A kind of basic oxide modified boron nitride catalyst and its preparation method and application

A technology of basic oxide and boron nitride, which is applied in the field of basic oxide modified boron nitride catalyst and its preparation, can solve the problem of low reactivity and achieve simple preparation method, good application prospect and easy availability of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Catalyst Preparation:

[0029] (1) To a solution of methanol and water at a weight ratio of 1: 40ml 5 mixed solution consisting of boric acid and was added 0.618g 18.018g urea and stirred 12h, the resulting mixed solution in a constant temperature water bath at 8h crystal 80 ℃, and the resulting crystal placed in a vacuum oven dried 100 ℃ for 12h, 2h and finally calcined raw boron nitride material prepared at 1000 ℃ in nitrogen, referred to as BN;

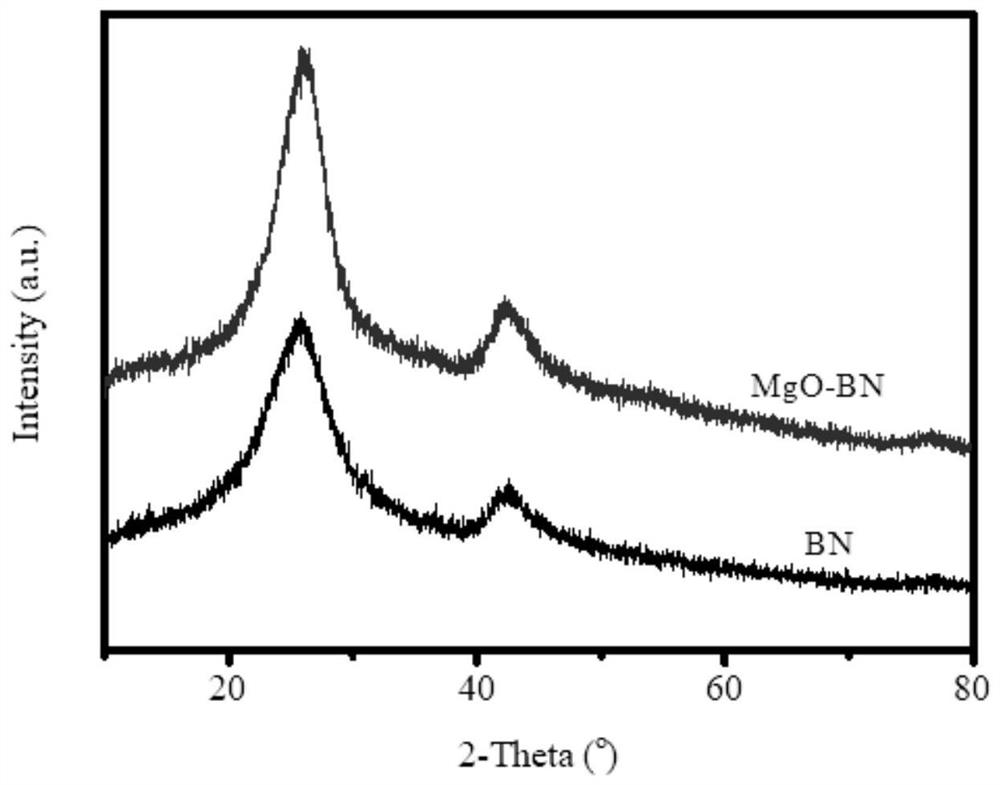

[0030] (2) 0.0065g of magnesium nitrate hexahydrate was added to 10mL of ethanol and stirred to dissolve, then added 0.1g step (1) prepared in the original boron nitride material, the resulting mixture was mixed uniformly in a constant temperature water bath after 80 ℃ and stirred until all the solvent was evaporated, the resulting solid was dried 12h 80 deg.] C in a vacuum oven, then calcined at 2h modification made to the basic oxide catalyst is boron in air at 800 deg.] C, referred to as MgO- the content of BN, wherein, BN wa...

Embodiment 2

[0035] Preparation of catalyst:

[0036] (1) 0.618 g of boric acid and 18.018 urea were added to 40 ml of a mixed solution composed of methanol and water and stirred for 6 h, and the resulting mixed solution was placed in a constant temperature water bath, then the resulting crystal was placed in 40 ° C was dried in a vacuum drying tank for 24 h, and finally the original boron nitride material was obtained at 700 ° C for 6 h in nitrogen.

[0037] (2) 0.065 g of hexahydrate is added to 10 mL of ethanol and stirred and dissolved, then the original boron nitride material prepared in 0.1 g of step (1), mixing the resulting mixture at a constant temperature water bath, 40 ° C Stirring was stirred to all solvent evaporation, and the obtained solid was dried in a vacuum drying tank at 40 ° C for 24 h, and then calcined in 400 ° C for 2 h in the air. BN-1, where the content of BN is 90%.

[0038] The catalyst assessment conditions are in Example 1. The results of the assessment are shown ...

Embodiment 3

[0040] The methanol and water in step (1) were converted to 1: 50 by weight, and the amount of urea was adjusted to 30.9 g; the amount of six hydrolysis nitrate in step (2) was adjusted to 0.0337 g, and other conditions did not change. This example catalyst can be obtained, which is mgO-BN-2, wherein the content of BN is 95%.

[0041] The catalyst assessment conditions are in Example 1. The results of the assessment are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com