Method for preparing modified lignin poly-carboxylic-acid cement dispersant

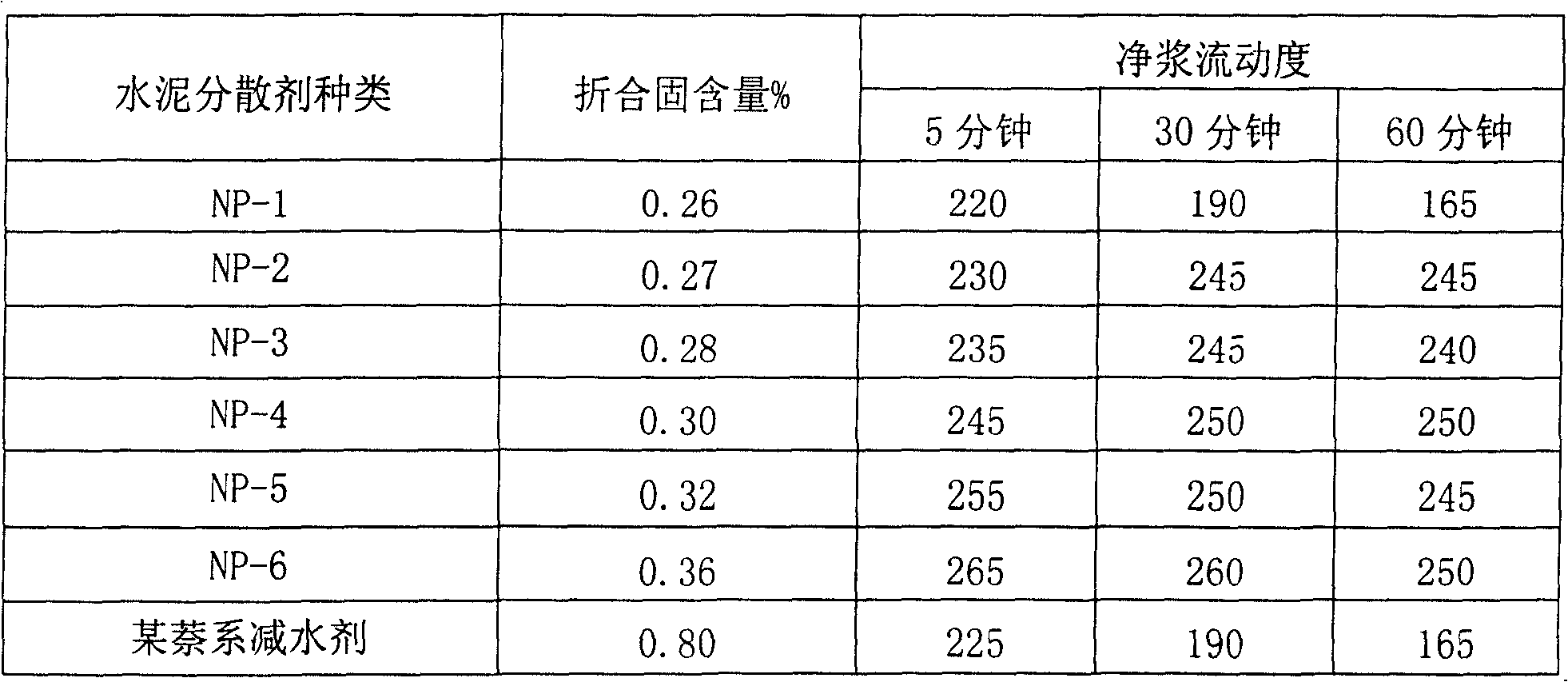

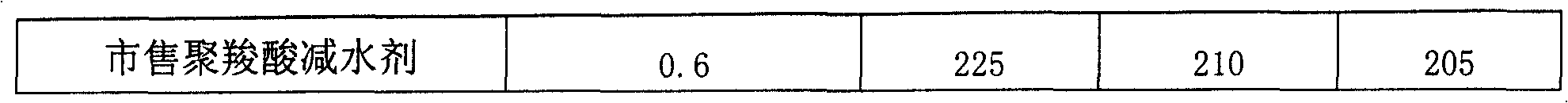

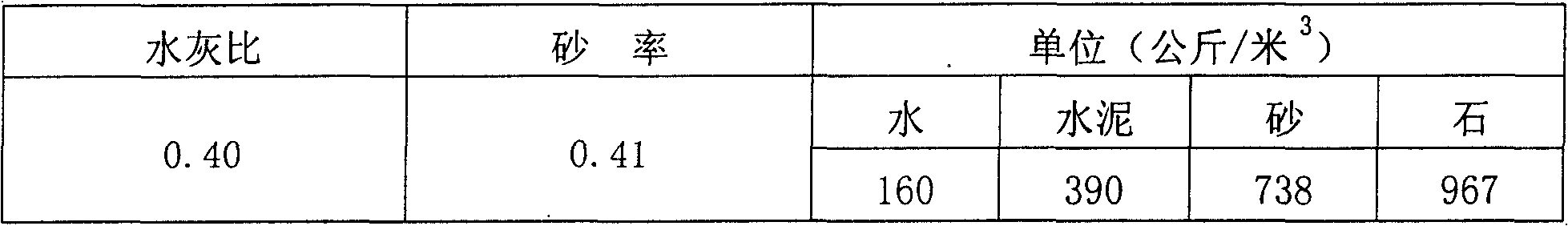

A technology of cement dispersant and plain polycarboxylate, which is applied in the field of preparation of modified lignin polycarboxylate cement dispersant, can solve the problem of rapid hardening of concrete slump loss, and the synthesis process of polycarboxylate water reducer Complicated, poor concrete predictability and other problems, to achieve the effect of good cement adaptability and compatibility, high cost performance, and small slump loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of modified lignin polycarboxylate cement dispersant is characterized in that comprising following weight components and steps:

[0026] A. Take 30-60 parts of lignosulfonate aqueous solution with a solid content of 20-40%, put it into the reaction kettle, stir and heat up to 50-80°C, and then put in 5-9 parts of sodium dichromate and 10 parts of polyvinyl alcohol in turn. -20 parts, 5-18 parts of acrylic acid, 0.1-3 parts of initiator, and react at a temperature of 80-100°C for 3-5 hours to obtain a modified lignosulfonate aqueous solution.

[0027] B. Put 10-35 parts of maleic anhydride, 20-60 parts of hydroxyacrylate, 10-25 parts of styrene and 1-5 parts of peroxide into the reaction kettle, stir and heat up, and react at 80°C-160°C 2-6 hours, obtain polycarboxylate modifier;

[0028] C. Put 200-400 parts of water, 10-40 parts of ammonium persulfate, and 10-18 parts of sulfite into the reaction kettle in sequence, raise the temperature to 40-6...

Embodiment 1

[0031] Take 40 parts of lignosulfonate aqueous solution with a solid content of 20-40%, put it into the reaction kettle, stir and heat up to 60°C, then put in 6 parts of sodium dichromate, 15 parts of polyvinyl alcohol, 10 parts of acrylic acid, persulfate 0.1 part was reacted at a temperature of 90° C. for 4 hours to obtain a modified lignosulfonate aqueous solution.

Embodiment 2

[0033] Take 30 parts of lignosulfonate aqueous solution with a solid content of 20-40%, put it into the reaction kettle, stir and heat up to 60°C, then put in 5 parts of sodium dichromate, 10 parts of polyvinyl alcohol, 5 parts of acrylic acid, persulfate 1 part was reacted at a temperature of 90° C. for 5 hours to obtain a modified lignosulfonate aqueous solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com