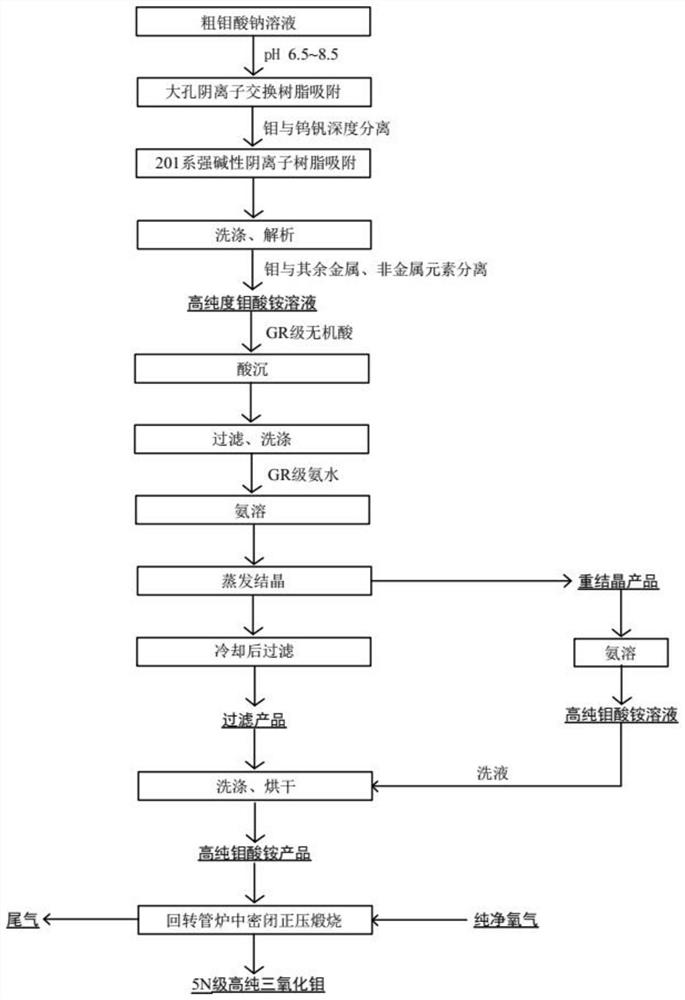

Production process of 5N-grade high-purity molybdenum trioxide

A molybdenum trioxide and production process technology, applied in the field of 5N grade high-purity molybdenum trioxide production process, can solve the problems of non-purity high-purity molybdenum trioxide products and production processes, and achieve prevention and control of equipment and environmental pollution, process parameters Precisely Controlled Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The thick sodium molybdate solution in the present embodiment is that the molybdenum-containing waste catalyst reclaims through Na 2 CO 3 The sodium molybdate solution obtained by leaching has pH: 6-6.5, molybdenum concentration: 58.32g / l, tungsten concentration: 1.28g / l, vanadium concentration: 2.53g / l.

[0030] refer to figure 1 , the flow process of the present embodiment 5N level high-purity molybdenum trioxide production process mainly comprises:

[0031] 1. Multi-stage ion exchange deep impurity removal

[0032] (1) Separation of molybdenum and tungsten vanadium

[0033] NaOH is used to adjust the pH value of the crude sodium molybdate solution to 7.5, and it is adsorbed by D301 macroporous anion exchange resin at a linear velocity of 0.5m / h. During the adsorption process, both tungsten and vanadium are adsorbed on the resin in the form of anions. The solution out of the column is mainly sodium molybdate. When tungsten appears in the column solution and the tu...

Embodiment 2

[0044] The thick sodium molybdate solution in this embodiment is the sodium molybdate solution after the molybdic acid prepared by waste molybdenum alloy is dissolved in NaOH and deaminated. The pH of the solution is 10~11. l, vanadium concentration: 0.05g / l.

[0045] refer to figure 1 , the flow process of the present embodiment 5N level high-purity molybdenum trioxide production process mainly comprises:

[0046] 1. Multi-stage ion exchange deep impurity removal

[0047] (1) Separation of molybdenum and tungsten vanadium

[0048] HCl is used to adjust the pH of the crude sodium molybdate solution to 8.0, and it is adsorbed by D314 macroporous anion exchange resin at a linear speed of 2.0 m / h. During the adsorption process, both tungsten and vanadium are adsorbed on the resin in the form of anions. The solution out of the column is mainly sodium molybdate. When tungsten appears in the column solution and the tungsten concentration reaches 10 mg / l, the adsorption stops. At ...

Embodiment 3

[0059] The crude sodium molybdate solution in this example is a low-grade molybdenum calcine NaOH leaching solution, the solution pH is 8-8.5, the molybdenum concentration is 54.2g / l, the tungsten concentration is 0.28g / l, and the vanadium concentration is 0.08g / l.

[0060] refer to figure 1 , the flow process of the present embodiment 5N level high-purity molybdenum trioxide production process mainly comprises:

[0061] 1. Multi-stage ion exchange deep impurity removal

[0062] (1) Separation of molybdenum and tungsten vanadium

[0063] The crude sodium molybdate solution is adsorbed by D231 macroporous anion exchange resin, and the adsorption linear velocity is 3.0m / h. During the adsorption process, both tungsten and vanadium are adsorbed on the resin in the form of anions. The solution out of the column is mainly sodium molybdate. When tungsten appears in the column solution and the tungsten concentration reaches 10 mg / l, the adsorption stops. At this time, the vanadium i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com