Wrinkle chasing mechanism

The technology of a ventilator and a water collecting tank is applied in the directions of shoe-making machinery, clothing, application, etc., which can solve the problems of increasing the difficulty of processing, scalding leather, and low efficiency of wrinkle removal, etc., and achieves the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

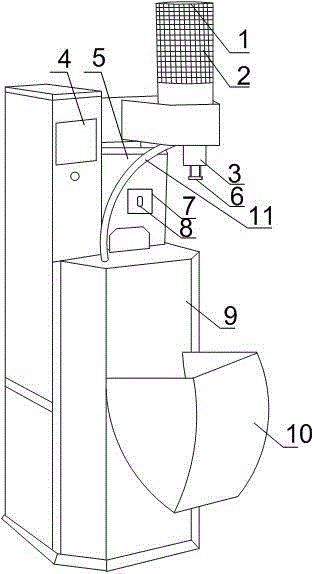

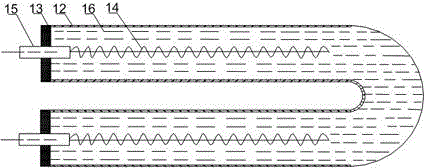

[0019] Such as figure 1 As shown, the present embodiment includes a support 9, and the support 9 is provided with a fan, an air inlet pipe 1, an air outlet pipe 2, a pressure roller 6 and a water collection tank 5, and the air inlet pipe 1 is arranged above the fan , the air outlet pipe 2 is arranged below the fan, the pressure roller 6 is placed directly below the air outlet pipe 3, and a collection frame 10 is fixedly arranged on the support 9, and the frame opening of the collection frame 10 faces the pressure roller 6, also includes a heater and an atomizing device, the heater is located between the ventilator and the air outlet pipe 2, the atomizing device is arranged in the water collection box 5, and the water collection box 5 is connected to the heater through a conduit 11; The heater includes a housing and a plurality of heating tubes 12, the heating tubes 12 are placed in the housing, and a plurality of through holes are opened on the housing, the heating tubes 12 in...

Embodiment 2

[0022] Such as figure 1 As shown, on the basis of Embodiment 1, the present embodiment is also provided with a sensor 7 and an alarm 8 connected to each other on the water collection tank 5, the sensor 7 is placed in the water collection tank 5, and the alarm 8 is placed in the water collection tank 5. Outside the water collection tank 5; due to the high requirements of the wrinkle removal process, it takes more time during processing, and the demand for water in the water collection tank 5 is relatively large; when the water level in the water collection tank 5 is low, set it in the water collection tank 5 The sensor 7 inside transmits the water level information to the alarm 8, and the alarm 8 sends a prompt alarm in time, and the operator replenishes the water quantity in time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com