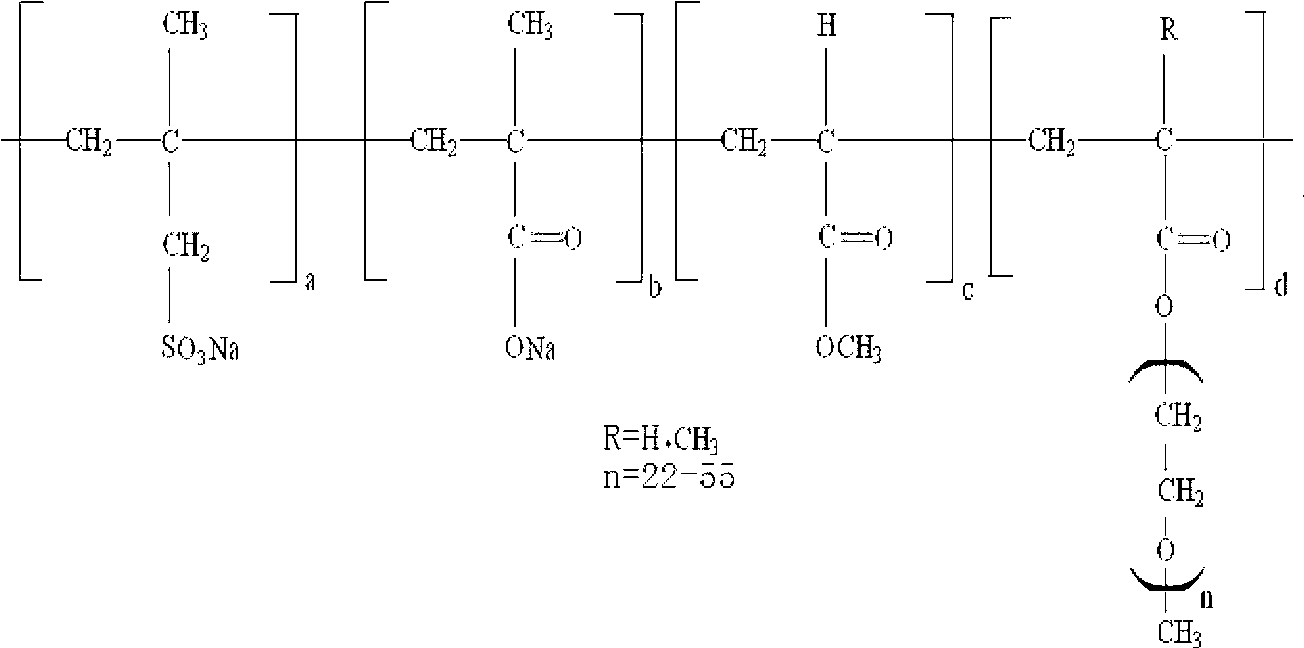

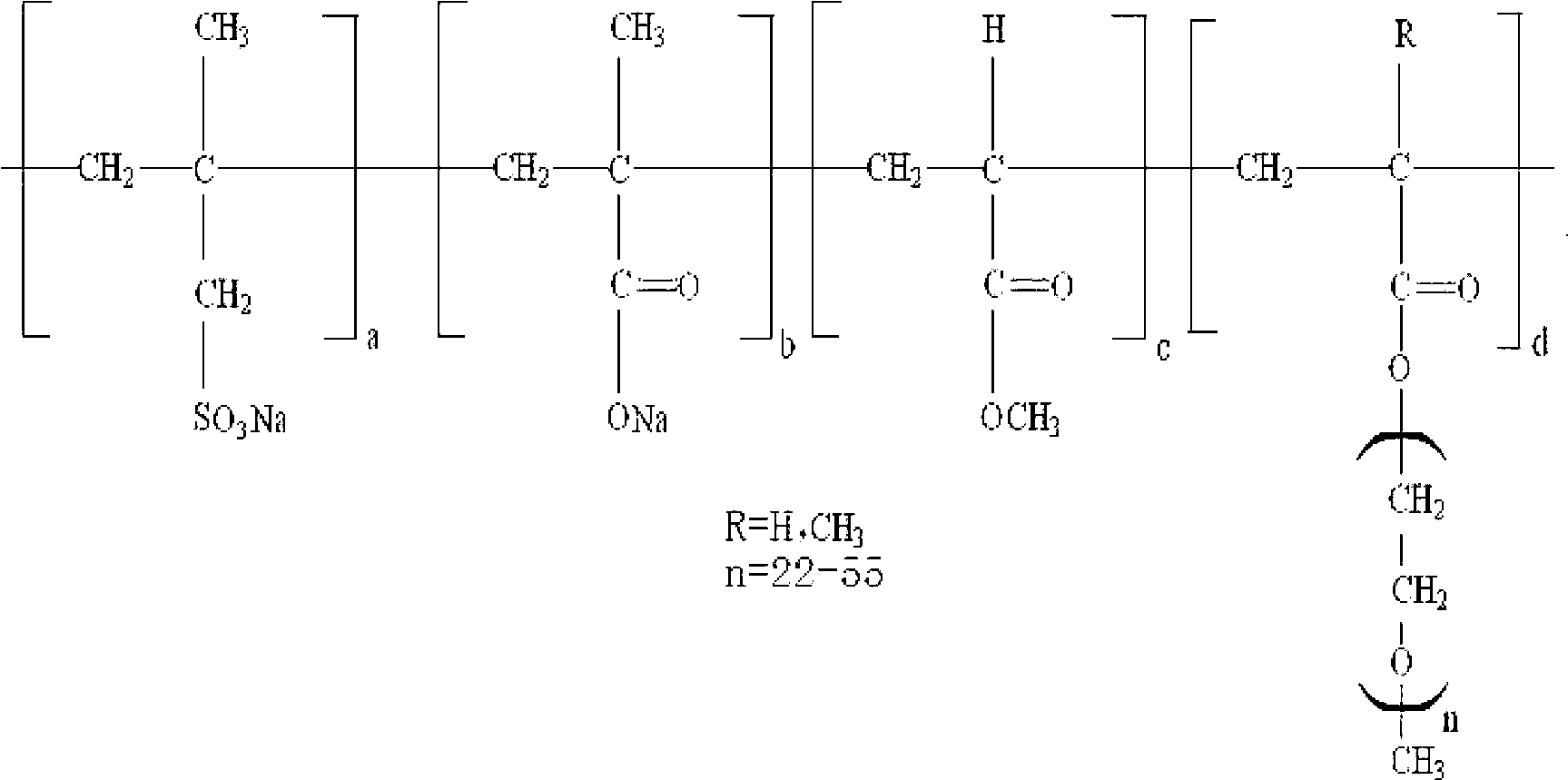

Universal polycarboxylic acid water reducing agent and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of concrete admixture, can solve the problems of poor slump retention and complex production process of water reducing agent, and achieve stable product performance, easy control of reaction conditions, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Optimum matching ratio

[0020] Put 100.00 parts of allyl polyether with a molecular weight of 2000, 15 parts of maleic anhydride and some water into a reaction container, raise the temperature, stir at a temperature of 70±5°C to completely dissolve the reactants, and then drop into the container 10.80 parts of acrylic acid, 4.74 parts of sodium methacrylic sulfonate, 2.13 parts of methyl acrylate and 40 parts of deionized water are solubilized with 24.00 parts of 5% ammonium persulfate solution and 10.00 parts of a 10% solution by mass. Ethanol, control the dropping speed, finish dropping in 100±10 minutes, keep the temperature at 70±5°C, and continue the reaction for 4 hours. After cooling, 2.53 parts of 40% sodium hydroxide solution was added to adjust the pH to 6.5±0.5 to obtain the polycarboxylate high-performance concrete water reducer of the present invention.

Embodiment 2

[0022] Put 100.00 parts of polyoxyethylene ether with a molecular weight of 2000, 15 parts of maleic anhydride and 100.00 parts of water into a reaction container, raise the temperature, stir at a temperature of 70±5°C to completely dissolve the reactants, and then drop into the container 10.80 parts of acrylic acid, 4.74 parts of sodium methacrylic sulfonate, 2.13 parts of methyl acrylate and 52 parts of deionized water were solubilized with 12.00 parts of 5% ammonium persulfate solution and 10.00 parts of 10% by mass solution sulfhydryl Ethanol, control the dropping speed, finish dropping in 100±10 minutes, keep the temperature at 70±5°C, and continue the reaction for 4 hours. After cooling, 2.53 parts of 40% sodium hydroxide solution was added to adjust the pH to 6.5±0.5 to obtain the polycarboxylate high-performance concrete water reducer of the present invention.

Embodiment 3

[0024] Put 100.00 parts of polyoxyethylene ether with a molecular weight of 2000, 15 parts of maleic anhydride and 100.00 parts of water into a reaction container, raise the temperature, stir at a temperature of 80±5°C to completely dissolve the reactants, and then drop into the container 10.80 parts of acrylic acid, 4.74 parts of sodium methacrylic sulfonate, 2.13 parts of methyl acrylate and 47 parts of deionized water are solubilized with 12.00 parts of 5% ammonium persulfate solution and 15.00 parts of 10% by mass solution sulfhydryl Ethanol, control the dropping speed, finish dropping in 100±10 minutes, keep the temperature at 80±5°C, and continue the reaction for 4 hours. After cooling, 2.53 parts of 40% sodium hydroxide solution was added to adjust the pH to 6.5±0.5 to obtain the polycarboxylate high-performance concrete water reducer of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com