Quenching furnace with methanol gasifying device

A technology of gasification device and quenching furnace, which is applied in the direction of quenching device, heat treatment equipment, manufacturing tools, etc., can solve the problems of incomplete gasification and decomposition, damage to the furnace body and workpiece, pollution of the environment, etc., to achieve uniform distribution and fullness, improve quality, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

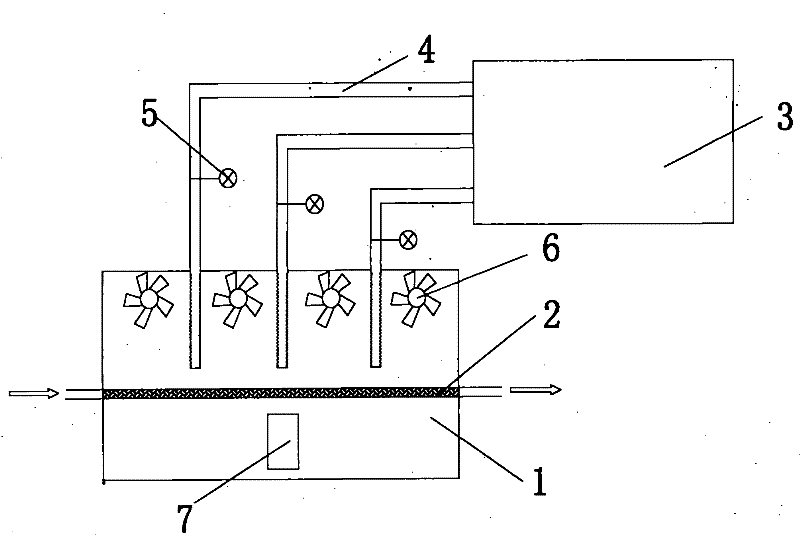

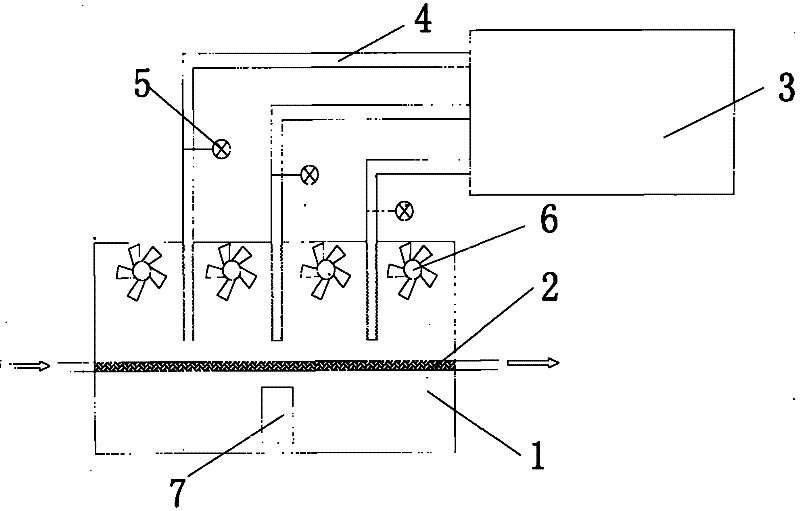

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, a quenching furnace with a methanol gasification device includes a quenching furnace 1 and a methanol gasification device 3, and a mesh belt 2 for conveying workpieces is arranged horizontally in the quenching furnace 1; three inlets are arranged on the top of the quenching furnace 1 The pipelines 4 in the quenching furnace are all provided with a valve 5 for controlling the opening and closing of the pipelines on each pipeline 4 . The air inlet of the pipeline 4 is connected through the methanol gasification device 3. In the quenching furnace 1, a fan 6 is arranged beside the gas outlet of the pipeline 4; Display device 7 is connected with stretching into the oxygen carbon head in quenching furnace 1. The working process of the quenching furnace with methanol gasification device is introduced below:

[0015] 1. Methanol is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com