Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "No carbon deposits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

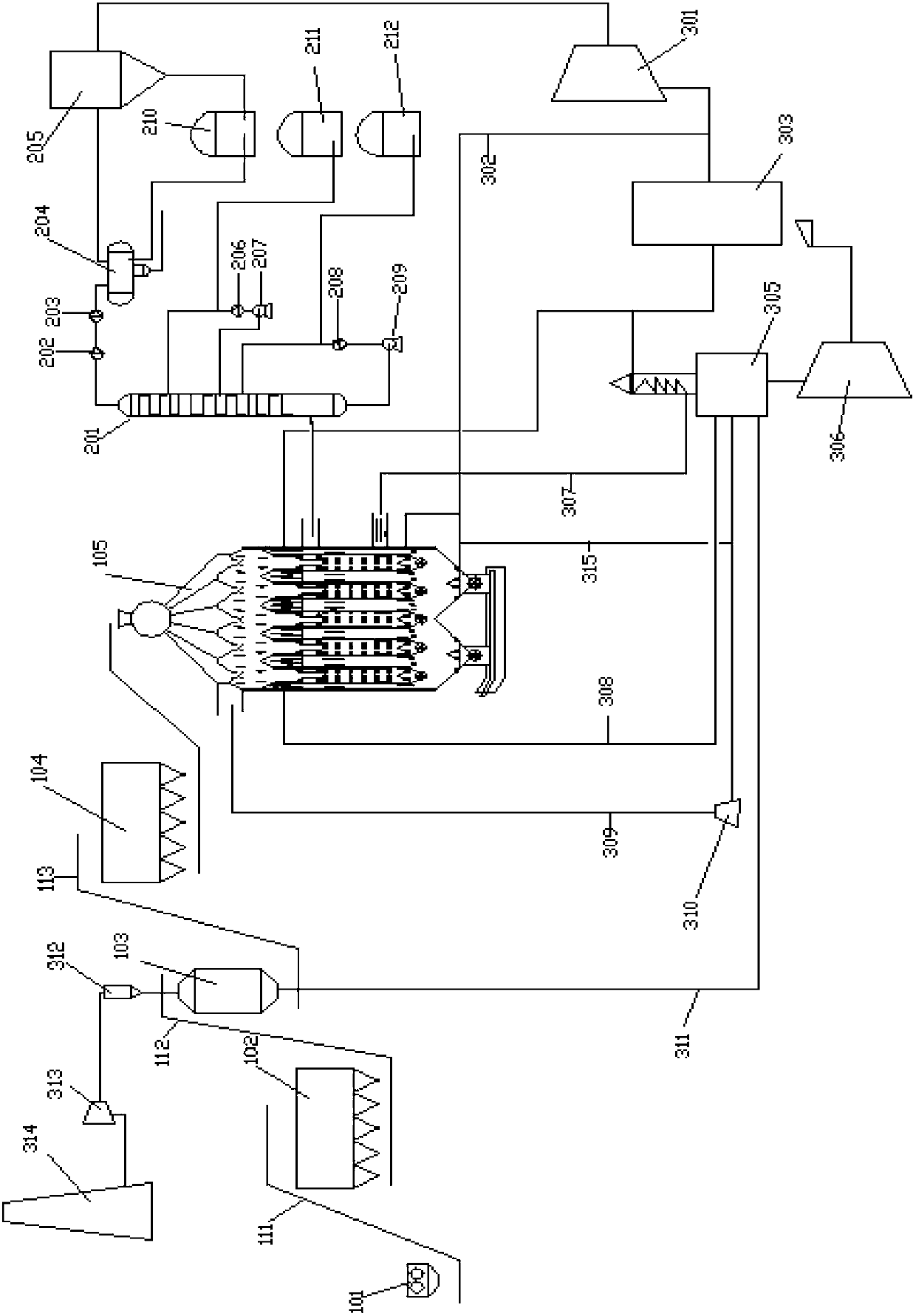

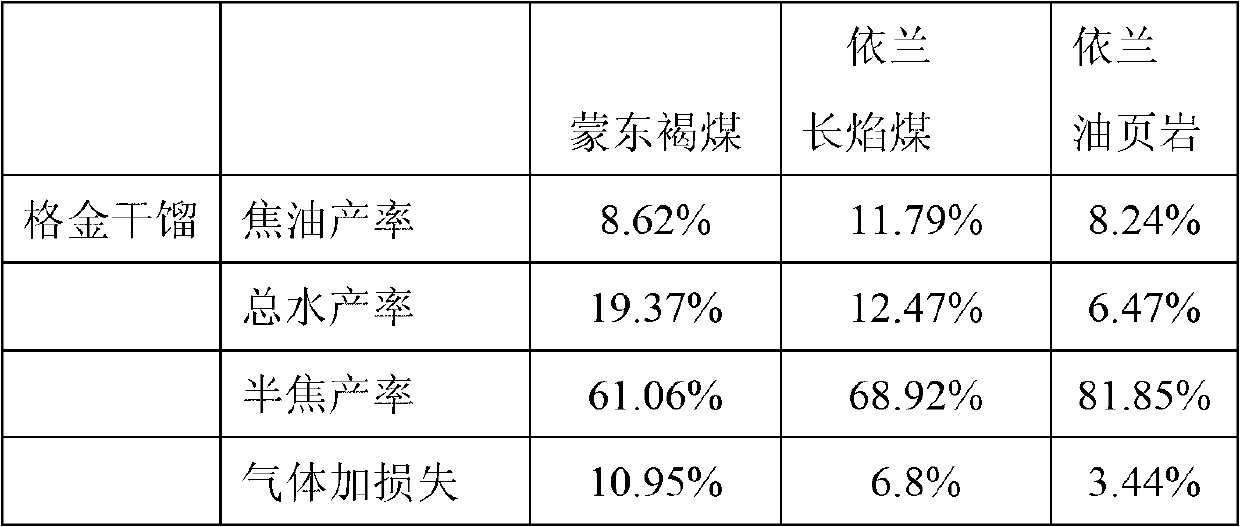

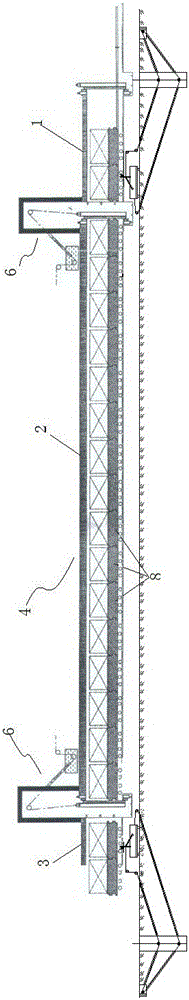

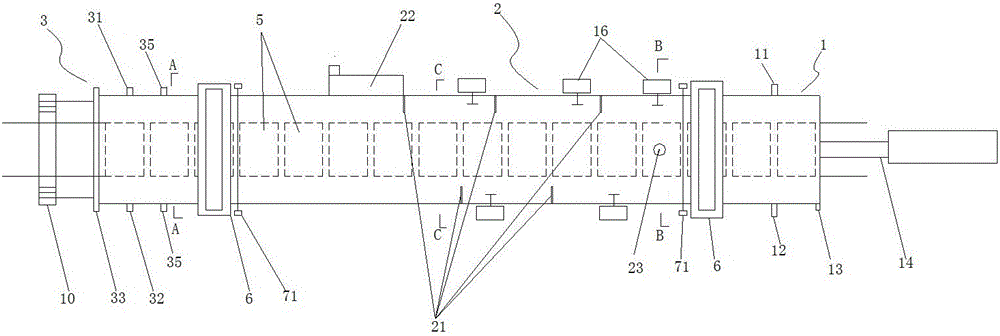

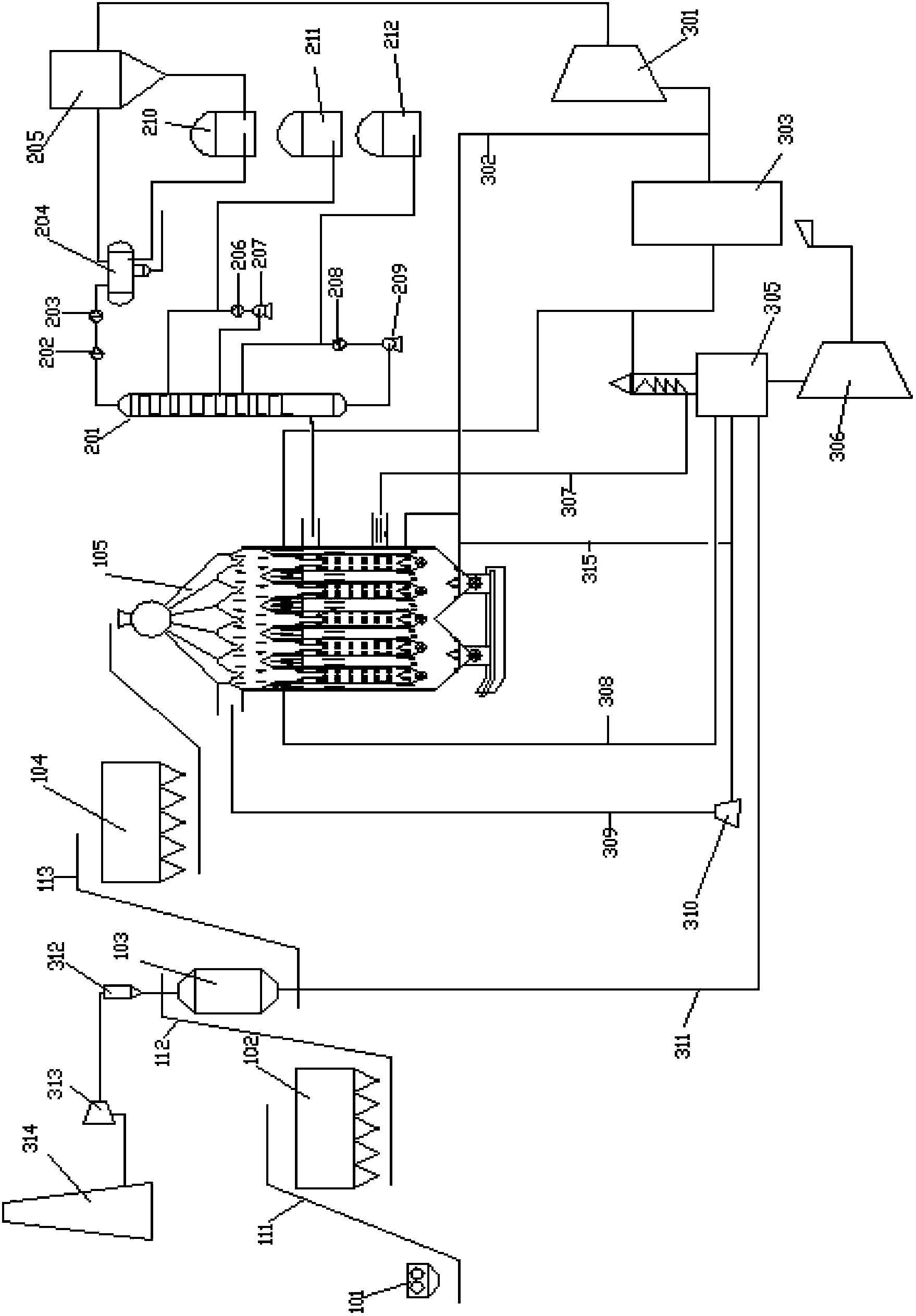

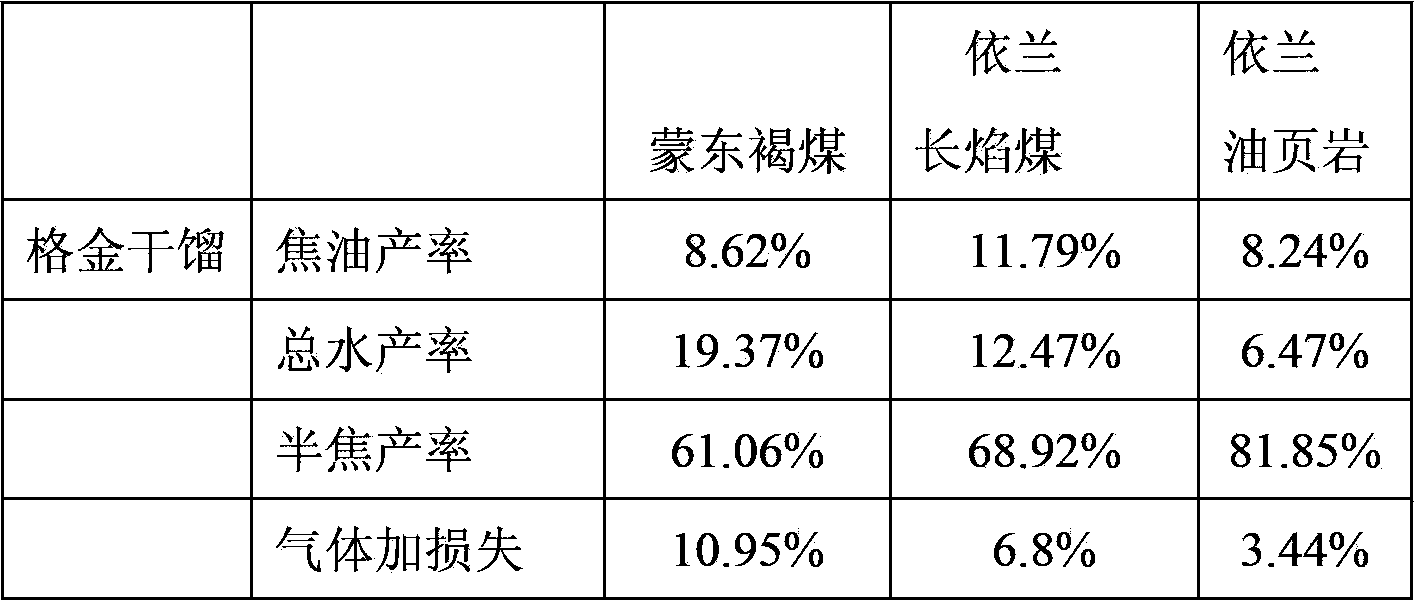

Tunnel pipe thin-layer retort for coal and oil shale and retort process thereof

InactiveCN103013544AImprove heat transfer performanceIncrease profitChemical industrySpecial form destructive distillationThin layerOil shale gas

The invention discloses a tunnel pipe thin-layer retort for coal and oil shale and a retort process thereof, relates to a retort and a process for producing coal tar and shale oil, and solves the problems that the conventional retorts and processes have large heat loss at semicoke cooling sections, the retort time is difficultly controlled accurately, the oil yield is low and the treatment capacity of the single furnace is small. The retort comprises a drying section, a retort section, a high temperature cooling section and a low temperature cooling section, wherein the semicoke cooling section is divided into two sections by a roller feeding machine, heat exchange of cooling wind is carried out at the high temperature semicoke section, the low temperature cooling section is communicated with a tunnel pipe, and drying gas enters the drying section via the tunnel pipe. According to the process, retort oil gas led out from a retort oil gas outlet of a retort furnace is purified and then used as circulation retort gas, and gas led out from a drying gas outlet of the retort furnace is used as the circulation drying gas to carry out retort. With the retort and the retort process, an addition of 20 percent of semicoke residual heat is recovered from per ton raw material, the retort time is accurately controlled, the oil yield is high, and the treatment amount of the single furnace is large; and the retort and the retort process are mainly applied to the field of coal chemical industry.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM +1

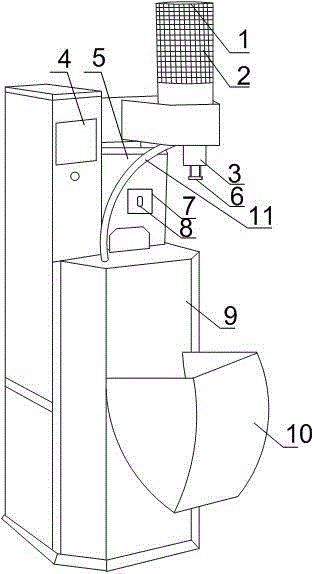

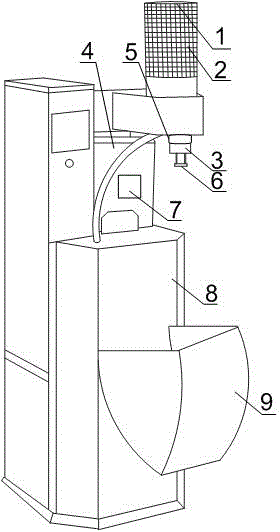

Wrinkle chasing mechanism

InactiveCN104621861AImprove efficiencyTo avoid the phenomenon of stopping heating after burning outShoemaking devicesWrinkleEngineering

The invention discloses a wrinkle chasing mechanism. The wrinkle chasing mechanism comprises a support, and the support is provided with a ventilator, an air inlet pipe, an air outlet pipe, a pressing roller and a water collection tank. The air inlet pipe is arranged on the upper portion of the ventilator, the air outlet pipe is arranged on the lower portion of the ventilator, and the pressing roller is arranged under the air outlet pipe. The support is further fixedly provided with a collection frame, and a frame opening of the collection frame is arranged under the pressing roller. The wrinkle chasing mechanism further comprises a heater and an atomization device, the heater is located between the ventilator and the air outlet pipe, the atomization device is arranged in the water collection tank, and the water collection tank is connected with the heater through a guide pipe. Through the matching usage of mixed gas and the pressing roller, smooth processing can be quickly performed on leather facing, and when the leather facing drops, the collection frame arranged under the pressing roller can avoid the leather facing from being damaged caused by landing; atomized water vapor and the air heated by the heater are mixed and act on the leather facing through the air outlet pipe, and the leather facing wrinkle chasing efficiency can be improved under the rolling effect of the pressing roller.

Owner:CHENGDU FENGFAN TECH

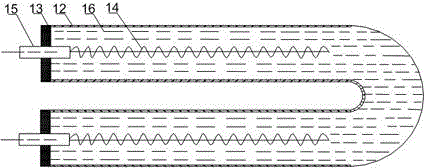

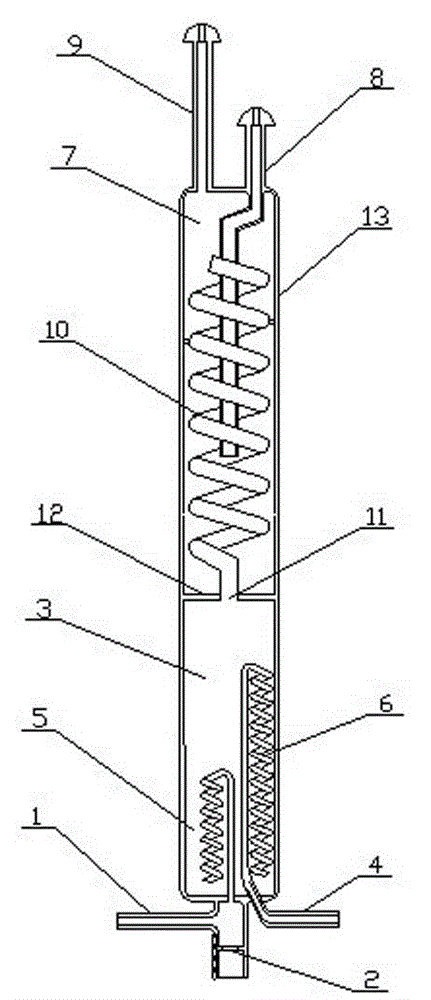

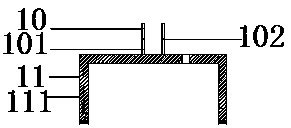

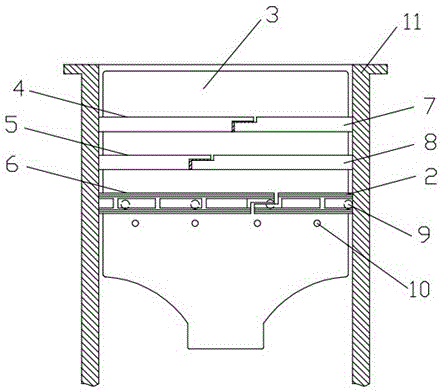

High-capacity quartz combustion tube for oil product analysis

InactiveCN103604904AFull combustion reactionBurn completelyChemical analysis using combustionPreparing sample for investigationCombustion chamberEngineering

The invention relates to a high-capacity quartz combustion tube for oil product analysis. The high-capacity quartz combustion tube is characterized by being provided with two combustion chambers, wherein a spiral carrier gas preheating tube and an oxygen preheating tube are arranged inside the first combustion chamber; a spiral combustion-supporting tube is arranged inside the second combustion chamber; the two adjacent combustion chambers are spaced by a partition plate with a through hole; a blowback oxygen inlet is formed at the outlet end of the combustion tube. The quartz combustion tube is mainly used for measuring the contents of total sulfur, total nitrogen and total chlorine in petrochemical products; conventional sample amount of 10-20 microlitres in oil product analysis is prominently improved by 5-10 times so as to be up to 100 microlitres, and carbon deposition is not caused, so that a measurement signal is relatively enhanced, and the low-content total sulfur, total nitrogen total sulfur and total chlorine detection sensitivity is prominently improved; the lower limit of detection is 0.05mg / L, and the detection limit is as low as 0.01mg / L.

Owner:江苏东华分析仪器有限公司

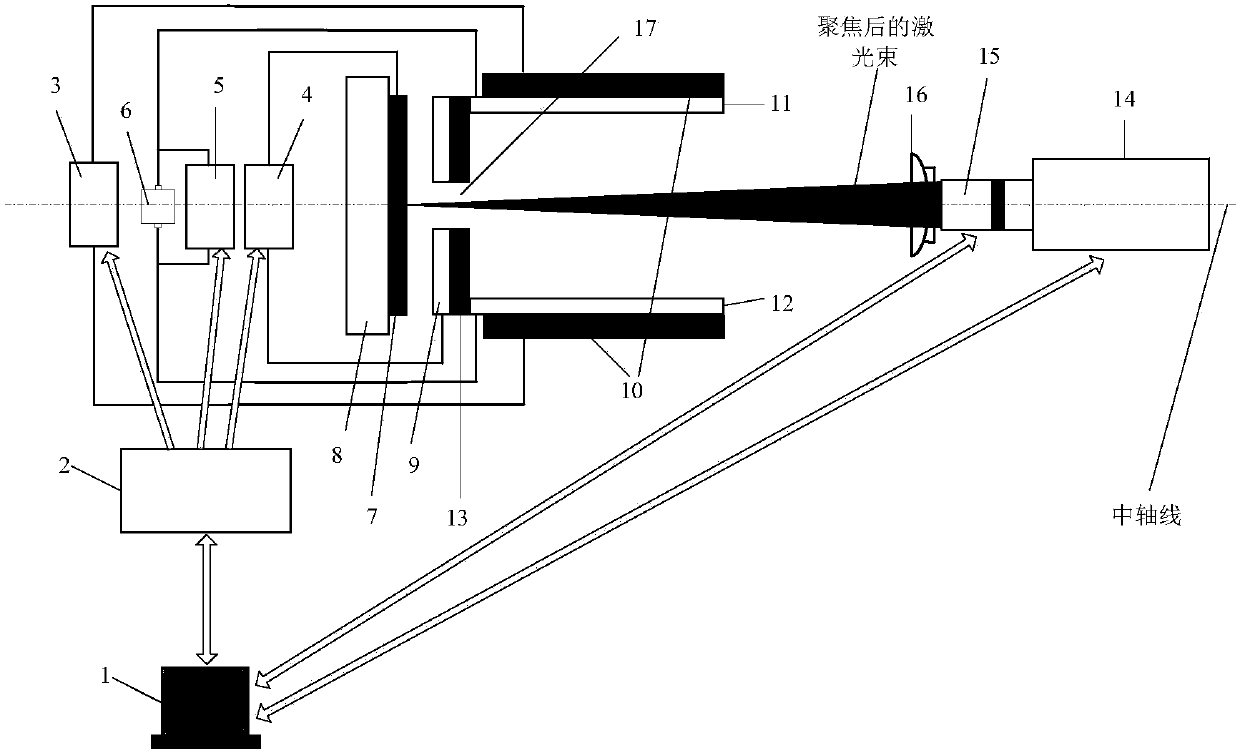

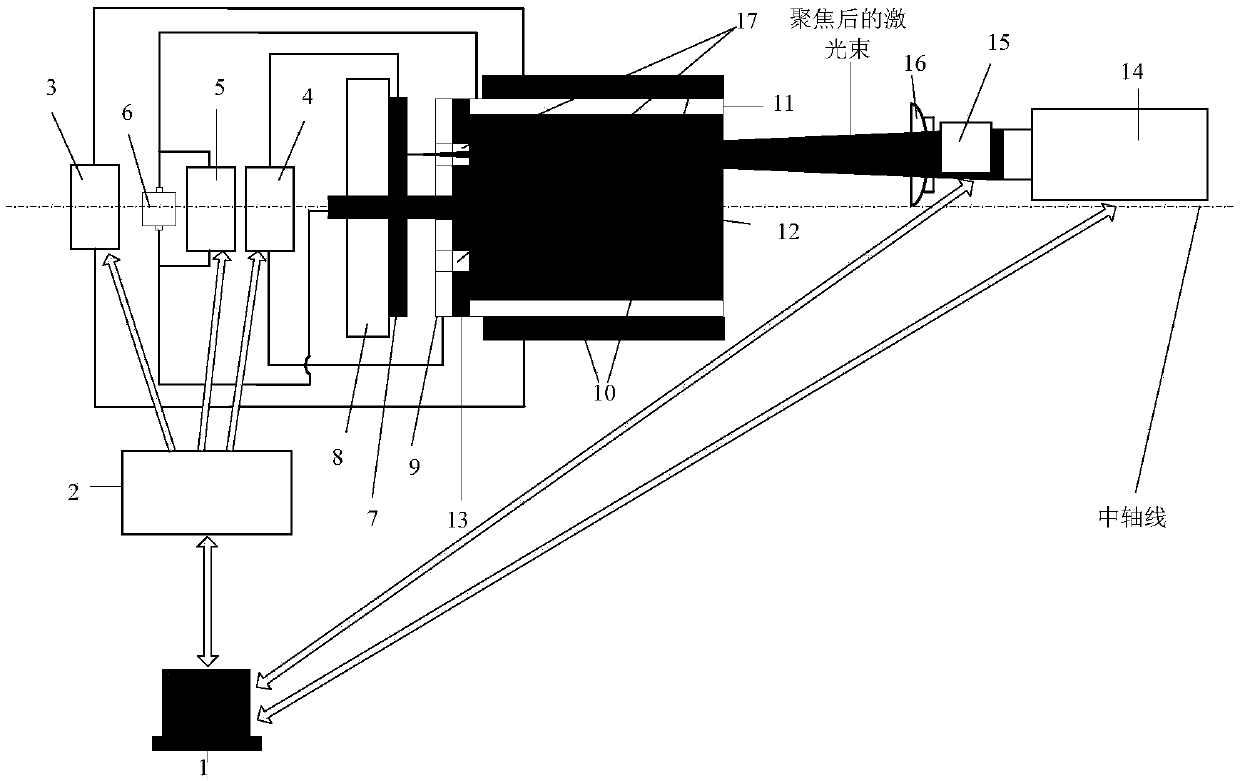

Reflecting type laser-electromagnetic field coupling thrustor

ActiveCN107939625AAccurate quality controlImprove propulsion efficiencyMachines/enginesUsing plasmaElectromagnetic field couplingThrust efficiency

The invention relates to a reflecting type laser-electromagnetic field coupling thrustor which comprises a laser system, an electromagnetic accelerating electrode assembly and a static electric fieldassembly. The electromagnetic accelerating electrode assembly comprises an electromagnetic accelerating cathode, an electromagnetic accelerating anode and an electromagnetic accelerating electrode power source; the static electric field assembly comprises a static electric field accelerating electrode, a working medium and a static electric field accelerating power source, the static electric field accelerating power source provides power for the working medium and the static electric field accelerating electrode, and a potential difference is formed between the working medium and the static electric field accelerating electrode to form a static electric field; laser plasmas generated by ablation of the working medium by laser beams enter the static electric field, when the laser plasmas accelerated by the static electric field move to the position between the electromagnetic accelerating cathode and the electromagnetic accelerating anode, discharge arcs can be induced to be generated,the laser plasmas are heated by the discharge arcs and are further ionized, the laser plasmas are sprayed out in an accelerated manner under the joint effect of lorentz force and aerodynamic force, and thrust is accordingly generated. The reflecting type laser-electromagnetic field coupling thrustor has the beneficial effects that the thrust is adjustable, the thrust efficiency is high, and the thrust density is large.

Owner:NAT UNIV OF DEFENSE TECH

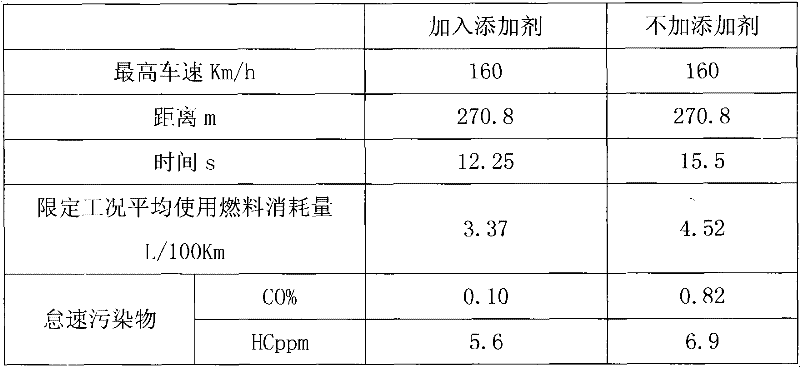

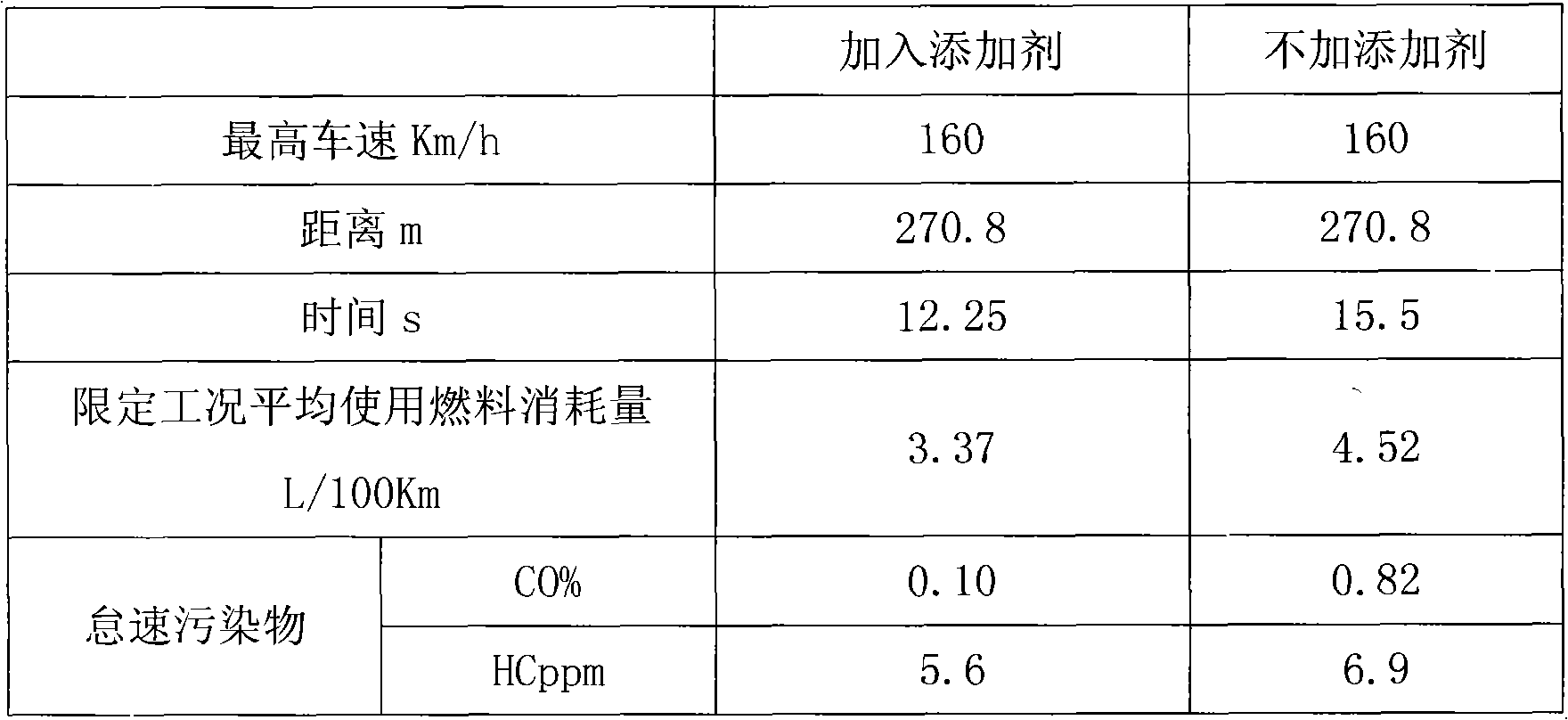

A kind of vehicle fuel containing methanol

ActiveCN102277207AReduce corrosionBurn fully and save fuelLiquid carbonaceous fuelsPollutantAutomotive engineering

The invention relates to vehicle fuel containing methanol. The vehicle fuel comprises the following components by volume: 5-95% of methanol and 0.3-10.2% of additive or 5-95% of methanol, 0.1-90% of gasoline and 0.3-10.2% of additive. The vehicle fuel has high octane value, is economical and energy-saving, can reduce emission of gas pollutants and can relatively prolong the service lives of the vehicles even if the content of methanol is higher. Besides, the vehicle fuel overcomes the following common defects of the vehicles using the methanol gasoline: the engine has difficulty in cold start and is easy to corrode and swell; and the fuel is unstable and easy to layer in the case of long-term storage.

Owner:贯昌军

Industrial gas synergist

The invention relates to an industrial gas synergist. The industrial gas synergist is prepared by 80 percent of carbon alkane (C5H12), 4 percent of n-propanol (C3H80), 3.7 percent of hexane (C6H14), 0.8 percent of cyclohexane (C6H12), 8 percent of Mobil (isoparaffin solvent), 3.5 percent of kerosene (CH3(CH2)nCH3) and 0.025 percent of paint. The preparation method of the industrial gas synergist comprises the following steps: taking the carbon alkane (C5H12); adding n-propanol (C3H80) and Mobil (isoparaffin solvent) and stirring for 3 hours; then, adding the hexane (C6H14) and the cyclohexane(C6H12) and suitably sealing for 8 hours; controlling temperature to be about 30 DEG C; adding the kerosene (CH3(CH2)nCH3) and stirring for 1 hour; and finally adding the paint to prepare a finished product. The industrial gas synergist is innoxious and noncorrosive and has special efficacy, such as combustion supporting, polymerization suppression, catalysis, cracking, and the like.

Owner:孙中伟

Direct hydrocarbon fuel solid oxide fuel cell anti-carbon deposition anode and a preparation method thereof

InactiveCN101515647AStable structureMeet the requirements of conductivityCell electrodesSolid electrolyte fuel cellsHydrogenFuel cells

The invention relates to an anti-carbon deposition solid oxide fuel cell anode material and a preparation method thereof. The composition of the anode material is xSr (1-1.5y) My TiO3-(1-x) CeO2. In the formula, x is equal to 0.3-0.7, and y is equal to 0.04-0.4; M is La, Y or Sm. The adulteration amount of La, Sr and Y is respectively 0.2-0.4mol%, 0.1-0.3mol% and 0.02-0.08mol%. Compared with the traditional nickel- yttrium oxide stabilized zirconia anode taking hydrogen as fuel, the anode material can take hydrocarbon having low price and rich reserve volume as fuel, so as to reduce the cost of a solid oxide fuel cell and be beneficial to accelerating the commercial development of the solid oxide fuel cell.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

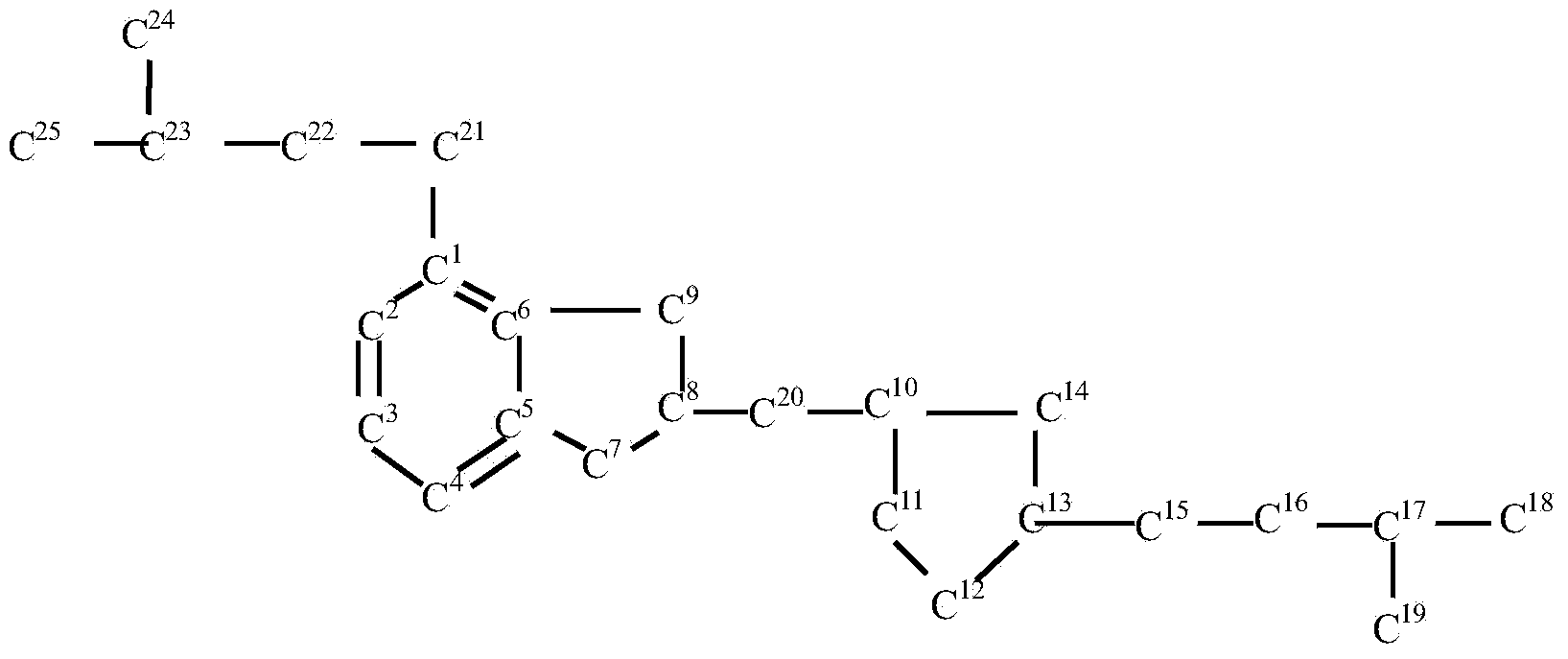

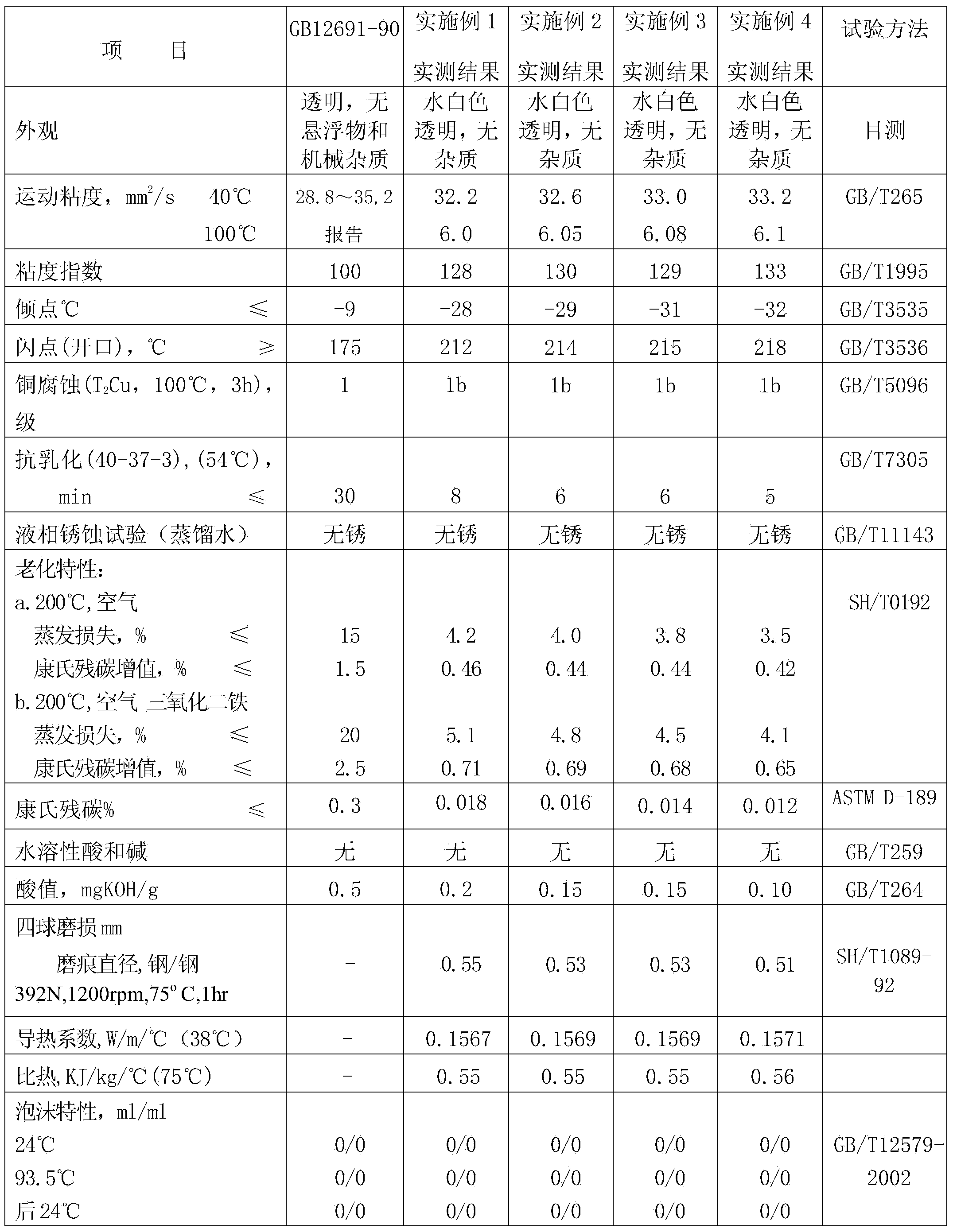

Air compressor oil and preparation method thereof

ActiveCN103897790AThe effect is positive and obviousGood high temperature oxidation resistanceLubricant compositionAir compressionPhenolic antioxidant

The invention relates to air compressor oil, comprising a phenolic antioxidant, a phenylamino antioxidant, an olefine acid antioxidant, a metal deactivator, an ash-free antiwear agent, a defoamer, a light-sensitive agent, a hydrogenation paraffin base oil fraction, a hydrogenation naphthenic base oil and a hydrogenated alkyl high boiling substance. The invention also provides a preparation method of the air compressor oil. The air compressor oil disclosed by the invention has excellent high-temperature carbon deposit resistance, excellent high-temperature oxidation resistance, and excellent abrasion resistance, and simultaneously has excellent lubricating property, anti-foaming property and demulsibility on the product, the cost performance of the product is improved, the performances of the synthetic air compressor oil and composite synthetic air compressor oil are achieved, and the long-term work requirements of single-screw and dual-screw air compressors are completely met.

Owner:上海中孚油品集团有限公司

Composite liquid fuel and its preparing method

InactiveCN1425744ANo pollution in the processNo harmLiquid carbonaceous fuelsLiquid fuelStearic acid

The composite liquid fuel consists of glycol, ethanol, propanol, propyl ether, ethyl acetate, stearic acid, petroleum ether and inorganic combustion improver KNO3 or NaNO3. The fuel of the present invention is used mainly for self-supporting hot pot and in field cooking and may be also used in household. The fuel of the present invention is non-toxic, smell-less, pollution-less, safe, high in heat value and stable in combustion and produces no carbon deposit to blacken kitchen ware.

Owner:SOUTH CHINA UNIV OF TECH

Vamp wrinkle removing mechanism

The invention discloses a vamp wrinkle removing mechanism. The vamp wrinkle removing mechanism comprises a rack, a fan, a water tank and a collecting frame, wherein the fan and the water tank are arranged on the rack; an air inlet is formed in the top of the fan; the bottom of the fan is provided with an air outlet and a pressing roll; the pressing roll is placed right below the air outlet; the collecting frame is fixed on the rack; an opening of the collecting frame faces the lower portion of the pressing roll; and an air pressure switch is arranged at a position of the air outlet. The air pressure switch arranged at the position of the air outlet is a detecting element, a microswitch is pushed by static pressure of air, so that switch-on and switch-off of current is realized; and when air cannot be discharged from the fan smoothly, a heating wire can be stopped from heating by the air pressure switch, and the loss rate of the heating wire is reduced.

Owner:何阳

Low-carbon gasoline and preparation method thereof

The invention relates to low-carbon gasoline and a preparation method thereof. The low-carbon gasoline comprises the following components in percentage by volume: 10-25 percent of hydrogen cracking gasoline, 3-15 percent of methyl tertiary butyl ether, 25-50 percent of No.90 gasoline and 30-50 percent of low-carbon mixed alcohol. According to the low-carbon gasoline and the preparation method thereof, preparation conditions are simple; various components are sequentially added into an oil tank at normal temperature and normal pressure and are uniformly stirred to obtain the low-carbon gasoline; the prepared low-carbon gasoline has clear and bright color and favorable perception; the power performance of the No.90 gasoline is effectively improved; the low-carbon gasoline is fully combusted without generating carbon deposit; and the emission of carbon diode, carbon monoxide and sulfur dioxide in tail gas are effectively reduced. Therefore, according to the low-carbon gasoline, the carbon and the pollution to the atmosphere are reduced; an automobile fuel system is not needed to be changed; and the adverse influence on an engine is reduced.

Owner:环球瞭望(北京)石化产品有限公司

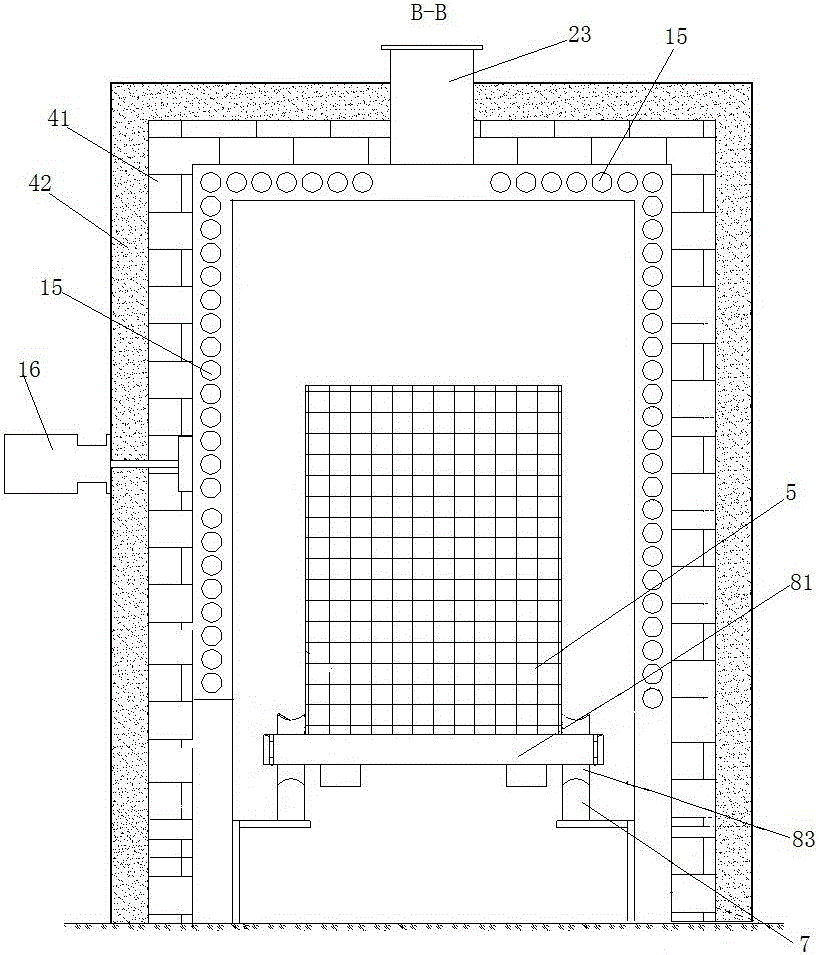

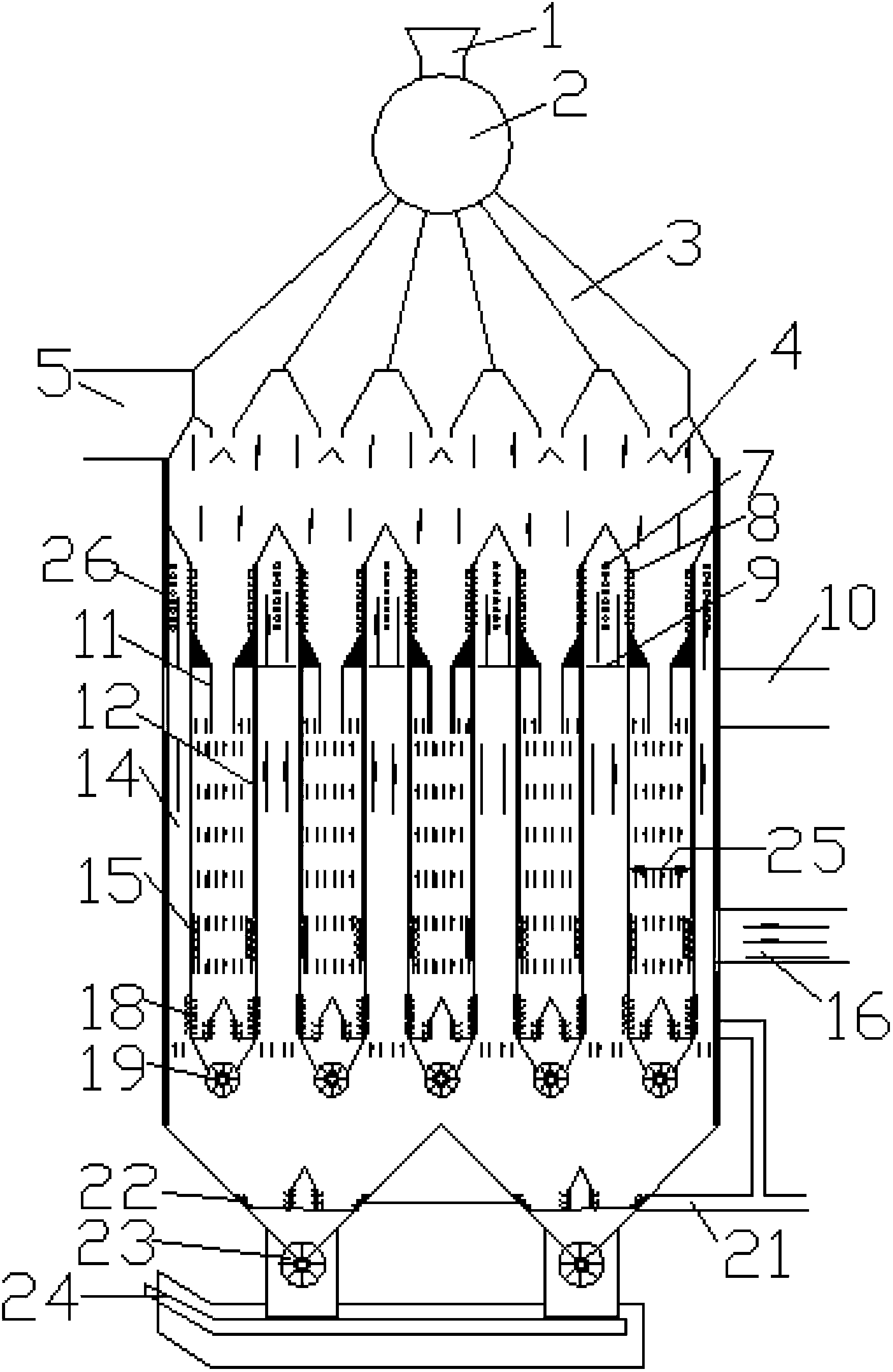

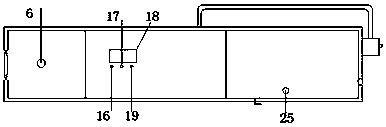

High-efficiency tunnel-type intermittent pyrolysis furnace

PendingCN106398731AAffecting workWork pressure is normalBiofuelsIndirect heating destructive distillationFurnace temperatureCombustion chamber

The invention discloses a high-efficiency tunnel-type intermittent pyrolysis furnace. The high-efficiency tunnel-type intermittent pyrolysis furnace comprises a tunnel-type furnace body, wherein the furnace body is divided into a drying area, a pyrolysis area and a cooling area; a reticular furnace frame is arranged in the furnace body; sealing doors which can fully isolate the pyrolysis area into a closed chamber are arranged at a boundary between the drying area and the pyrolysis area and a boundary between the pyrolysis area and the cooling area; a burning chamber is connected onto the furnace body in the pyrolysis area, a smoke outlet is formed in the furnace body in the pyrolysis area, a plurality of fire tubes are arranged on the inner wall of the furnace body in the pyrolysis area and the top of the inner chamber of the furnace body, an inlet of each fire tube is communicated with the burning chamber and an outlet of each fire tube is communicated with the smoke outlet. Since the fire tubes are arranged in the furnace, pyrolysis gas is prevented from entering the furnace and influencing the working of a burner, the working pressure of the burner can be guaranteed to be normal and the furnace temperature can be guaranteed to increase and decrease according to the needs. Moreover, cumbersome steps of opening and closing movable guide rails are omitted, the manpower is saved and the operation is simpler. An ejector rod with cooling guarantees that the sealing doors can be tightly pressed without causing failure and thereby the sealing performance is guaranteed.

Owner:肖国雄

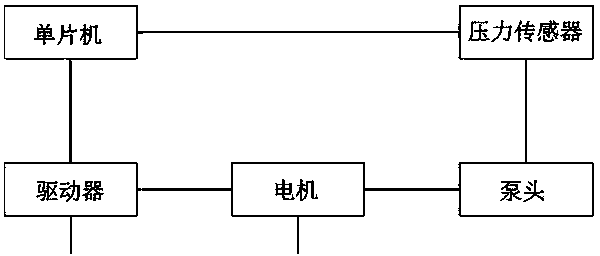

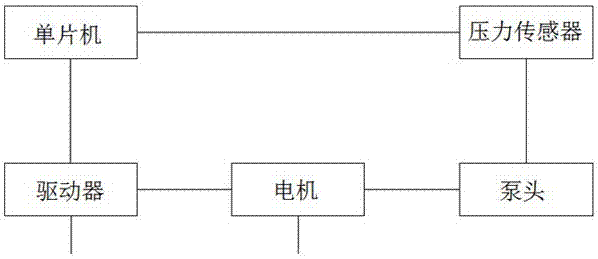

Intelligent control application of motor

ActiveCN104218871AExtended service lifeFix damageElectric motor controlPump controlControl switchLife time

The invention relates to an intelligent control application of a motor. The intelligent control application comprises a single-chip microcomputer, a driver, a pressure sensor, the motor and a pump head; the driver and the pressure sensor are both electrically connected with the single-chip microcomputer under weak current; the motor is electrically connected with the driver; the pump head is in drive connection with the motor; the pressure sensor is in sensing connection with the pump head. The driver is externally connected with a first conducting wire carrying high current. The motor is externally connected with a second conducting wire carrying high current. The driver and the motor are connected with a third conducting wire carrying high current. The intelligent control application has the advantages that control of weak current control signals is achieved through mechanical-loss-free electronic devices and the high-power motor, service lives of electric products can be greatly prolonged, the problem that traditionally excess current directly carried by a sensor or a control switch causes damage or shortened life to the sensor or the control switch is solved, no carbon accumulation occurs during long-term running, and running is safe and reliable.

Owner:东莞市有意思电子科技有限公司

Tunnel pipe thin-layer retort for coal and oil shale and retort process thereof

InactiveCN103013544BImprove heat transfer performanceIncrease profitChemical industrySpecial form destructive distillationThermodynamicsCoal chemical industry

The invention discloses a tunnel pipe thin-layer retort for coal and oil shale and a retort process thereof, relates to a retort and a process for producing coal tar and shale oil, and solves the problems that the conventional retorts and processes have large heat loss at semicoke cooling sections, the retort time is difficultly controlled accurately, the oil yield is low and the treatment capacity of the single furnace is small. The retort comprises a drying section, a retort section, a high temperature cooling section and a low temperature cooling section, wherein the semicoke cooling section is divided into two sections by a roller feeding machine, heat exchange of cooling wind is carried out at the high temperature semicoke section, the low temperature cooling section is communicated with a tunnel pipe, and drying gas enters the drying section via the tunnel pipe. According to the process, retort oil gas led out from a retort oil gas outlet of a retort furnace is purified and then used as circulation retort gas, and gas led out from a drying gas outlet of the retort furnace is used as the circulation drying gas to carry out retort. With the retort and the retort process, an addition of 20 percent of semicoke residual heat is recovered from per ton raw material, the retort time is accurately controlled, the oil yield is high, and the treatment amount of the single furnace is large; and the retort and the retort process are mainly applied to the field of coal chemical industry.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM +1

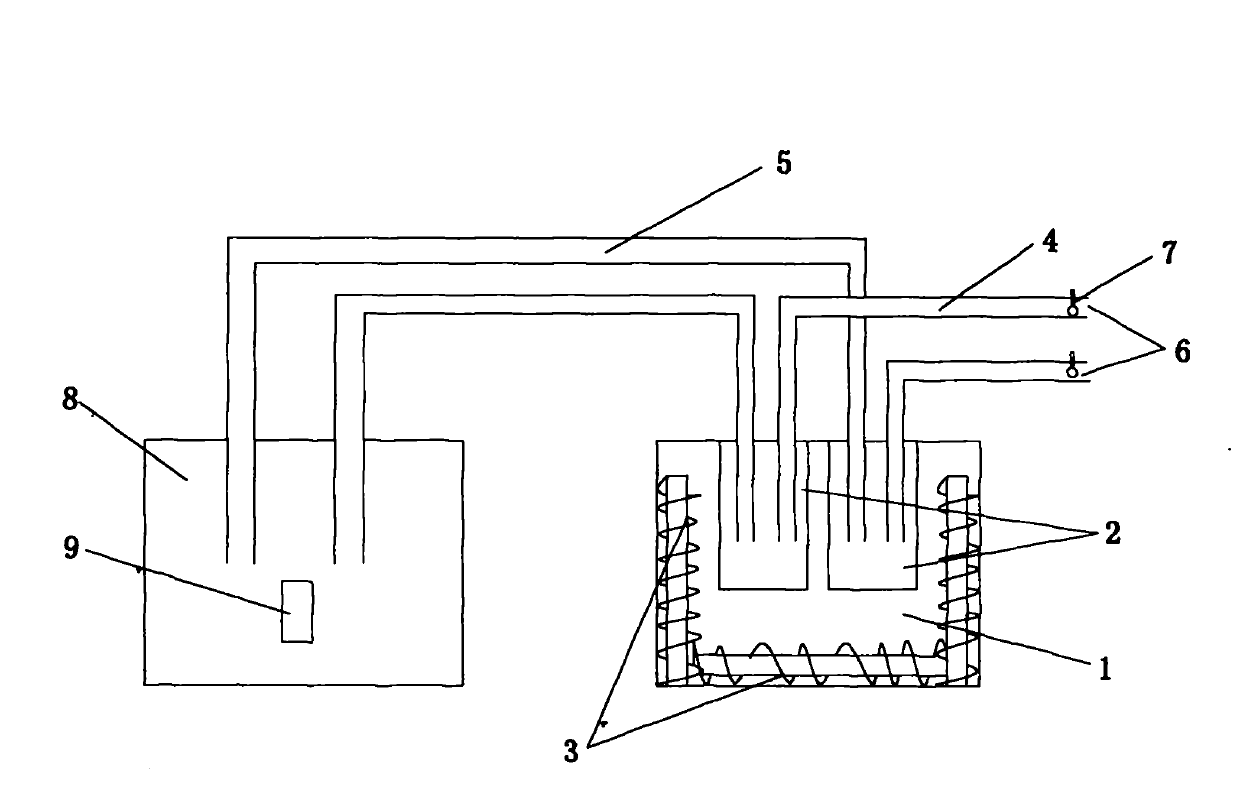

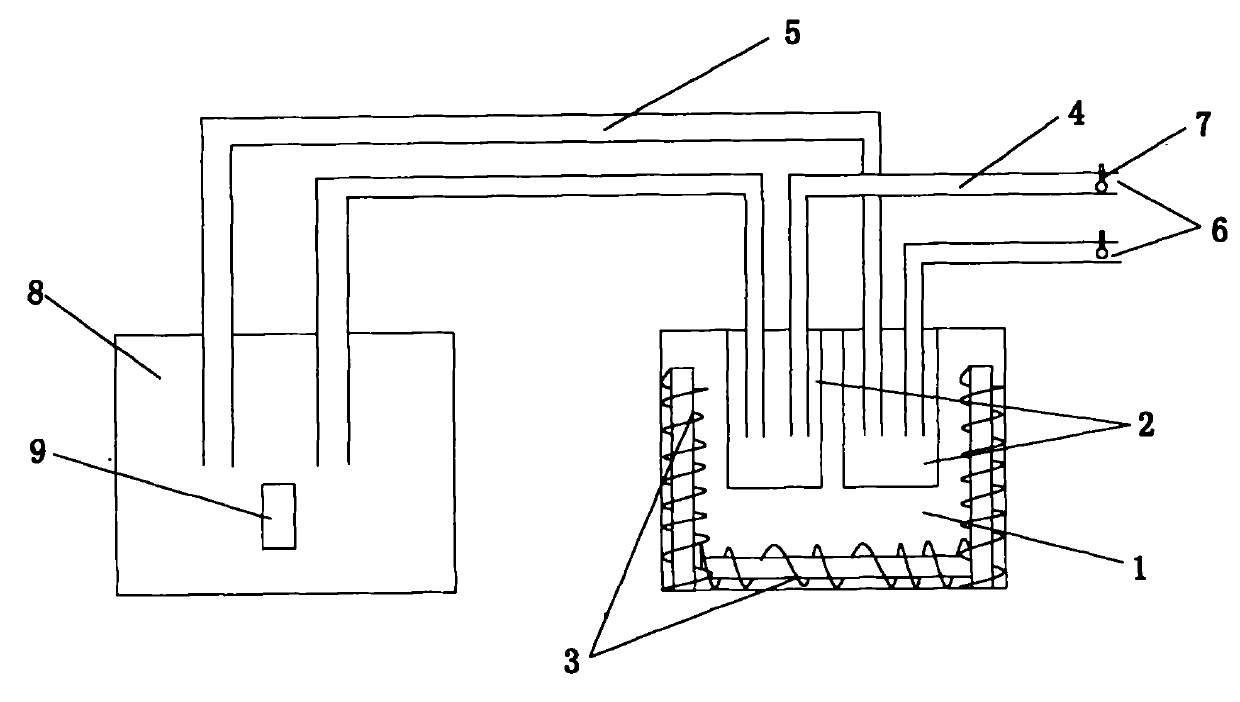

Quenching device for gasification of methanol

InactiveCN101906515AImprove qualityReduce scrap rateHydrogenQuenching devicesDecompositionDisplay device

Owner:MORGAN HARDWARE KUSN

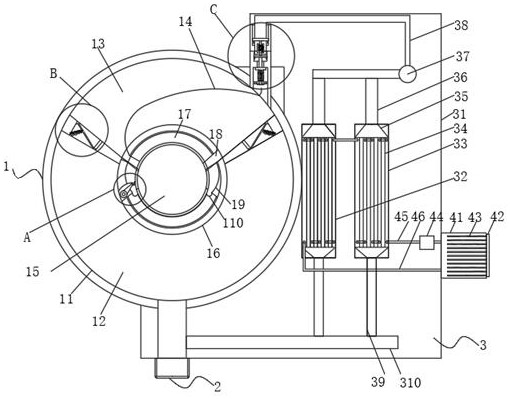

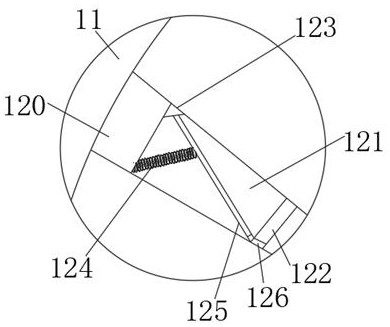

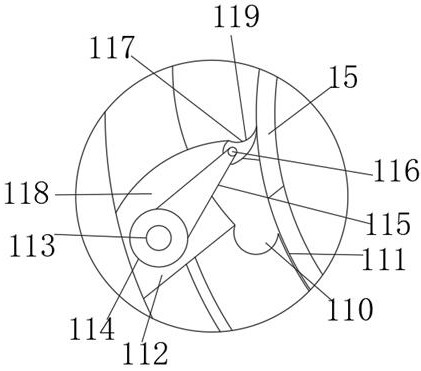

Centrifugal pump lubricating oil supply system and circulating method thereof

InactiveCN113007577AImprove cleanlinessProtection securityLubrication elementsThermodynamicsEngineering

The invention relates to the technical field of centrifugal pump lubrication, in particular to a centrifugal pump lubricating oil supply system and a circulating method thereof. The centrifugal pump lubricating oil supply system comprises a lubricating assembly, wherein a circulating device is fixedly connected to the bottom of the lubricating assembly, a filter pipe fitting is inserted into the bottom of the circulating device, a water temperature adjusting device is fixedly connected to the right side of the circulating device, and the top of the circulating device communicates with a pressure reverse stopping device. The lubricating assembly is improved, lubricating oil is concentrated above a rotating shaft, the rotating shaft is continuously lubricated in an infiltrating mode, the lubricating oil is gathered in an oil channel, the smearing area of the lubricating oil is increased, the heat dissipation effect is improved, oil on the rotating shaft is scraped away through a scraping strip, and therefore, long-time detention of oil on the rotating shaft is avoided, the cleanliness of lubricating oil is guaranteed, the use period and the replacement period are prolonged, carbon deposition and impurities are avoided in the process, and the safety of the rotating shaft is protected.

Owner:王悦

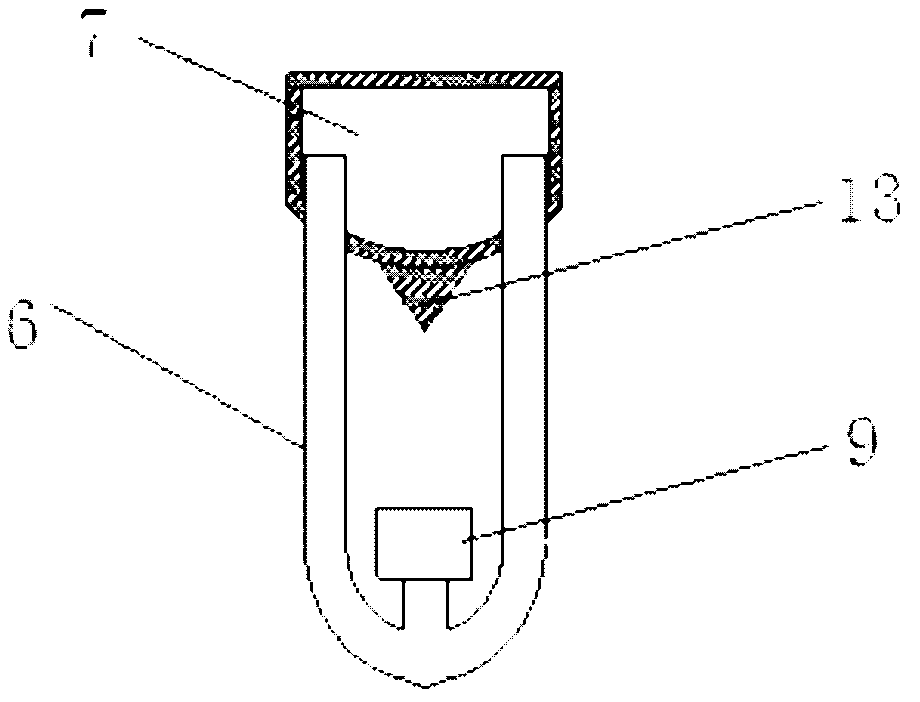

Range type reaction kettle using hydroxy fuels

InactiveCN102425791ASimple reaction conditionsNo carbon depositsBurnersVaporizationCarbon deposition

The invention relates to a kitchen range, in particular to a special range type reaction kettle burning hydroxy fuels. The range type reaction kettle using the hydroxy fuels comprises a preheating oil pan; an annular gas storage cavity is arranged on the preheating oil pan; an annual first-stage vaporization cavity and an annular second-stage vaporization cavity are arranged at the inner side of the annual primary vaporization cavity; the second-stage vaporization cavity is arranged on the first-stage vaporization cavity; a fourth-stage vaporization cavity is arranged in the middle part of the annular gas storage cavity; a U-shaped third-stage ascending vaporization pipe and a U-shaped fifth-stage descending vaporization pipe are connected at the bottom of the fourth-stage vaporization cavity; an injection cavity is arranged at a groove part of the U-shaped fifth-stage descending vaporization pipe; and the gas storage cavity is connected with the U-shaped third-stage ascending vaporization pipe through a gas transmission pipe. The range type reaction kettle using the hydroxy fuels of the invention provides a good reaction condition for liquid hydroxy fuels; the fuels are fully vaporized after passing through the vaporization cavities; the vaporized hydroxy fuels are fully burned; the burning temperature can reach about 1200 DEG C; no carbon deposition is generated; and black smoke does not exist.

Owner:成都星火燎原能源科技有限公司

Method for catalytic hydrogenation of furfural under supercritical carbon dioxide and catalyst preparation method

InactiveCN104059035BAchieve conversionNo carbon depositsOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsLiquid productPalladium on carbon

The invention relates to the field of preparation of biologic oil, and provides a furfural catalytic hydrogenation method under supercritical carbon dioxide and a method for preparing catalysts. The furfural catalytic hydrogenation method under supercritical carbon dioxide comprises the steps that furfural and palladium and carbon catalysts are added to a reaction still, then the reaction still is sealed, hydrogen is introduced into the reaction still to remove the air in the reaction still, liquefied carbon dioxide is injected into the sealed reaction still through a plunger metering pump, the pressure of the carbon dioxide is made to be above the critical pressure when the carbon dioxide is in an overcritical state, furfural catalytic hydrogenation and upgrading are carried out under the overcritical condition of the carbon dioxide, and a needed liquid product is prepared. The method for preparing the palladium and carbon catalysts comprises the steps of pre-processing of a carrier and preparation of the palladium and carbon catalysts (Pd / C catalysts). In the reaction process, the catalysts have no carbon accumulation phenomenon, can be recycled, largely reduce generation of by-products, and improve the selectivity of the products.

Owner:ZHEJIANG UNIV

Vehicle fuel containing methanol

ActiveCN102277207BGuaranteed cleanlinessIncrease the degree of atomizationLiquid carbonaceous fuelsGasolineProduct gas

Owner:贯昌军

Hardening furnace

InactiveCN108220570AReduce scrap rateExtended service lifeFurnace typesHeat treatment process controlRejection rateQuenching

The invention discloses a hardening furnace, and belongs to the field of metal heat treatment equipment. According to the hardening furnace, a water tank and a smoke sucker are installed in a coolingarea. When a workpiece enters a charging basket and quickly enters a water pool, the smoke sucker starts up at the same time to suck the smoke and stores the smoke in the smoke sucker. When the temperature displayed on a temperature display screen is low, a smoke switch is turned on to send the smoke in the smoke sucker to a functional main body so that the smoke can be recycled to raise the temperature and reduce the pollution. Additionally, an operation switch is turned on, the water tank sprays water into the cooling area through spraying balls so as to remove oil smoke which deposits on the inner wall in quantity and discharge the oil smoke out through a drain pipe, and consequently, it is avoided that cleaning is troublesome, no carbon deposition occurs, the service life of the hardening furnace is prolonged, the quality of quenching workpieces is improved, and the rejection rate of the workpieces is decreased. With the hardening furnace, it is solved that because a hardening furnace in the prior art is poor in smoke exhaust effect, extra oil smoke deposits on the inner wall or the bottom in quantity and forms a carbon deposition layer under the high temperature, and cleaningis troublesome.

Owner:吴亚琴

New energy compound diesel

InactiveCN110835559AReduce noiseReduce consumptionLiquid carbonaceous fuelsFuel additivesPtru catalystNew energy

The invention discloses new energy compound diesel, comprising diesel, oleic acid, and methanol as main raw materials. An appropriate cetane number synergist is added for compounding to form the new energy compound diesel. In winter, a small amount of a catalyst is used to adjust the condensation point index of the compound diesel. The 0# to -35# compound diesel can be prepared. The new energy compound diesel is characterized in that the new energy compound diesel makes full use of petroleum by-products and renewable biofuel, which is conducive to saving resources and improving the utilizationrate, and has the effect of saving energy, reducing emissions and purifying air. The new energy compound diesel has stable physical and chemical indicators, and the quality meets the national qualitystandards for diesel with the same label. The new energy compound diesel can be mixed with national standard diesel at any ratio, or can be used alone.

Owner:于文学

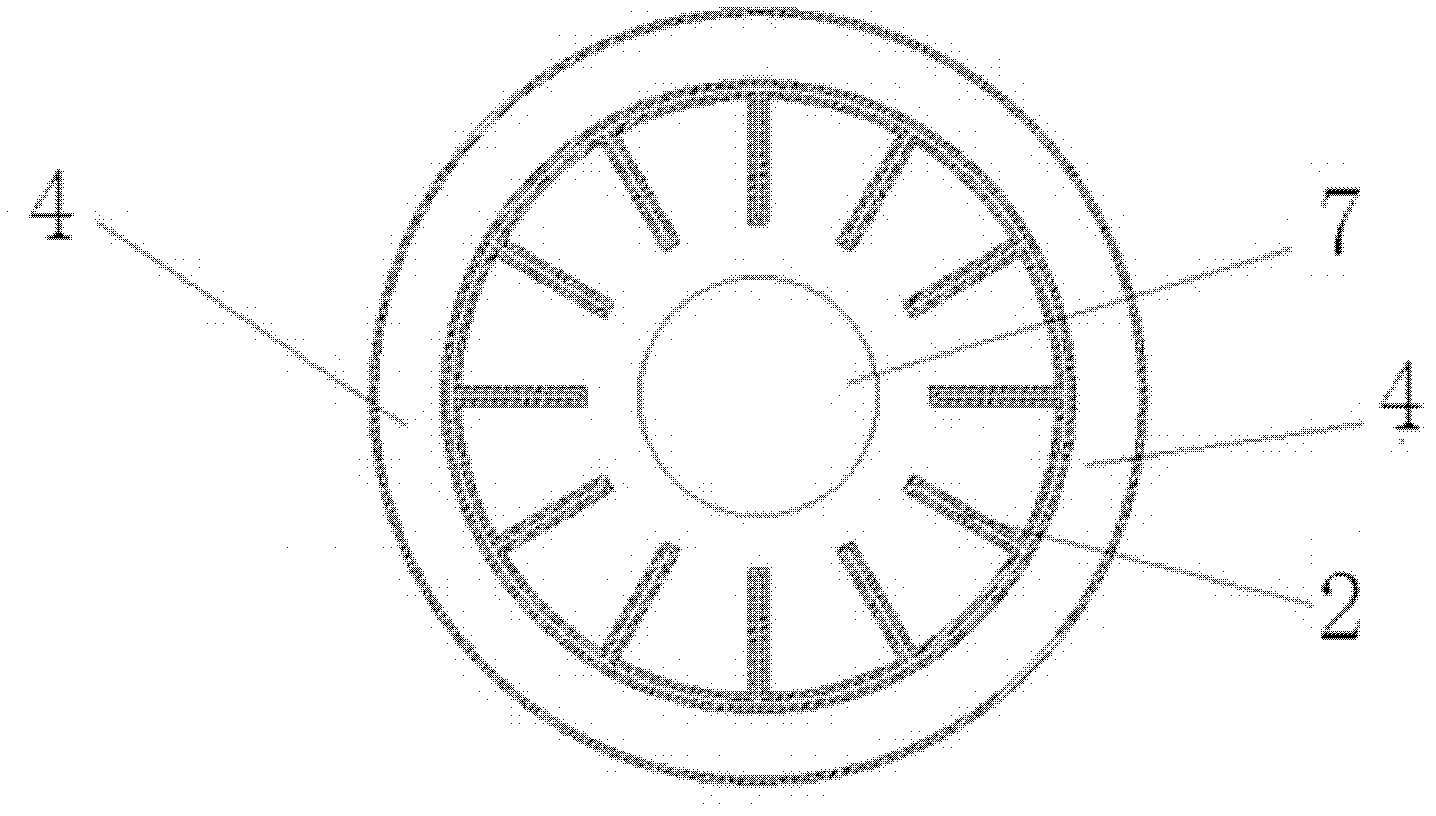

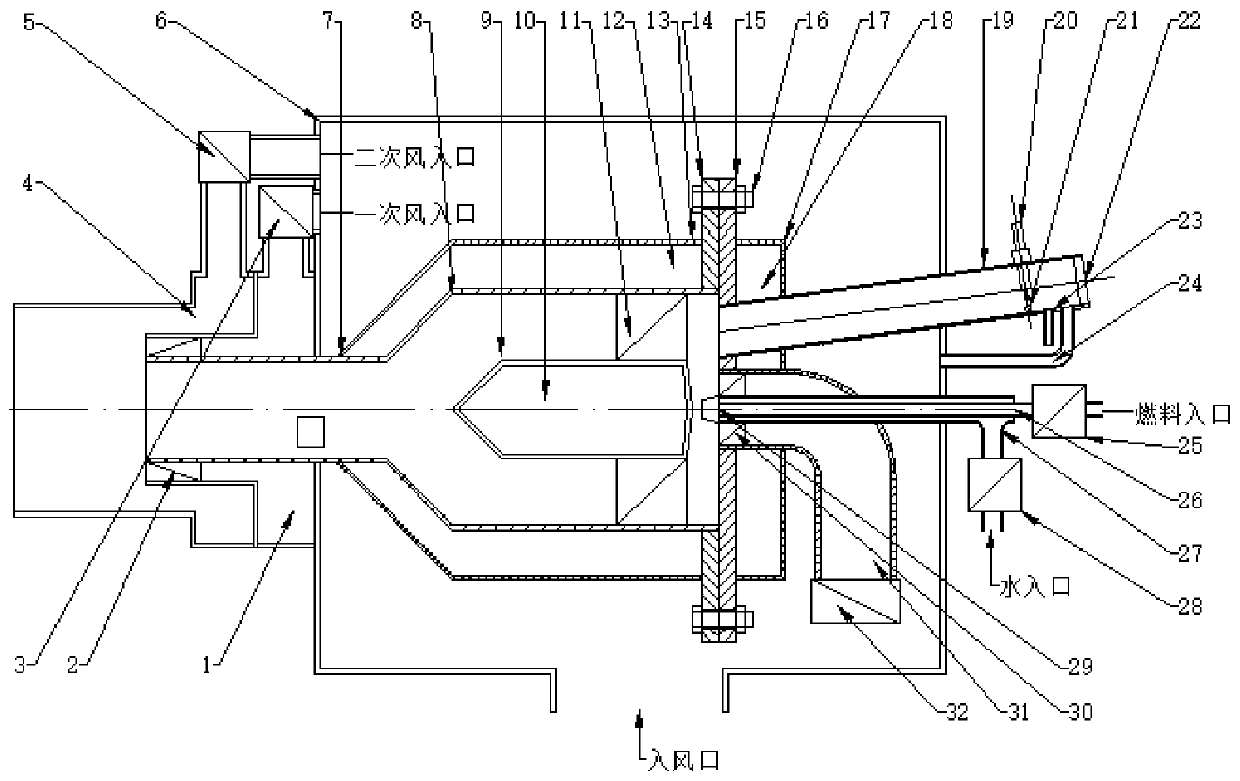

Binary horizontal burner

PendingCN110542086ATake advantage ofBurn fullyBurnersNon-combustible gases/liquids supplyCombustorOxygen delivery

The invention discloses a binary horizontal burner, and relates to a burner. According to the binary horizontal burner, the problems that an existing atomizing burner is high in energy consumption andpollute the environment, and an existing gasification burner easily generates carbon deposit are solved. A damping heat collector is arranged at the center of a cavity through a fuel guide plate, a gland flange is detachably connected to a cavity flange, an ignition observation tube is obliquely arranged, one end of the ignition observation tube communicates with the gland flange, the other end of the ignition observation tube is provided with an observation mirror, an ignition liquid input tube communicates with the ignition observation tube, one end of an oxygen delivery tube communicates with the ignition observation tube, the other end of the oxygen delivery tube communicates with an air box, an ignition needle and an ignition pool plate are arranged in the ignition observation tube,one end of a fuel tube is connected with the gland flange, one end of the fuel tube is provided with a mixing nozzle, the other end of the fuel tube is connected with a water supply tube, and one endof a main air tube is provided with air guide plates in the circumferential direction of the main air tube. The binary horizontal burner is used for a boiler, a hot blast heater and a drying furnace.

Owner:王振琦

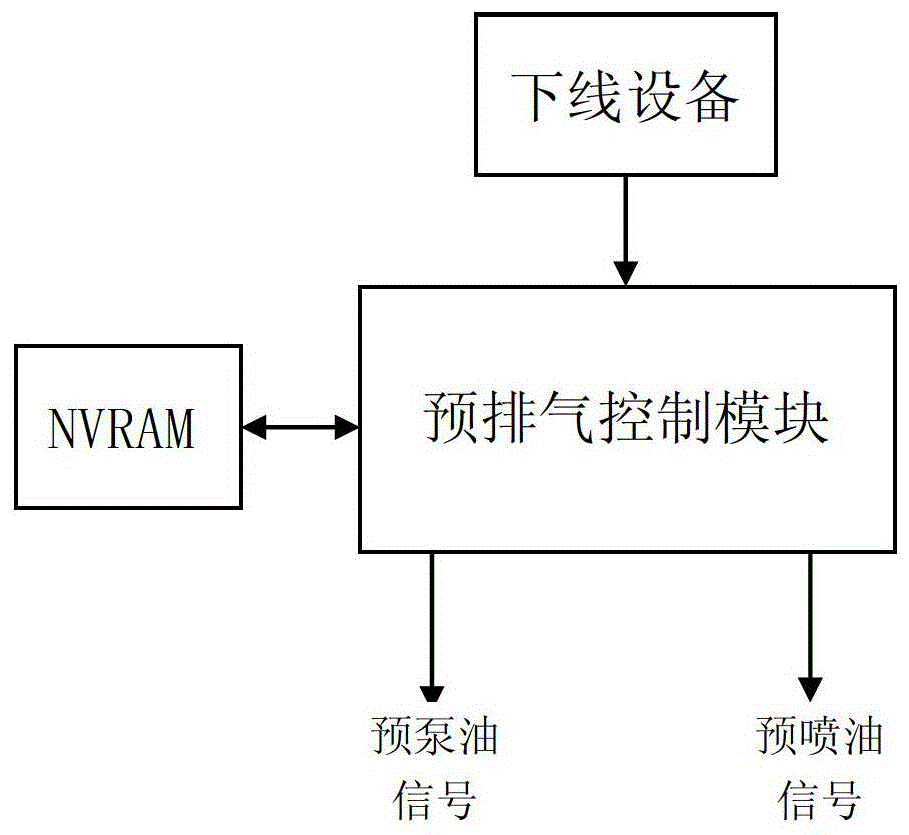

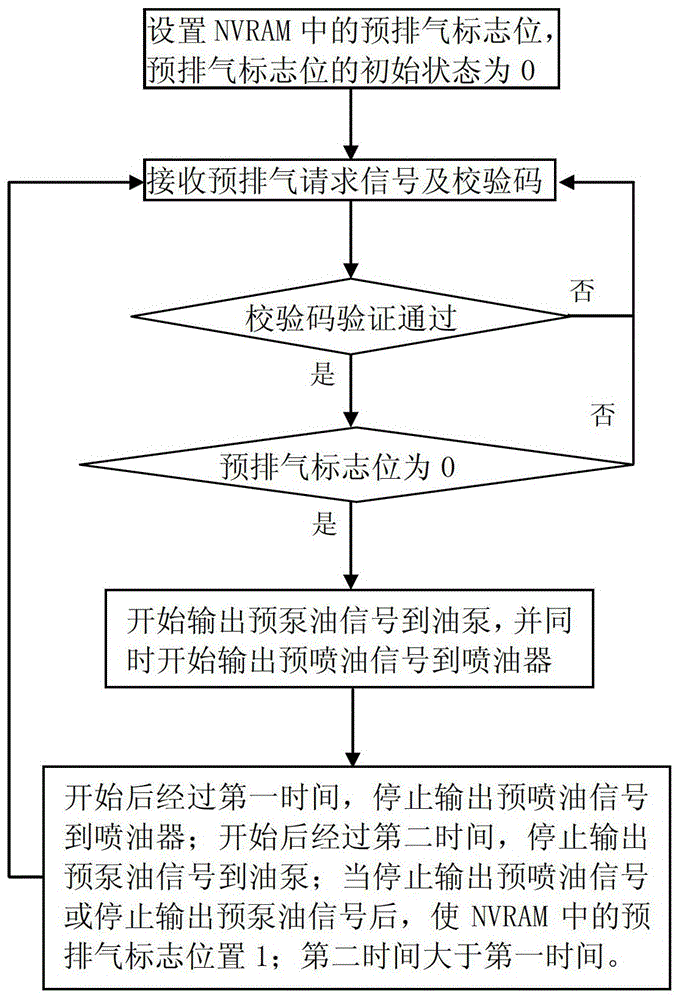

Vehicle pre-exhaust control system

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

New energy compound gasoline

InactiveCN110835563AReduce noiseReduce consumptionLiquid carbonaceous fuelsFuel additivesPtru catalystNew energy

The invention discloses new energy compound gasoline, comprising, by weight, 40 to 90 parts of gasoline, 10 to 60 parts of absolute ethanol, 1 to 25 parts of methanol, 1 to 30 parts of n-butanol, 1 to15 parts of triethanolamine, 1 to 30 parts of ethylene glycol, 1 to 18 parts of oleic acid and 0.1 to 0.5 part of a catalyst. Compared with the prior art, raw materials are widely available, the costis low, the manufacturing process is simple, refining is not needed, and the new energy compound gasoline is convenient and safe to use, enhances the power of an engine, reduces noise, increases thecombustion value, reduces fuel consumption, and enables the fuel to be fully burned without generating carbon deposits, which meets national energy conservation and environmental protection requirements.

Owner:于文学

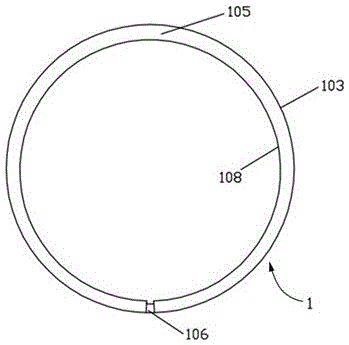

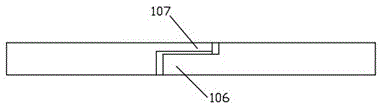

Pistons with clearance paired energy-saving and environment-friendly piston rings

ActiveCN103397950BReduce direct impactReduce the working environment temperatureMachines/enginesPistonsManufacturing technologyCombustion

The invention relates to the technical field of internal combustion engine accessory manufacturing, in particular to a piston of an energy-saving environment-friendly mounting clearance pairing piston ring. The piston of the energy-saving environment-friendly mounting clearance pairing piston ring comprises a piston body, a first gas ring and a second gas ring, wherein the first gas ring and the second gas ring are installed on the piston body, one end of an opening of a ring body of each gas ring serves as an extending portion, the other end of the opening of the ring body of each gas ring serves as a lap-joint portion, each lap-joint portion corresponds to each extending portion in length, when lap joint is carried out on each lap-joint portion and each extending portion in a vertical mode to enable the ring body of each gas ring to form the whole circle, a gap which cannot expand along with increase of the abrasion loss of each gas ring is formed between the slope of each extending portion and the slope of each lap-joint portion, a fixed matched proportion is arranged between the gap formed between the slopes at the position of the lap joint of the opening of the first gas ring and the gap formed between the slopes at the position of the lap joint of the opening of the second gas ring, and the value of the fixed matched proportion is 0.035mm-0.18mm to 0.02mm-0.12mm. The piston of the energy-saving environment-friendly mounting clearance pairing piston ring can greatly improve the sealing performance and the compression pressure of an air cylinder, fuel oil can carry out sufficient combustion, the phenomenon of carbon deposit can never happen, consumption of the fuel oil and consumption of engine oil are reduced, pollution emission is reduced, and various mechanical property indexes and various economic indexes of an internal combustion engine are greatly improved.

Owner:CHONGQING JIANGRUN PISTON RING

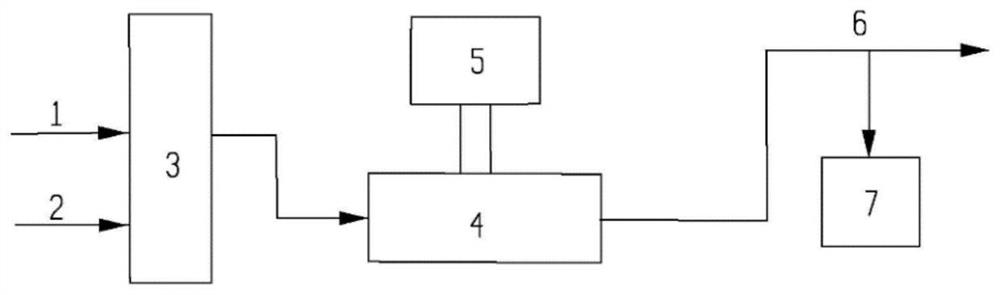

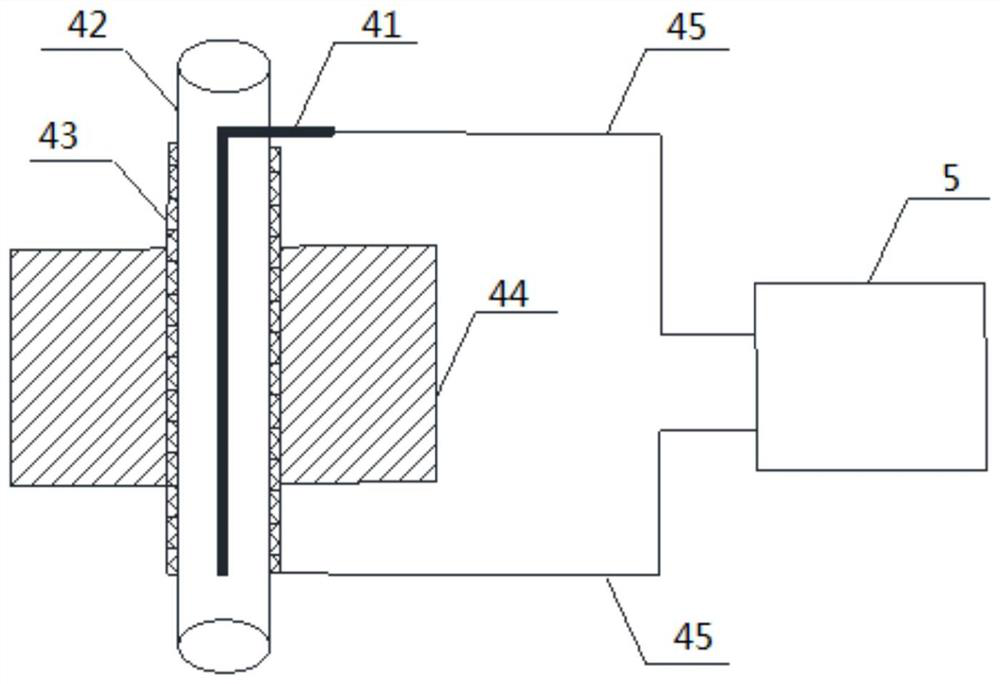

A method and device for producing synthesis gas by plasma-catalyzed dry reforming of methane

ActiveCN111547681BExtend your lifeImprove inactivation and other issuesHydrogenHydrogen/synthetic gas productionPtru catalystPhysical chemistry

The invention discloses a method and a device for producing synthesis gas by plasma catalytic methane dry reforming, and belongs to the technical field of methane and carbon dioxide reforming. The method includes: reacting carbon dioxide and methane under the coupled action of low-temperature plasma and a catalyst to generate synthesis gas mainly composed of carbon monoxide and hydrogen. This process can carry out reforming of methane and carbon dioxide at a lower reaction temperature and lower reaction pressure, reducing energy consumption of the device; supplementing the heat of the reaction unit through the heating furnace, it is easier to control the reaction depth and the conversion rate of raw materials, Does not produce a large amount of carbon deposits, thus prolonging the life of the catalyst. The device used includes a raw material gas distribution unit and a reaction unit. The gas outlet of the raw material gas distribution unit is connected to the inlet of the reaction unit. An ionization chamber is formed between the two electrodes in the reaction unit, and an insulating medium is arranged in the ionization chamber. The heating furnace is surrounded by the ground electrode, and the two electrodes are used for electrical connection with the low-temperature plasma power supply.

Owner:CHINA PETROLEUM & CHEM CORP +1

Additive for new energy compound gasoline

InactiveCN110835564AImprove performanceEasy to cleanLiquid carbonaceous fuelsFuel additivesPtru catalystNew energy

The invention discloses an additive for new energy compound gasoline. The additive comprises following raw materials by weight: 10-60 parts of absolute ethanol, 1-25 parts of methanol, 1-30 parts of n-butanol, 1-15 parts of triethanolamine, 1-30 parts of ethylene glycol, 1-18 parts of oleic acid and 0.1-0.5 part of a catalyst. The additive has widely available raw materials, low cost, and a simplemanufacturing process, does not need refining, is convenient and safe to use, improves engine power, reduces noise, improves the combustion value, reduces consumption of fuel, and enables the fuel tobe fully burned without carbon deposits, which meets the national energy-saving and environmental protection requirements.

Owner:于文学

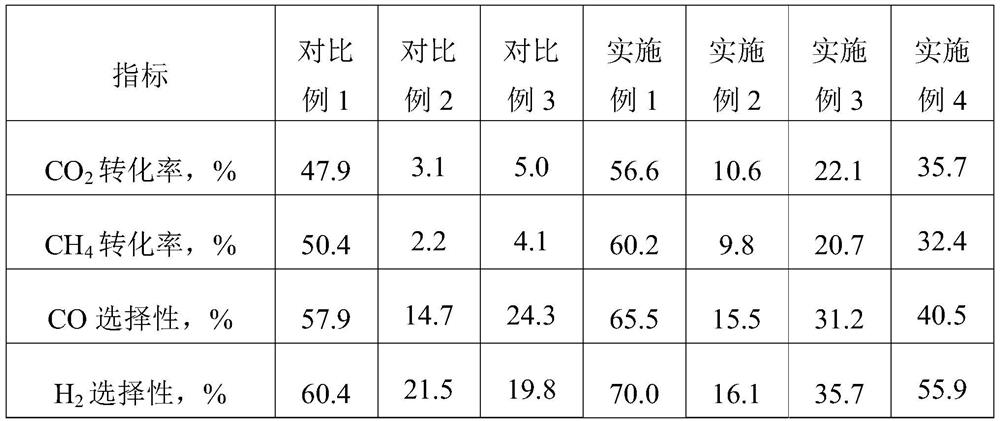

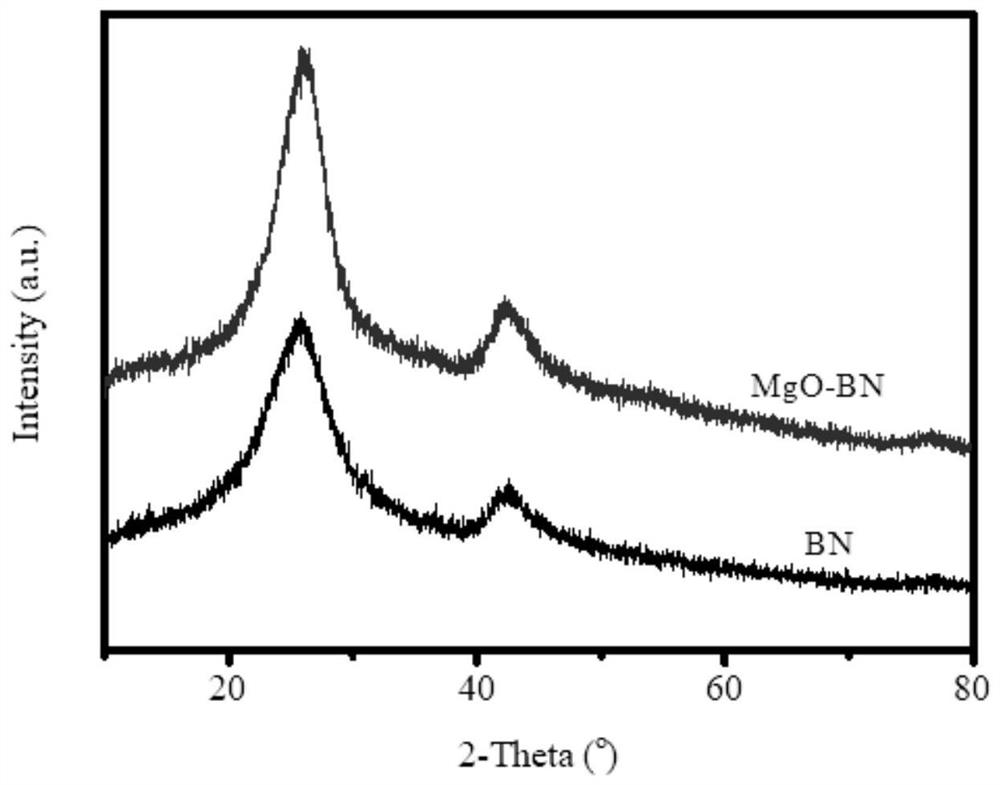

A kind of basic oxide modified boron nitride catalyst and its preparation method and application

ActiveCN111151287BIncrease reaction rateHigh selectivityPreparation by oxidation reactionsPhysical/chemical process catalystsPtru catalystBoron nitride

The invention discloses a basic oxide modified boron nitride catalyst and its preparation method and application. The catalyst is composed of basic oxide and boron nitride. The preparation method of the catalyst is as follows: adding boric acid and urea to a mixed solution composed of methanol and water to crystallize the original boron nitride material; then, adding an alkaline oxide precursor salt by impregnation, and then roasting in air A basic oxide-modified boron nitride catalyst is prepared. The obtained catalyst is heated and activated by feeding inert gas and oxygen-containing gas; finally feeding methane and oxygen to catalyze the selective oxidation of methane to produce formaldehyde and methanol. The method provided by the present invention belongs to the first time that basic oxide is added to boron nitride material as an auxiliary agent as a catalyst for the direct oxidation of methane to produce carbon-platform molecules such as formaldehyde and methanol, and has high catalytic efficiency and selectivity , has great potential for industrial application.

Owner:XIAMEN UNIV

A kind of intelligent control application of electric motor

ActiveCN104218871BExtended service lifeFix damageElectric motor controlPump controlMicrocontrollerControl signal

The intelligent control application of a kind of electric motor of the present invention, comprises single-chip microcomputer, and the driver and the pressure sensor that are connected with single-chip microcomputer respectively weakly, and the motor that is electrically connected with driver, and the pump head that is connected with motor drive, and described pump head The sensor is connected to a pressure sensor; the driver is externally connected with a high-current load wire; the motor is externally connected with a high-current load wire, and the driver is connected to the motor with a high-current load wire. The invention realizes the control signal of the micro-current to control the high-power motor load of the electronic device without mechanical loss, which can greatly prolong the service life of the electrical product, and solve the problem of excessive load current directly controlled by the sensor or control switch in the past. The control switch is damaged or the life is shortened. Long-term work will not produce carbon deposition, which is safe and reliable.

Owner:东莞市有意思电子科技有限公司

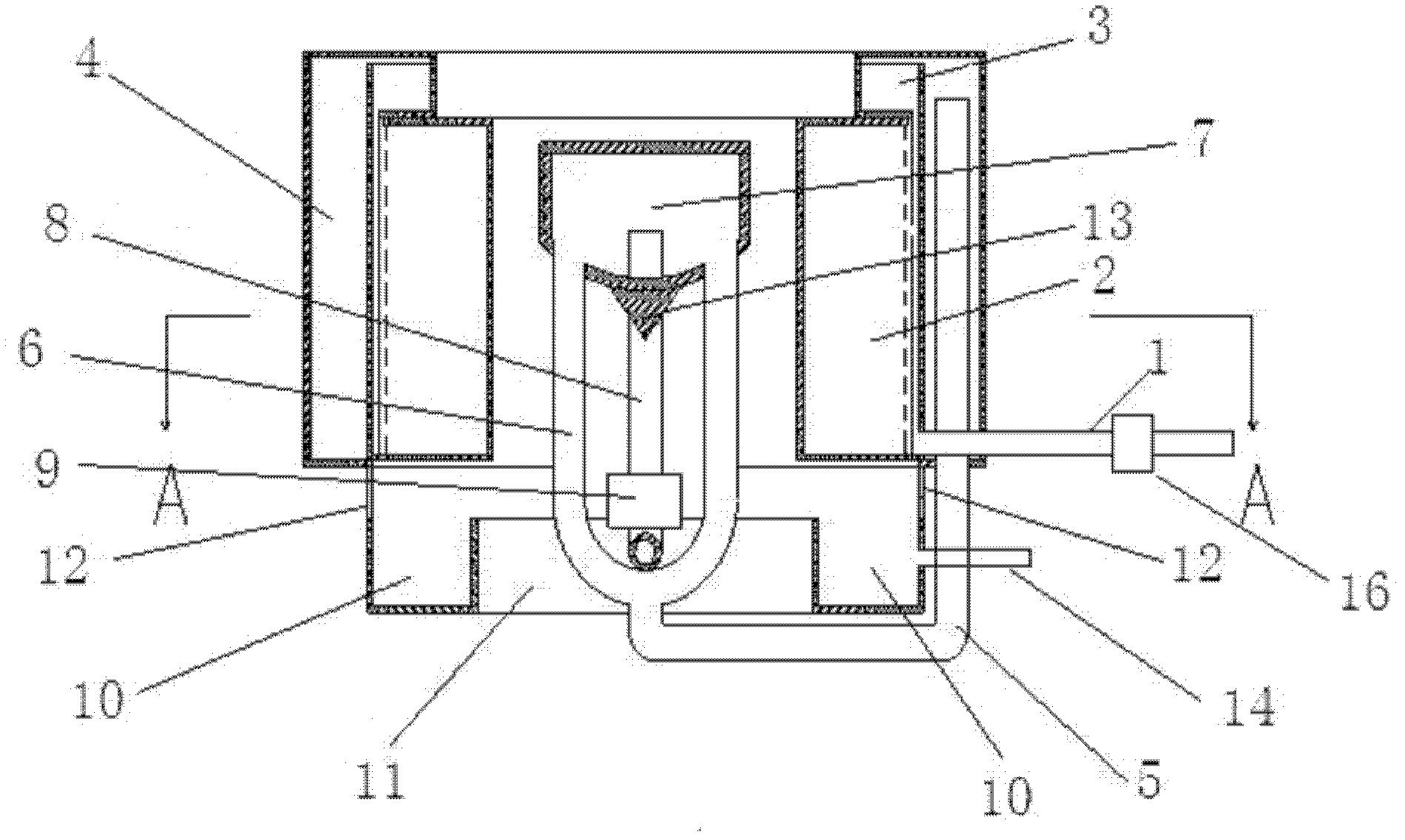

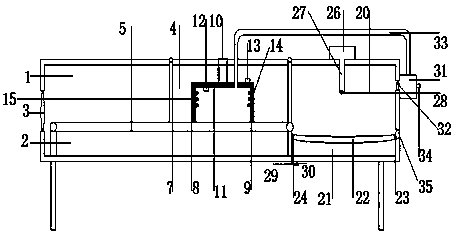

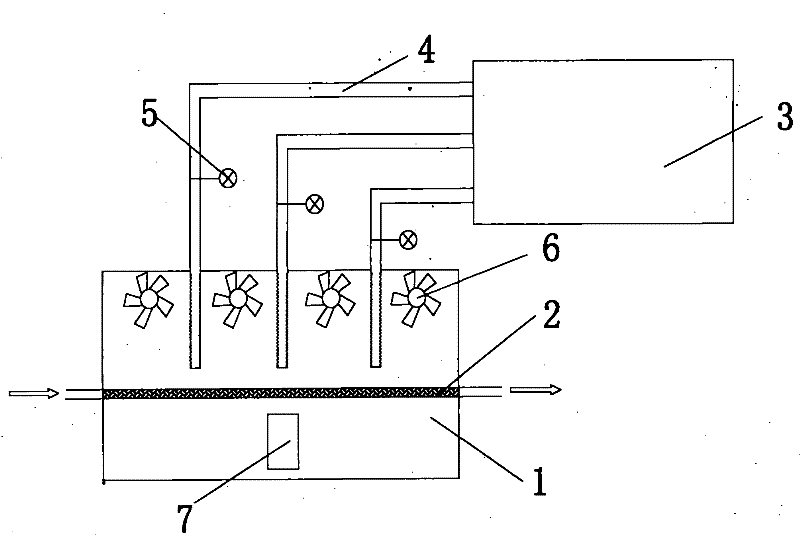

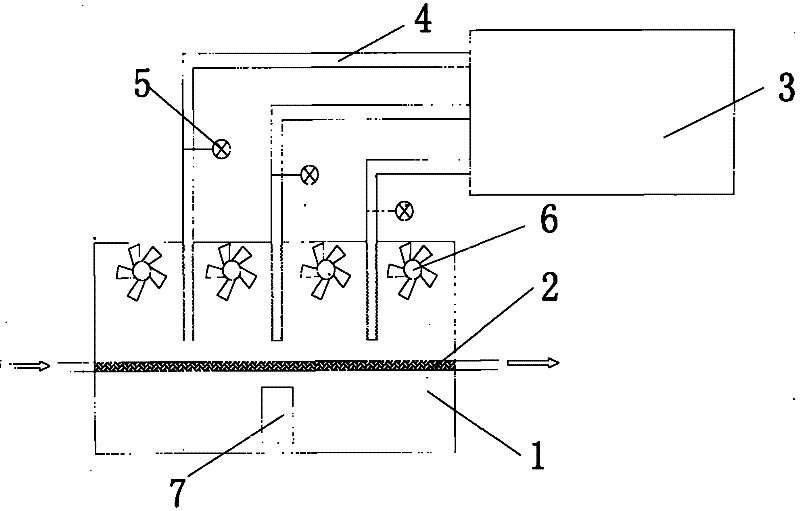

Quenching furnace with methanol gasifying device

InactiveCN101886157BExtended service lifeImprove qualityQuenching devicesDecompositionDisplay device

The invention discloses a quenching furnace with a methanol gasifying device, comprising the quenching furnace which is interlay horizontally provided with a mesh belt for conveying workpieces. The quenching furnace is characterized by also comprising the methanol gasifying device; a plurality of pipelines communicated with the quenching furnace are arranged on the top of the quenching furnace; the air inlets of the pipelines are communicated and connected with the methanol gasifying device; in the quenching furnace, fans are arranged beside the air outlets of the pipelines; a main control chamber of the quenching furnace is provided with a CP value display device; and the CP value display device is connected with an oxygen-carbon head. The invention solves the problems of incomplete gasification and decomposition of liquid methanol in the quenching furnace, damage of a furnace body and the workpieces and environment pollution in the prior art and provides the quenching furnace with the methanol gasifying device, thereby enabling the methanol to be gasified and cracked in the methanol gasifying device; and in addition, the invention can well control the flow of gasified methanol, thereby enabling a methanol gas to be uniformly distributed.

Owner:MORGAN HARDWARE KUSN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com