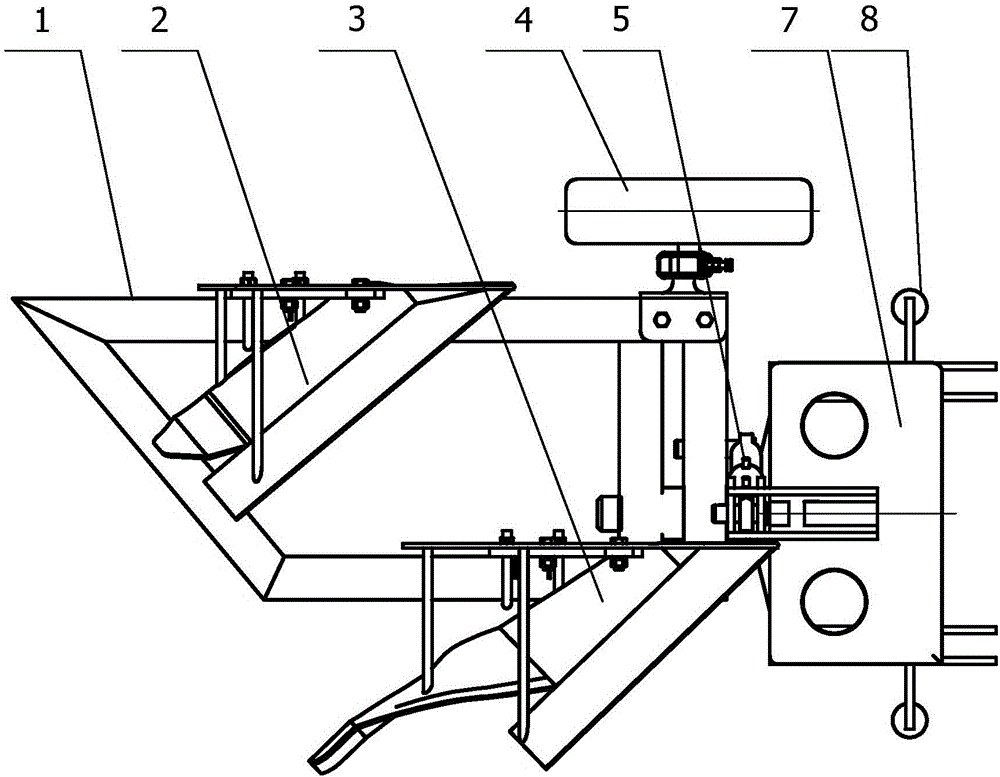

Equipment capable of spraying biogas slurry and turning over and burying straws and stratified straw returning method

PendingCN107517609AImplement the flip functionAccelerate the rate of decaySpadesPloughsTransmitted powerAutomotive engineering

The invention relates to equipment capable of spraying biogas slurry and turning over and burying straws and a stratified straw returning method. The equipment capable of spraying biogas slurry and turning over and burying straws includes a rack, a pushing plow, a ditching plow, a ground wheel component, a hydraulic cylinder, a hanger, a connecting shaft, a biogas slurry spraying system and a power system. The hanger is connected with the front end of the rack in the advancing direction through the connecting shaft, and the rack can rotate around the connecting shaft. Biogas slurry spraying components are arranged at the upper portion of the hanger. The hydraulic cylinder is obliquely arranged on one side of the connecting shaft. One end of the hydraulic cylinder is connected with the hanger, while the other end is connected with the rack. The power system is connected with the hydraulic cylinder to transmit power and drive the hydraulic cylinder to stretch out and draw back and drive the rack to turn over 180 degrees around the connecting shaft. The ground wheel component is arranged at the left side of the rack in the advancing direction, the pushing plow and the ground wheel component are arranged at the same side of the rack, and the ditching plow is arranged at the right side of the rack in the advancing direction. The equipment achieves a turn-over function of operating plows as an upper plough share and a lower plough share work alternately. Therefore, the work efficiency is improved, the labor intensity is reduced, and the stratified straw returning purpose is achieved.

Owner:LIAONING ACAD OF AGRI SCI

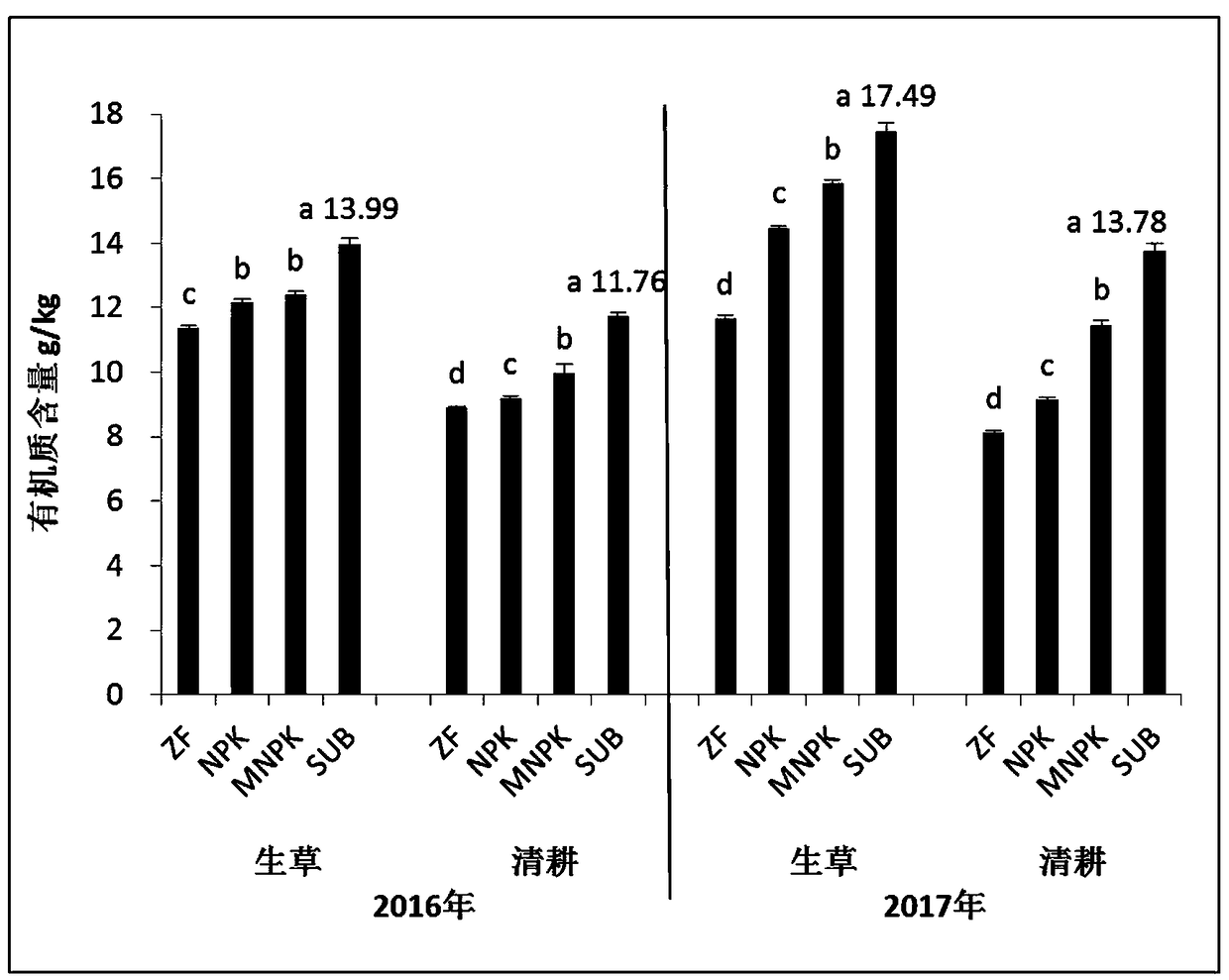

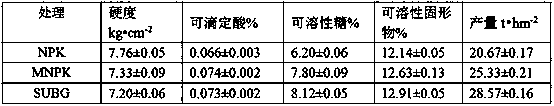

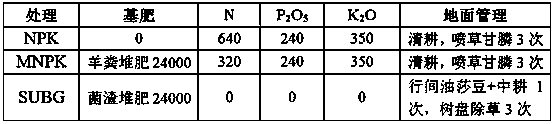

Northern orchard ecological soil conservation fertilizing method

ActiveCN109121629AImprove qualityIncrease productionBioloigcal waste fertilisersFertilising methodsYellow NutgrassGreen manure

The invention discloses a northern orchard ecological soil conservation fertilizing method which includes the steps: I mushroom dreg composting fermentation; II mushroom dreg compost and biological inoculant application; III land preparation; IV cyperus esculentus seed treatment; V cyperus esculentus sowing; VI cyperus esculentus intertillage; VII trace-element fertilizer application to differentfruit trees as required in a growth and development period; VIII cyperus esculentus turnover; IX mushroom dreg application, cyperus esculentus planting and turnover according to the step I to the stepVIII every year of following years. A 'cyperus esculentus green manure, mushroom dreg compost and biological inoculant' method is adopted, cover crops, organic materials and biological inoculants areused in a combined manner, a northern orchard ecological soil conservation fertilizing mode is provided, technical guidance is provided for application of the method to northern ecological and efficient fruit production, and the method is of great significance for chemical fertilizer and pesticide application reduction, agricultural production quality and efficiency improvement, agricultural ecological system quality and stability improvement, green rural construction and sustainable development.

Owner:INST OF AGRI ENVIRONMENT & RESOURCE SHANXI ACAD OF AGRI SCI

Flue gas desulfurization process of zinc smelting system

InactiveCN109569255AHigh removal ratePrevention and Control of PollutionGas treatmentDispersed particle separationHigh resistanceTower

The invention relates to a flue gas desulfurization process of a zinc smelting system. The flue gas desulfurization process includes separating metal zinc from zinc dross after ball-milling of the zinc dross, and subjecting dross powder to defluorination and dechlorination until the fluorine content and the chlorine content in the zinc dross are not more than 0.1% and 0.3% respectively; performingpulping by a pulping tank, and further grinding zinc oxide after a vertical milling process to form ZnO ore pulp; spraying the prepared ZnO ore pulp into an absorption tower for primary desulfurization, secondary desulfurization and tertiary desulfurization. The flue gas desulfurization process has the advantages of high desulfurization efficiency, less proneness to clogging of nozzles and pipelines, low medicament cost and high resistance to sulfur dioxide impact load.

Owner:ZHUZHOU SMELTER GRP

Environmentally-friendly desulfurization process for zinc smelting system

InactiveCN109954381AHigh removal ratePrevention and Control of PollutionDispersed particle separationSlurrySulfur dioxide

The invention relates to a flue gas desulfurization process used for a zinc smelting system. The process comprises the following steps: preparing ZnO slurry: after zinc scum is casted, performing ballmilling, separating metal zinc, performing defluorination and dechlorination on the scum powder until the fluorine content is not more than 0.1% and the chlorine content is not more than 0.3% in thezinc scum, performing slurrying in a slurrying tank, allowing the obtained slurry to enter a vertical mill process, and further grinding the zinc oxide to form ZnO slurry; performing first-stage desulfurization: spraying a prepared ZnO slurry into a first-stage absorption tower, and reacting the ZnO slurry with sulfur dioxide in washed zinc smelting system flue gas; performing second-stage desulfurization, and performing third-stage desulfurization. The process is characterized in that zinc sulfite slurry formed after the reaction is concentrated, the supernatant is discharged into an aerationoxidation tank, after the bottom stream is filtered, the filtrate is discharged into the aeration oxidation tank, the solution obtained by oxidation in the aeration oxidation tank returns to the slurrying tank in the ZnO slurry preparation part for recycling, after a zinc ion concentration in the solution reaches 150 g / L, the material is sent to a zinc purification system for further treatment without deposition, and the filter residues are sent to a zinc sulfite bin to be treated together with other zinc-containing materials for comprehensive recovery of zinc. The process provided by the invention has no harmful waste gas, waste residues or waste water.

Owner:ZHUZHOU SMELTER GRP +1

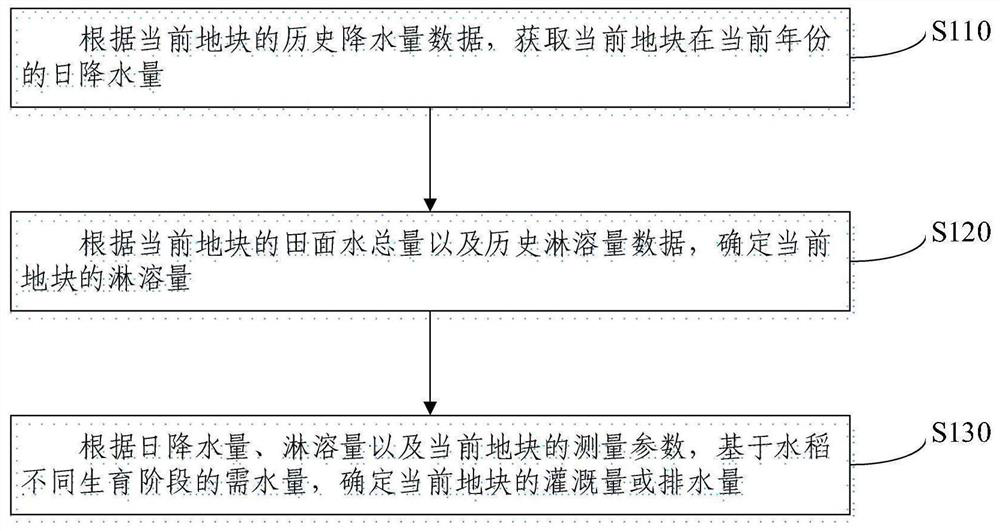

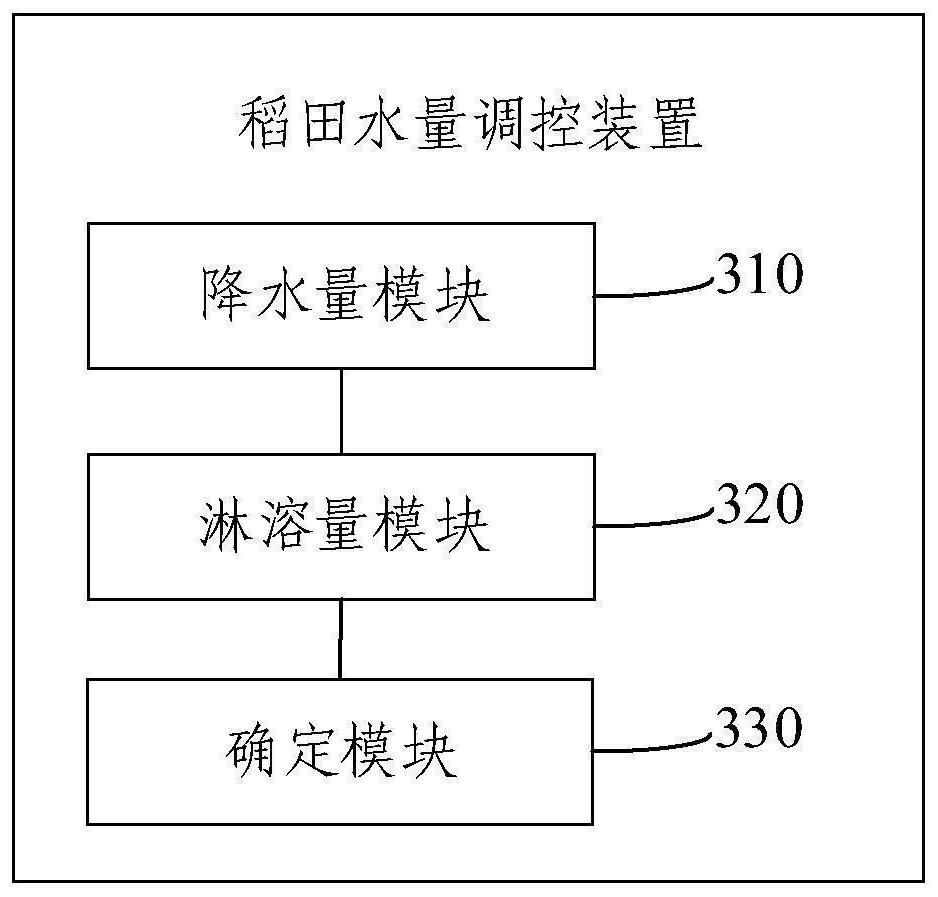

Precision regulation and control method and device for rice field water volume

PendingCN113205244APrecise regulationPrevention and Control of PollutionWatering devicesResourcesWater dischargeSoil science

The invention provides a regulation and control method and device for rice field water volume. The method comprises the following steps: acquiring daily precipitation of a current land parcel in the current year according to historical precipitation data of the current land parcel; determining the leaching amount of the current land parcel according to the total field surface water amount and historical leaching amount data of the current land parcel; according to the daily precipitation amount, the leaching amount and the measurement parameters of the current land parcel, determining the irrigation amount or the water discharge amount of the current land parcel based on the water demand amount of the rice in different growth stages. According to the regulation and control method and device for rice field water volume, timely and accurate regulation and control of the rice field water volume can be achieved, so that water resources are saved while water required by normal growth of rice is guaranteed, and nitrogen and phosphorus non-point source pollution of the rice field can be effectively prevented and controlled.

Owner:INST OF PLANT PROTECTION & SOIL FERTILIZER HUBEI ACAD OF AGRI SCI

Vehicle fuel oil evaporation control system and method thereof

ActiveCN101368530BPrevention and Control of PollutionReduce connectionsNon-fuel substance addition to fuelMachines/enginesGasoline fuelMethanol fuel

The invention belongs to the automobile structure field and discloses an automobile fuel evaporation control system; a gasoline fuel tank (1) and a methanol fuel tank (2) are connected with an active carbon tank (10) through a fuel vapor tube (7); the fuel vapor tube (7) is communicated with the methanol fuel tank (2) through methanol tank gravity valves (8, 9) and communicated with the gasoline fuel tank (1) through a gasoline tank gravity valve (6). The invention also provides a fuel evaporation control method adopted by the control system. When the technical proposal is adopted, the gasoline vapor and the methanol vapor are effectively avoided from polluting the environment; the oil vapor is recovered to have the oil-saving effect and reduce the oil consumption. The automobile fuel evaporation control system and the control method have the advantages of simple structure, reasonable design, less pipeline connection, low cost, convenient application, mounting and being applicable to the fuel evaporation discharge control of the flexible fuel automobiles.

Owner:CHERY AUTOMOBILE CO LTD

Deep-sea Bacillus circulans and application thereof in suppression of aflatoxin

InactiveCN105039199AHigh biosecurityNo inhibitionBacteriaMicroorganism based processesChymotrypsinBacterial strain

The invention provides a deep-sea bacterial strain capable of preventing and controlling aflatoxin, and particularly relates to a Bacillus circulans FA13 bacterial strain which is formed by separating light-yellow ooze sediment in water of 3203m in depth in South Atlantic, collected in the China General Microbiological Culture Collection Center and numbered as CGMCC No.10663. After the FA13 bacterial strain is fermented under optimized conditions and obtained fermentation supernate is diluted by 30 times, the fermentation supernate can still kill spores of aflatoxin producing bacteria and suppress producing of aflatoxin 100%, in other words, the fermentation supernate has capability of suppressing production of aflatoxin from a growing source, has no suppression effect on intestinal flora and unicellular fungus saccharomyces cerevisia and has higher using safety; active metabolite in fermentation liquid is stable in property and resistant to high temperature, acid and alkali and degrading of pepsin, trypsin and chymotrypsin. The FA13 bacterial strain and a fermentation product thereof can be used for effectively preventing and controlling aflatoxin pollution of feed, grain and field crops.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Proteus mirabilis phage and application thereof

PendingCN113980913AHigh amplification efficiencyPrevention and Control of PollutionAntibacterial agentsViral/bacteriophage medical ingredientsP. mirabilisBiotechnology

The invention discloses a proteus mirabilis phage vB_PmiP_pPm05, and an application of the proteus mirabilis phage vB_PmiP_pPm05 in the inhibition or killing of proteus mirabilis in food. The proteus mirabilis phage vB_PmiP_pPm05 is high in amplification efficiency, can be massively amplified in a short time, is wide in temperature and acid-base tolerance range, can effectively prevent and control food pollution caused by proteus mirabilis, and does not influence the texture and flavor of food.

Owner:GUANGXI UNIV

A method and application for evaluating nitrate nitrogen leaching in farmland soil

ActiveCN105911250BAvoid pollutionPrevention and Control of PollutionEarth material testingFertilising methodsSoil scienceNitrate nitrogen

The invention discloses a method for evaluating nitrate nitrogen leaching loss in farmland soil, which is implemented according to the following steps: divide the soil profile into surface soil, middle soil, and bottom soil; obtain the respective values of surface soil, middle soil, and bottom soil respectively. The percentage of soil physical clay content; obtain the surface soil texture coefficient, middle soil texture coefficient and bottom soil texture coefficient respectively; based on the importance of nitrate nitrogen leaching in farmland soil, assign weights to each layer of soil to obtain the surface layer Soil texture coefficient weight, middle soil texture coefficient weight and bottom soil texture coefficient weight; calculate soil nitrate nitrogen leaching loss index and determine evaluation standards. The present invention evaluates the degree of soil nitrate nitrogen leaching, and then determines the nitrogen application amount and fertilization method of crops according to the evaluation standards to avoid the pollution of groundwater caused by nitrate nitrogen leaching caused by excessive use of nitrogen fertilizer.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT HEBEI ACADEMY OF AGRI & FORESTRY SCI

Method for prevention and control of cadmium contamination of traditional Chinese medicine rhizoma coptidis

ActiveCN110140620APromote growth and developmentIncrease vitalityBiocidePlant growth regulatorsMedicineChinese drug

The invention discloses a method for prevention and control of cadmium contamination of traditional Chinese medicine rhizoma coptidis. The method includes steps: (1) performing topdressing from September to October in the current year of rhizoma coptidis planting and in May in the second, third, fourth and fifth years, and after transplanting, performing topdressing once in autumn (September-October) in the second, third and fourth year, wherein topdressing is carried out for eight times to promote growth and activity of rhizoma coptidis and lays a foundation for prevention and control of cadmium absorption; then, after topdressing in autumn (September-October) in the second, third and fourth year after transplanting in the step (1), performing earth-up operation by adopting a cadmium blocking agent, wherein a spraying quantity of the cadmium blocking agent is 75-100Kg / mu, chelation of the cadmium blocking agent with cadmium in soil is realized, cadium absorption of rhizoma coptidis isreduced, stress resistance of rhizoma coptidis is improved, the self-protection performance of rhizoma coptidis is improved, plasma membrane damages of roots and leaves under cadmium stress are reduced, antioxidant enzyme activity of the leaves under cadmium stress is improved, the antitoxic performance of rhizoma coptidis is improved, system immunity is enhanced, cadmium accumulation is inhibited, and prevention and control of cadmium contamination are realized.

Owner:GUANGZHOU XINNONGKE FERTILIZER SCI & TECH

Lake water pollution prevention and control method and device

InactiveCN101774718BPrevention and Control of PollutionImprove self-cleaning abilityMultistage water/sewage treatmentWater/sewage treatment by heatingEngineeringPollution prevention

The invention relates to a lake water pollution prevention and control method and a device; the device comprises a wastewater and sewage deep treatment and reuse station, a lake water circulating purification treatment station, an organic pyrolysis treatment station and a water pollution emergency treatment station. The method comprises the following steps: the wastewater and sewage are discharged into a sedimentation tank, and then conveyed to water treatment equipment by a water pump, and the water treated by the water treatment equipment is conveyed to a clean water tank to be reused; the lake water flows into a collecting tank through a grid arranged at a water intake, and then conveyed to filter equipment by the water pump through a water pipe; the water treated by the filter equipment flows into the water treatment equipment, and the water treated by the water treatment equipment flows into the clean water tank; and the water in the clean water tank is conveyed to a spray pipe by the water pump through a water return pipe paved in a lake, and sprayed out by a sprinkler head on the spray pipe.

Owner:张大伟 +1

A kind of 5n level high-purity molybdenum trioxide production process

ActiveCN112744864BHigh purityProcess parameters are precisely controlledMolybdeum compounds preparationMolybdenum oxides/hydroxidesIon exchangeEngineering

The invention provides a 5N grade high-purity molybdenum trioxide production process, using crude sodium molybdate containing tungsten, vanadium and other impurity elements as raw material, through multi-stage ion exchange to achieve: deep separation of molybdenum and metal impurities, molybdenum and non-metallic Impurities are separated in depth, and the obtained high-purity sodium molybdate solution is transformed to obtain high-purity ammonium molybdate solution. After the high-purity ammonium molybdate solution is formed into a solid product by acid precipitation, the whole process of closed transportation and operation is adopted to finally obtain the total product impurities. 5N grade high-purity molybdenum trioxide with content ≤10ppm. The technical parameters of the production process of the invention are precisely controlled, and the equipment and environmental pollution are strictly prevented and controlled.

Owner:成都虹波钼业有限责任公司 +1

Method for efficiently preventing and controlling cadmium pollution in wheat-corn rotation system

InactiveCN112931094AReduce the cost of prevention and controlLow efficiencyMagnesium fertilisersAlkali orthophosphate fertiliserRoot uptakeNaphthalene

The invention relates to the field of environmental governance methods, and particularly discloses a method for efficiently preventing and controlling cadmium pollution in a wheat-corn rotation system. The method mainly comprises the following steps: applying a fertilizer A which is composed of urea, calcium phosphate, Fe3O4@C-NH2, manganese sulfate, zinc sulfate and magnesium sulfate after wheat reviving, applying the fertilizer A in a corn seedling stage after wheat harvesting, spraying a fertilizer B which is prepared from nano magnesium sulfate, humic acid, Fe3O4@C-NH2, alkyl naphthalene sulfonate and water onto leaf surfaces of the wheat and the corn in a wheat and corn elongation stage, and spraying a fertilizer C which is prepared from nano manganese sulfate, nano zinc sulfate, humic acid, Fe3O4@C-NH2, alkyl naphthalene sulfonate and water onto ears of the wheat and the corn after the grain filling stage of the wheat and the grain flowering stage of the corn. According to the method, roots are controlled and prevented from absorbing cadmium in soil in the seedling stage, leaves are controlled and prevented from absorbing cadmium in atmospheric dust fall in the elongation stage, the ears are controlled and prevented from absorbing cadmium in atmospheric dust fall in the grain filling stage of the wheat and the grain flowering stage of the corn, and the purposes of relay prevention and control in the growth stage, crop rotation system prevention and control and prevention and control cost reduction are achieved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

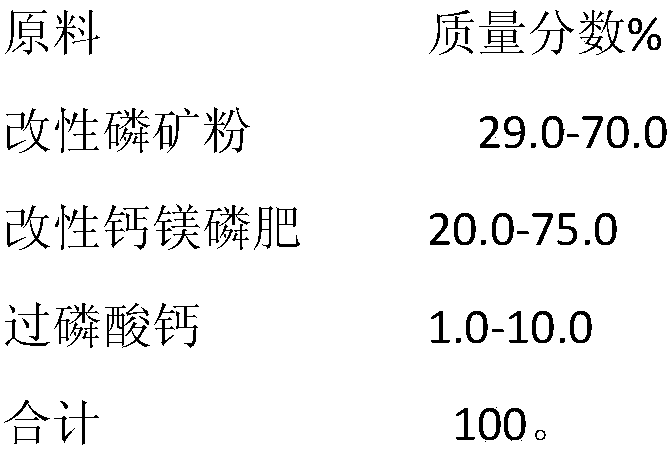

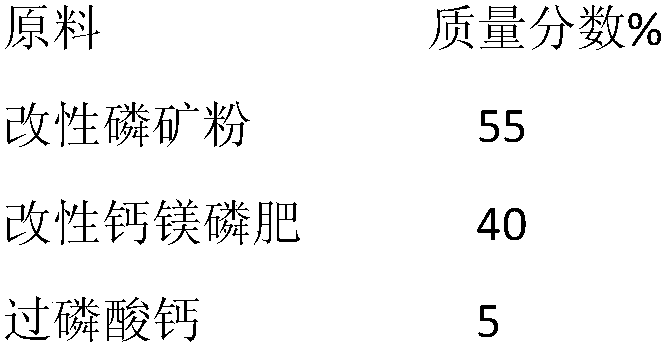

Modified phosphate fertilizer for preventing and controlling heavy metal pollution in farmland and application method thereof

ActiveCN108911908AEfficient passivationReduce cadmium contentSuperphosphatesFertilising methodsFood safetyCadmium Cation

The invention discloses a modified phosphate fertilizer for preventing and controlling heavy metal pollution in a farmland and an application method thereof. The modified phosphate fertilizer is prepared from modified phosphate rock powder, modified calcium magnesium phosphate fertilizer and calcium superphosphate in a certain proportion. The modified phosphate fertilizer is applied to a tillage layer before crop planting to achieve the purpose of passivating heavy metal cadmium in soil and preventing cadmium from transporting to edible parts of crops. The modified phosphate fertilizer can significantly reduce the cadmium content in the edible parts of rice, vegetables and other crops, significantly reduces the effectiveness of the cadmium in soil, and conforms agricultural products produced in the farmland with mild or moderate heavy metal pollution to food safety standards. At the same time, the modified phosphate fertilizer can provide abundant phosphorus nutrition. After applying the modified phosphate fertilizer, no phosphorus fertilizer is needed. The application amount is 30-150 kg / mu, and the cost is low.

Owner:SOUTH CHINA AGRI UNIV

Application of fertilizers that can improve soil fertility in winter wheat planting without topdressing

ActiveCN111264115BHigh organic contentSimple structureFertilising methodsSoil-working methodsSoil scienceSoil organic matter

Taking into account the application of fertilizers that improve the fertilizer of soil fertilizer in winter wheat, fertilizer exemption and planting. The fertilizers involved in the present invention include organic organic fertilizer and chemical fertilizer, and chemical fertilizers include the following components: slowly controlling nitrogen release fertilizer, quick -acting nitrogen fertilizer, phosphate fertilizer, potassium fertilizer; the fertilizer involved in the present invention involvedApplying method: The straw is crushed and spread evenly on the surface, sprinkled biological organic and chemical fertilizers evenly, deepen the soil for 20‑25cm or deep loosening 35‑40cm before all fertilizers.On the surface, spinning, the depth is 10‑15cm, so that the soil layer and organic organic fertilizer are fully mixed. The fertilizer is planted and sowed wheat and applied chemical fertilizer.After labor investment, it can quickly increase the organic matter content and bi fertilizer of the soil, have water retention, and improve the soil structure, and play a role in increasing production and efficiency.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI +1

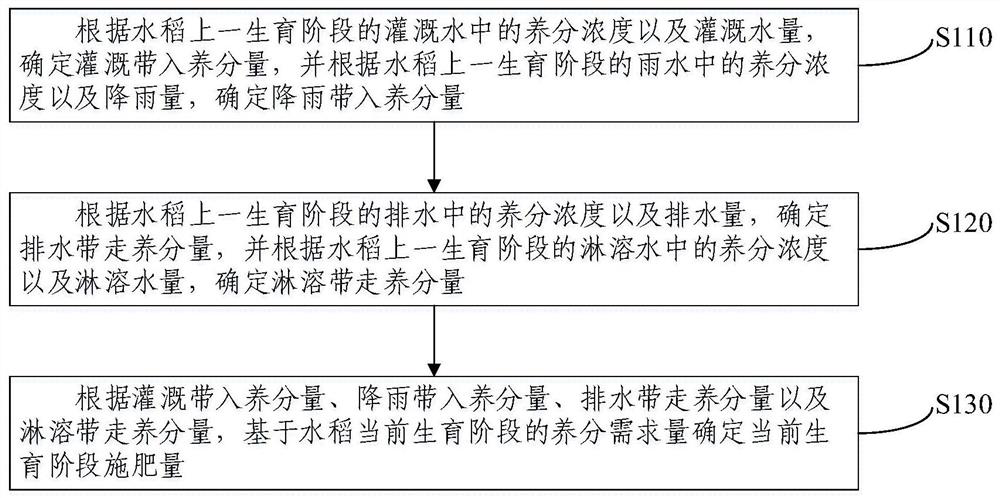

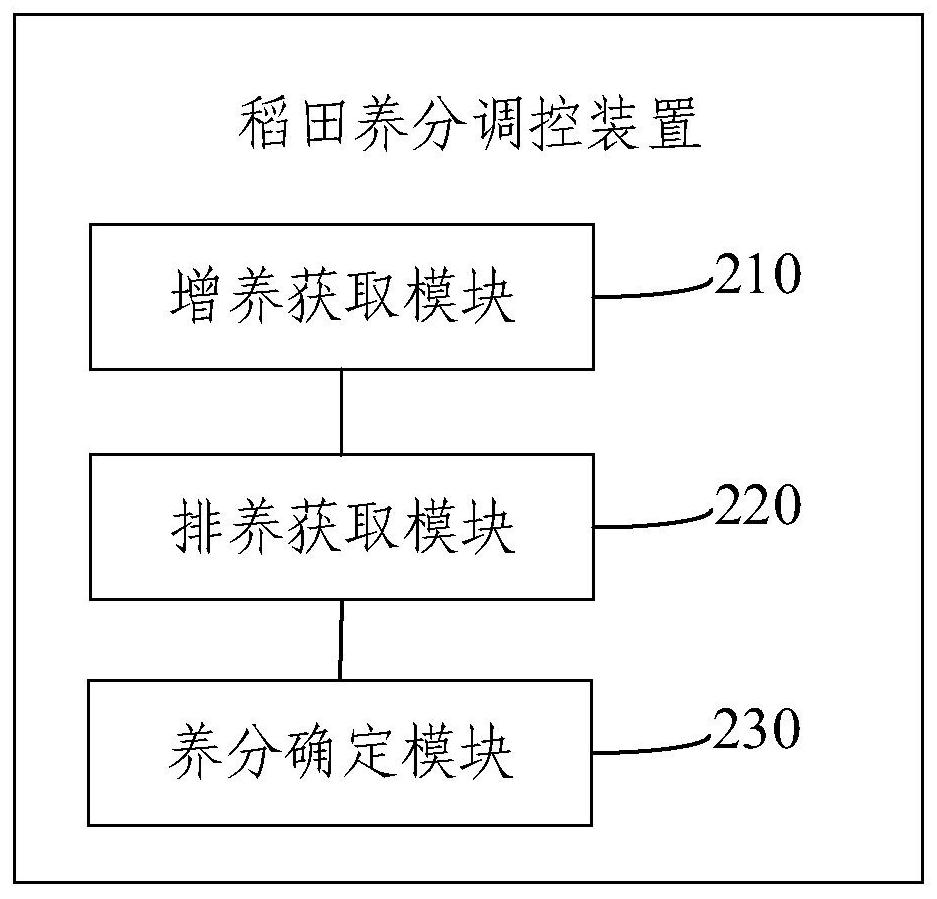

Rice field nutrient regulation and control method and device

PendingCN114303559AGuaranteed outputPrevention and Control of PollutionFertilising methodsPaddy fieldIrrigation water

The invention provides a rice field nutrient regulation and control method and device. The method comprises the following steps: determining the nutrient amount brought by irrigation according to the nutrient concentration and irrigation water amount in irrigation water in the previous growth stage of rice, and determining the nutrient amount brought by rainfall according to the nutrient concentration and rainfall in rainwater in the previous growth stage of rice; according to the nutrient concentration and the displacement in the drained water of the previous growth stage of the rice, determining the nutrient content of the drained water belt, and according to the nutrient concentration and the leaching water volume of the leaching water of the previous growth stage of the rice, determining the nutrient content of the leaching belt; according to the amount of nutrient brought by irrigation, the amount of nutrient brought by rainfall, the amount of nutrient taken away by drainage and the amount of nutrient taken away by leaching, the fertilization amount of the current growth stage is determined on the basis of the nutrient demand of the current growth stage of rice. The rice field nutrient regulation and control method and the rice field nutrient regulation and control device provided by the invention can realize dynamic and accurate regulation and control of the rice fertilization amount.

Owner:INST OF PLANT PROTECTION & SOIL FERTILIZER HUBEI ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com