Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "No crystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

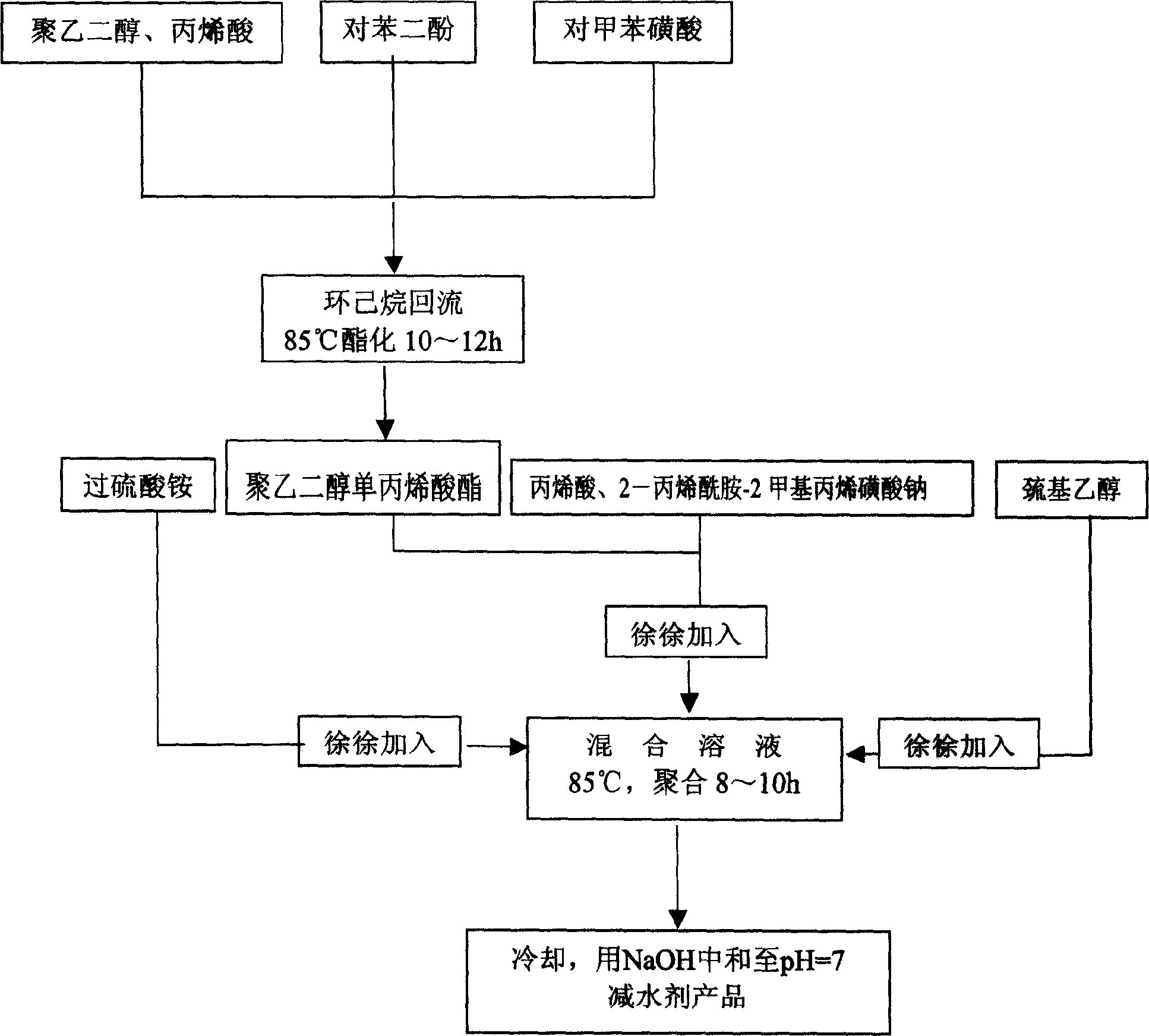

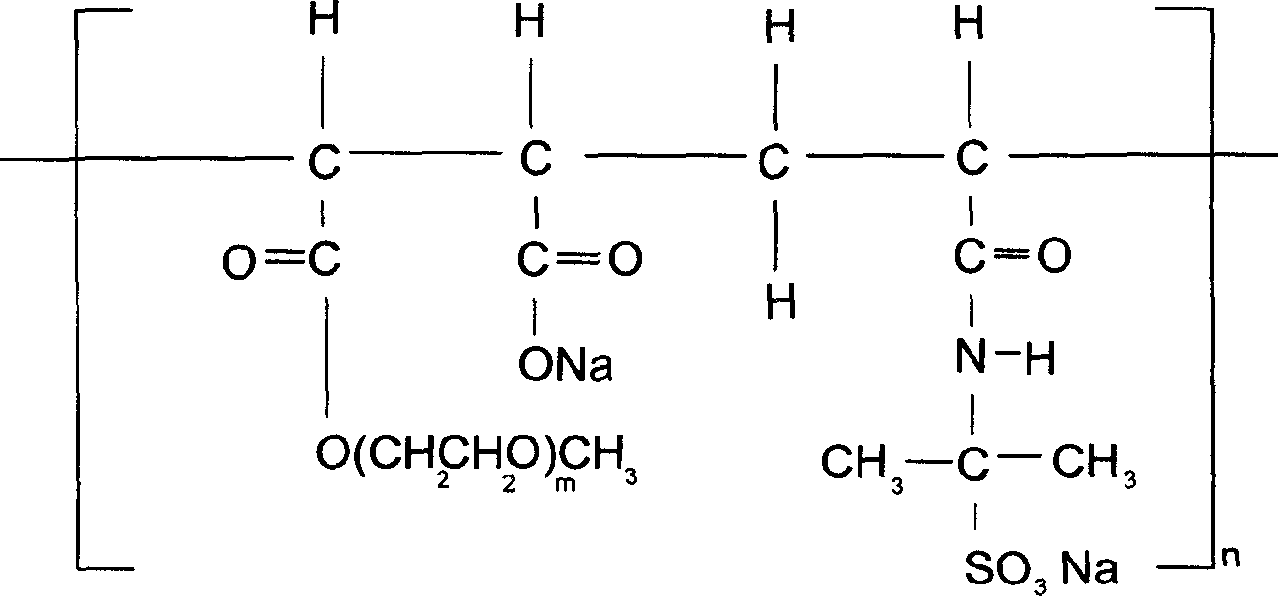

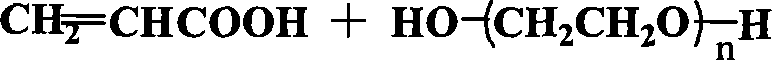

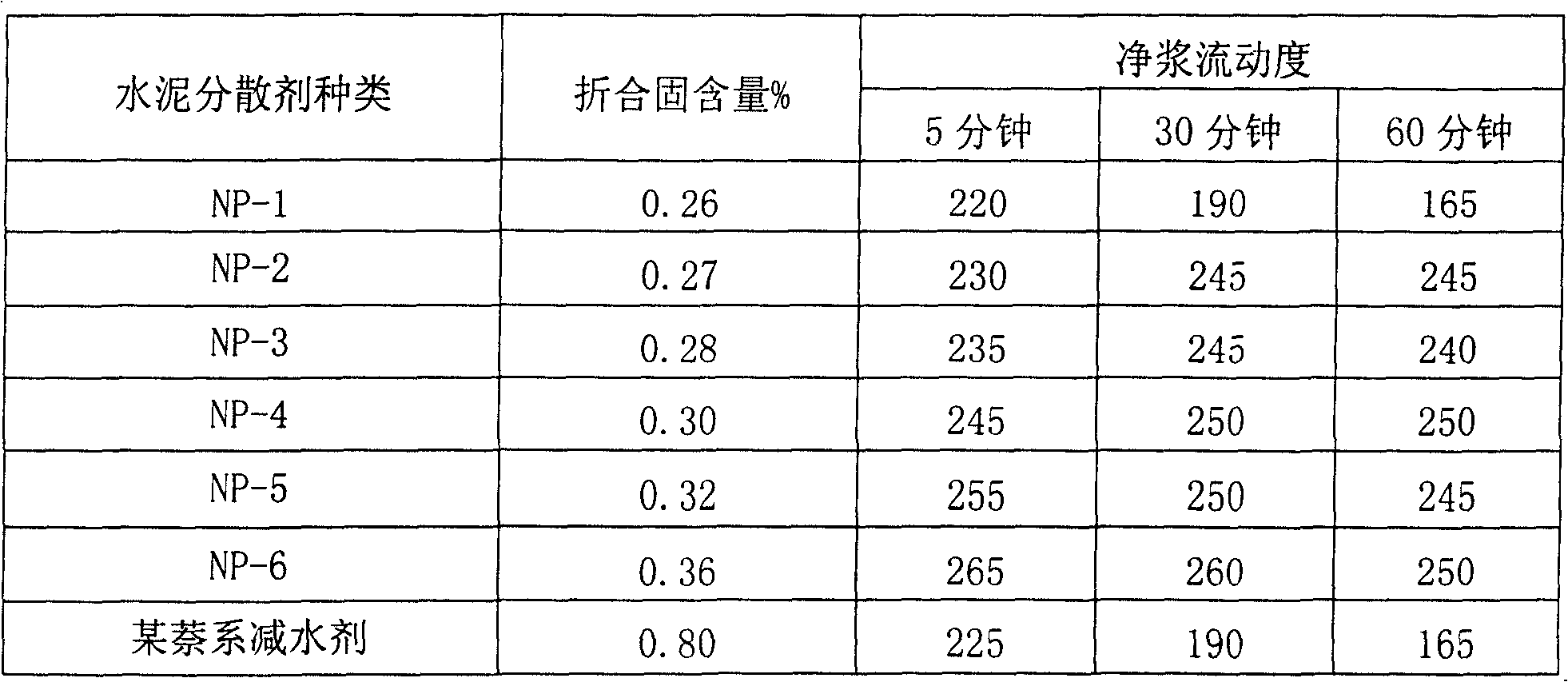

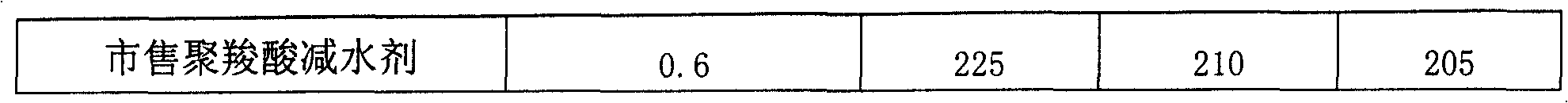

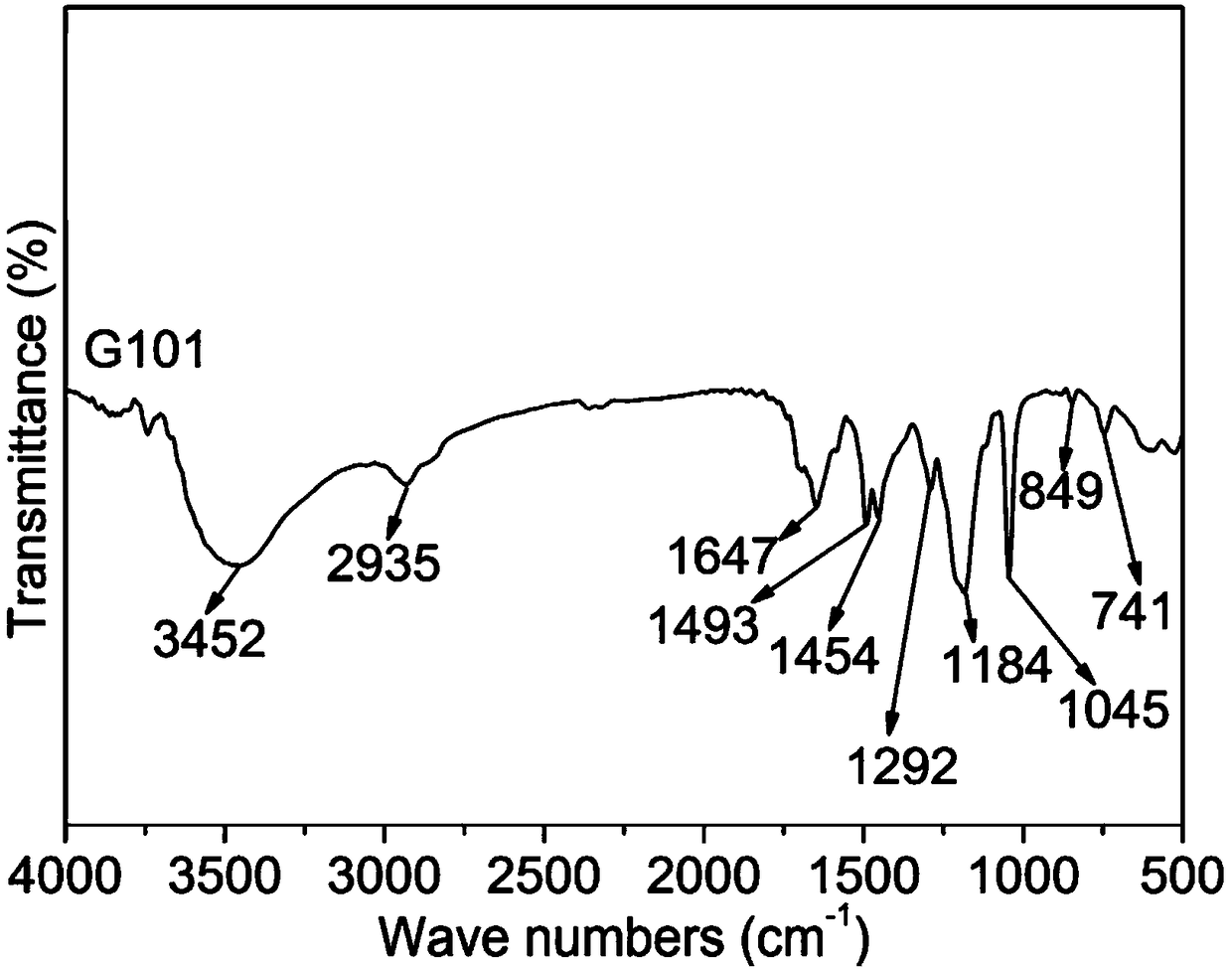

Concrete water reducing agent of polyacrylic acid and its synthesis process

InactiveCN1636921AConstant reaction temperatureThe feeding procedure is simpleDouble bondHigh performance concrete

The concrete water reducing agent of polyacrylic acid is prepared through esterification between polyglycol and acrylic acid to obtain esterified product, and the copolymerization of the esterified product with acrylic acid, 2-acrylamide-2-methyl propenyl sodium sulfonate and other sulfonate with unsaturated double bond. The concrete water reducing agent has weight average molecular weight of 20000-60000, concrete water reducing rate over 35 %, concrete compression strength raised by 100-300 % in 3 days, 40-80 % in 28 days and 30-50 % in 90 days, no loss in 2-hr slump of concrete, raised concrete placeability, etc. and is suitable for matching with flyash, slag and other active admixture to prepare high performance concrete.

Owner:WUHAN UNIV OF SCI & TECH

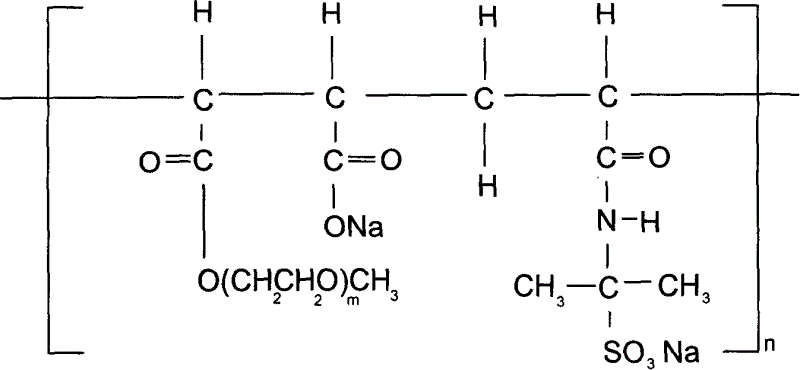

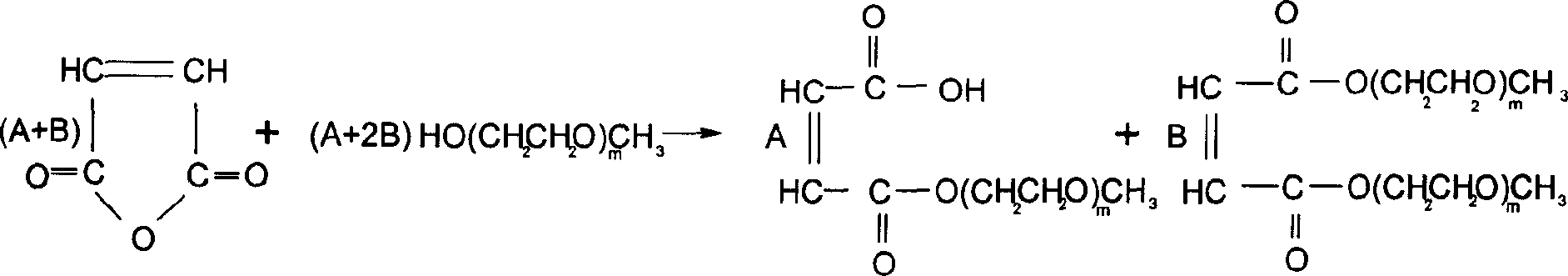

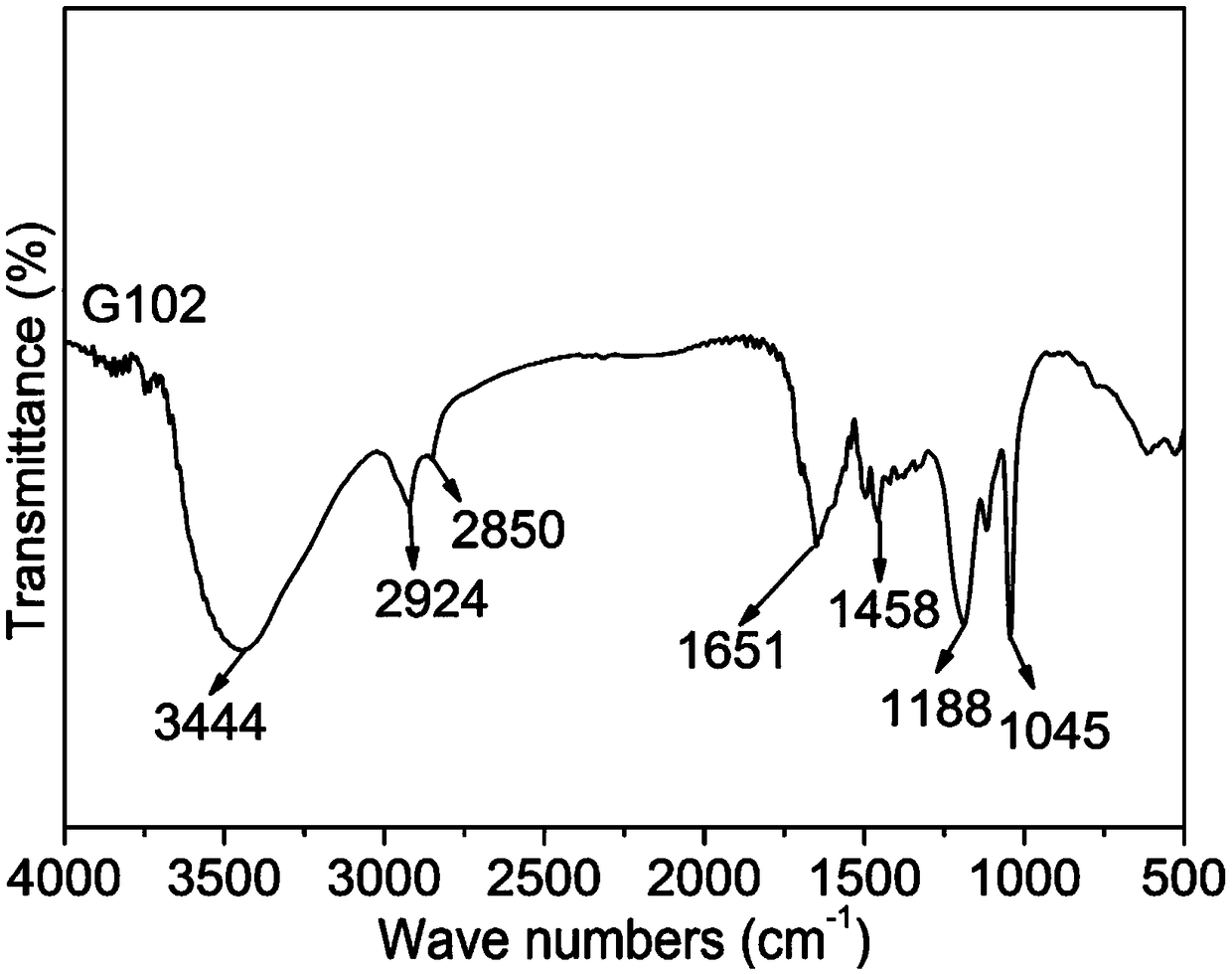

Maleic acid anhydride series concrete water-reducing agent and preparation process thereof

InactiveCN1792960AThe feeding procedure is simpleReaction conditions are easy to controlMaleic anhydrideMaterials science

A maleic anhydride series water-reducing agent for concrete is prepared through reaction between methoxy polyethanediol and maleic anhydride to generate monomethoxy polyethanediol maleate, and copolymerizing on 2-acrylamide-2-sodium methylpropyl sulfonate. Its advantages are high water-reducing effect, low content of alkali, and high flowability and low slump of concrete.

Owner:WUHAN UNIV OF TECH

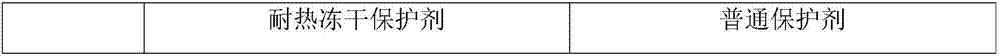

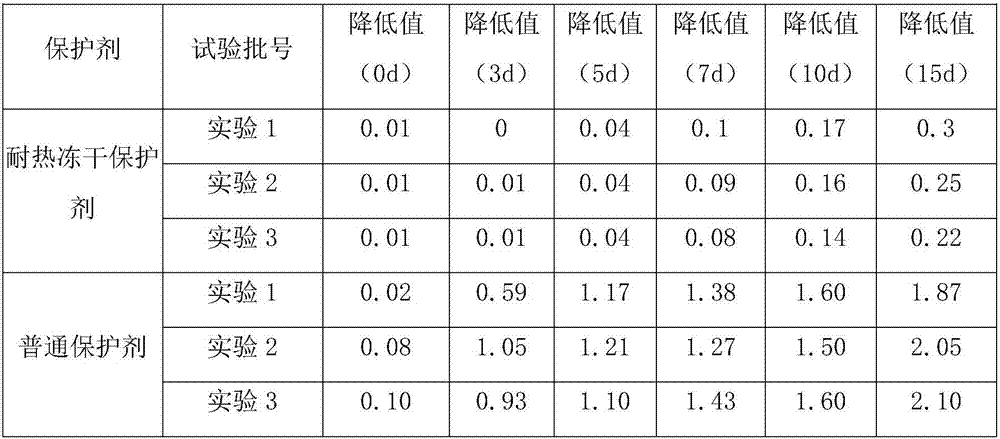

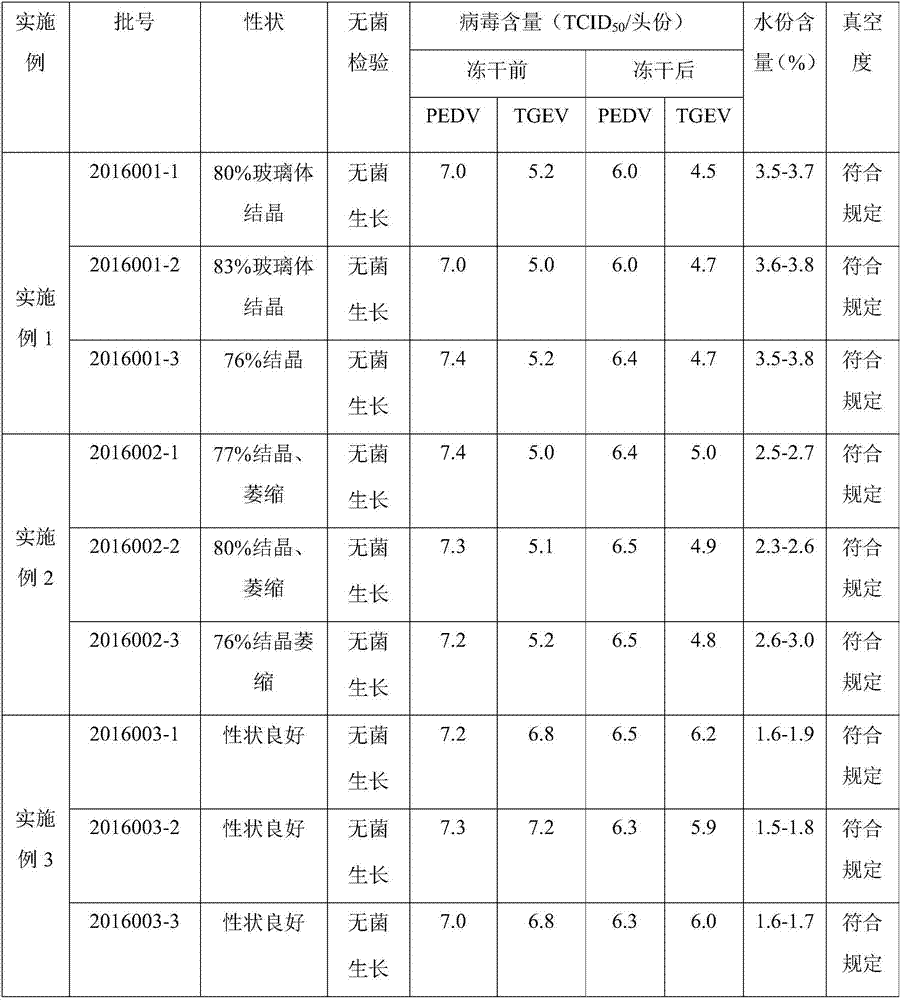

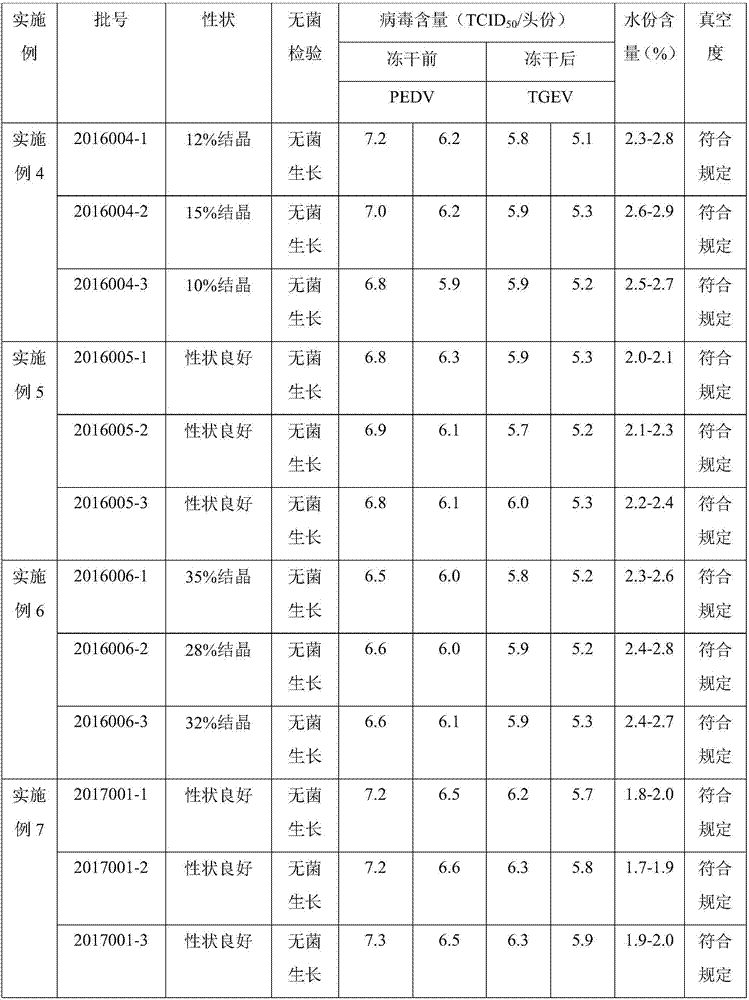

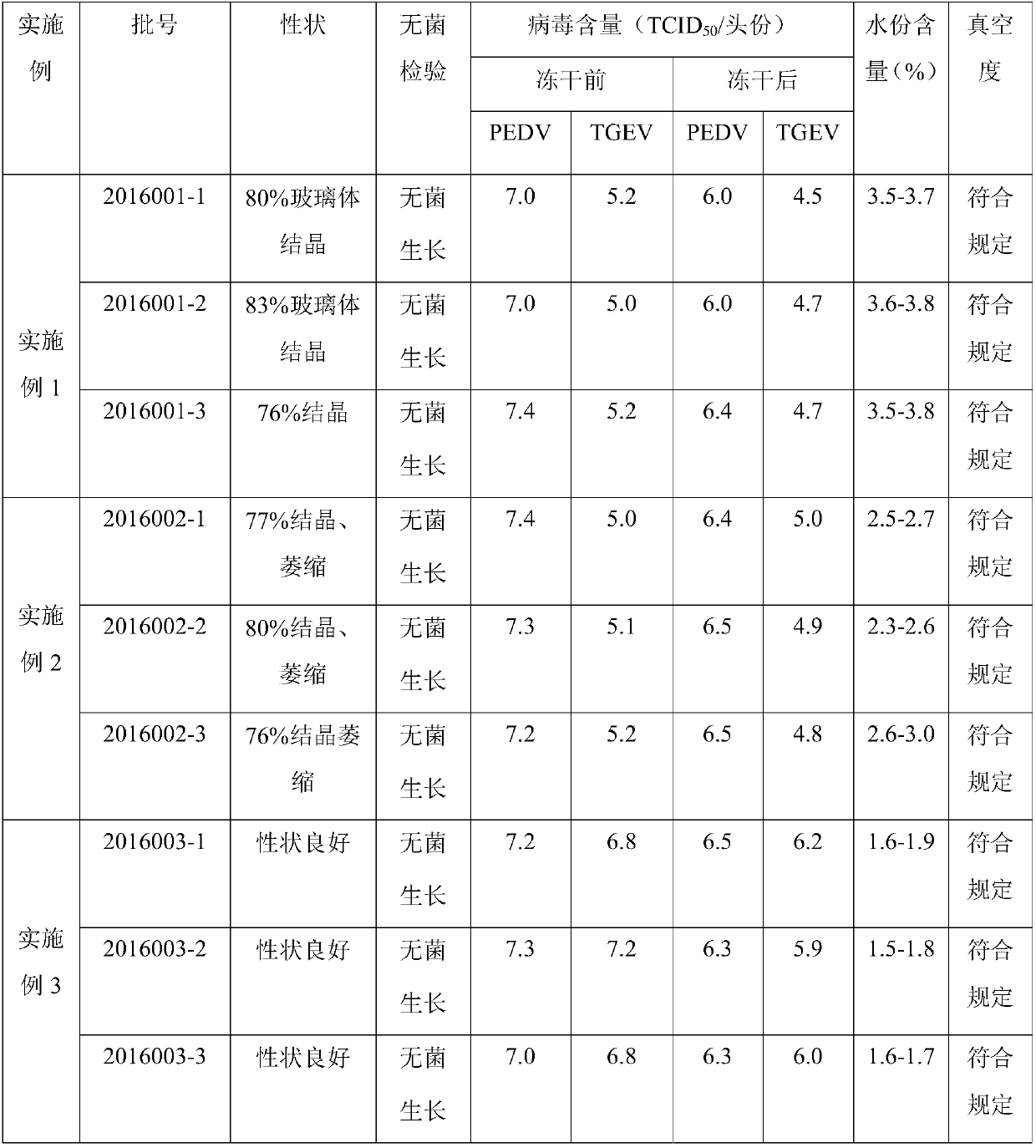

Heatproof lyoprotectant for live vaccine against pseudorabies and preparation method thereof, and lyophilized vaccine and preparation method thereof

ActiveCN107281481AFunction increaseImprove protectionViral antigen ingredientsAntiviralsMonosodium glutamateSucrose

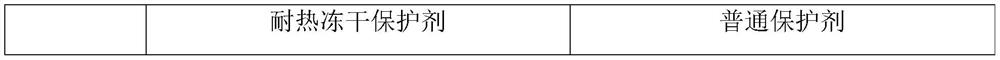

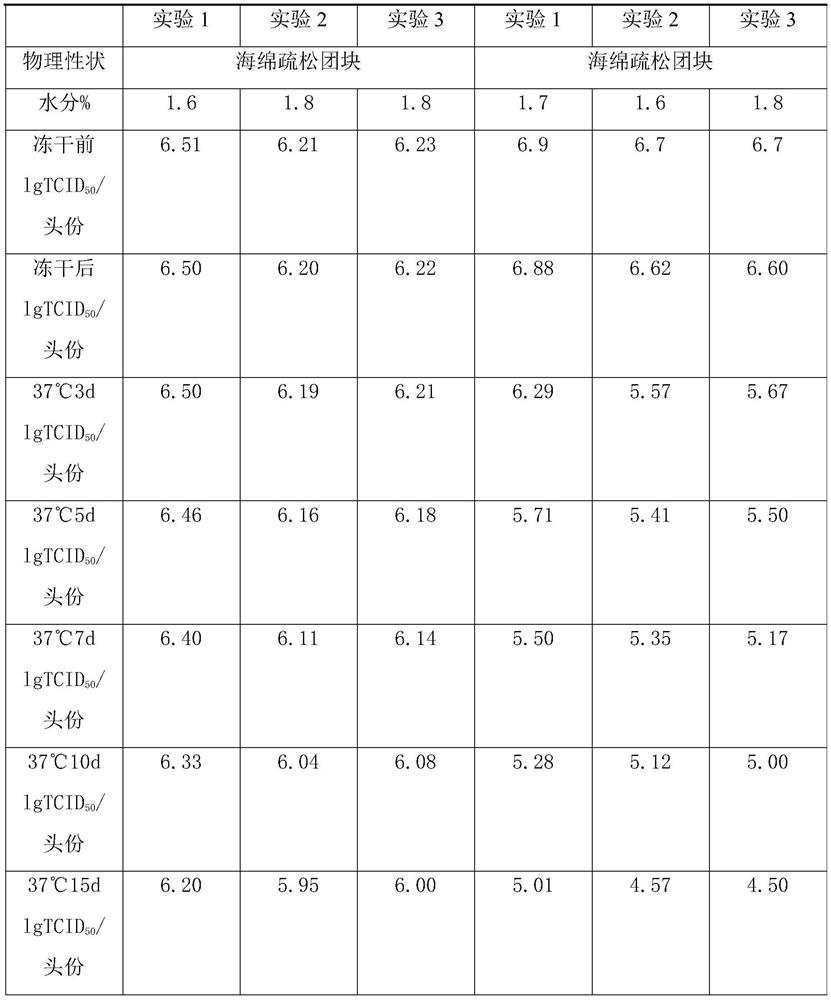

The invention provides a heatproof lyoprotectant for a live vaccine against pseudorabies. The heatproof lyoprotectant comprises, by weight, 3 to 10 parts of gelatin, 1 to 5 parts of trehalose, 5 to 15 parts of sucrose, 0.1 to 2 parts bovine serum albumin, 1 to 8 parts of tryptone, 2 to 10 parts of enzyme-hydrolyzed casein, 1 to 5 parts of thiourea, 0.8 to 2 parts of L-monosodium glutamate, 0.1 to 3 parts of arginine, 0.5 to 5 parts of polyvinylpyrrolidone (PVP-K30) and 0.1 to 2 parts of mannitol. The invention also discloses a preparation method of the heatproof lyoprotectant and a lyophilized vaccine prepared from the heatproof lyoprotectant. When the heatproof lyoprotectant is used for protecting the vaccine and a specific lyophilization process is employed, lyophilization loss of viruses can be effectively reduced, the temperature tolerance of the viruses can be improved, and the vaccine can still maintain good physical properties and titer after long-term storage; i.e., the vaccine has stable characters and has the characteristics of heat resistance and long storage time.

Owner:SICHUAN HUAPAI BIO PHARMA

Honey kumquat tea and preparation technique

InactiveCN101341914AEliminate darkening factorsAlleviate skin diseasesTea substituesFood preparationLiver stomachIndigestion

The invention provides honey kumquat tea and a preparation process thereof; the honey kumquat tea comprises 35 percent to 45 percent of kumquat, 15 percent to 25 percent of sugar, 35 percent to 45 percent of garden honey, 0.5 percent of salt, 0.1 percent to 0.5 percent of citric acid and 5 percent to 10 percent to clear water; the finished product is prepared by the following steps: raw material selection, raw material processing, boiling, cooling, honey adding, canning, sealing, etc. The process organically integrates kumquat with honey, has the technical effect of regulating the flow of qi, relieving depression, eliminating phlegm, relieving a cough, sobering up, curing chest distress and hepatic depression, liver-stomach disharmony, indigestion and anorexia, is suitable to be taken with water, can be used for seasoning as delicious pulp and has high practicality.

Owner:郭毅

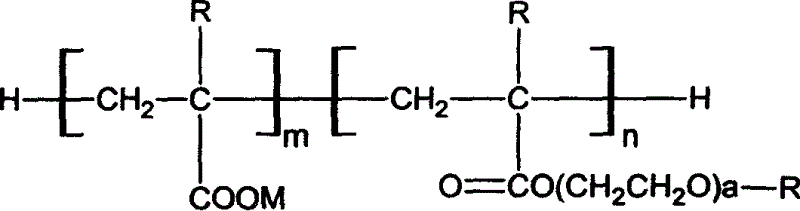

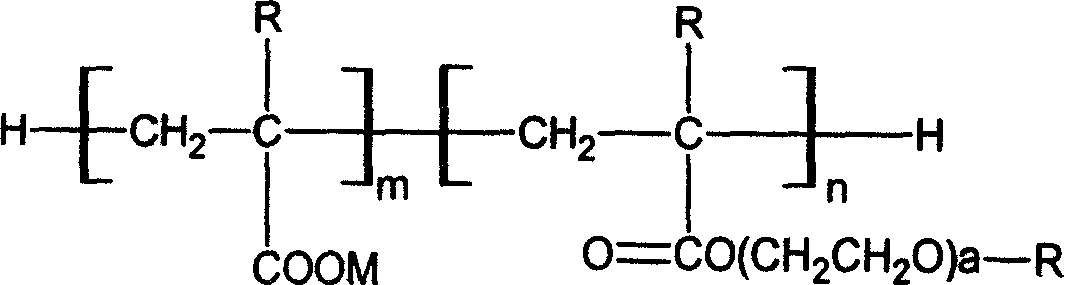

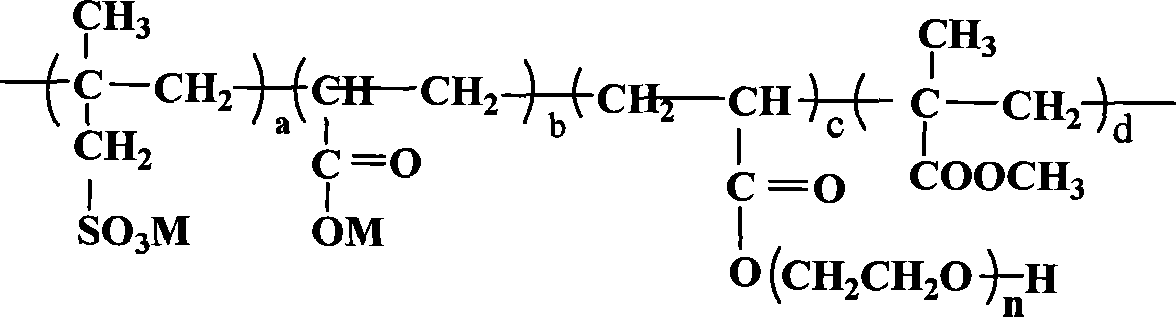

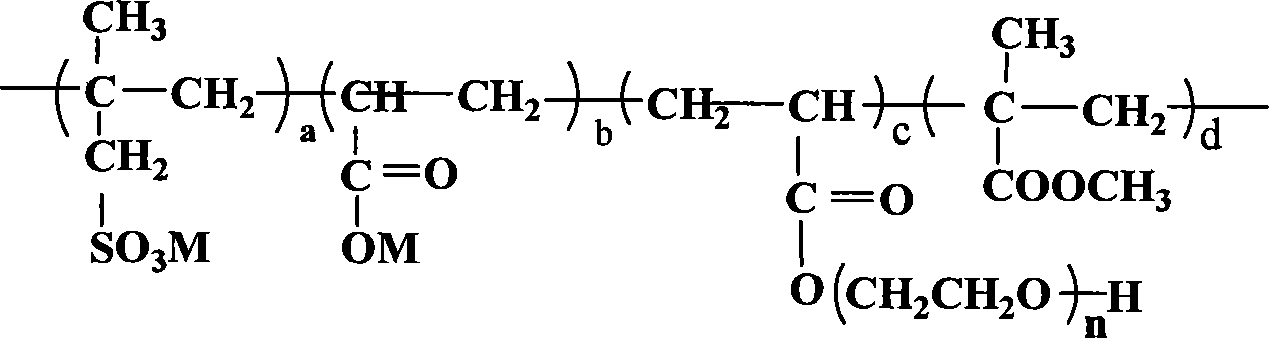

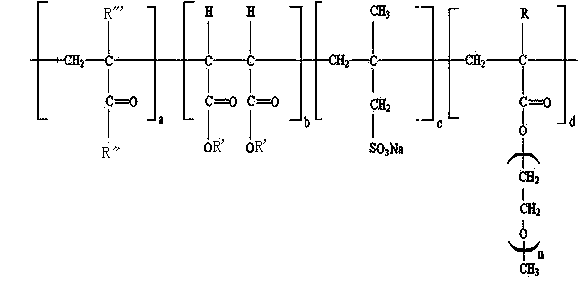

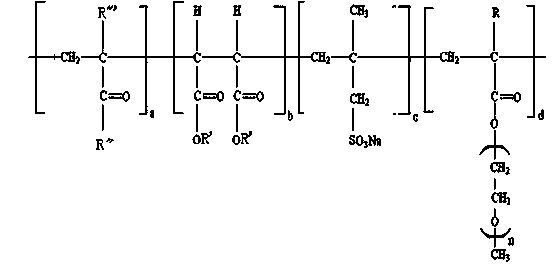

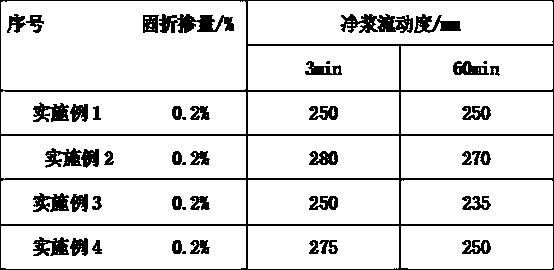

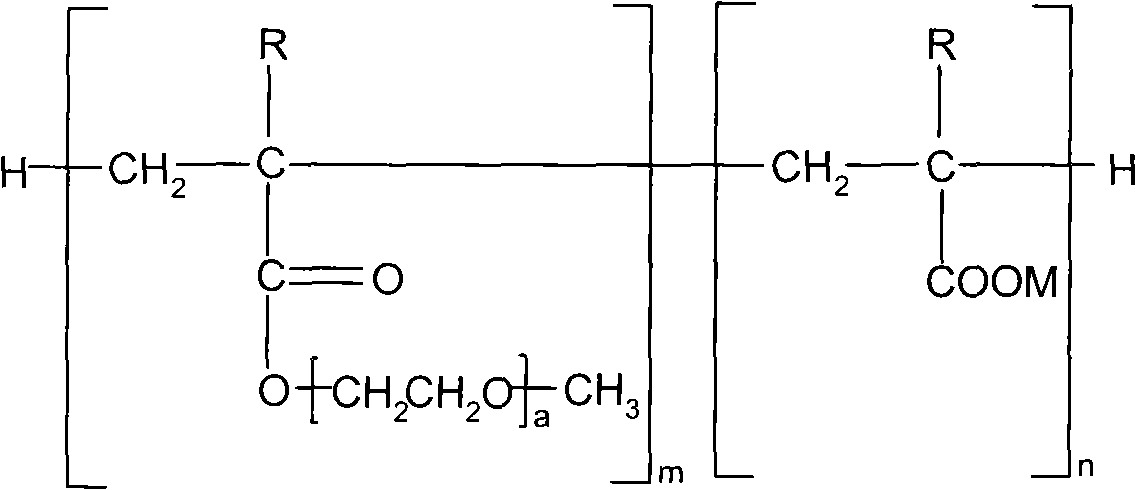

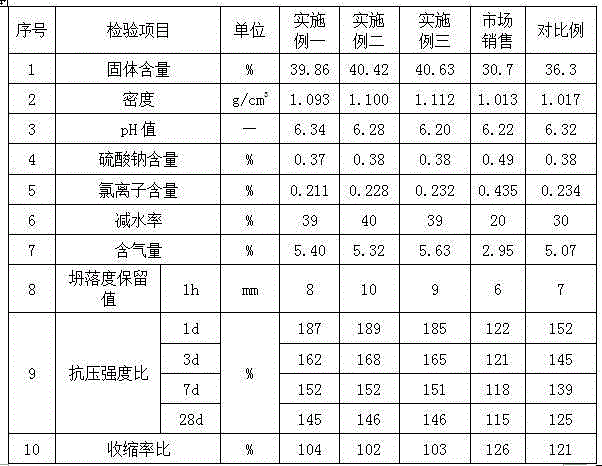

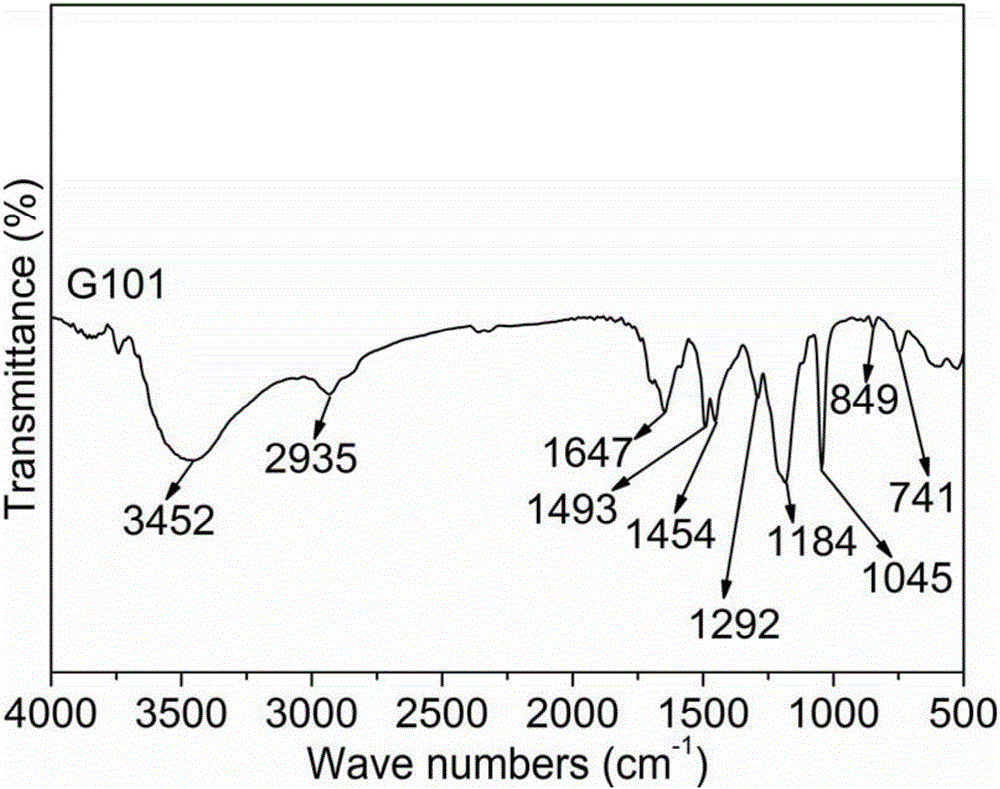

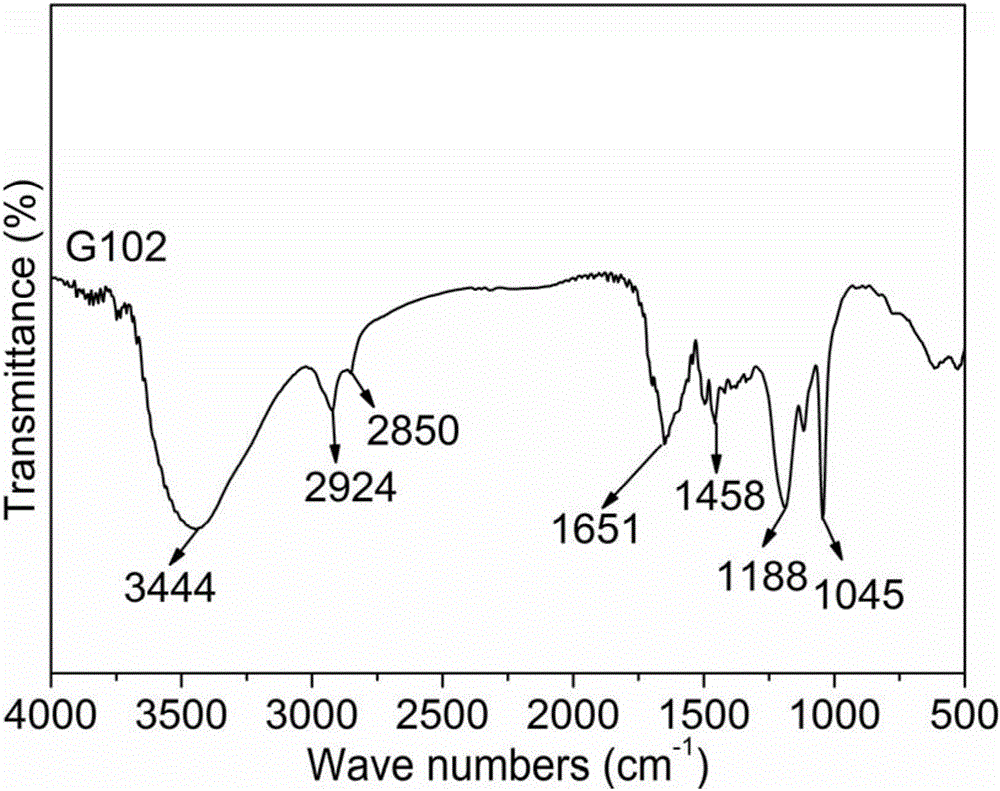

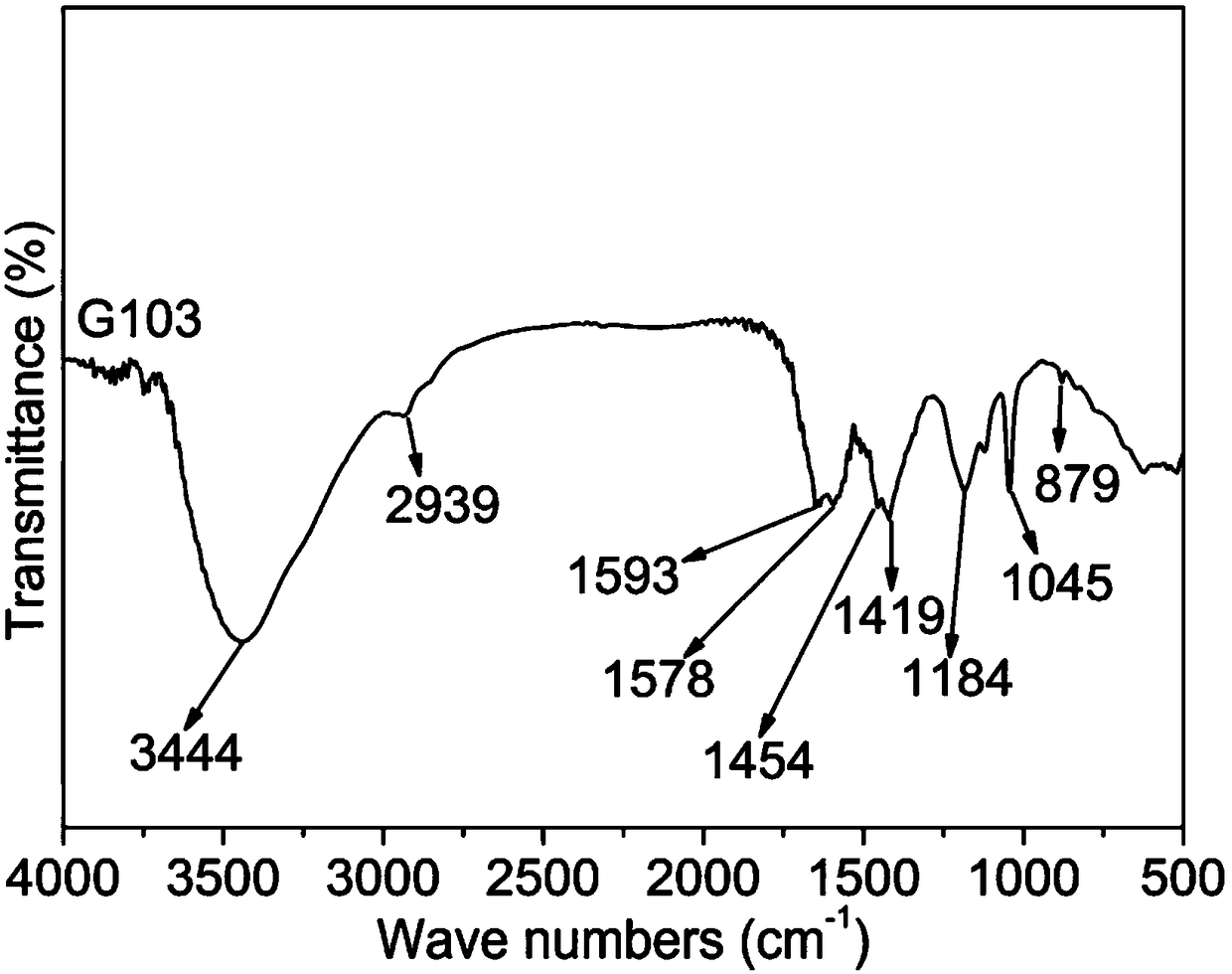

Polycarboxylic acids series water reducer and method for making same

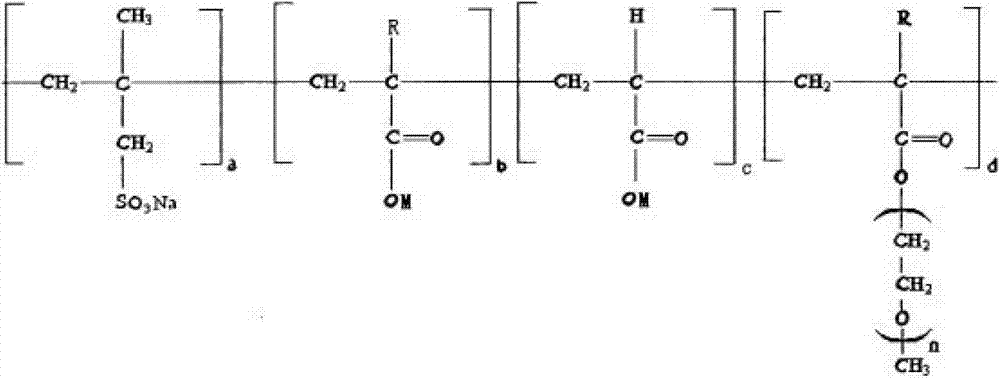

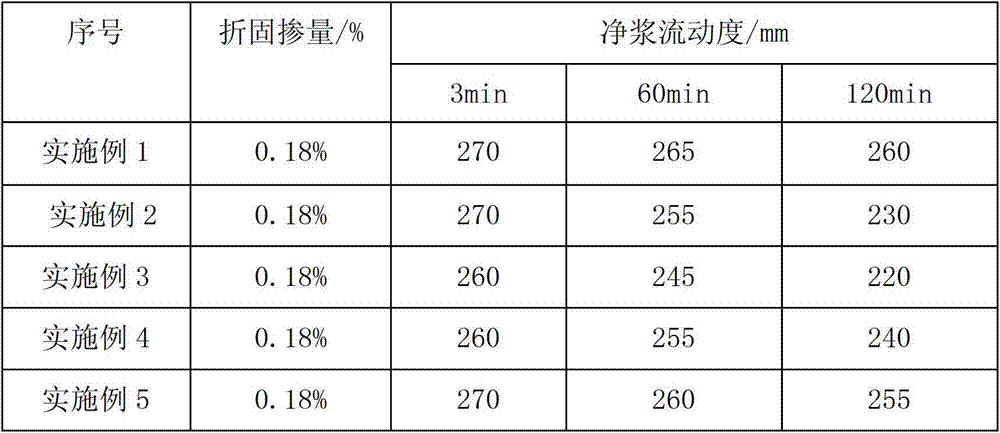

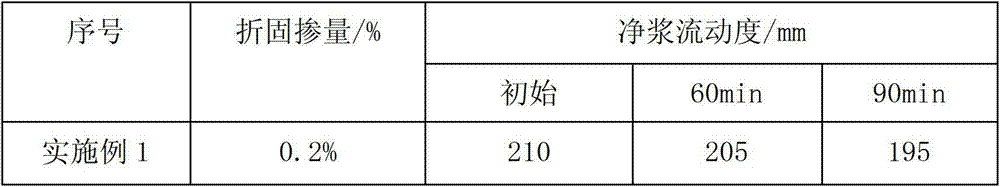

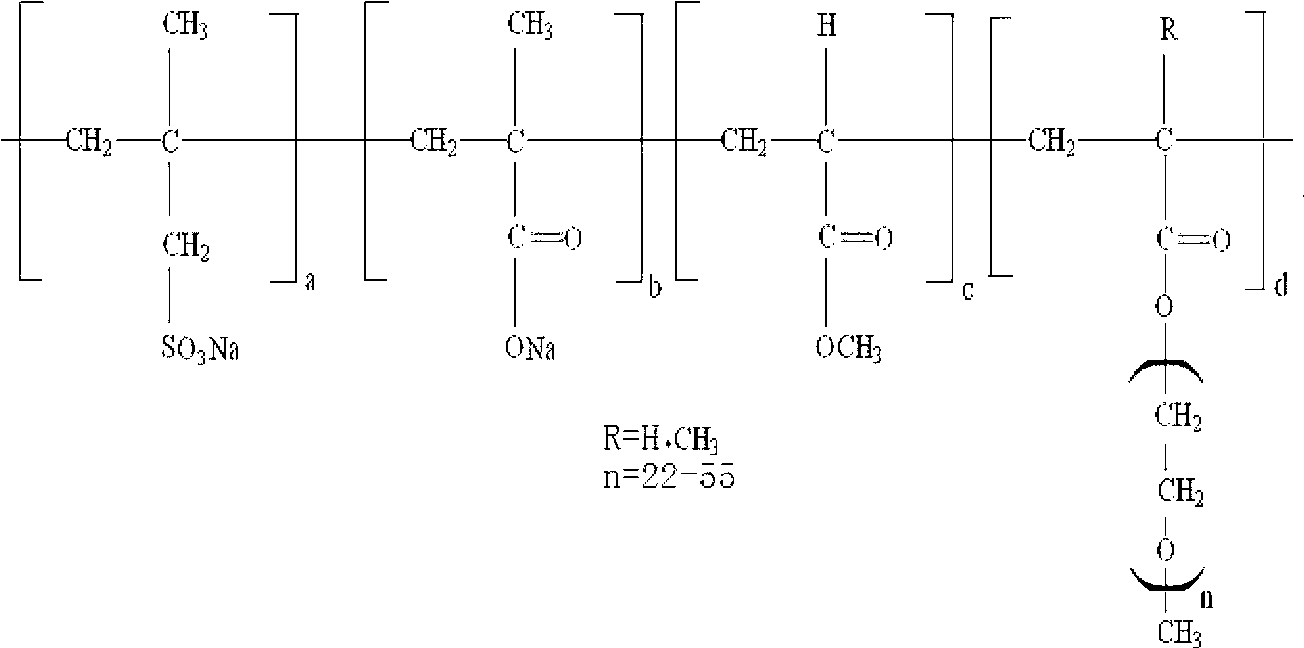

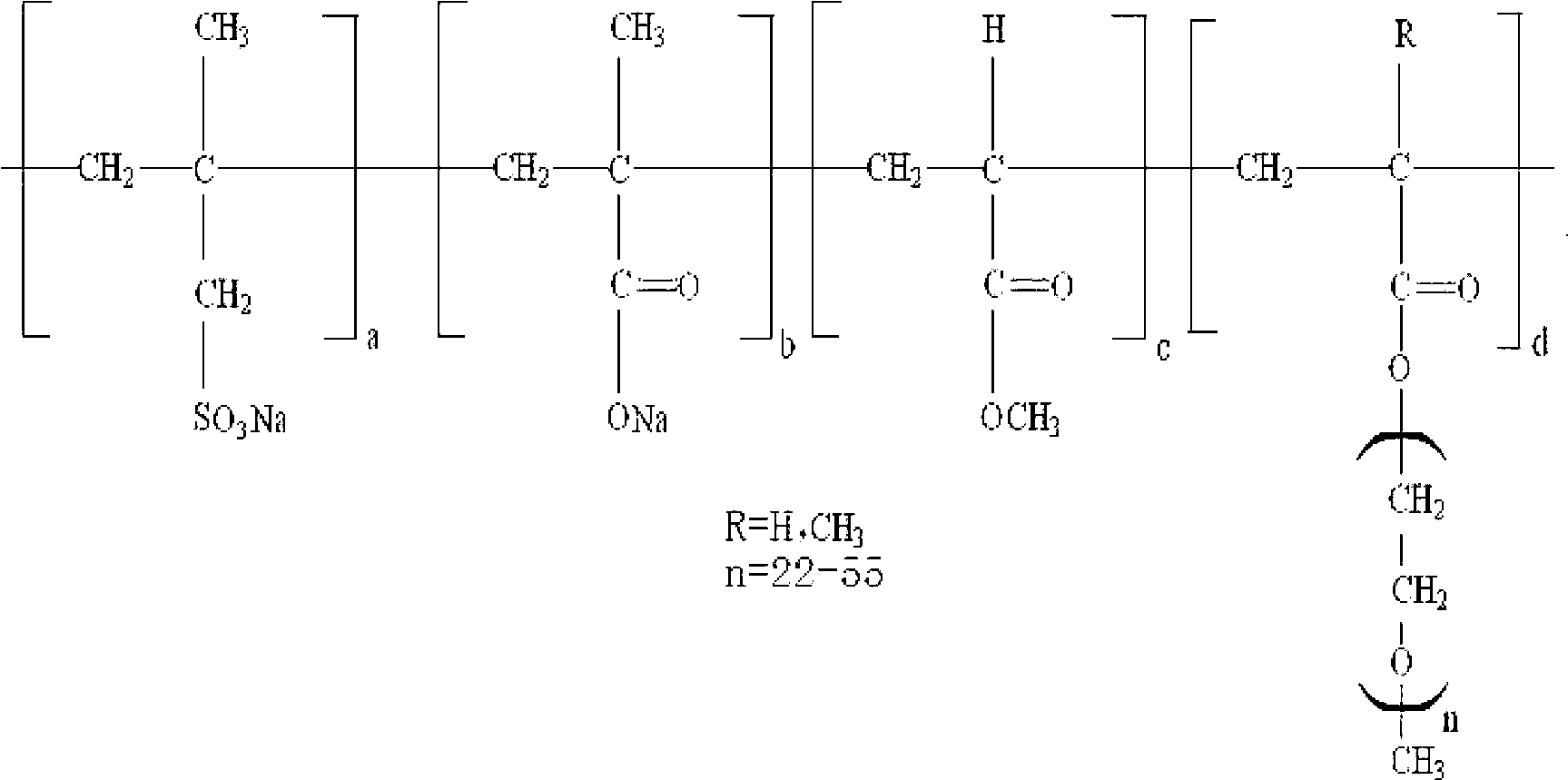

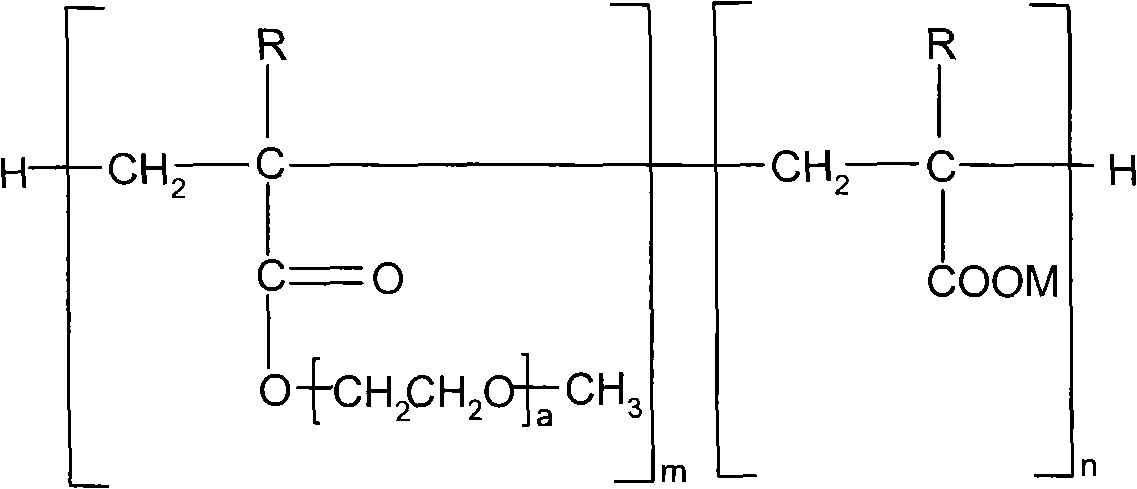

The invention discloses a polycarboxylate type water reducer, the molecule chains of the water reducer contains two different-length polyethylene oxide side chains, the polycarboxylate type water reducer not only have high water reducing rate, but also have excellent plasticizing effect and can self-control the concrete slurry fluidity and gradual slurry fluidity variety, thereby overcoming the problems that the prior water reducer has poor cement plasticizing effect and low water reducing rate. The polycarboxylate type water reducer does not contain chloride ion and has corrosion on reinforced concrete and strong adaptability, and can applied for various specs of cements, and has stable performance and no delamination and sedimentation for long-term storage, and no crystallization in winter; the product has no toxicity and pollution, and no formaldehydel and is safe for environment. The invention also discloses a preparation method of the polycarboxylate type water reducer.

Owner:SICHUAN NORMAL UNIVERSITY

Carboxylate water reducing agent and preparation method thereof

ActiveCN103396031AExcellent and stable productionExcellent and stable production processHigh strength concreteSide chain

The invention discloses a polycarboxylate water reducing agent, which is a water reducing agent containing side chains of carboxy, sulfo and polyoxyethylene and prepared from monomers such as allyl polyether, acrylic acid and / or derivatives thereof, sodium methallyl sulfonate and aliphatic mercapto acid through polymerization reaction of free radicals and neutralization under an H2O2-Vc oxidation-reduction initiating system. The polycarboxylate water reducing agent is low in alkali content, high in water reducing rate and labor-saving in concrete operation; a cement mixture has high flowability, high slump loss resistance and good workability; and the polycarboxylate water reducing agent serving as an important component of high-performance concrete can be widely applied to premixed and cast-in-place concrete of various industrial and civil buildings, and particularly, has excellent performance in high-strength concrete.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH +1

Universal polycarboxylic acid water reducing agent and preparation method thereof

ActiveCN102992682AConstant reaction temperatureThe feeding procedure is simpleSide chainMethyl group

The invention relates to a universal polycarboxylic acid water reducing agent and a preparation method thereof. The universal polycarboxylic acid water reducing agent is of a liquid state and has the solid content of 40%. The universal polycarboxylic acid water reducing agent is the water reducing agent which is prepared from monomers such as allyl polyether, and maleic anhydride, (meth)acrylic acid or itaconic acid, methyl acrylate and sodium methallyl sulfonate through polymerization under the effects of a molecular weight chain initiator and a chain transfer agent and neutralization; and the water reducing agent contains carboxyl, sulfonic group and an allyl polyether side chain. The universal polycarboxylic acid water reducing agent disclosed by the invention is low in alkali content, high in water-reducing rate, labor-saving in concrete operation, simple in production process, easy in reaction condition control and free of environmental pollution; the cement mixture has high mobility and slump keeping property, and good peaceability; and the universal polycarboxylic acid water reducing agent disclosed by the invention can be used as an important component of high-performance concrete, and can be widely applied to stirred and cast-in-place concrete and ready-mixed concrete for various industrial and civil buildings.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH +1

High-performance polycarboxylate superplasticizer synthetized by low temperature method, and preparation method thereof

The invention relates to a high-performance polycarboxylate superplasticizer synthetized by a low temperature method, and a preparation method thereof. The high-performance polycarboxylate superplasticizer is in a liquid state; the solid content of the high-performance polycarboxylate superplasticizer is 40%; the high-performance polycarboxylate superplasticizer is the polycarboxylate superplasticizer which contains a sulfo group, an ester group, carboxyl, and a methyl allyl polyethenoxy ether side chain and is prepared from methyl allyl polyethenoxy ether, and monomers such as acrylic acid, dimethyl maleic anhydride and sodium methallyl sulfonate by sequentially carrying out polymerization and neutralization under the effects of a molecular chain initiator and a chain transfer agent. The high-performance polycarboxylate superplasticizer disclosed by the invention is low in alkali content, high in water-reducing rate and simple in production technology, and reaction conditions are easy to control; normal-temperature production, and energy conservation and consumption reduction are achieved; the environmental pollution is not generated.

Owner:湖南加美乐素新材料股份有限公司

Polyurethane reaction ball and preparing method thereof

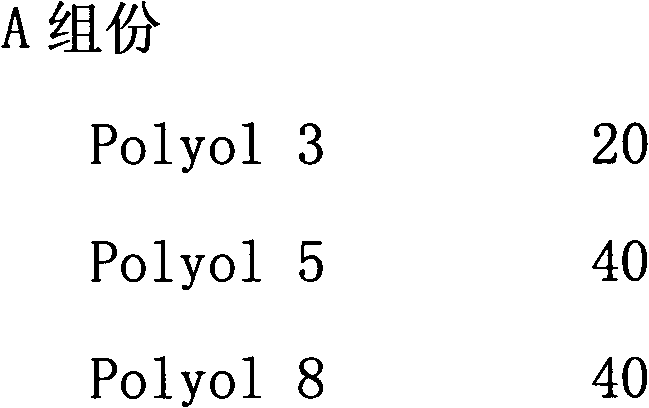

The invention discloses a polyurethane reaction ball which is a microcellular polyurethane elastomer prepared through raw materials including polymer component A and prepolymer component B. The invention further discloses a method for preparing the reaction ball, which includes: mixing and stirring polyether polyols, foaming agents, chain extenders, color paste and catalysts to obtain the polymer component A; and evenly mixing and stirring the polymer component A and the prepolymer component B according to a certain proportion at temperature of 5-32 DEG C, and pouring the mixture into a reaction ball mold for aging to obtain the polyurethane reaction ball. The foam density of the reaction ball is 100-600kg / m<3>, hardness of the reaction ball is Shore A40+ / -10, free-falling resilience can reach 80-90%, and property requirements of high-level reaction balls are met. In addition, the polyurethane reaction ball and the preparing method thereof have good technology processing characteristics, spalling during contraction and mold opening is avoided, and product defective percentage is reduced.

Owner:WANHUA CHEM BEIJING +2

Table rose sauce and preparation method thereof

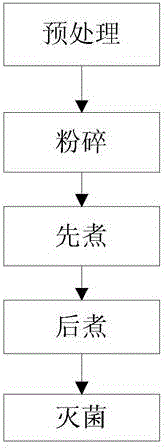

ActiveCN104055060ASmooth tasteRetain colorFood ingredient functionsFood preparationBiotechnologyGlucose-Fructose Syrup

The invention relates to table rose sauce and a preparation method thereof. The preparation method comprises the following steps: performing superfine grinding on edible rose petals to obtain rose powder; mixing the rose powder, glucose syrup, white granulated sugar and purified water, adjusting the pH value to be 1.8-2.2 by using citric acid to obtain a mixed solution, and heating the mixed solution to obtain a rose solution with sugar content of not less than 50%; adding pectin and salt into the rose solution, and boiling to obtain rose sauce; sterilizing the rose sauce in a water bath with temperature of 80-85 DEG C to obtain a finished product of rose sauce. According to the preparation method, the technical problems of instable quality and poor sensory quality of rose sauce in the prior art are solved, and the table rose sauce is stable in quality, bright in color, fragrant in smell, comfortable in mouth feel and wide in application range.

Owner:HUNAN AGRI PRODS PROCESSING INST

Preparation method of ultra-low hydration heat polycarboxylate-based water reducing agent

InactiveCN101284717AHigh compressive strengthImprove appearance qualityPolymer scienceThermal insulation

The invention relates to a method for preparing an ultra-low hydration-heat polycarboxylate-based water reducing agent. Methacrylic acid and Monomer methylacrylic acid polyethylene glycol single armor ether ester (MAAMPEA) water solution, initiator and modifier solution are simultaneously and slowly added into the solvent water drop by drop within 6 to 7 hours at the temperature of 80 DEG C to 90 DEG C, then the solvent water is subjected to thermal insulation for 4 to 5 hours at 90 DEG C to 95 DEG C and is naturally cooled down to the room temperature, and finally NaOH is used to adjust the pH value to 7 to 8, thereby obtaining the ultra-low hydration-heat polycarboxylate-based water reducing agent. The reaction conditions are easily controlled, no organic solvent is used during the polymerization process, and the process is simple with no industrial pollution. The concrete prepared by adopting the ultra-low hydration-heat polycarboxylate-based water reducing agent has the advantages as follows: when the mixing amount of the water reducing agent with the concentration being 25 wt percent is 1.0% of the concrete weight, the water reducing ratio can reach 30 percent, the 3d compressive strength of the concrete can be improved by more than 60 percent, the 28d compressive strength can be improved by more than 50 percent, and the 90d compressive strength can be improved by 30 percent.

Owner:WUHAN UNIV OF TECH

Polyether ester polyurethane, method for preparing same and application of polyether ester polyurethane

The invention belongs to the technical field of polyurethane synthesis, and discloses polyether ester polyurethane, a method for preparing the same and application of the polyether ester polyurethane.The method includes adding initiators and catalysts I into 1,5-di-oxacycloheptane-2-ketone to obtain mixtures, carrying out reaction on the mixtures in solvents I at the temperature of 20-60 DEG C and synthesizing poly-1,5-di-oxacycloheptane-2-ketone polyether ester diol; adding the poly-1,5-di-oxacycloheptane-2-ketone polyether ester diol into diisocyanate and solvents II to obtain mixtures, heating the mixtures until the temperatures of the mixtures reach 60-100 DEG C, adding catalysts II into the mixtures, carrying out reaction to obtain prepolymers, then adding chain extenders into the prepolymers, carrying out reaction, and cooling mixed systems until the temperatures of the mixed systems reach the room temperature so as to obtain the polyether ester polyurethane. The1,5-di-oxacycloheptane-2-ketone is used as a monomer for the polyether ester polyurethane. The polyether ester polyurethane, the method and the application have the advantages that the polyether ester polyurethane isgood in biocompatibility, is amorphous and can be used for degrading polyurethane elastomers, and the degradation rate can be controlled.

Owner:GUANGDONG UNIV OF TECH

Production technology of polycarboxylate superplasticizer

A production technology of a polycarboxylate superplasticizer comprises the following steps: weighing the following components at weight ratio according to the technological process: 2500-2800 parts of methyl acrylic polyether (VPEG-2400), 120-150 parts of acrylic acid, 450-550 parts of hydroxyethyl acrylate, 3-8 parts of vitamin C, 15-25 parts of 3-mercaptopropionic acid, 15-25 parts of hydrogen peroxide with the volume concentration of 27.5% and 2750-3440 parts of deionized water. The raw materials of the polycarboxylate superplasticizer are rich in source, easy to acquire and relatively low in cost, the manufacturing technology is simple, the production conditions are mild, during production, no hazardous materials is emitted and lots of by-products cannot be produced, and the requirements for energy saving and environmental protection are satisfied. Besides, the produced polycarboxylate superplasticizer not containing chloride ions is non-corrosive to steel bars, high in adaptability, suitable for cement of various specifications and models, stable in performance, free from layering and sedimentation after being stored for a long time, crystallization-free in winter, nontoxic and pollution-free, and safe to the environment.

Owner:HUBEI TENGCHEN TECH CO LTD

High-efficiency water reducing agent with good compatibility and preparation method of water reducing agent

The invention relates to a high-efficiency water reducing agent with good compatibility. A preparation method of the high-efficiency water reducing agent includes the steps: 1) in parts by weight, mixing 40-50 parts of sulfonation agents, 0-50 parts of liquid caustic soda and 150-180 parts of water to dissolve, then adding 50-60 parts of acetone, uniformly mixing the raw materials, and adding 15-150 parts of modifying agents to perform sulfonation reaction; 2) continuously dropping 135-165 parts of formaldehyde into an obtained solution system after sulfonation is finished, keeping the temperature of 95-98 DEG C after the formaldehyde is completely dropped to perform condensation reaction to obtain the high-efficiency water reducing agent with good compatibility. The high-efficiency water reducing agent with good compatibility has the advantages that the water reducing agent is low in mixing amount, high in water reducing rate and stable in product performance, and the high-efficiency water reducing agent can be compounded with traditional polycondensation-type high-efficiency water reducing agents such as naphthalene series and aliphatic series and high-performance water-reducing agents such as polycarboxylic acid.

Owner:WUHAN UNIV OF TECH +1

Suckercide and application thereof in Chinese tamarisk bonsai cultivation

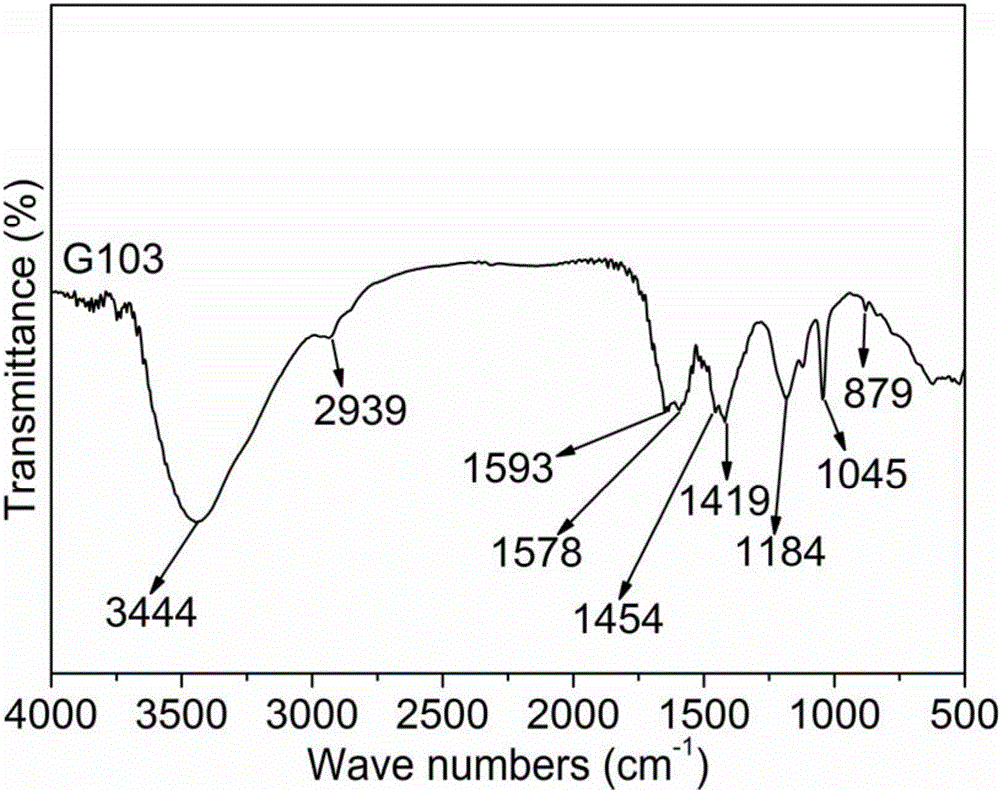

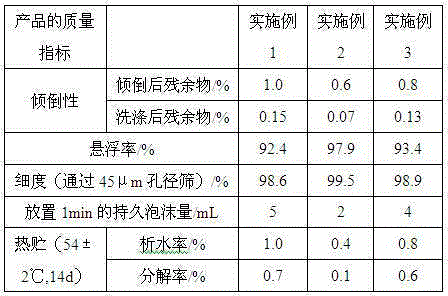

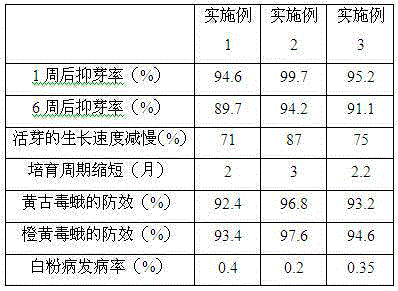

InactiveCN105145656AGood dumpingGood heat storage stabilityBiocidePlant growth regulatorsMenthoneEugenol

The invention provides a suckercide which comprises napropamide, metolachlor, red clover extract, eugenol, chavicol, cinnamyl aldehyde, l-menthone, alpha-cedrene, salicylic acid and 2-chloro-N,N,N-trimethylethanaminium chloride. The invention further provides application of the suckercide in Chinese tamarisk bonsai cultivation. The suckercide has the advantages that the suckercide is suspoemulsion and good in pourability, and the suspension rate of the effective constituents of the suckercide is 92.4-97.9%; particles capable of passing a sieve with meshes of 45 micrometers account for 98.6-99.5% of the suckercide; the lasting foam amount of the suckercide is 2-5mL after the suckercide stands for 1 minute; the suckercide is good in heat storage stability and low temperature stability; the suckercide is good in bud inhibiting effect when being applied to the Chinese tamarisk bonsai cultivation, and bud inhibiting rate reaches 94.6-99.7% one week after the suckercide is used.

Owner:WEIFANG YOURONG IND

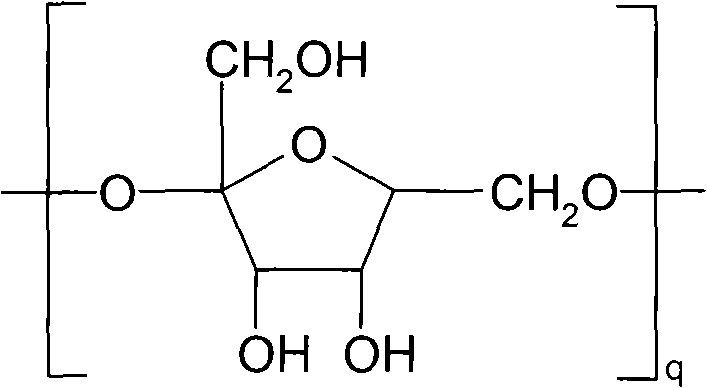

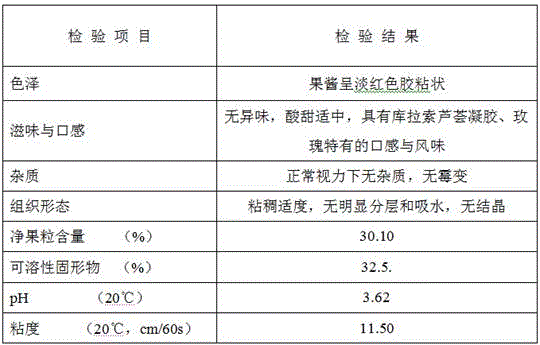

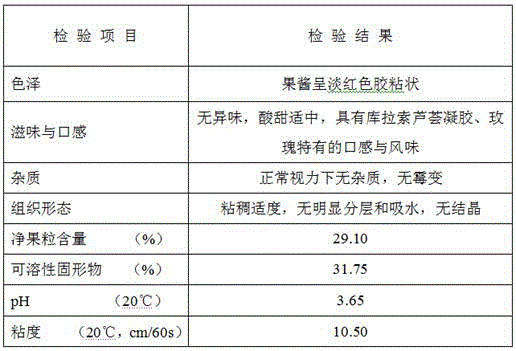

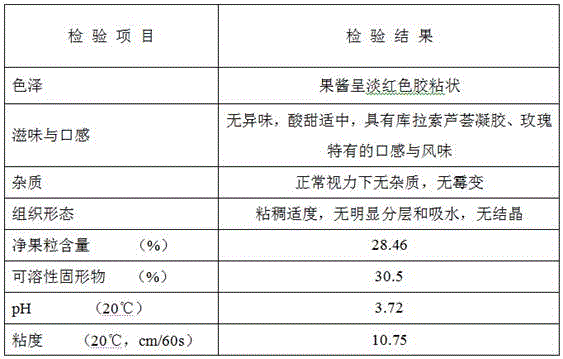

Aloe gel rose jam preparation method

The invention discloses an aloe gel rose jam preparation method, which comprises the following steps that aloe is peeled, the obtained aloe pulp is cut into diced aloe pulp, and the diced aloe pulp is placed into water for boiling, drained and screened to obtain aloe particles; petals of edible rose flowers are cleaned after screening and removing impurities, and then are shredded or sliced to obtain treated petals; and the treated petals, sugar and thickener are added into the aloe particles for uniformly mixing, and then conventional sterilization is carried out to obtain the aloe gel rose jam. The flavor and the taste of the aloe jam prepared by adding the edible rose flowers are greatly changed, and the special plant flavor of the aloe is covered by the strong rose fragrance, so that the product is more popular with the public. The aloe gel rose jam is in the form of a light red glue, free from extraneous odor, moderate in sour and sweet, free of obvious layering and water absorption, and free of crystallization; the aloe gel rose jam has specific taste and flavor of aloe vera gel and rose; the color is attractive; the color and the taste are not liable to change; and the shelf life is long.

Owner:云南万绿生物股份有限公司

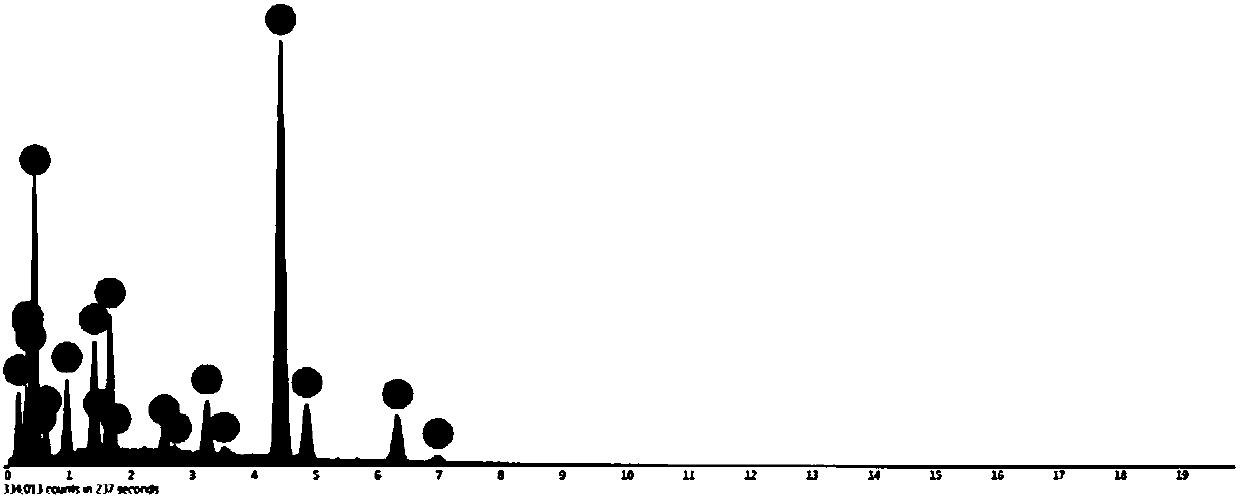

Production method of water-soluble ammonium polyphosphate liquid

InactiveCN107892287AShort production processLess investmentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphoric acidWater soluble

The invention discloses a production method of a water-soluble ammonium polyphosphate liquid. The method comprises the following steps: taking industrial phosphoric acid, liquid ammonia and gas ammonia as raw materials, preparing a high-temperature molten material through a tubular neutralization polycondensation reaction and a polymerization-kettle further neutralization condensation polymerization, and then carrying out cooling in a water-soluble ammonium polyphosphate water agent preparation tank with a cooling jacket for preparing the ammonium polyphosphate liquid. A water-soluble ammoniumpolyphosphate solid does not need to be prepared firstly, and the water-soluble ammonium polyphosphate water agent can be directly produced on a device. The production process is short, the equipmentinvestment is small, the production operation is simple and convenient, the product quality is good, and the production cost is low.

Owner:SHIFANG CHANGFENG CHEM CO LTD

Method for preparing modified lignin poly-carboxylic-acid cement dispersant

This invention relates to preparation method of modified lignin poly carboxylic acid cement dispersant, belongs to concrete admixture. The process: whip amd heating-up lignin sulfonate to 50 to 80 deg, in turns add sodium dichromate 5 to 9 shares, polyvinyl alcohol 10 to 20 shares, acroleic acid 5 to 18 shares, initiator 0.1 to 3 shares, at temperature 80 to 100 deg, take reaction for 3 to 5 hours, gain modified lignin sulphonate water solution. The product brings the cement good consistency, not bleed air, without bleeding, good degree of fluidity and good flexibility.

Owner:武汉海德天物新材料有限公司

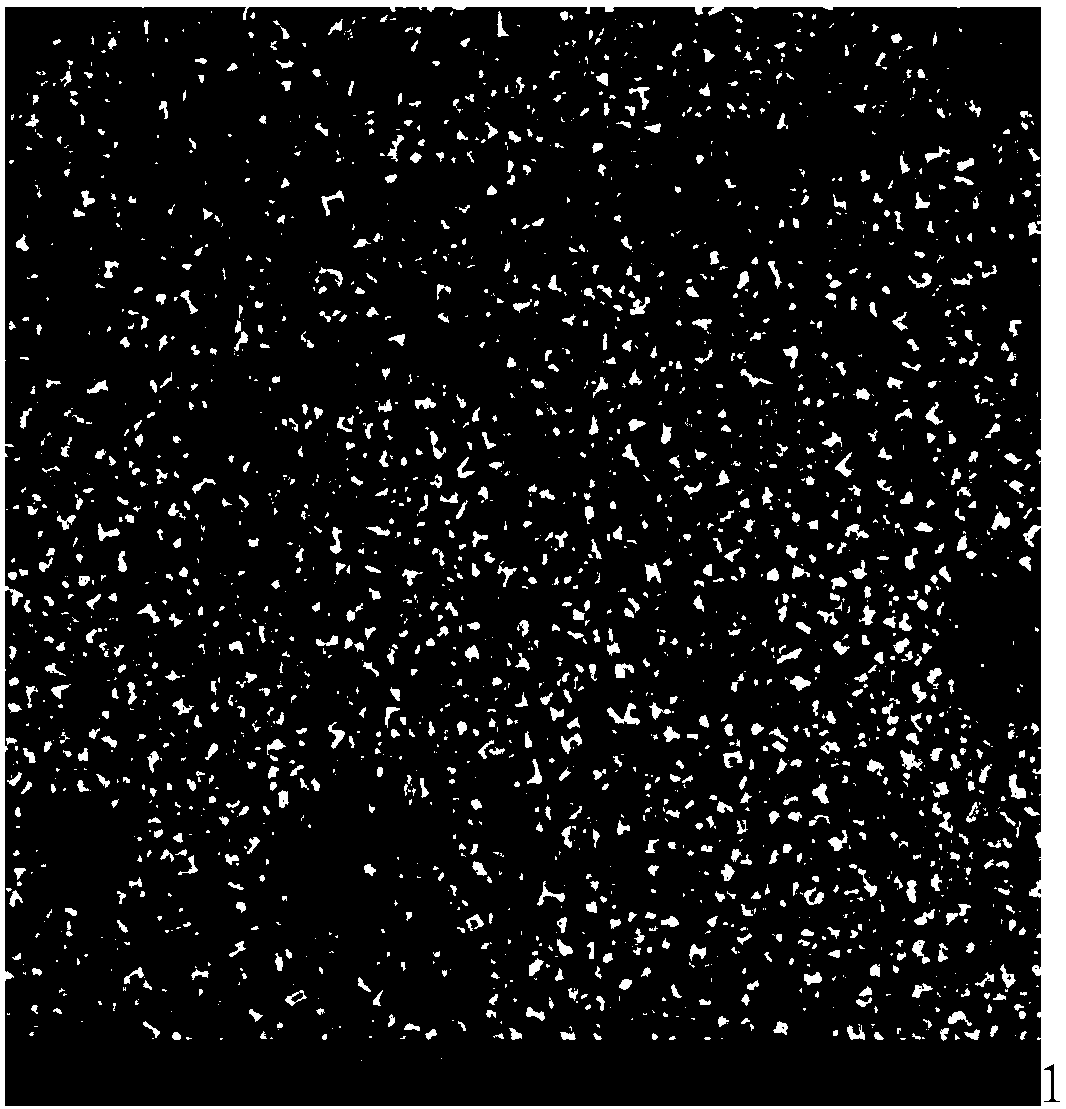

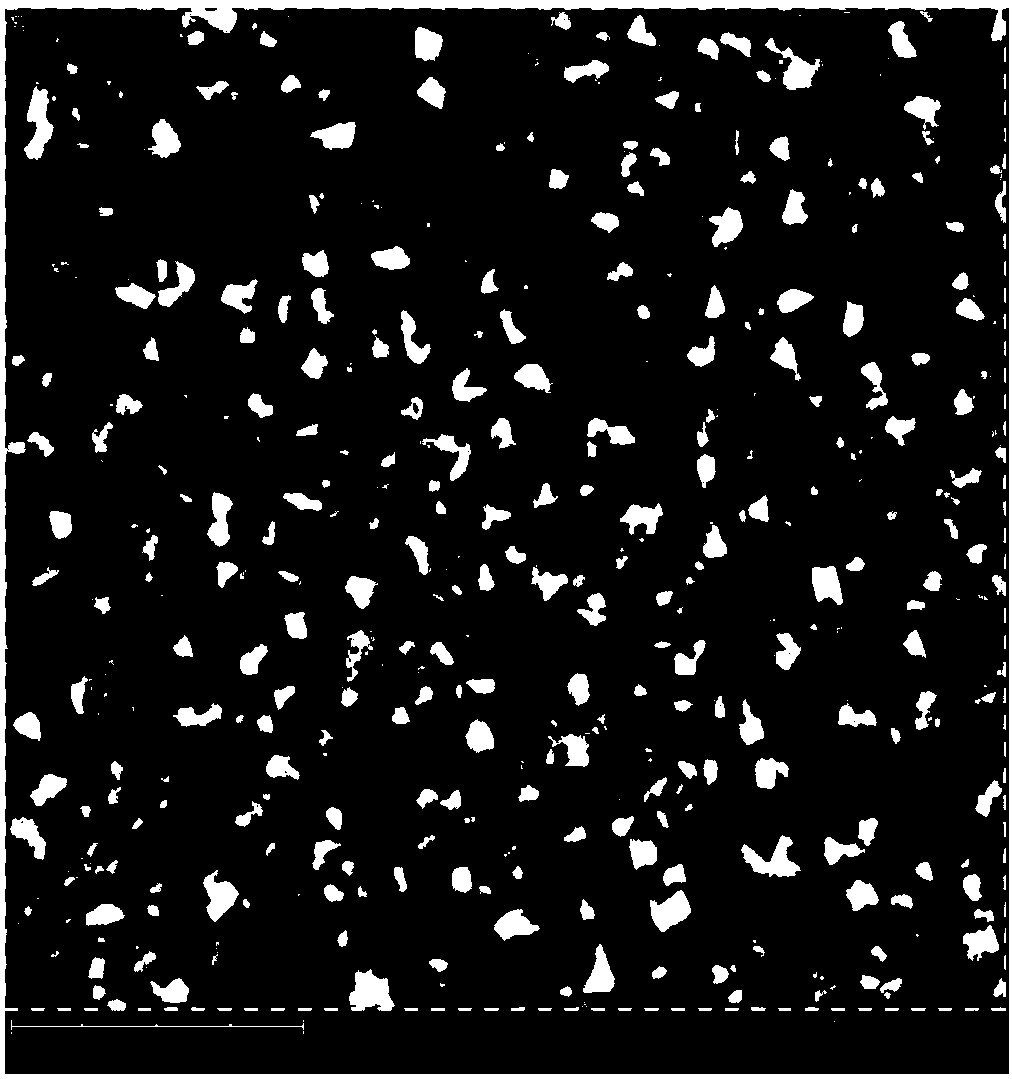

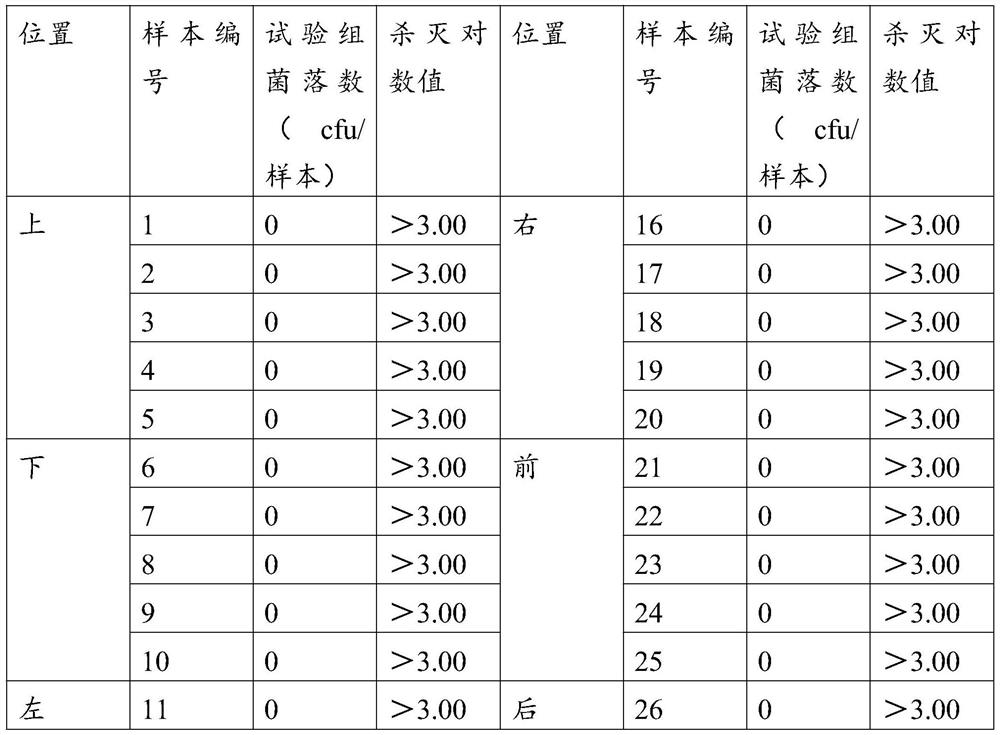

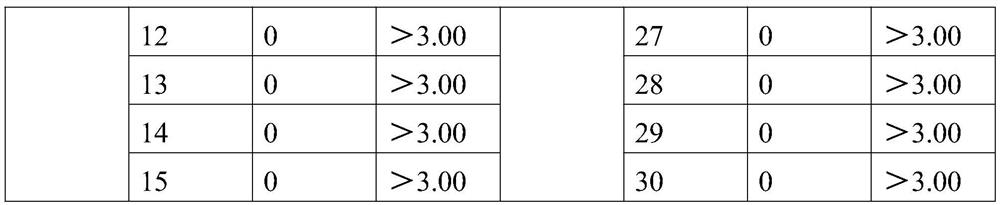

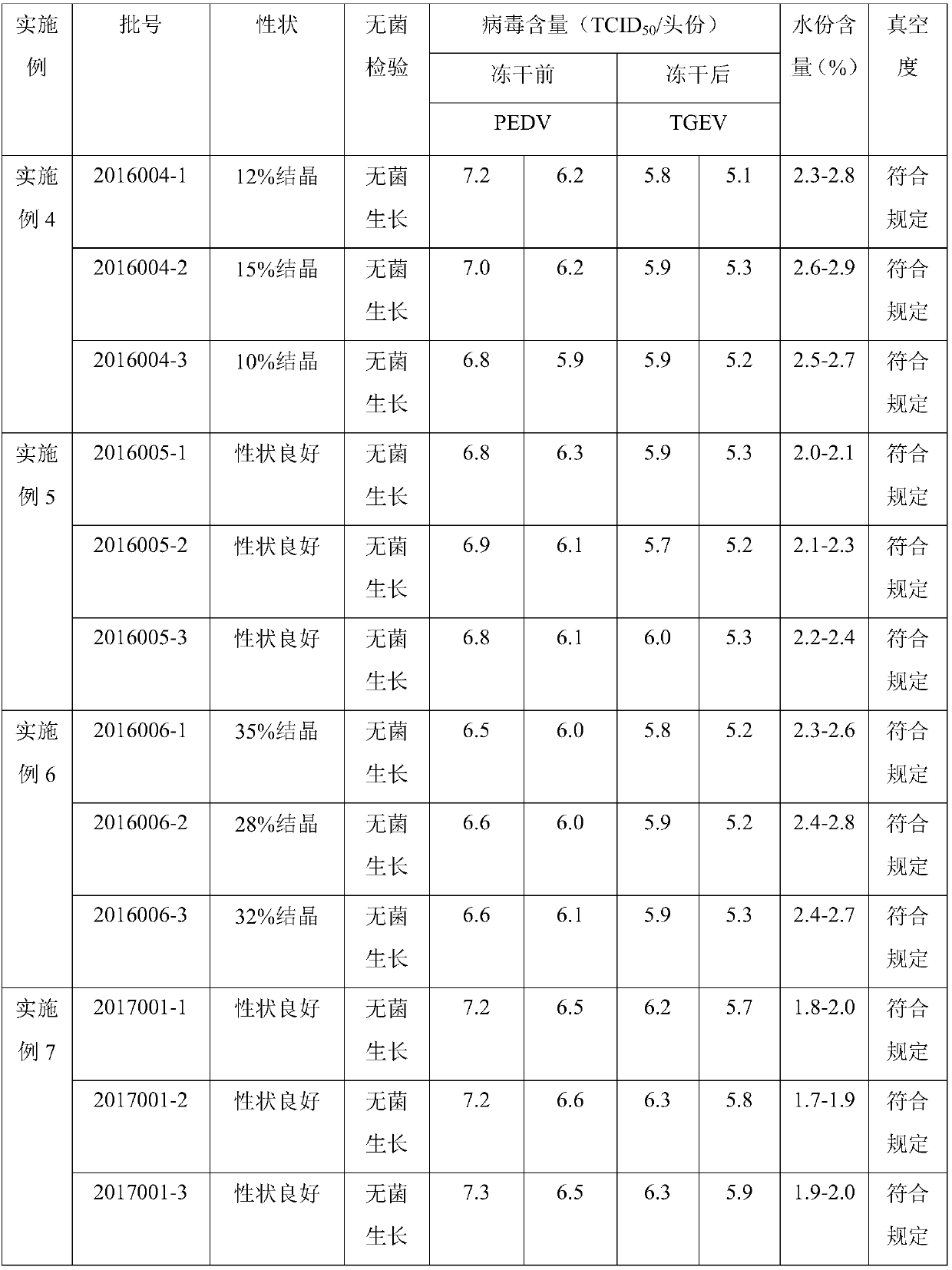

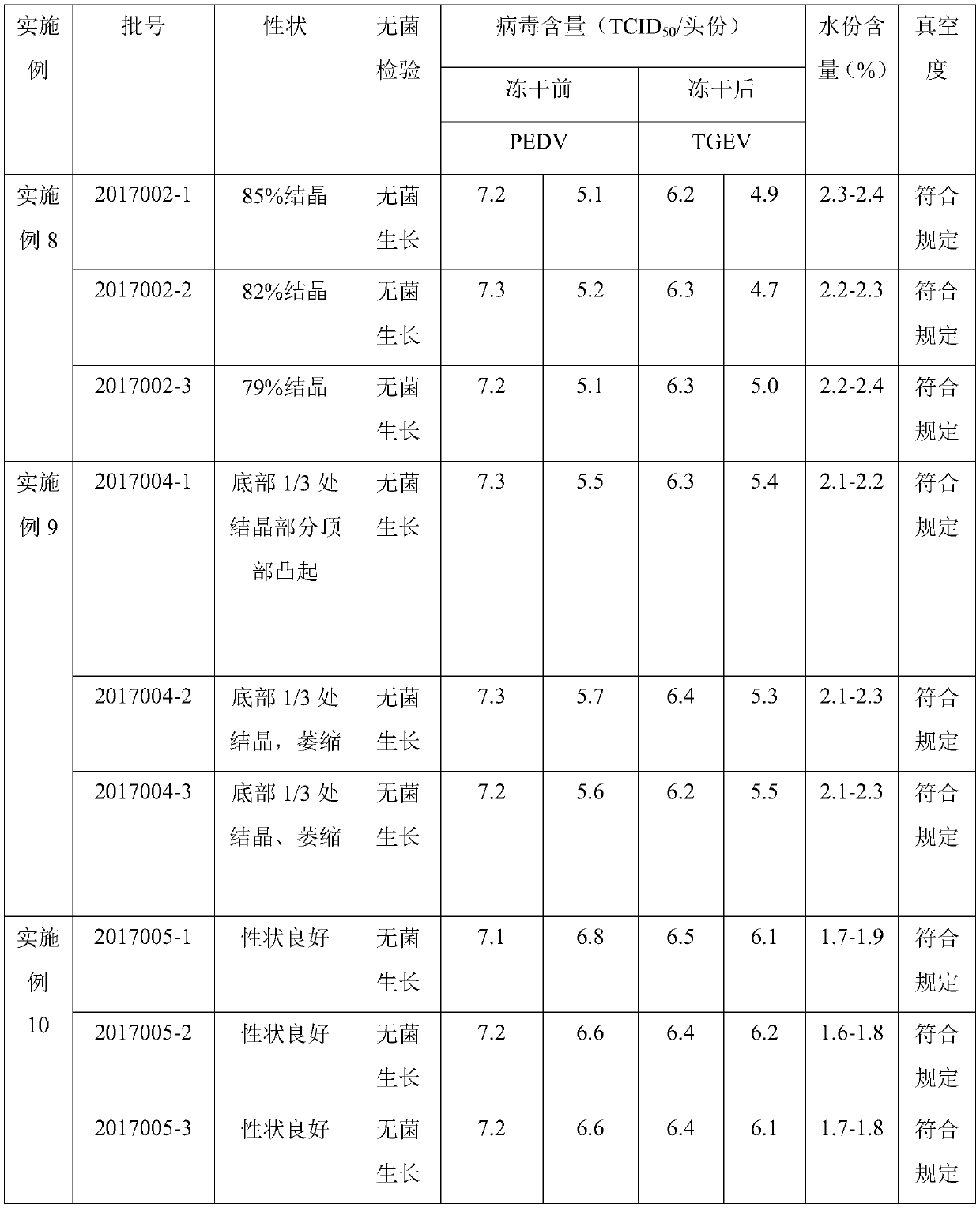

Freezing-drying method for live vaccine

ActiveCN107543373ANo crystalAvoid large ice crystalsDrying solid materials without heatAntiviralsFreeze-dryingVacuum sublimation

The invention discloses a freezing-drying method for live vaccine. The freezing-drying method comprises the steps that the eutectic point range of a to-be-frozen and to-be-dried vaccine is tested, then, the live vaccine is placed in a vacuum freezing-drying machine pre-cooled to 0+ / -1 DEG C, when the temperature of a plate layer of the vacuum freezing-drying machine is reduced to be higher than the eutectic point of the live vaccine by 1-2 DEG C, the current state is kept for 1-2 h, and continuous cooling is conducted with the rate of 1 DEG C / h till all vaccine is frozen; and cooling is immediately conducted to the temperature needed for sublimation, and finally vacuum sublimation is conducted according to the normal procedure. The product obtained through the method is not provided with large ice crystals, sublimation is easy, and after freezing-drying, a good product physical behavior can be obtained, and the freezing-drying titer losses are minimal.

Owner:SICHUAN HUAPAI BIO PHARMA

Method for preparing corrosion prevention coating with titanium in blast furnace slag

The invention provides a method for preparing a titanium layer on the surface of low-carbon steel with a fused salt electrodeposition method by using titanium in blast furnace slag. Fused salt compositions adopted in the method include NaCl, KCl, NaF and titanium-containing blast furnace slag. The invention further provides a preparation method of corrosion prevention steel. The preparation methodincludes the following steps that the fused salt electrodeposition method is used for depositing the titanium layer on the steel surface; and fused salt compositions adopted in the fused salt electrodeposition method include NaCl, KCl, NaF and titanium-containing blast furnace slag. According to the method, the titanium-containing blast furnace slag, the NaCl, the KCl and the NaF are used as a fused salt system; and when the fused salt electrodeposition method is used for preparing the titanium deposition layer, titanium ions can better exist in the fused salt system in a low-valent oxidationstate, no disproportionated reaction happens in the fused salt electrodeposition process, and therefore the quality of the titanium deposition layer can be improved, and dendritic or powdered crystals can be basically avoided. The fused salt electrodeposition method is used for preparing the titanium corrosion prevention coating, and thus the corrosion resistance of a steel substrate can be improved obviously.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

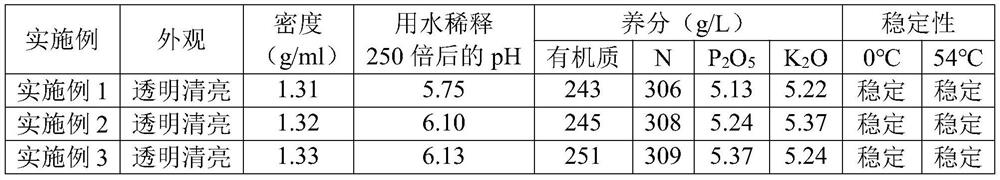

Clear liquid type organic high nitrogen fertilizer and preparation method thereof

InactiveCN113387750AEasy to buyFull of nutritionAmmonium salt fertilisersLiquid fertilisersOrganic acidO-Phosphoric Acid

The invention belongs to the field of liquid fertilizers, and particularly relates to a clear liquid type organic high nitrogen fertilizer comprising the raw materials in parts by weight: 11 to 16.5 parts of pure water, 26.5 to 27.5 parts of urea, 33.5 to 35.5 parts of ammonium nitrate, 0.5 to 0.65 part of organic acid, 0.5 to 0.65 part of 85% phosphoric acid, 22 to 24 parts of polymeric alcohol and 0.5 to 0.7 part of potassium hydroxide. The invention also discloses a preparation method of the high nitrogen fertilizer, wherein the preparation method comprises the following steps: (1) adding pure water into a reaction kettle, starting a stirrer, slowly adding the potassium hydroxide and the organic acid, and stirring until the potassium hydroxide and the organic acid react completely; (2) adding the urea and the polymeric alcohol into the reaction kettle, stirring, then adding the ammonium nitrate, and continuously stirring until no visible substance appears; (3) adding 85% phosphoric acid into the reaction kettle, turning on heating equipment of the reaction kettle, and stirring until the reaction is complete and the solution system is stable; and (4) standing the materials in the reaction kettle to normal temperature, filtering, and carrying out sampling inspection. The clear liquid type organic high nitrogen fertilizer is prepared in a chemical reaction and physical mixing mode, and the product is comprehensive in nutrient, stable in character and remarkable in fertilizer efficiency.

Owner:郑州郑氏化工产品有限公司

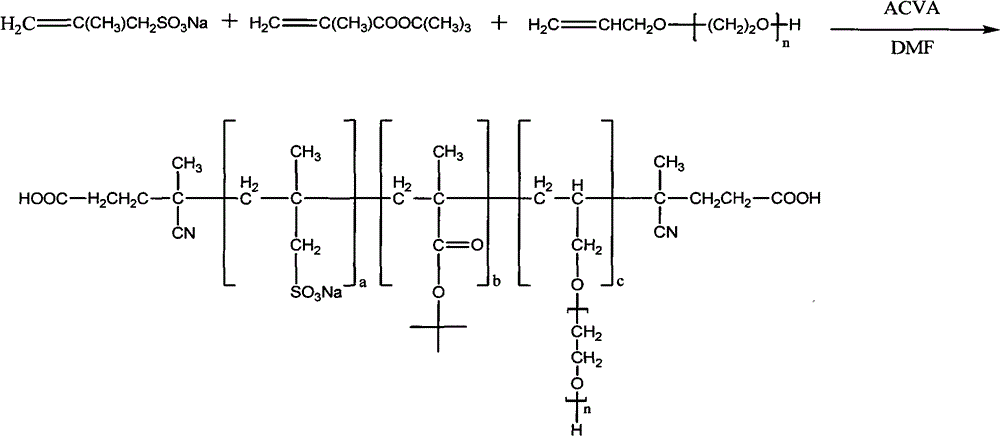

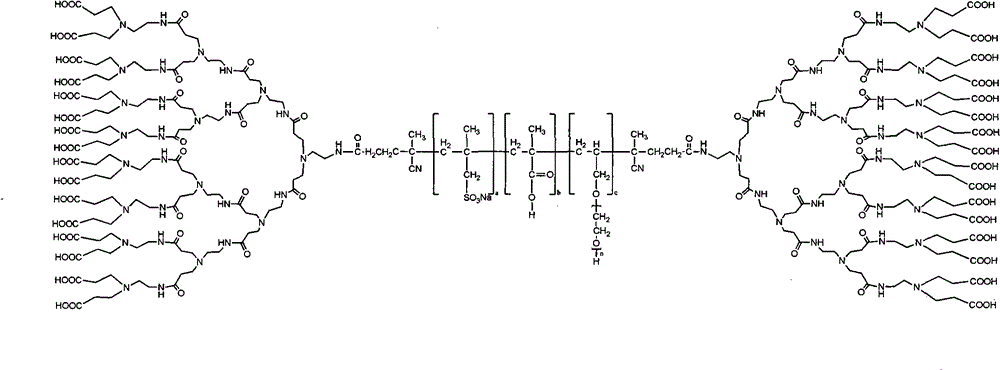

Hyper-branched polycarboxylate high-efficiency water reducing agent and preparation method thereof

The invention relates to a hyper-branched polycarboxylate high-efficiency water reducing agent and a preparation method thereof. The water reducing agent is prepared by polymerizing one of tert-butyl acrylate and methyl tert-butyl acrylate with sodium methyl-acryl sulfonate and allyl polyethenoxy ether to form a copolymer main chain, and then performing condensation polymerization on one of acrylic acid and methacrylic acid with ethylene diamine to form a hyper-branched polyamide structure which is grafted to two ends of the main chain. The preparation method comprises the following steps: (1)preparing the sodium methyl-acryl sulfonate into solution with DMF, and heating the solution in a nitrogen atmosphere; (2) dissolving the other two monomers and an initiating agent into the DMF to prepare mixed solution, and dripping the mixed solution into the step (1) to react for 1 to 20 hours; (3) adding a condensating agent CDI after the reaction and performing condensation reaction by usingN-methyl morpholine as an organic base, the ethylene diamine and the acrylic acid as the monomers and the DMF as a solvent; and (4) performing vacuum distillation to remove the residual monomers andthe solvent, and refluxing for 2 to 5 hours by using methylene chloride solution of trifluoroacetic acid to obtain the water reducing agent. The hyper-branched polycarboxylate water reducing agent hasthe advantages of low admixture, high water reducing rate, small slump loss, good compatibility with cement, no corrosivity to steel bars, strong frost resistance and the like.

Owner:厦门路桥翔通建材科技有限公司 +1

A heat-resistant freeze-drying protectant for pseudorabies live vaccine, preparation method, freeze-dried vaccine and preparation method

ActiveCN107281481BAccelerated sublimationAvoid sublimationViral antigen ingredientsAntiviralsMonosodium glutamateSucrose

The invention provides a heatproof lyoprotectant for a live vaccine against pseudorabies. The heatproof lyoprotectant comprises, by weight, 3 to 10 parts of gelatin, 1 to 5 parts of trehalose, 5 to 15 parts of sucrose, 0.1 to 2 parts bovine serum albumin, 1 to 8 parts of tryptone, 2 to 10 parts of enzyme-hydrolyzed casein, 1 to 5 parts of thiourea, 0.8 to 2 parts of L-monosodium glutamate, 0.1 to 3 parts of arginine, 0.5 to 5 parts of polyvinylpyrrolidone (PVP-K30) and 0.1 to 2 parts of mannitol. The invention also discloses a preparation method of the heatproof lyoprotectant and a lyophilized vaccine prepared from the heatproof lyoprotectant. When the heatproof lyoprotectant is used for protecting the vaccine and a specific lyophilization process is employed, lyophilization loss of viruses can be effectively reduced, the temperature tolerance of the viruses can be improved, and the vaccine can still maintain good physical properties and titer after long-term storage; i.e., the vaccine has stable characters and has the characteristics of heat resistance and long storage time.

Owner:SICHUAN HUAPAI BIO PHARMA

Complete-element chelating highly effective trace fertilizer and method for manufacturing same

ActiveCN101134688BLower EC valuePrevent salinizationFertilizer mixturesTrace elementINCREASED EFFECT

The present invention discloses one series of all-component chelated high efficiency trace element fertilizers containing trace elements essential for crops and its production process. The trace element fertilizers are produced through recipe design, chelation reaction of chelating agent and trace elements, addition of magnesia for pH value regulation and addition of dispersant. The trace elementfertilizers are high quality chemical fertilizers with raised nutrient contents, lowered conductivity, capacity of promoting the absorption of crop, obvious yield increasing effect and other advantages.

Owner:上海永通生态工程股份有限公司

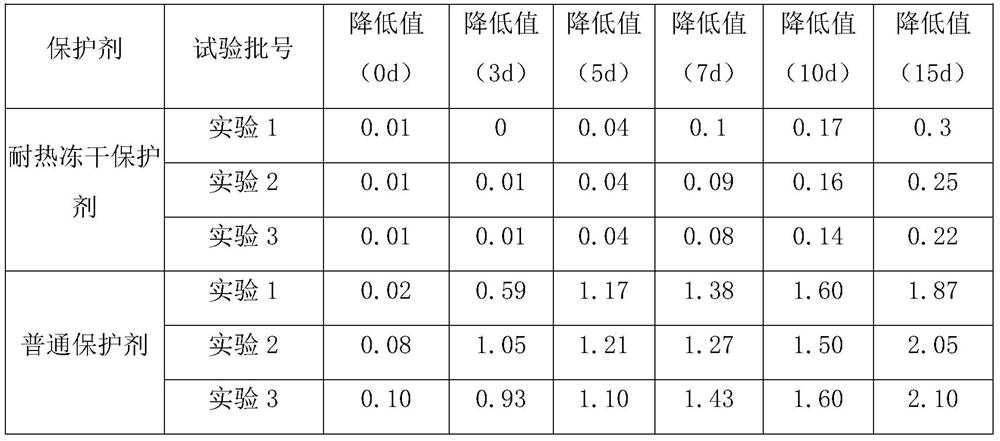

Extraction method of tobramycin

ActiveCN109705174AHigh purityNo crystalSugar derivativesSugar derivatives preparationActivated carbonTobramycin

The present invention provides an extraction method of tobramycin. The extraction method comprises the following steps: (1) pH of a 5'carbamoyl tobramycin fermentation filtrate is adjusted to be 7.0-7.5, a cationic resin is added for absorption, water and ammonia water are used for rinsing, and an ammonia water eluent is collected; (2) the eluent is concentrated; (3) the obtained concentrate is hydrolyzed at an alkaline condition, pH of a hydrolyzate is adjusted to be 5.0-6.0, a cationic resin is used for decolorizing, a decoloring solution is connected, pH is adjusted to be 7.0-7.5, a medium-pressure chromatography self-prepared column equipped with a cationic resin is eluted with the water and ammonia water to collect an ammonia water eluent, then a strong alkaline anion resin is used for decoloring, and a decoloring solution is connected; and (4) the obtained decoloring solution is concentrated and then decolorized with activated carbon, and then spray-drying is conducted to obtaina finished product of the tobramycin. The method simplifies production processes, uses super nanofiltration, combines the medium-pressure chromatography self-prepared column technology, shortens production cycle, is free of solvent crystals and residual solvents, and reduces environmental discharge and treatment pressure.

Owner:NEW FOUNDER HLDG DEV LLC +2

Application of oleic acid alcohol ester surfactant

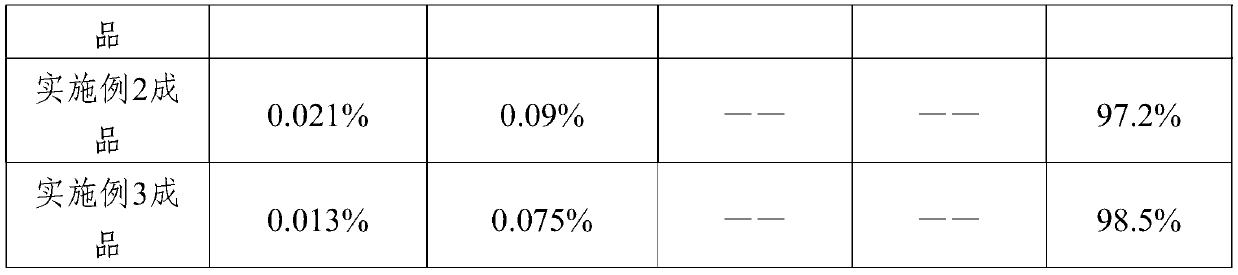

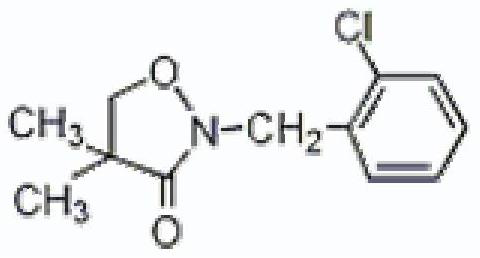

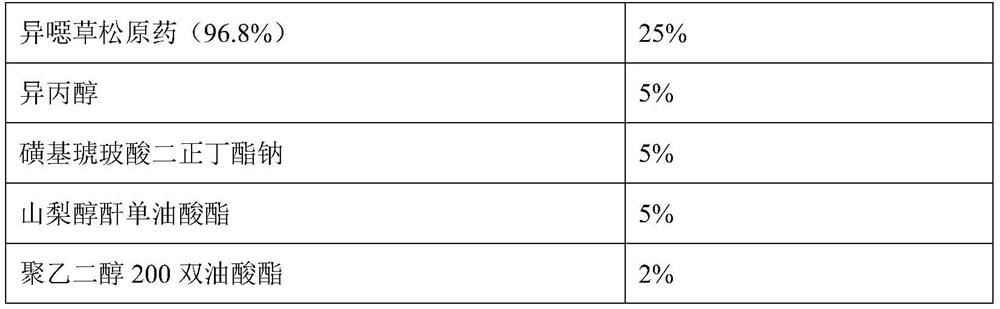

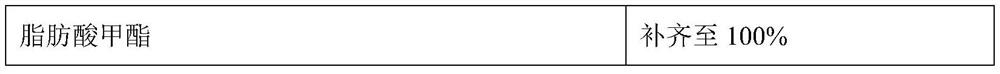

PendingCN113796376AStable physical and chemical propertiesLow temperature crystallizationBiocideSugarcane cultivationWeedActive agent

The invention relates to a herbicide composition, in particular to a herbicide composition taking an oleic acid alcohol ester-containing surfactant as a stabilizer and synergist. The herbicide composition comprises the following components in percentage by weight: 1-95% of an active component, 1-10% of an oleic acid alcohol ester-containing surfactant as a stabilizer and synergist, and the balance of other components, totaling 100%. The active component is a composition of clomazone. The clomazone weeding composition taking the oleic acid alcohol ester-containing surfactant as a stabilizer and synergist has stable physical and chemical properties, is qualified in various detection indexes within the shelf life of the product, and is free of crystallization and caking in 90 days at the temperature of -18 DEG C. A preparation of the weeding composition is mainly used for preventing and controlling annual gramineous weeds and broadleaf weeds in soybean, peanut, sugarcane, rape, potato and rice fields.

Owner:SHENYANG SINOCHEM AGROCHEMICALS R&D CO LTD +1

Disinfection solution used at low temperature of -18 DEG C, and preparation method thereof

PendingCN113729032AImprove filtering effectImprove protectionBiocideDisinfectantsSodium chlorateLiquid state

The invention discloses a disinfection solution used at a low temperature of -18 DEG C, and belongs to the technical field of disinfection solutions. The disinfection solution is specifically prepared from, by weight, 26% of calcium chloride, 1000-2000 ppm of sodium hypochlorite, 0.1% of sodium chloride, 0.0005% of sodium carbonate, and the balance of water. A preparation method of the disinfection solution comprises the following steps: (1) weighing raw materials for later use; (2) dissolving calcium chloride in water, and filtering to obtain a calcium chloride solution; adding a sodium hypochlorite solution into the calcium chloride solution, and dissolving to obtain a mixed solution; and (3) adding sodium carbonate into the mixed solution while stirring, adding a pH regulator to regulate the pH to 11-12 after the sodium carbonate is dissolved, continuously stirring for 15 minutes, and filtering to obtain the disinfection solution used at the low temperature of -18 DEG C. The disinfection solution provided by the invention can be kept in a liquid state at the low temperature of -18 DEG C, is free of precipitation and crystallization, and can effectively kill harmful germs at the low temperature of -18 DEG C.

Owner:山东永上生物科技有限公司

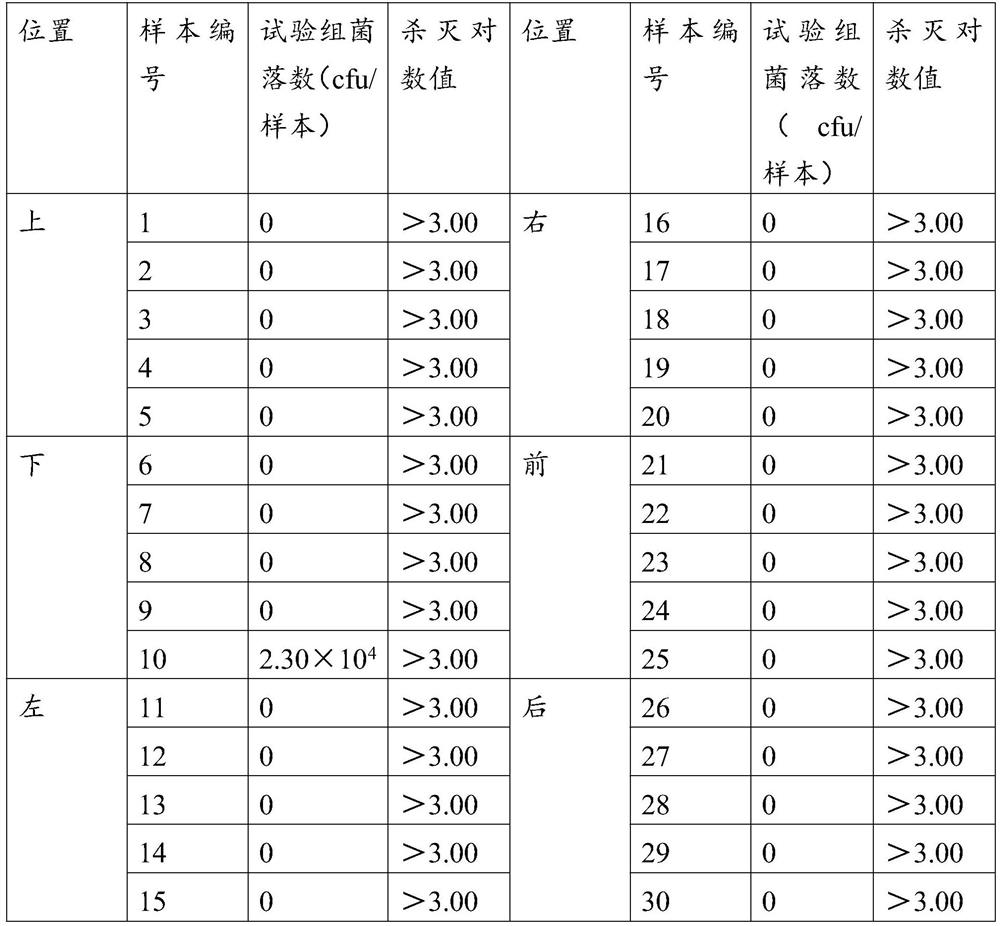

Decomposition resistant ps conductive masterbatch

ActiveCN112111122BExcellent high temperature resistance and physical and mechanical propertiesBroaden the field of applicationAntistatic MaterialsPolycarbonate

The invention discloses a decomposition-resistant PS conductive masterbatch. The decomposition-resistant PS conductive masterbatch includes the following raw materials by weight percentage: 5-10% of superconducting carbon black, 30-60% of high-impact polystyrene, toughened 18 to 30% of antioxidants, 3 to 9% of reinforcing agents, 0.2 to 0.8% of coupling agents, 0.2 to 1.2% of antioxidants, 0.2 to 1.2% of EBS, and 3 to 8% of EMA. In the present invention, superconducting carbon black is used as the conductive carrier, high impact polystyrene PS is used as the base material, and compound toughening agent, reinforcing agent, coupling agent, antioxidant, EBS and EMA are respectively used as lubricants. , dispersant and compatibilizer are compounded according to the appropriate ratio, and the obtained decomposition-resistant PS conductive masterbatch has excellent high temperature resistance and physical and mechanical properties; the decomposition-resistant PS conductive masterbatch can not only be used in polycarbonate and other needs The antistatic materials produced by high temperature co-extrusion can also be used in corresponding conductive and antistatic packaging materials such as electronics, electrical appliances, communications, aerospace, etc., to achieve safe and effective ESD protection for packaged electronic products.

Owner:浙江三和塑料有限公司

A high-efficiency water reducer with good compatibility and its preparation method

The invention relates to a high-efficiency water reducing agent with good compatibility. A preparation method of the high-efficiency water reducing agent includes the steps: 1) in parts by weight, mixing 40-50 parts of sulfonation agents, 0-50 parts of liquid caustic soda and 150-180 parts of water to dissolve, then adding 50-60 parts of acetone, uniformly mixing the raw materials, and adding 15-150 parts of modifying agents to perform sulfonation reaction; 2) continuously dropping 135-165 parts of formaldehyde into an obtained solution system after sulfonation is finished, keeping the temperature of 95-98 DEG C after the formaldehyde is completely dropped to perform condensation reaction to obtain the high-efficiency water reducing agent with good compatibility. The high-efficiency water reducing agent with good compatibility has the advantages that the water reducing agent is low in mixing amount, high in water reducing rate and stable in product performance, and the high-efficiency water reducing agent can be compounded with traditional polycondensation-type high-efficiency water reducing agents such as naphthalene series and aliphatic series and high-performance water-reducing agents such as polycarboxylic acid.

Owner:WUHAN UNIV OF TECH +1

A kind of freeze-drying method of live vaccine

ActiveCN107543373BNo crystalUniform sublimation rateDrying solid materials without heatAntiviralsFreeze-dryingVacuum sublimation

The invention discloses a freezing-drying method for live vaccine. The freezing-drying method comprises the steps that the eutectic point range of a to-be-frozen and to-be-dried vaccine is tested, then, the live vaccine is placed in a vacuum freezing-drying machine pre-cooled to 0+ / -1 DEG C, when the temperature of a plate layer of the vacuum freezing-drying machine is reduced to be higher than the eutectic point of the live vaccine by 1-2 DEG C, the current state is kept for 1-2 h, and continuous cooling is conducted with the rate of 1 DEG C / h till all vaccine is frozen; and cooling is immediately conducted to the temperature needed for sublimation, and finally vacuum sublimation is conducted according to the normal procedure. The product obtained through the method is not provided with large ice crystals, sublimation is easy, and after freezing-drying, a good product physical behavior can be obtained, and the freezing-drying titer losses are minimal.

Owner:SICHUAN HUAPAI BIO PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com