Vehicle fuel oil evaporation control system and method thereof

A control system and fuel oil technology, applied in the direction of charging system, adding non-fuel substances to fuel, engine components, etc., can solve the problems of unsolved fuel vapor control and recycling, technical solution applicability limitations, technical solution imperfections, etc. , achieve and control pollution environment, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

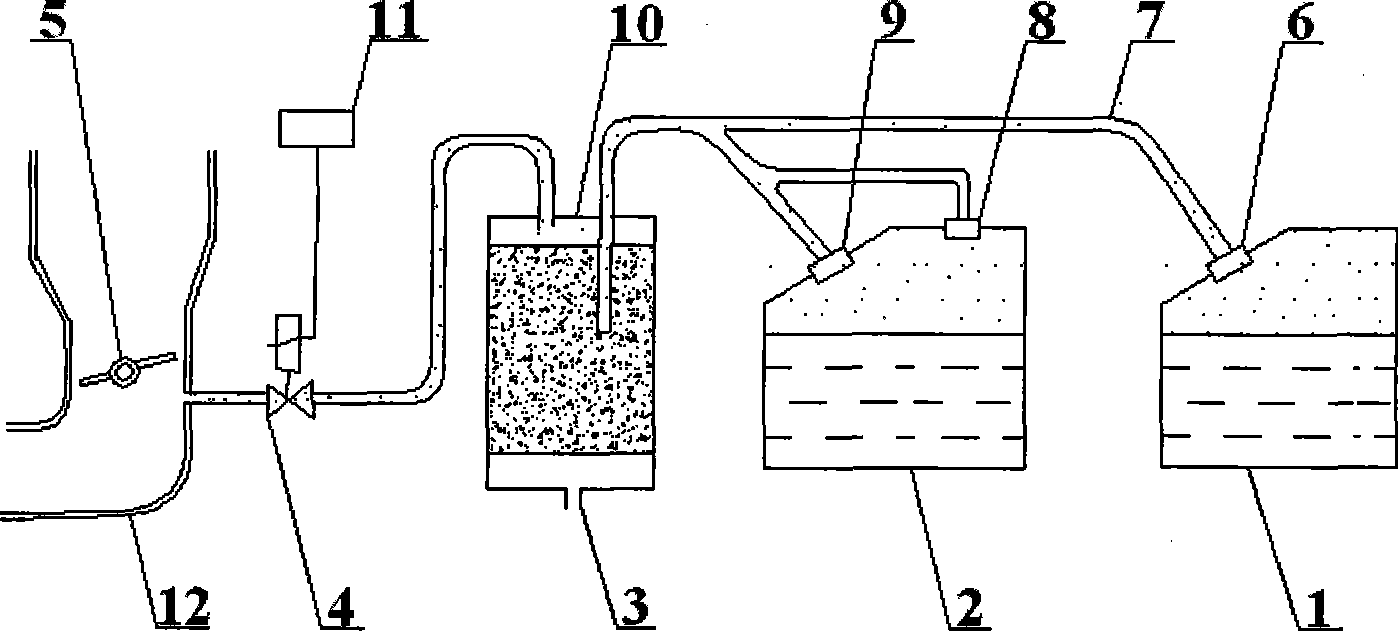

[0030] The fuel vapor pipe 7 communicates with the methanol fuel tank 2 through the methanol tank gravity valve 8 and the methanol tank gravity valve 9; the fuel vapor pipe 7 communicates with the gasoline fuel tank 2 through the gasoline tank gravity valve 6 .

[0031] This embodiment solves the problem under what conditions fuel vapor begins to flow to the activated carbon canister 10, that is, when the temperature is higher, the pressure of the fuel vapor in the gasoline fuel tank 1 and the methanol fuel tank 2 exceeds the gravity valve 8 of the methanol tank , Methanol tank gravity valve 9 and gasoline tank gravity valve 6 settings, these gravity valves can be opened automatically, and the high-pressure fuel vapor flows to the activated carbon tank 10 through the fuel vapor pipe 7. Therefore, the opening pressure of the above-mentioned gravity valve can be set according to the needs of different fuels and different vehicle models.

Embodiment 2

[0033] The pipeline between the activated carbon canister 10 and the engine intake pipe 12 of the vehicle fuel evaporation control system is the carbon canister output pipeline 13, and the carbon canister solenoid valve 4 is arranged on the pipeline, and the carbon canister solenoid valve 4 communicates with the canister through the signal line. The engine electronic control unit 11 (ECU) is connected, and the engine electronic control unit 11 (ECU) sends an open or close signal to the canister solenoid valve 4 .

[0034] The setting of the above structure makes the fuel evaporation control system coordinate with the overall working state of the engine, and its work is more reliable, its performance is better, and its efficiency is higher. Whether the carbon canister output pipeline 13 is open or not is controlled by the ECU of the engine and implemented by the opening and closing of the carbon canister electromagnetic valve 4 .

Embodiment 3

[0036]The activated carbon canister 10 is provided with a carbon canister atmosphere through hole 3 .

[0037] This structure enables the adsorption and recovery of vapor to form different circuits according to different conditions:

[0038] If the carbon canister solenoid valve 4 is closed and each gravity valve is opened, the high-pressure oil vapor filtered clean gas will be discharged from the carbon canister atmospheric hole 3;

[0039] If the carbon canister solenoid valve 4 is opened and each gravity valve is closed, the air will be sucked from the carbon canister atmospheric hole 3, and the fuel adsorbed on the activated carbon particles will be washed away, and will be sucked into the engine through the carbon canister output pipeline 13 in the form of oil and gas. combustion in the cylinder;

[0040] If the carbon canister electromagnetic valve 4 and each gravity valve are all opened, then determine the gas flow direction at the carbon canister atmospheric through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com