High-efficiency tunnel-type intermittent pyrolysis furnace

A tunnel-type furnace and tunnel-type technology are applied in the field of biomass fuel pyrolysis equipment, which can solve the problems of occupying cooling time, occupying heating time, and function failure, and achieve the effect of ensuring working pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

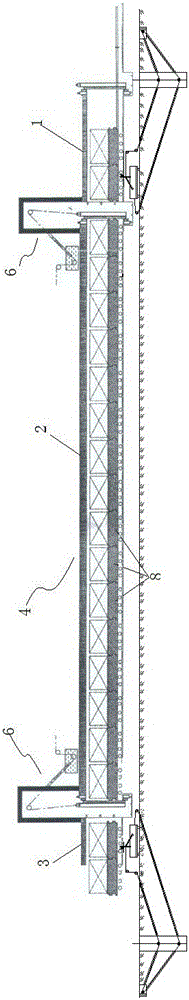

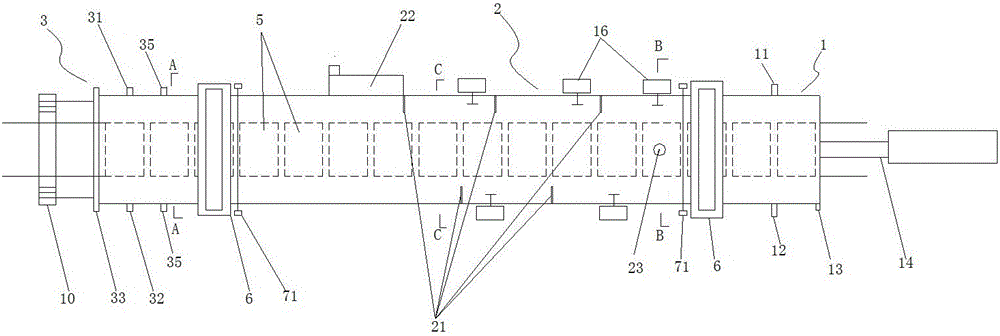

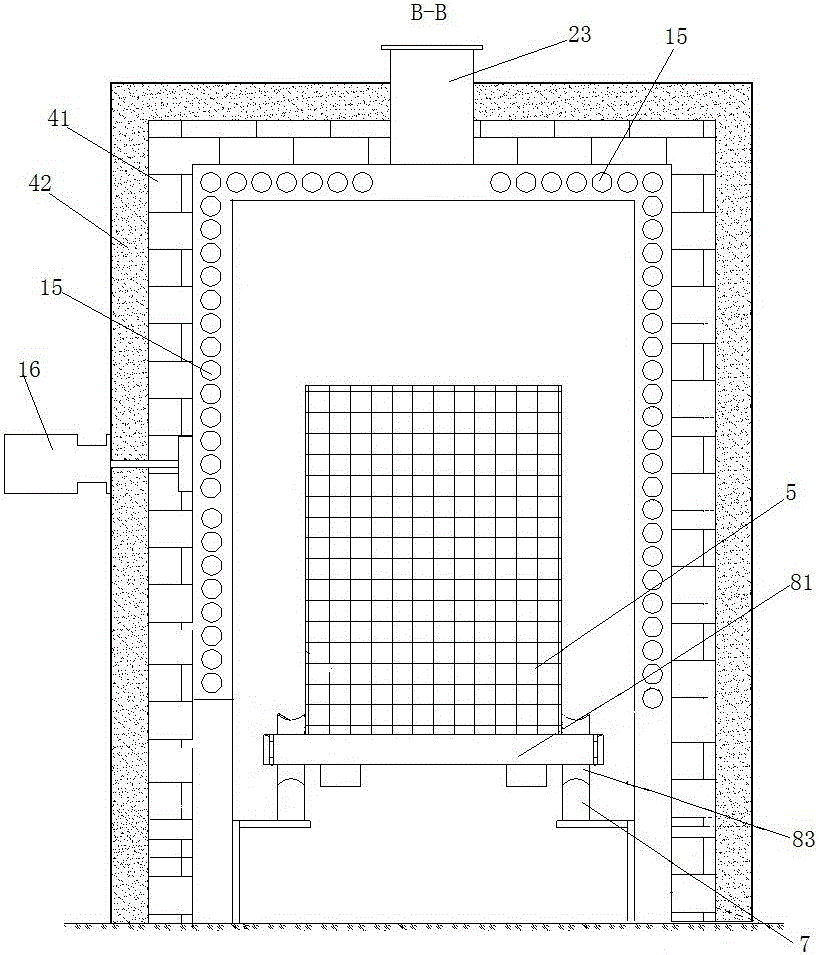

[0082] Such as Figure 1~10 As shown, a high-efficiency tunnel-type discontinuous pyrolysis furnace includes a tunnel-type furnace body 4, which is divided into a drying zone 1, a pyrolysis zone 2, and a cooling zone 3. The cross section of the furnace body 4 is rectangular or circular.

[0083] The inner bottom of the furnace body 4 is covered with a guide rail 7, and the guide rail 7 is provided with a mesh furnace frame 5 for filling the material to be heated, and at least four pairs of wheels 83 are provided at the bottom of the mesh furnace frame 5, and the wheels 83 are supported on the guide rail 7. on.

[0084] The guide rail 7 at the junction of the drying zone 1 and the pyrolysis zone 2 and the junction of the pyrolysis zone 2 and the cooling zone 3 is disconnected, and the width of the disconnection is greater than the thickness of the sealed door.

[0085] The distance between two adjacent wheels 83 of the net-shaped furnace frame 5 is greater than the width of the brea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com