Energy composition with function of improving decoration product performance and preparation method of energy composition

An energy composition and product technology, applied in the field of materials, can solve problems such as lack of funds for scientific research and technology, and inability to update advanced equipment, etc., and achieve the effects of efficient and extensive disinfection performance, strong adsorption force, and high-efficiency deodorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

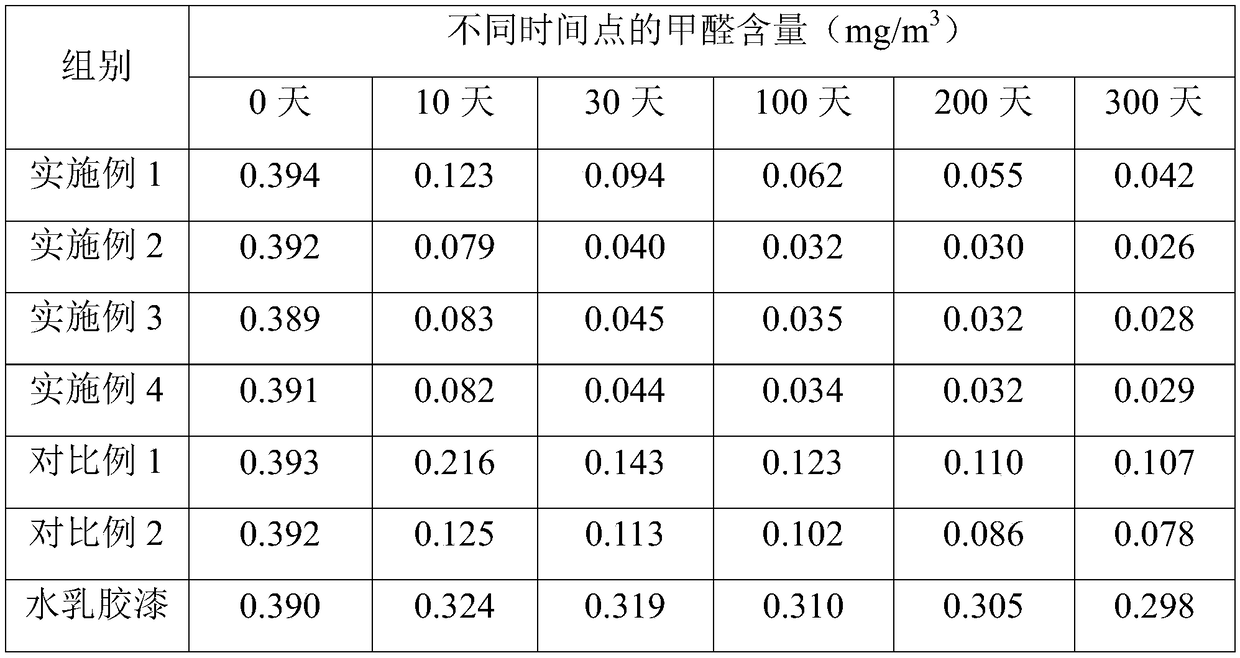

Examples

preparation example Construction

[0033] In addition, the present invention also provides a method for preparing the above-mentioned energy composition with improved performance of decoration products, comprising the following steps:

[0034] In the stirring state, put each raw material component into the mixing tank according to the metering, and mix and stir at room temperature for 85-95 minutes; the stirring speed is 50-100 rpm;

[0035] The agitated mixture is subjected to a qualification test, and after the test is qualified, it is discharged out of the tank to obtain an energy composition that can improve the performance of decoration products.

Embodiment 1

[0038] The present embodiment provides a kind of energy composition that can improve the performance of decoration products, and the raw material components include: 2.3 parts by weight of food-grade potassium sorbate, 3.0 parts by weight of food-grade sodium dehydroacetate, and 30 parts by weight of nano-anion powder Parts, 18.5 parts by weight of nanometer white bamboo charcoal powder, 29.5 parts by weight of nanometer titanium dioxide powder and 7.5 parts by weight of nanometer silver ions.

[0039]According to the above-mentioned raw materials, the preparation method provided by the invention is adopted to prepare an energy composition with improved decoration product performance:

[0040] In the stirring state, put each raw material component into the mixing tank according to the metering, and mix and stir at room temperature for 90 minutes; the stirring speed is 60 rpm;

[0041] The agitated mixture is subjected to a qualification test, and after the test is qualified, i...

Embodiment 2

[0043] The present embodiment provides a kind of energy composition that can improve the performance of decoration products, and the raw material components include: 2.3 parts by weight of food-grade potassium sorbate, 3.0 parts by weight of food-grade sodium dehydroacetate, and 30 parts by weight of nano-anion powder Parts, 31 parts by weight of nano tourmaline powder, 18.5 parts by weight of nano white bamboo charcoal powder, 32 parts by weight of nanometer medical stone powder, 29.5 parts by weight of nano titanium dioxide powder and 7.5 parts by weight of nanometer silver ion.

[0044] According to the above-mentioned raw materials, the preparation method provided by the invention is adopted to prepare an energy composition with improved decoration product performance:

[0045] In the stirring state, put each raw material component into the mixing tank according to the metering, and mix and stir at room temperature for 90 minutes; the stirring speed is 60 rpm;

[0046] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com