Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125results about How to "Heating fully and evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

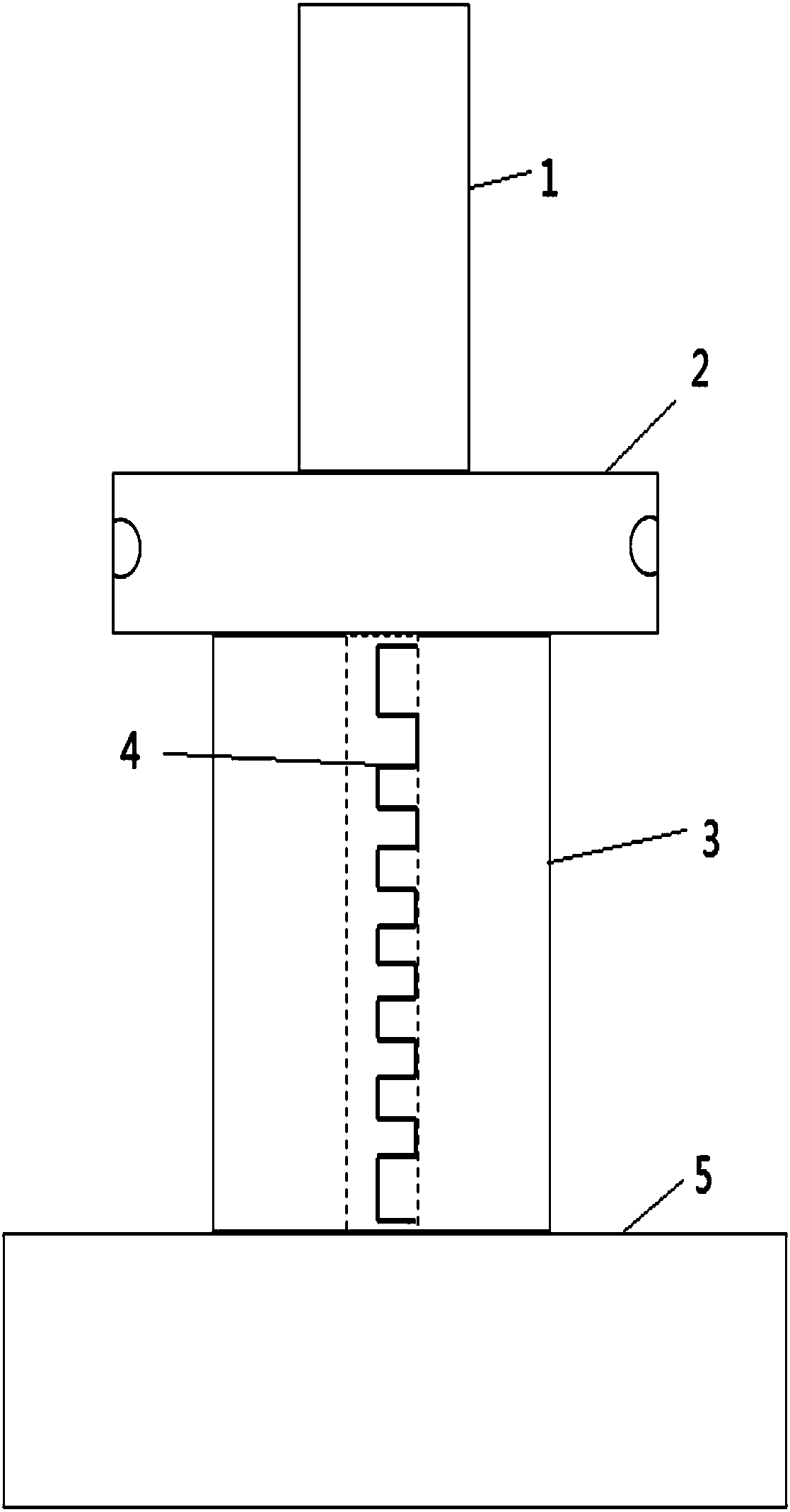

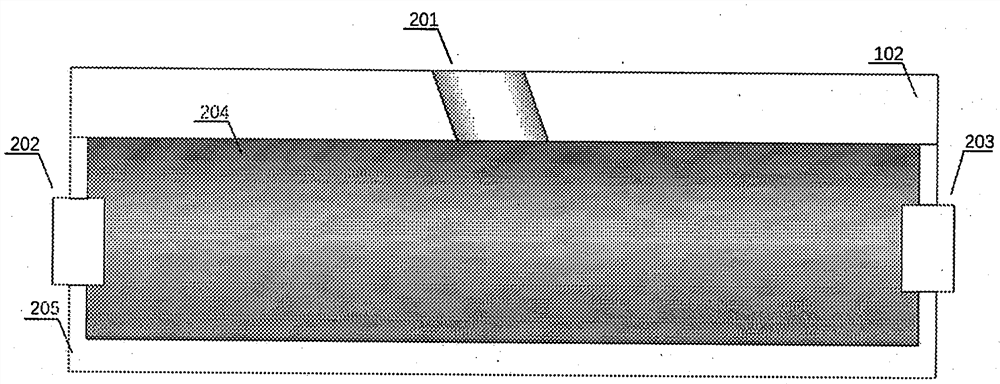

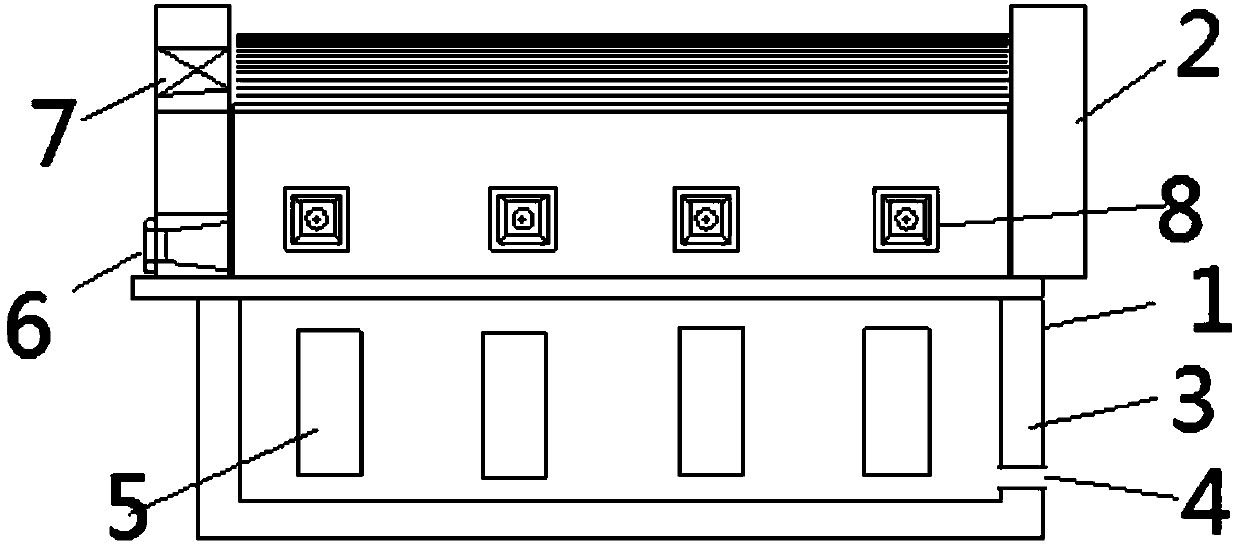

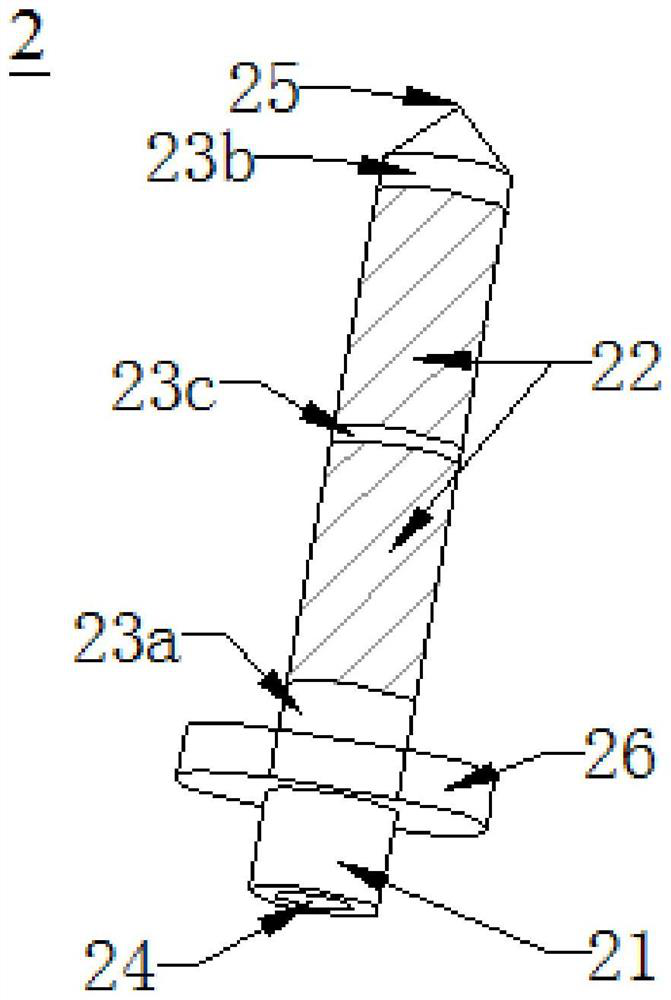

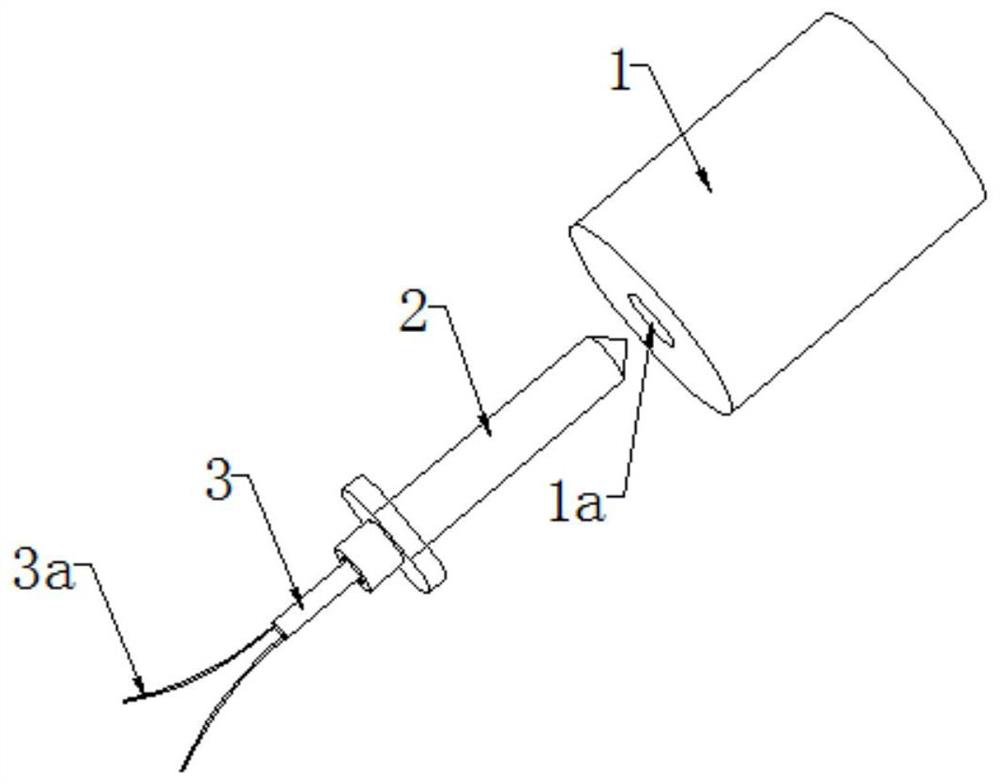

Low temperature tobacco smoking set heated by hot air

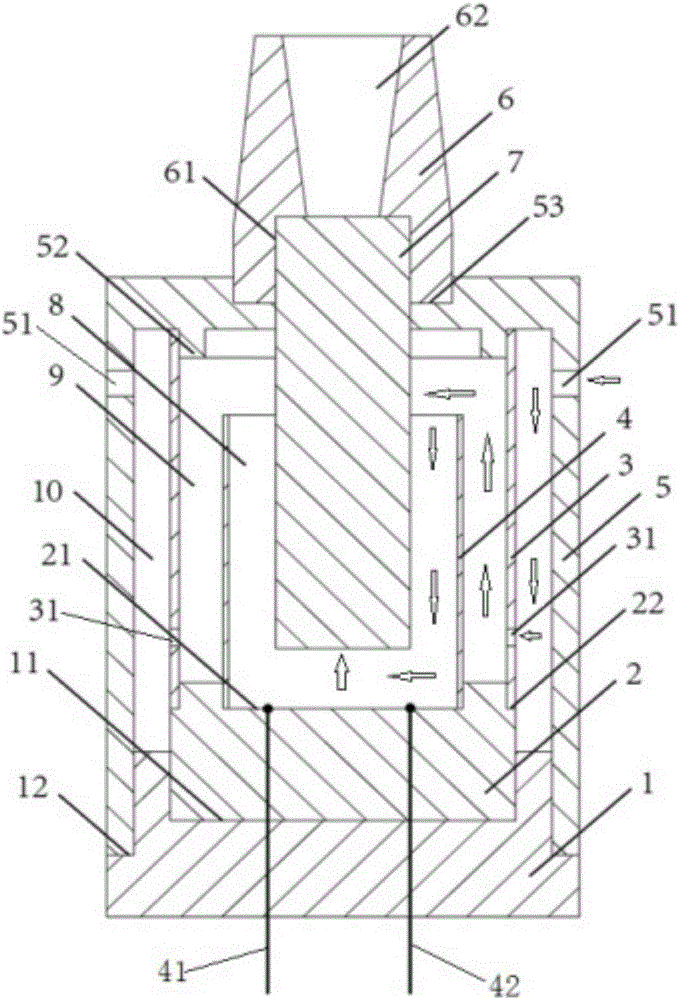

A low temperature tobacco smoking set heated by hot air comprises a base (1), an insulating seat (2), a tubular heating element (4), a strip top plate and a shell (5), wherein the base (1) is provided with a first outer ring bearing platform (12) and a first upper part center groove (11); the insulating seat (2) is mounted in a first round center groove; a second upper part round center groove (21) is arranged at the upper part of the insulating seat (2); the tubular heating element (4) is mounted in the second upper part round center groove (21); the strip top plate is located on the first outer ring bearing platform (12); a round bearing platform (53) is formed in the center of the top of the shell (5); a suction nozzle (6) provided with a gas guide channel (62) in the center is mounted on the round bearing platform in an insertion manner; an insertion hole, into which a cylindrical tobacco material (7) can be inserted, is formed in the center of the bottom of the suction nozzle; and a positive electrode (41) and a negative electrode (42) of the heating element respectively penetrate through the insulating seat and are connected with a power supply device. The smoking set has the advantages that the heating uniformity of the tobacco material can be improved, aroma components are promoted to be uniformly and fully released, the suction experience feeling is improved, and charring of the tobacco material is avoided, so as to reduce the generation of harmful substances.

Owner:云南拓宝科技有限公司

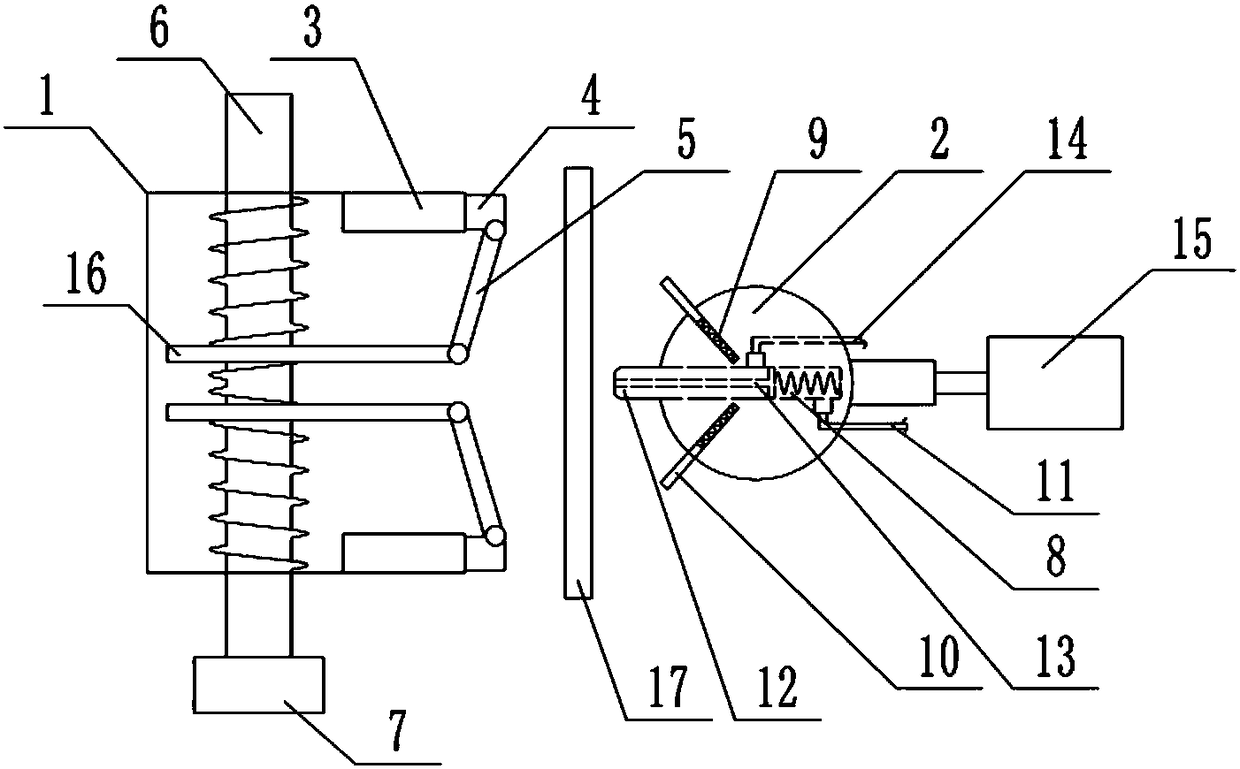

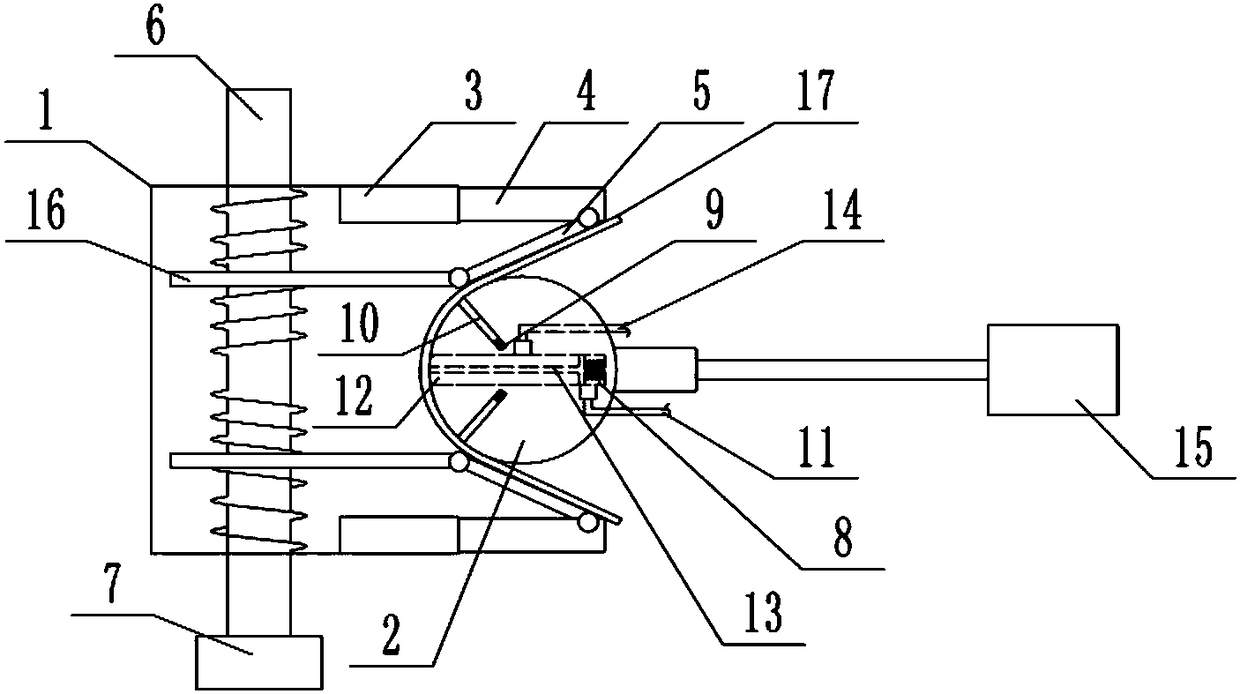

Spring type automatic frying pan

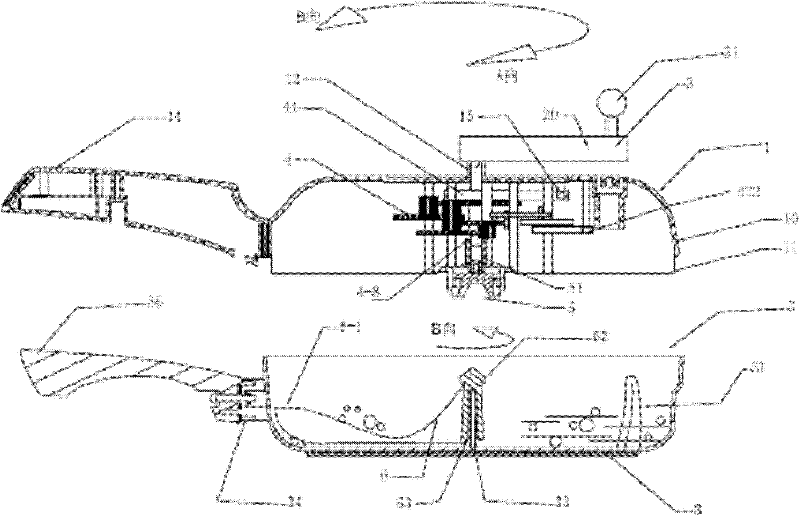

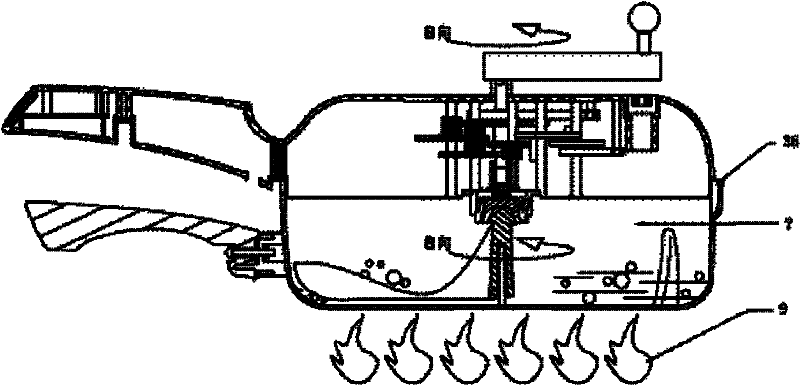

InactiveCN102327049AImplement auto-rotationHeating fully and evenlyCooking vesselsGear wheelIncreased torsion

The invention relates to a spring type automatic frying pan, which comprises a pan body. A mixing rake used for mixing food is arranged in the pan body, a spring type power device used for driving the mixing rake to rotate is connected with the mixing rake and comprises a power spring, a transmission gear group, a limiting swing rod component and a fixed-speed swing component connected sequentially, the power spring is used for storing energy, the transmission gear group is used for transferring energy, the limiting swing rod component is used for limiting the rotating speed of the transmission gear group, the fixed-speed swing component is used for determining the swinging frequency of the limiting swing rod component, and the spring type power device is also provided with a rotating handle used for increasing torsion of the spring. By adopting the spring type power-driven frying pan, automatic mixing of food can be achieved via the mixing rake under conditions with no power supply, a user can conveniently rotate the power spring to store energy due to the rotating handle of the spring type power device, the energy in the power spring can be realized at a constant speed due to combination of the limiting swing rod component and the fixed-speed swing component, the automatic mixing time is extended, and more full and uniform food heating can be ensured.

Owner:新兴县粤兴华不锈钢制品有限公司

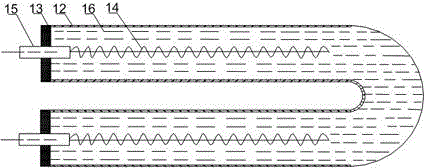

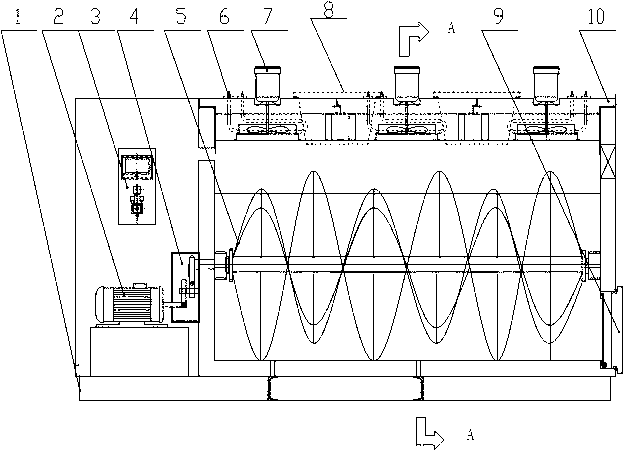

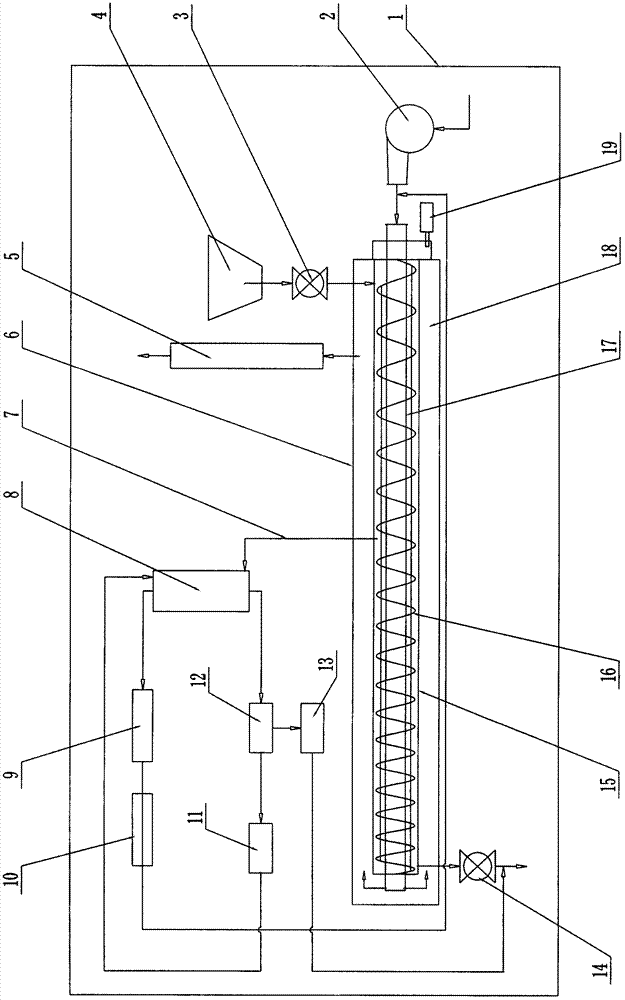

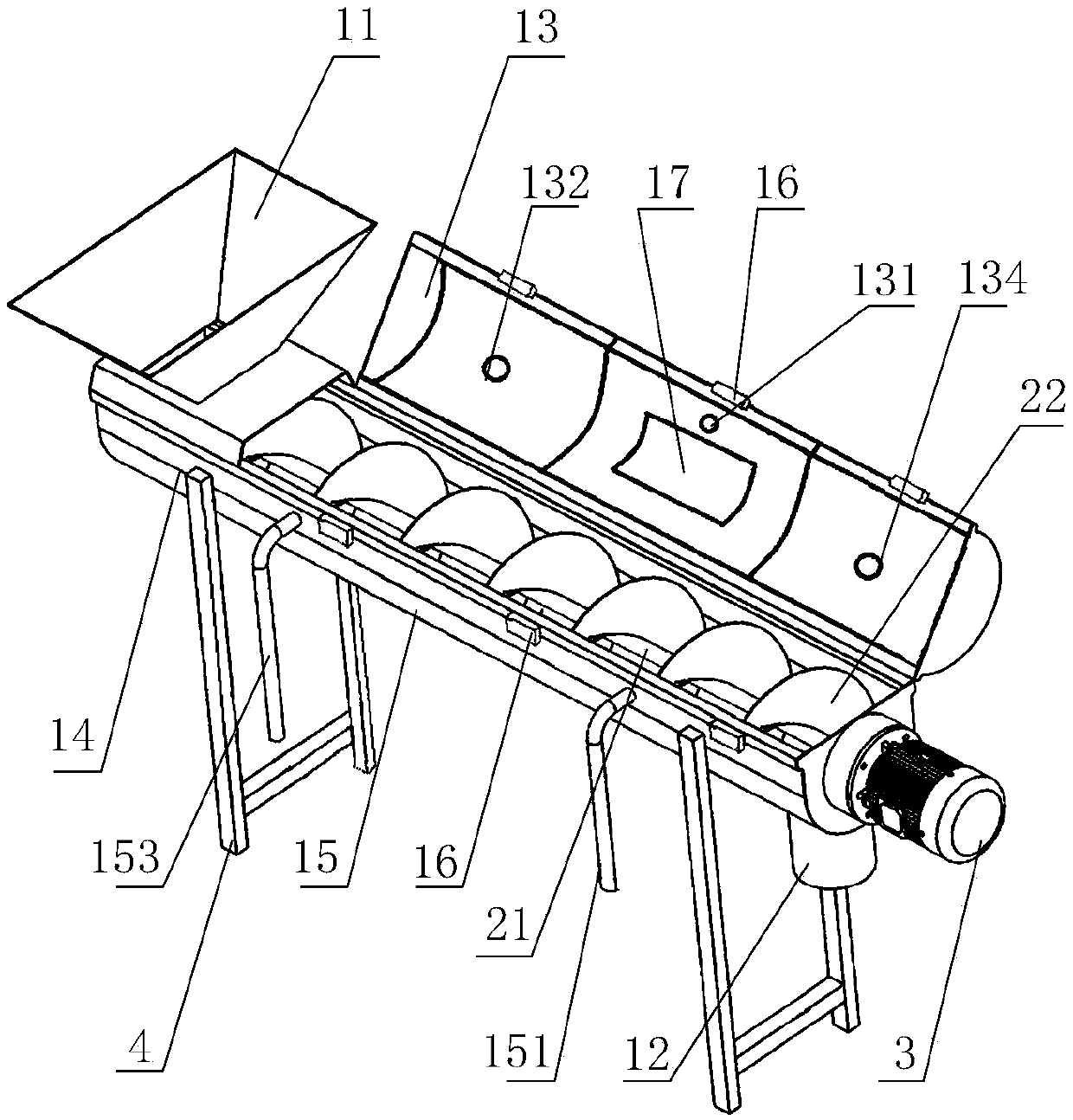

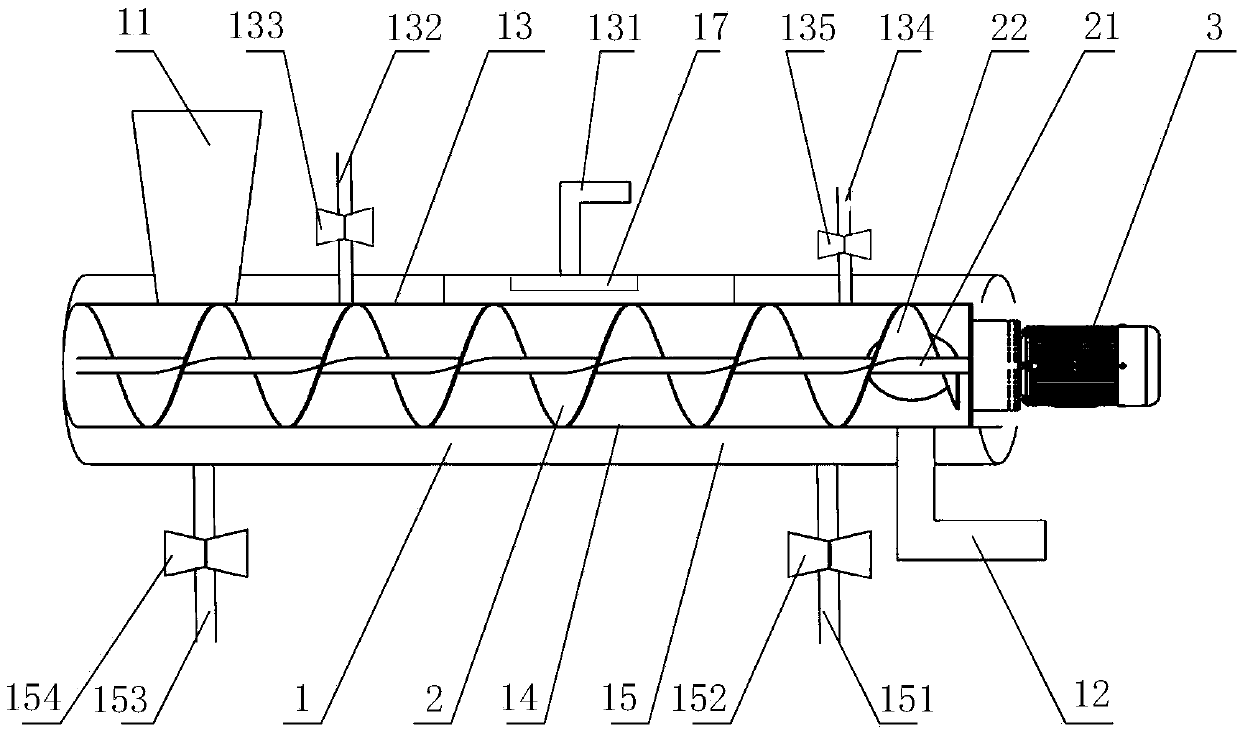

Efficient indirect thermal desorption device

ActiveCN105057337AEasy to solveHigh removal rateContaminated soil reclamationSpray towerActive carbon

The invention discloses an efficient indirect thermal desorption device, and belongs to a polluted soil remediation device. The efficient indirect thermal desorption device comprises a sledge body, wherein a material feeding hopper, a material feeding air lock, an outer barrel, a material discharging air lock, a motor, a combustor, a chimney, a spraying tower, an active carbon adsorption tank, a draught fan, an oil water separator, an air cooler and a water treatment device, wherein a heat preservation shell sleeves the outer barrel; a shaftless winch is arranged in the outer barrel; a combustion pipe is inserted into the shaftless winch; the outlet of the material feeding hopper is communicated with the inlet of the material feeding air lock; the outlet of the material feeding air lock is communicated with the material inlet above the right end of the outer barrel; the material outlet below the left end of the outer barrel is communicated with the inlet of the material discharging air lock. The efficient indirect thermal desorption device has the advantages of high treatment capacity, high pollutant removal rate, high thermal efficiency, good sealing property, smaller size and convenience in transportation and mounting when treating organic polluted soil, mercury polluted soil or petroleum polluted soil.

Owner:ZHEJIANG EASYCLEAN ENVIRONMENTAL TECH CO LTD

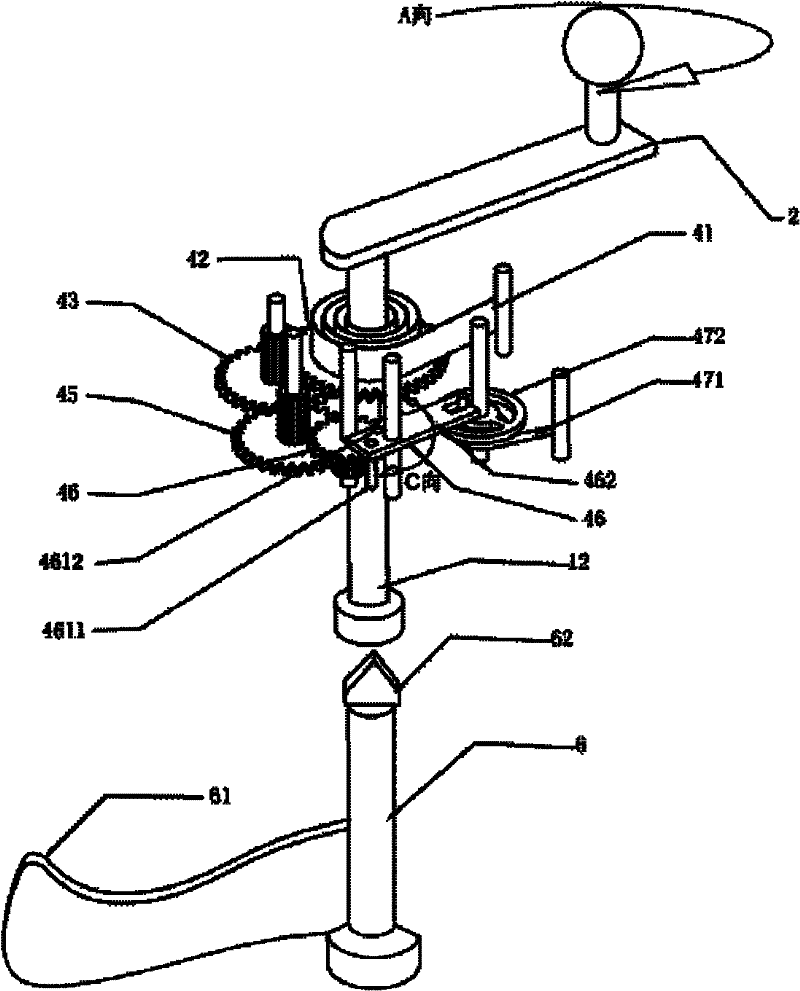

Wrinkle chasing mechanism

InactiveCN104621861AImprove efficiencyTo avoid the phenomenon of stopping heating after burning outShoemaking devicesWrinkleEngineering

The invention discloses a wrinkle chasing mechanism. The wrinkle chasing mechanism comprises a support, and the support is provided with a ventilator, an air inlet pipe, an air outlet pipe, a pressing roller and a water collection tank. The air inlet pipe is arranged on the upper portion of the ventilator, the air outlet pipe is arranged on the lower portion of the ventilator, and the pressing roller is arranged under the air outlet pipe. The support is further fixedly provided with a collection frame, and a frame opening of the collection frame is arranged under the pressing roller. The wrinkle chasing mechanism further comprises a heater and an atomization device, the heater is located between the ventilator and the air outlet pipe, the atomization device is arranged in the water collection tank, and the water collection tank is connected with the heater through a guide pipe. Through the matching usage of mixed gas and the pressing roller, smooth processing can be quickly performed on leather facing, and when the leather facing drops, the collection frame arranged under the pressing roller can avoid the leather facing from being damaged caused by landing; atomized water vapor and the air heated by the heater are mixed and act on the leather facing through the air outlet pipe, and the leather facing wrinkle chasing efficiency can be improved under the rolling effect of the pressing roller.

Owner:CHENGDU FENGFAN TECH

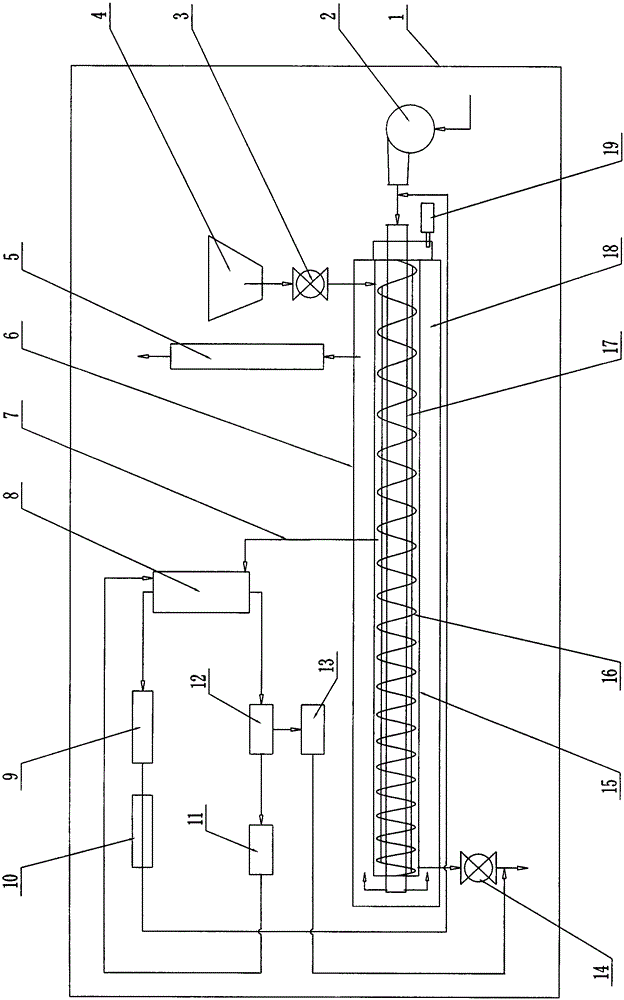

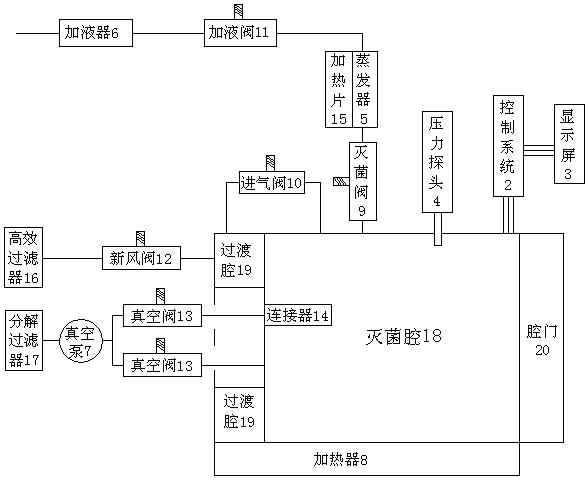

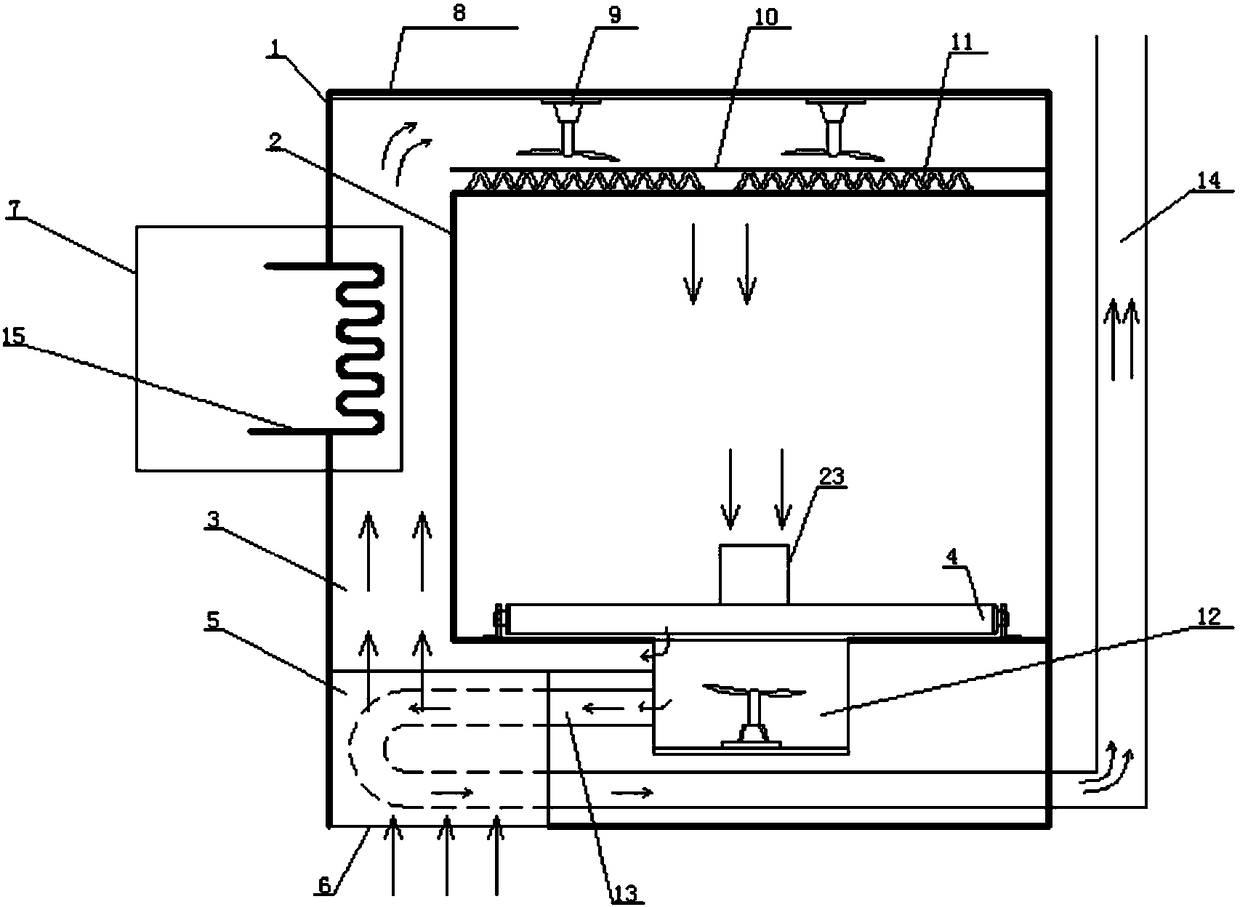

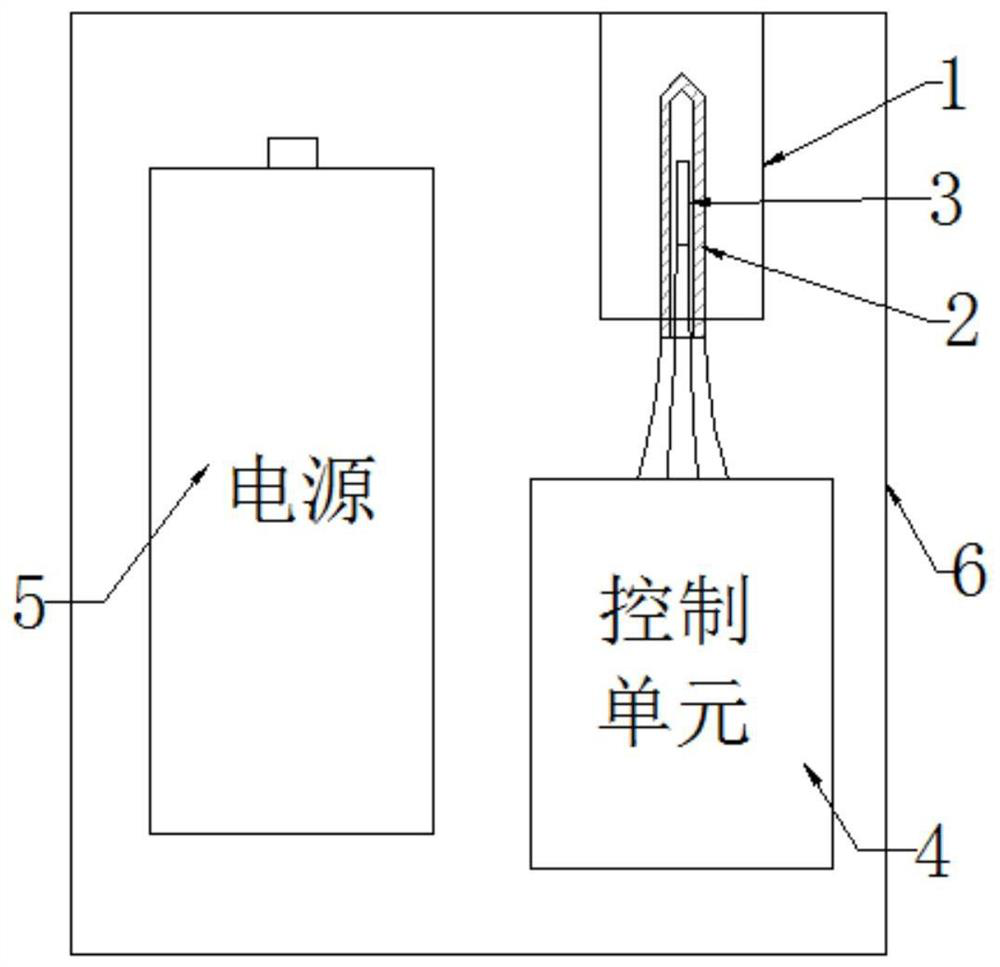

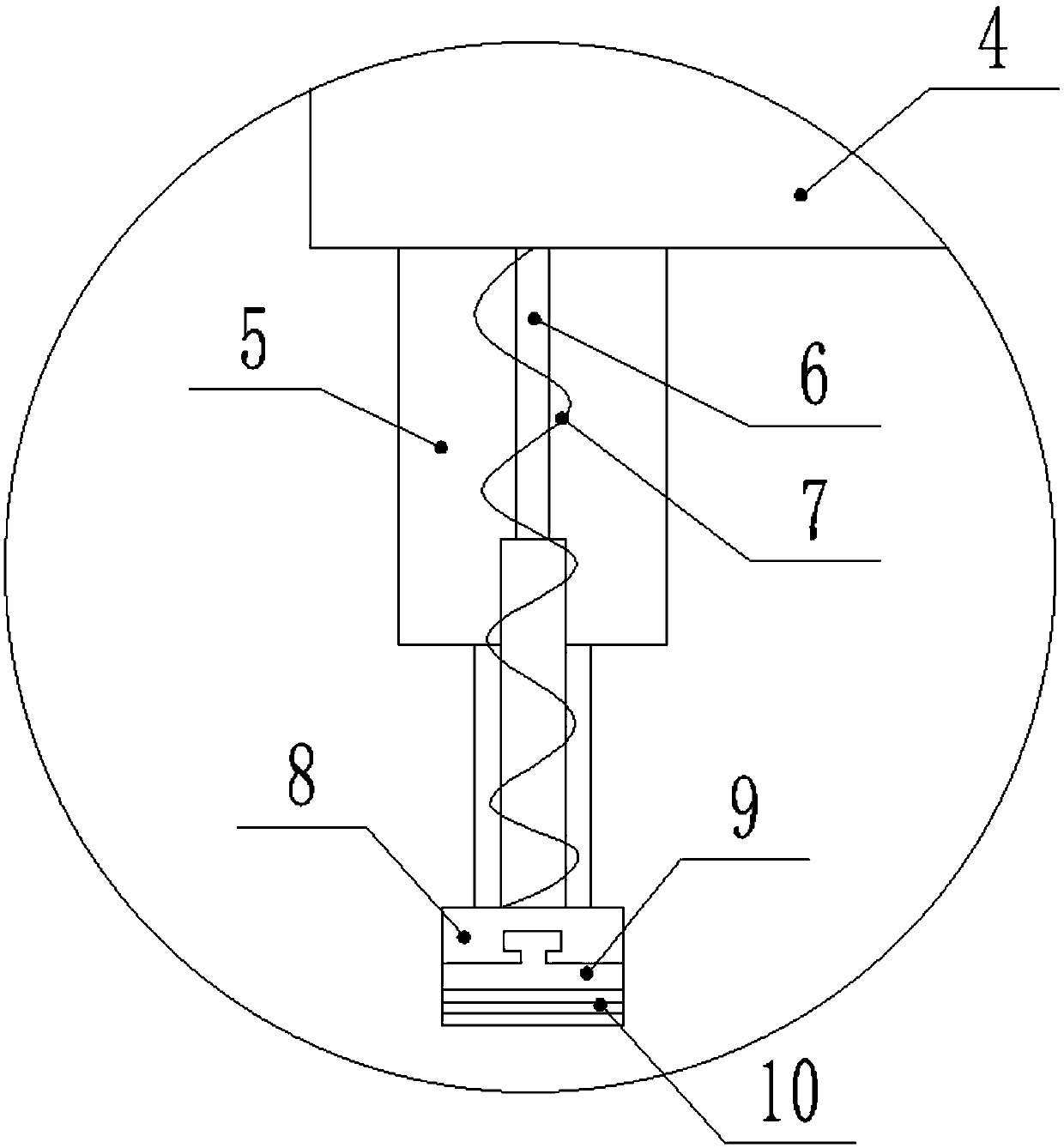

Hydrogen peroxide low-temperature sterilizing equipment and use method thereof

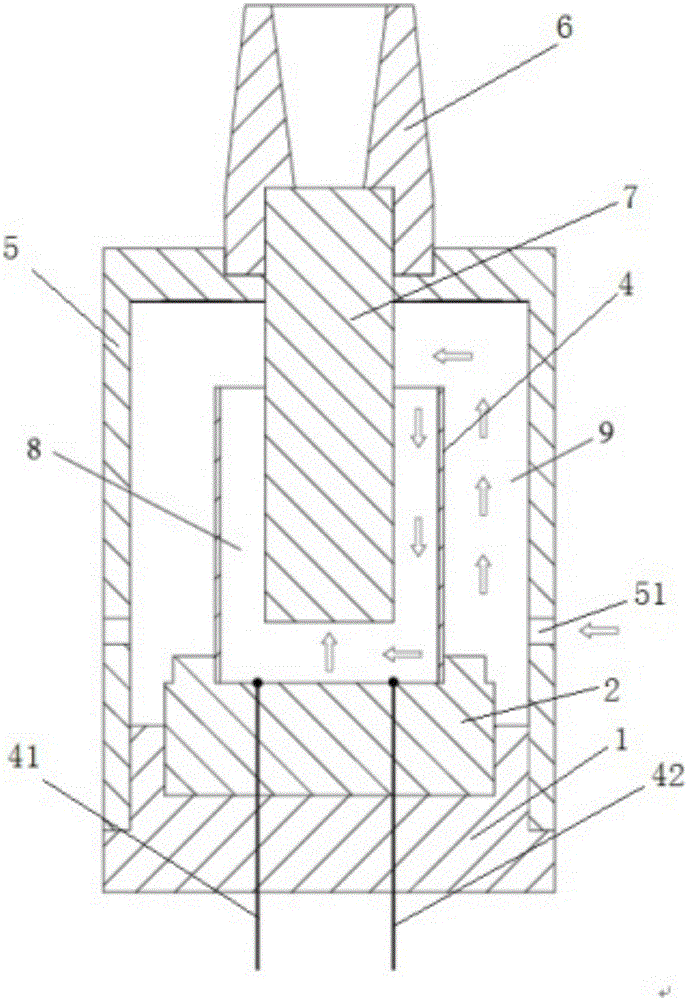

ActiveCN102350003AImproved vaporizationEasy dischargeChemicalsVacuum pumpLow temperature sterilization

The invention discloses hydrogen peroxide low-temperature sterilizing equipment and a use method thereof. The sterilizing equipment comprises a cavity body (1), an evaporator (5), a liquid feeder (6), a vacuum pump (7), a heater (8) and a high-efficiency filter (16), wherein the cavity body (1) is divided into a sterilizing cavity (18) and a transition cavity (19); the sterilizing cavity (18) is connected with the outlet end of the evaporator (5) through a sterilizing valve (9); the inlet end of the evaporator (5) is connected with the liquid feeder (6) through a liquid feeding valve (11); a heating sheet is arranged on the evaporator (5); the air suction end of the vacuum pump (7) is connected with the sterilizing cavity (18) through a vacuum valve (13); and the air outflow end of the vacuum pump (7) is connected with a decomposition filter (17). The sterilizing equipment can sterilize medical appliances at a low temperature, can carry out sufficient sterilization on the pipelines of the medical appliances with slender holes, and can also carry out filtration and decomposition on the used hydrogen peroxide vapor.

Owner:LAOKEN MEDICAL TECH

Convection conduction type electrical heating device for electric cooker

InactiveCN106388625AHeating fully and evenlyHeated evenly and fullyCooking-vessel materialsWarming devicesHeating effectEngineering

The invention discloses a convection conduction type electrical heating device for an electric cooker. A heating inner container is embedded into an outer container containing cavity of a metal heating outer container, the upper side end of the metal heating outer container is provided with a movable cover body at an opening of the upper end of the outer container containing cavity, a bottom surface thick film heating element is printed on the lower surface of the metal heating outer container, a side wall thick film heating element is printed on the outer surface of the side wall of the metal heating outer container, and a cover body thick film heating element is printed at a middle position of the lower surface of the movable cover body; the novel electric cooker electrical heating device also comprises a controller, and a temperature sensor is arranged on the lower surface of the metal heating outer container; and a food heating chamber is moulded inside the heating inner container, the heating inner container is suspended in the outer container containing cavity, and the outer surface of the heating inner container and the inner wall of the outer container containing cavity are arranged at intervals. The convection conduction type electrical heating device for the electric cooker has the advantages that a safe and nonradiative surround three-dimensional thick film heating way is adopted for heating and cooking food, and the food can be effectively, fully and uniformly heated. Therefore, the convection conduction type electrical heating device for the electric cooker has the advantages of novel structural design, high security and good heating effect.

Owner:DONGGUAN ZUOYOU ELECTRONICS TECH CO LTD

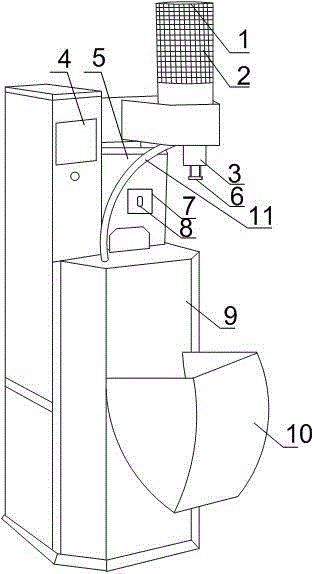

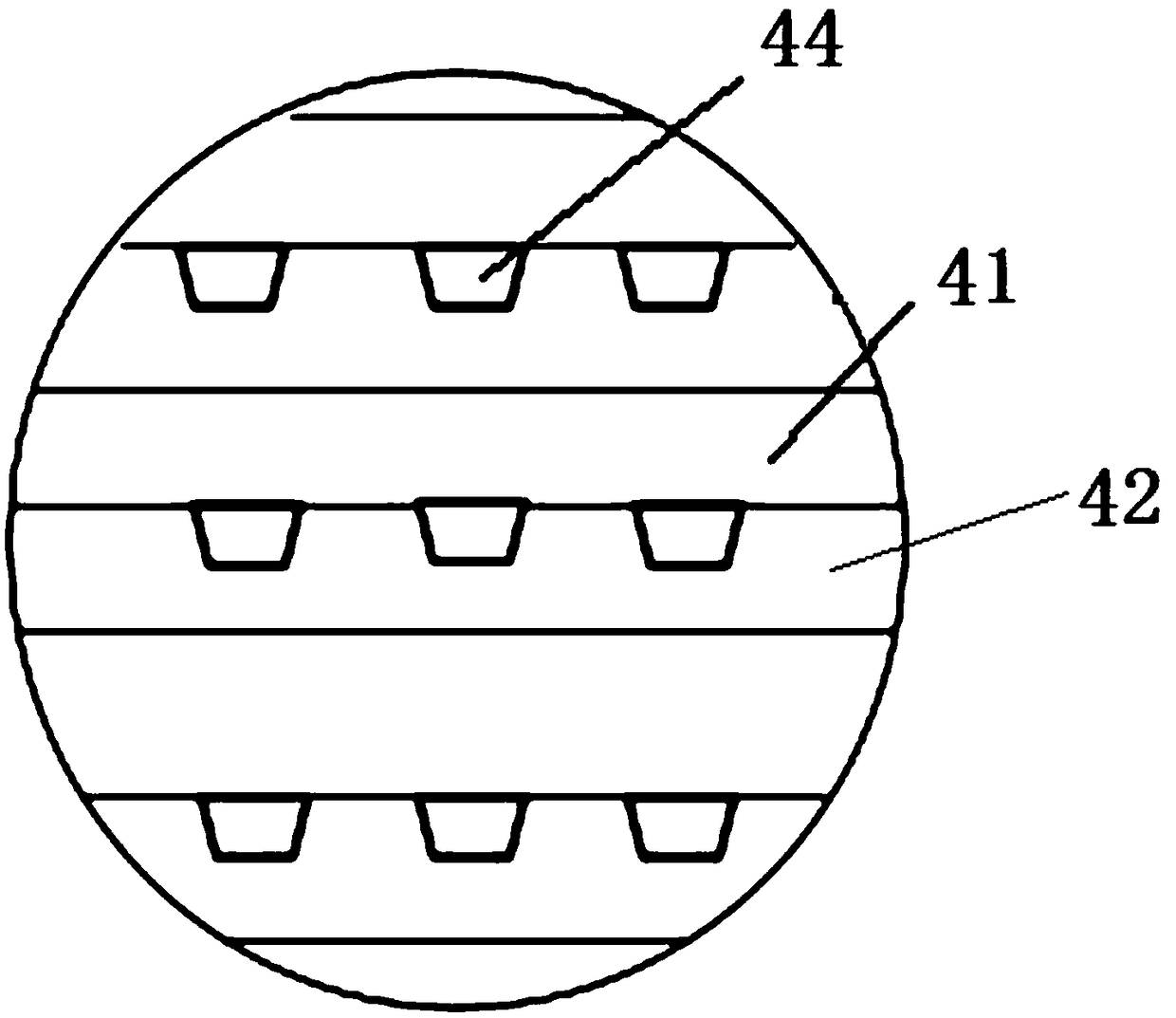

Electronic cigarette with fogging device

PendingCN108514158AExtended service lifeHeating evenlyTobacco devicesElectronic cigaretteEngineering

The invention provides an electronic cigarette with a fogging device, which comprises a cigarette holder, a smoke pipe with air holes, a fogging device and an oil storage chamber. the smoke pipe withair holes is arranged between the cigarette holder and the fogging device, and the smoke pipe with air holes comprises two layers of shells with the same size round holes, wherein one layer of the shells can rotate so as to change the coincidence part of the round holes so as to change the airflow size; the fogging device includes a micro-channel tube bundle, wherein the micro-channel tube bundlecomprises a plurality of micro-channel heaters, and the bottom of the micro-channel tube bundle is arranged in the oil storage chamber; a capillary is formed in the middle of each micro-channel heater, and a thin film micro-heater is sputtered on the tube wall of the capillary tube. According to the invention, the original structure of combination of resistance wire and cotton is replaced by thestructure of combination of micro heaters and the micro-channel, through the capillary phenomenon of microchannel, the micro heaters can be infiltrated uniformly and sufficiently by oil drops, the oil can be heated uniformly and sufficiently by the micro heaters with an array structure, so that the fogging effect of the tobacco oil is better, and the utilization rate of the tobacco oil is more sufficient.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

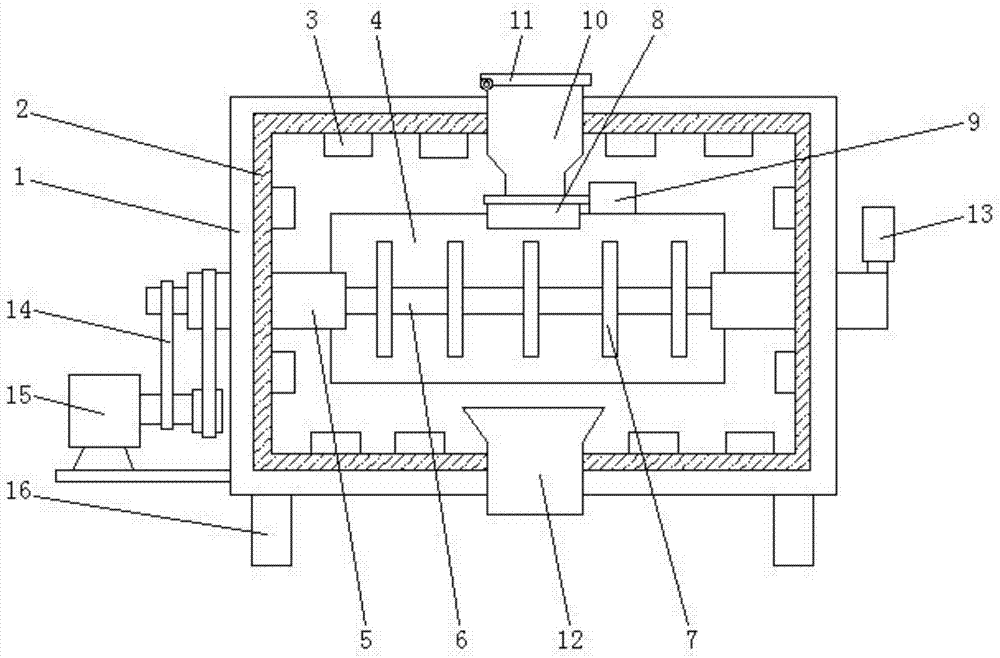

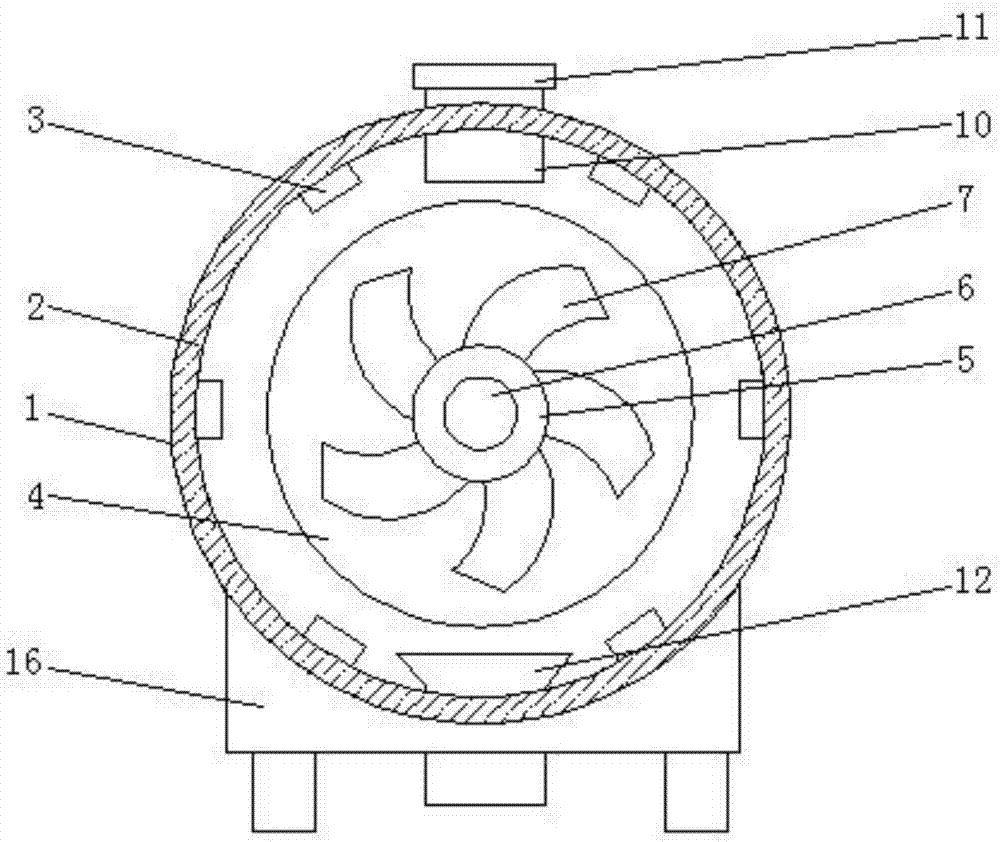

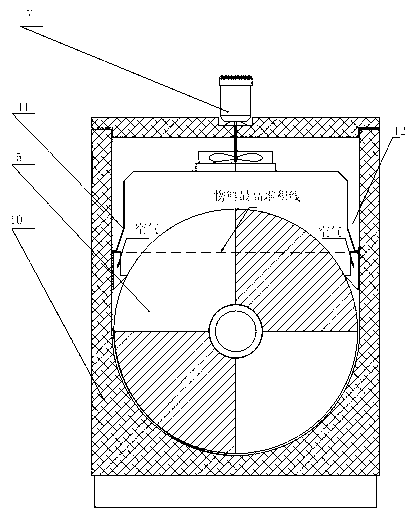

Using method of rotary type microwave metallurgical furnace

InactiveCN108007185ASimple structureUniform microwave emissionRotary drum furnacesEngineeringMicrowave emission

The invention discloses a using method of a rotary type microwave metallurgical furnace. An inner separating layer is attached to the inner wall of a furnace body, a plurality of magnetrons are installed on the inner wall of the inner separating layer and are evenly and symmetrically distributed, a horizontal furnace pipe is arranged in the center of an inner cavity of the furnace body, the left and right ends of the furnace pipe are rotationally connected to the left and right sides of the furnace body through an external rotating shaft correspondingly, the left end of the external rotating shaft penetrates the left side of the furnace body, an internal rotating shaft transversely penetrating the furnace body and the furnace pipe can be rotationally connected to the interior of the external rotating shaft, a plurality of rotating blades are welded to the internal rotating shaft and are evenly distributed to an inner cavity of the furnace pipe, a feeding opening is formed in the top ofthe furnace pipe, and a pneumatic gate valve is arranged at the top of the feeding opening. The rotary type microwave metallurgical furnace is simple in structure, stable, reliable, safe, efficient,even in microwave transmission and capable of achieving heat isolation and heat preservation; through dual rotation of the furnace pipe, material heating is more even and sufficient, and the smeltingefficiency is improved.

Owner:陕西盛华冶化有限公司

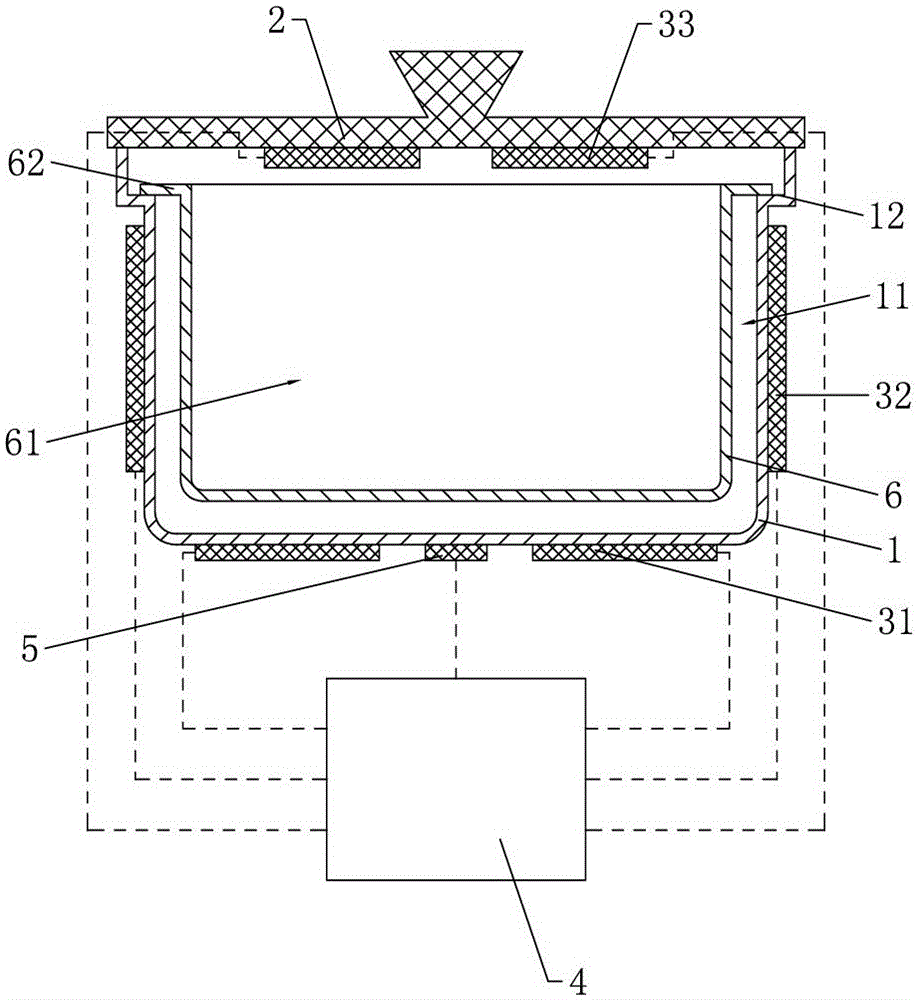

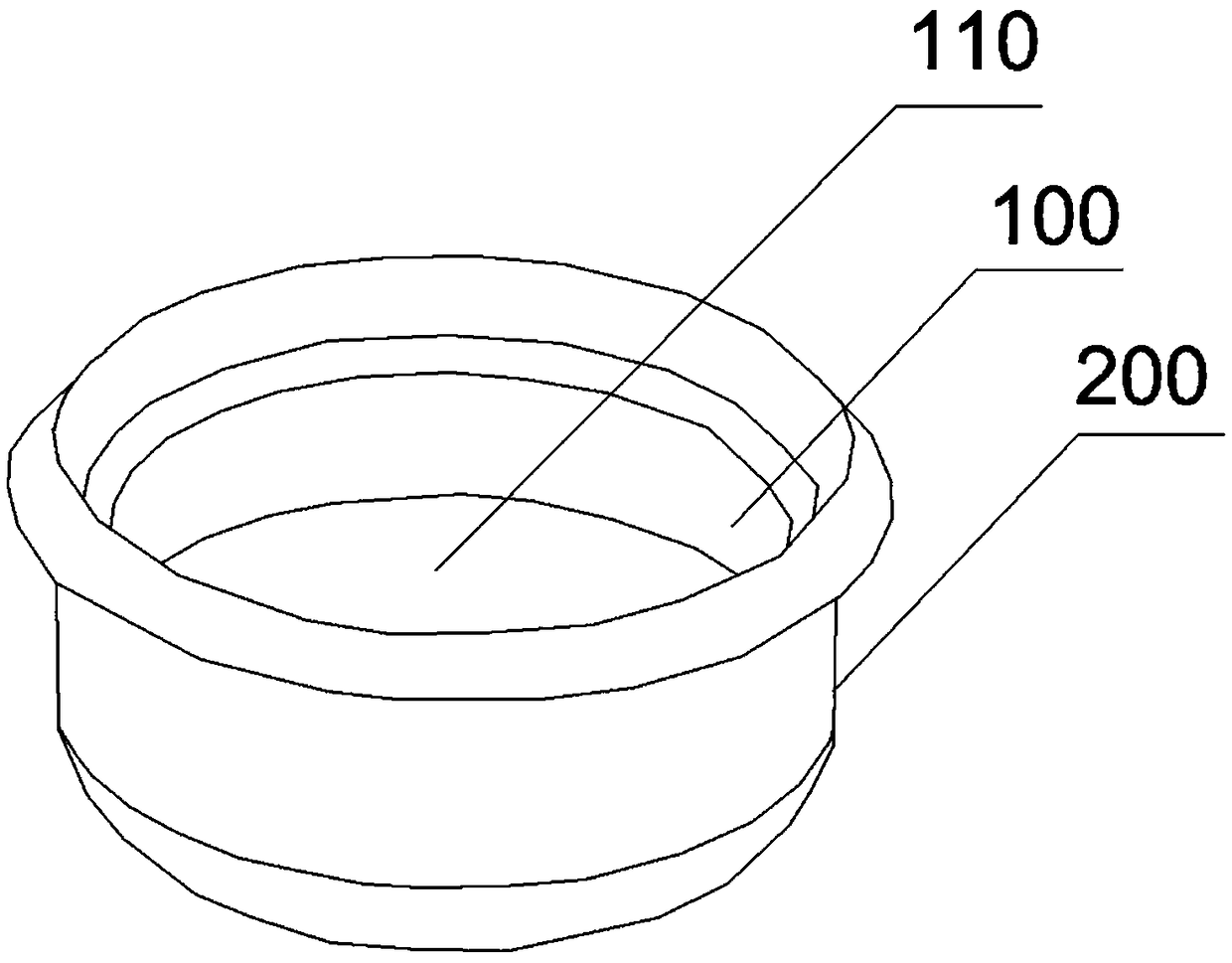

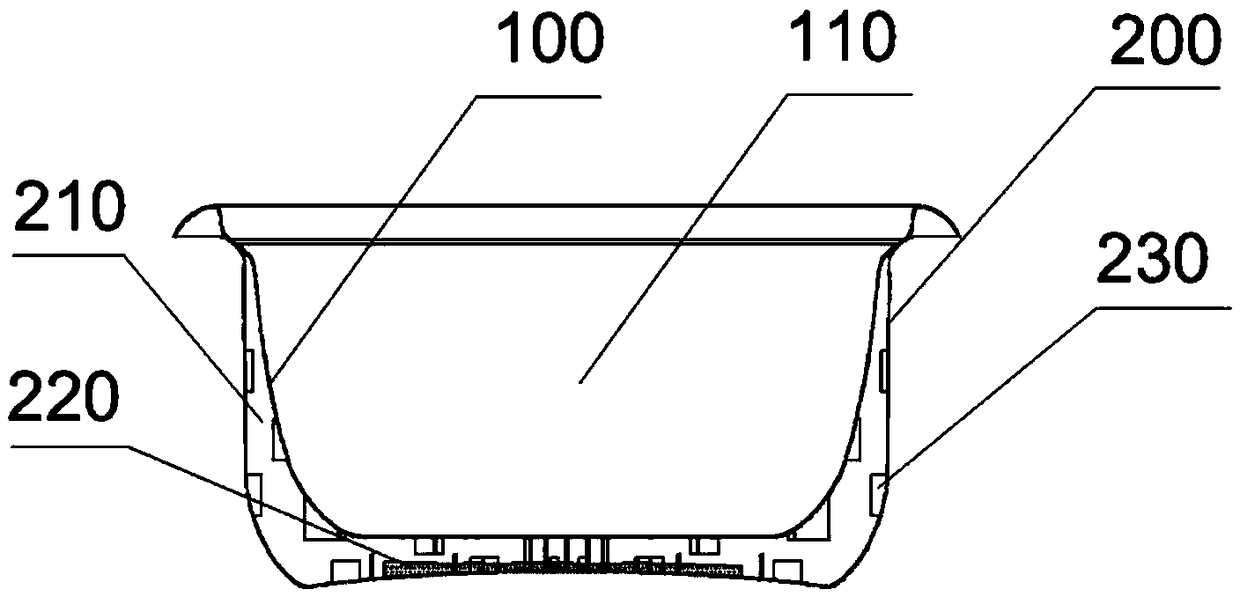

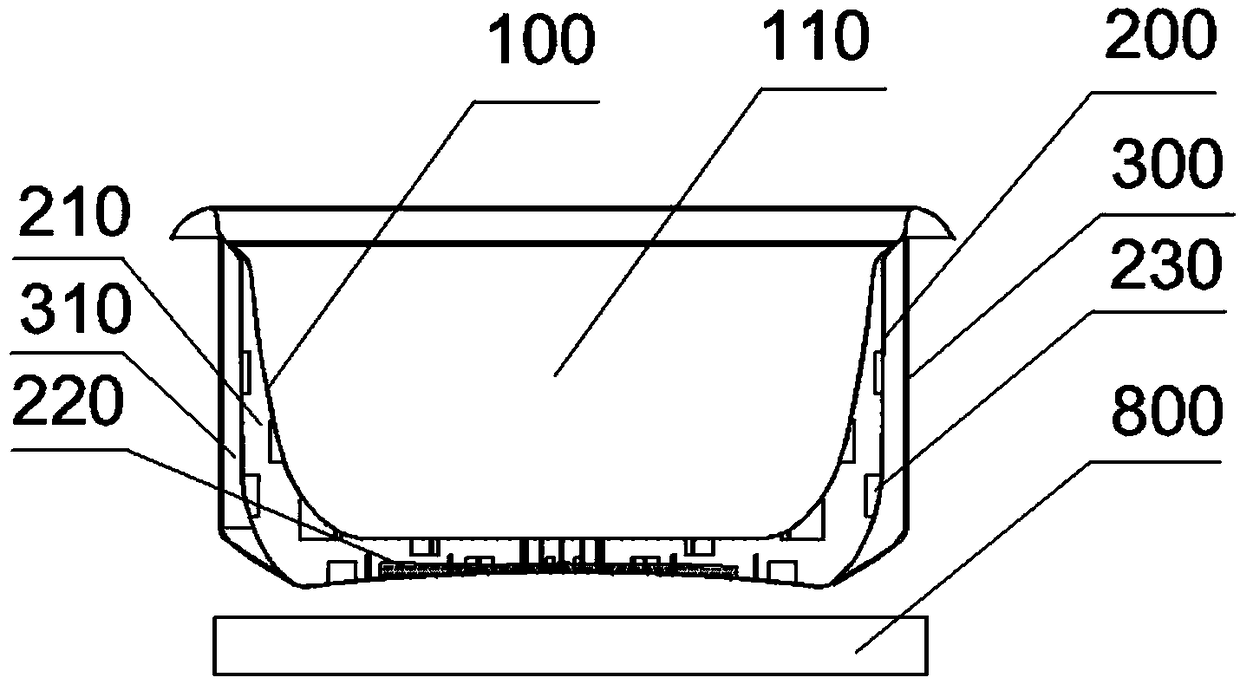

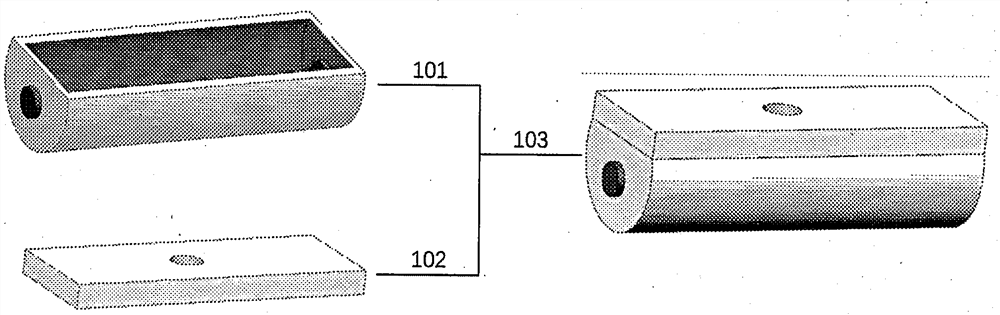

Heating container and electric rice cooker

ActiveCN109044081AReduce leakageGuaranteed heating effectCooking utensils shields/jacketsVessels with intergral heatingHeat conductingWorking temperature

The invention discloses a heating container, which comprises an inner container which is provided with an accommodating cavity for containing a substance to be heated and an opening; a heat-conductingshell which sleeves outside the inner container; the inner container is sealed with the top of the heat-conducting shell to form a heating cavity; the heating cavity is internally provided with a liquid-absorbing core containing a phase-change heat-conducting material; when the heat-conducting shell is heated and the working temperature of the phase-change heat-conducting material is reached, thephase-change heat-conducting material undergoes a phase change and releases heat to heat the inner container. The invention also discloses an electric rice cooker with the heating container. By usinga brand-new technology route, the surrounding and uniform heating of the whole inner container is achieved without using an IH heating mode, and the device has the advantages of simple structure, lowcost, high safety level and no electromagnetic radiation.

Owner:李子京

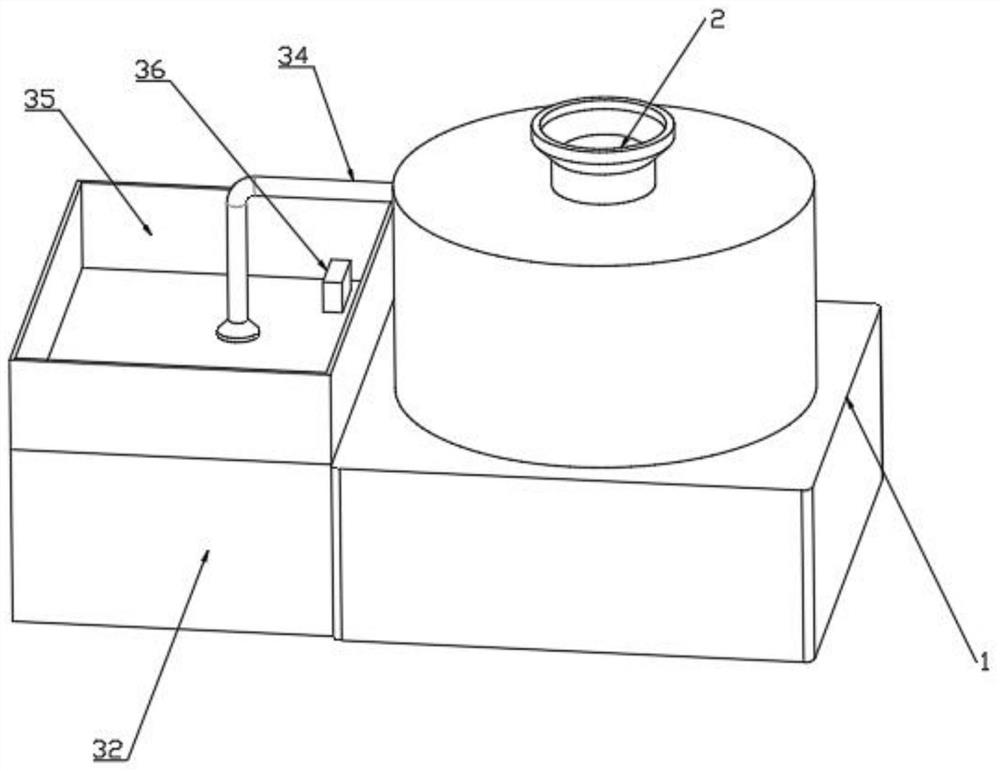

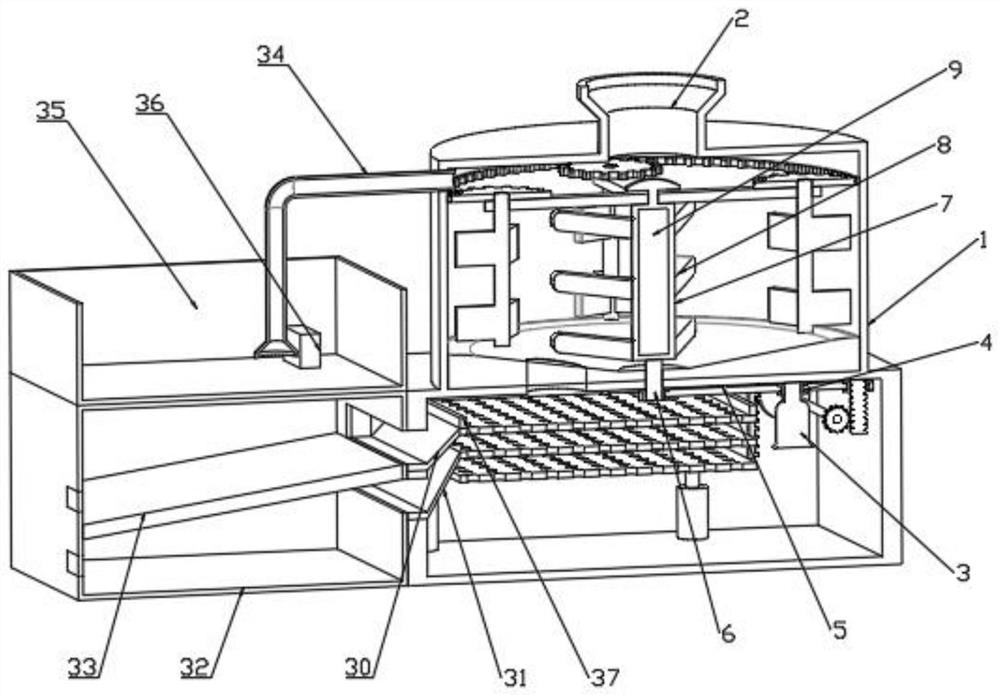

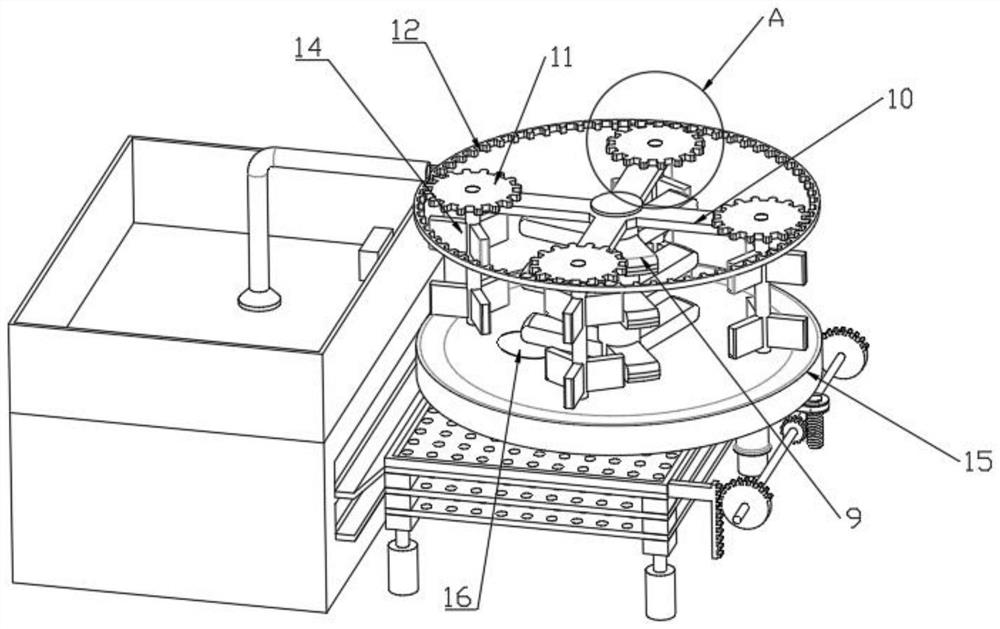

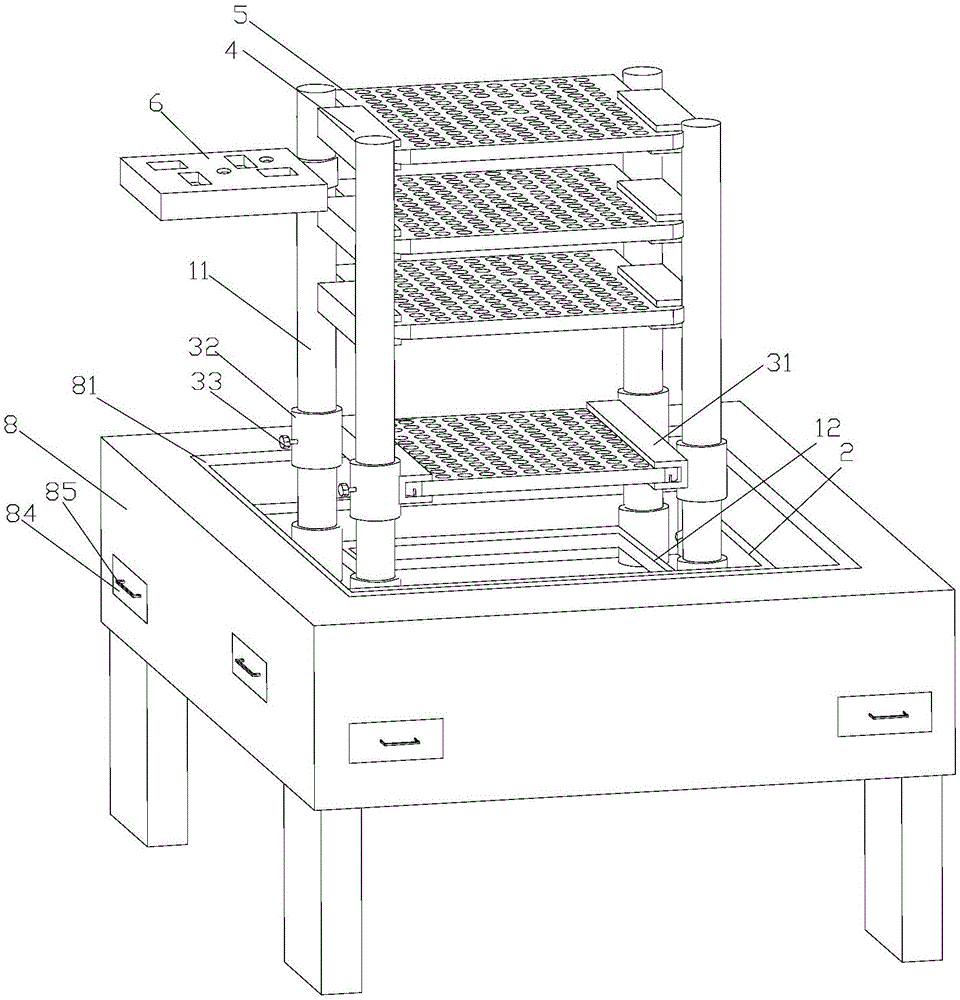

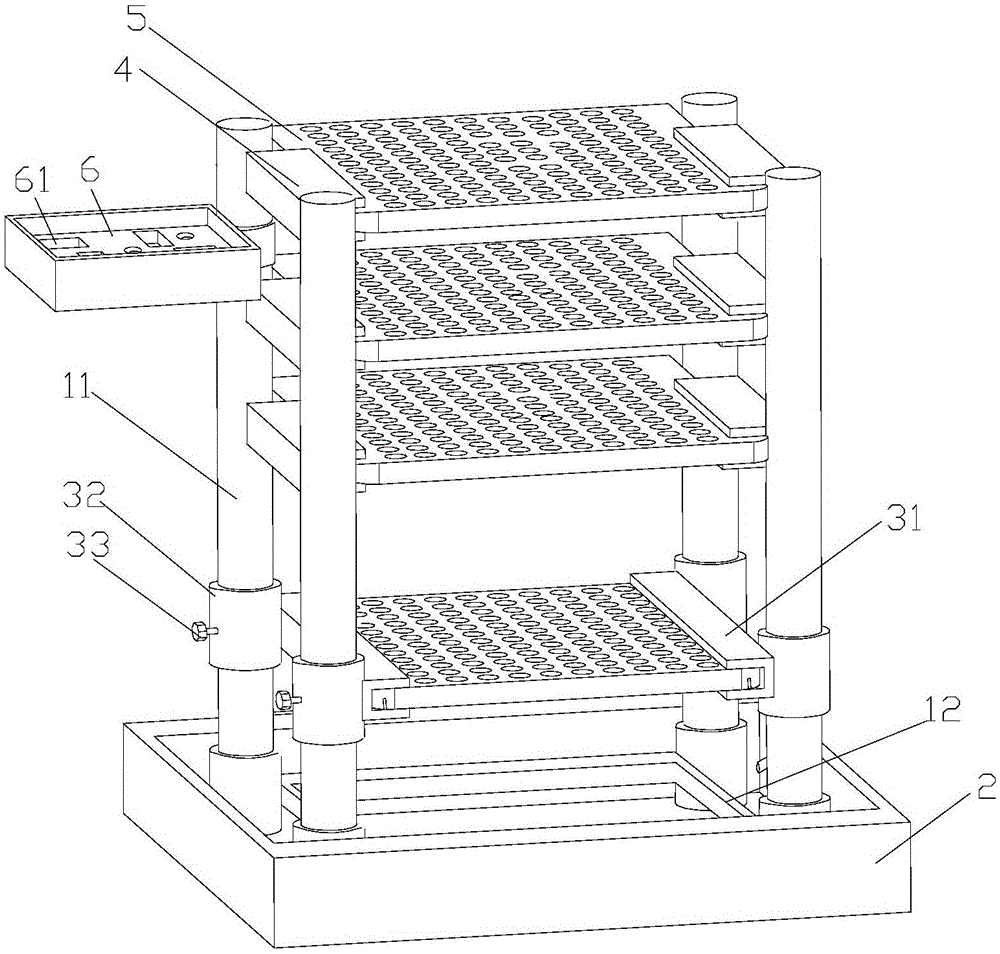

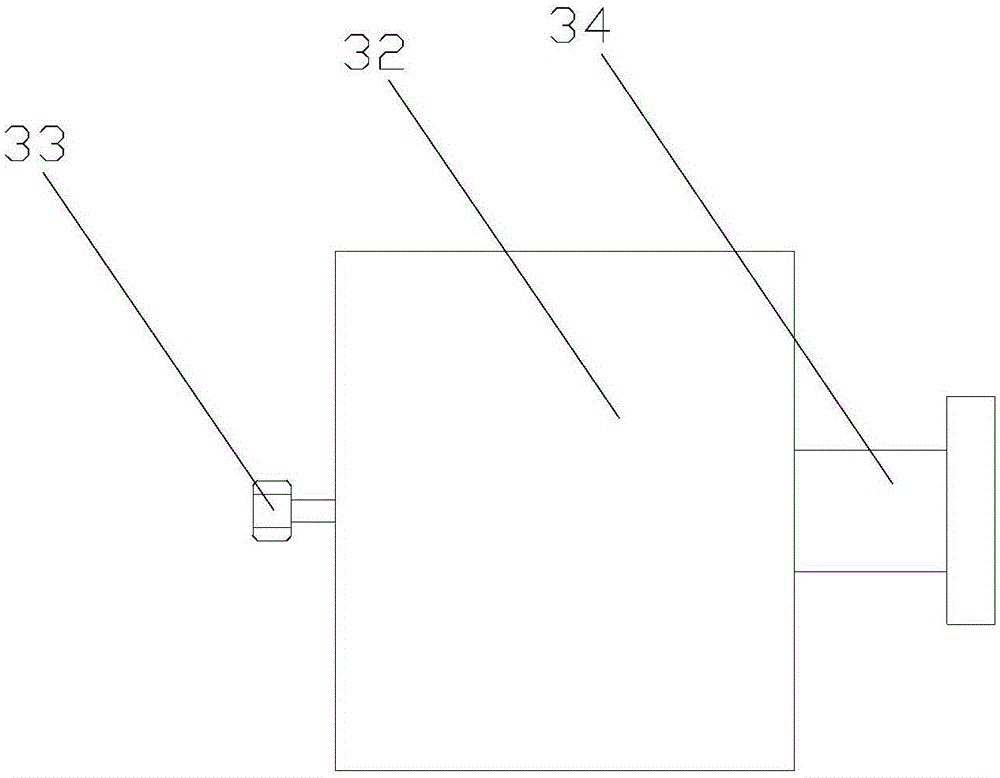

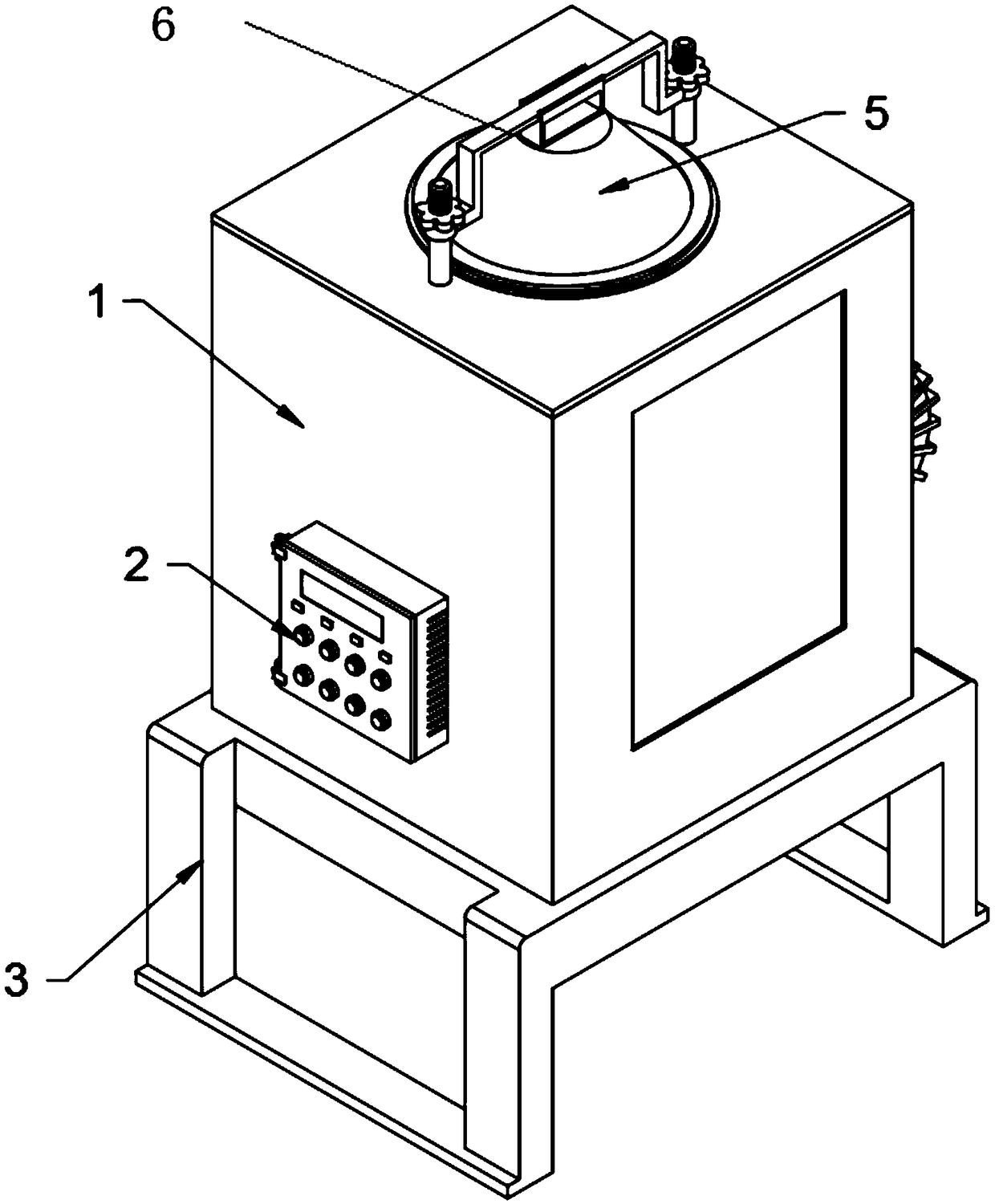

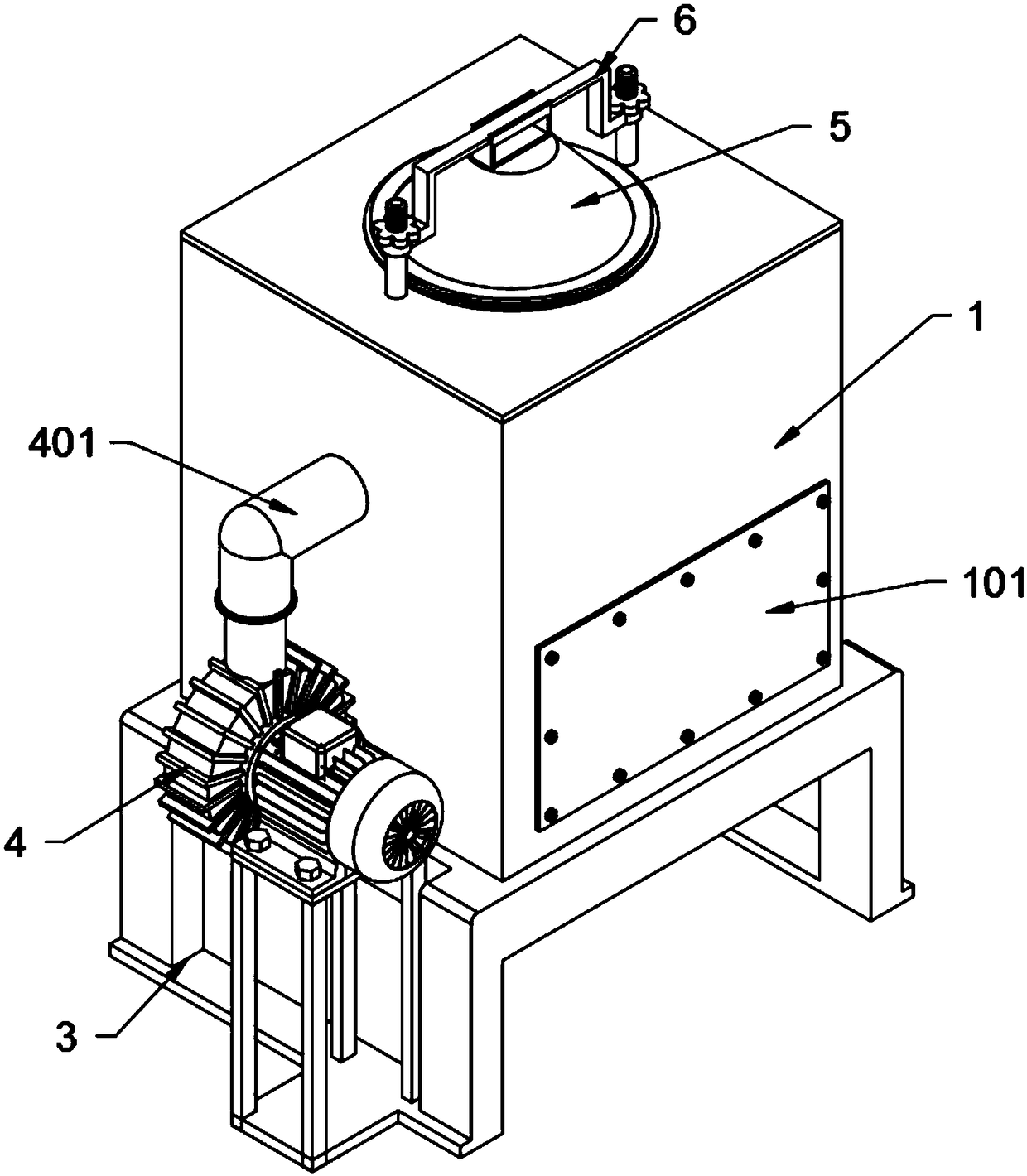

Full-automatic rapid high-temperature fermentation composting bin

InactiveCN103319222AHeating evenlyImprove insulation effectClimate change adaptationChemical industryThermal insulationEngineering

The invention discloses a full-automatic rapid high-temperature fermentation composting bin which comprises a fermentation box main body and a motor. The fermentation box main body and the motor are both fixedly arranged on a machine base. The box wall of the fermentation box main body is a double-layer structure. A thermal insulation material is filled between an inner box wall and an outer box wall. The top of the fermentation box main body is provided with an automatic insulation feed inlet. The top of the fermentation box main body is also provided with a circulating fan, fan blades of which are arranged inside the fermentation box main body. A far-infrared heating tube is arranged on an inner side of the top box wall of the fermentation box main body. A stirring device is disposed inside the fermentation box main body. The tail box wall of the fermentation box main body, close to the bottom of the fermentation box main body, is equipped with an automatic insulation discharge port. The full-automatic rapid high-temperature fermentation composting bin has beneficial effects as follows: heating efficiency is high; fermentation efficiency of materials is high; the technology is flexible to adjust; and labor cost can be reduced.

Owner:深圳庆能城市环保科技有限公司

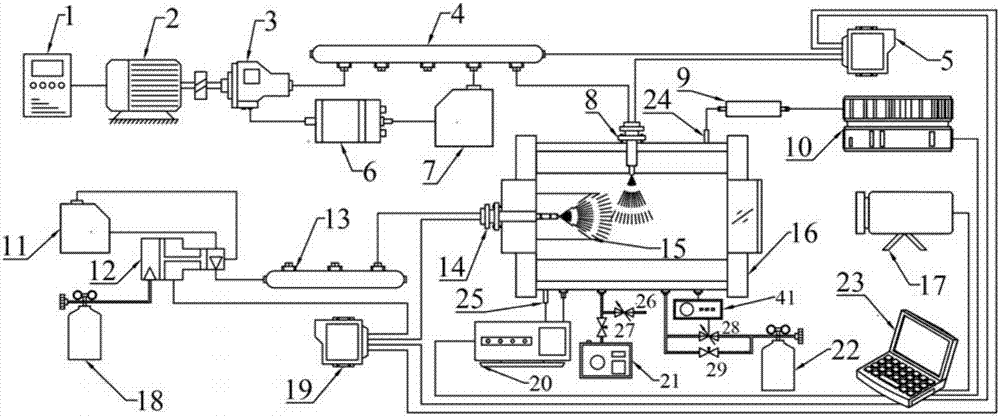

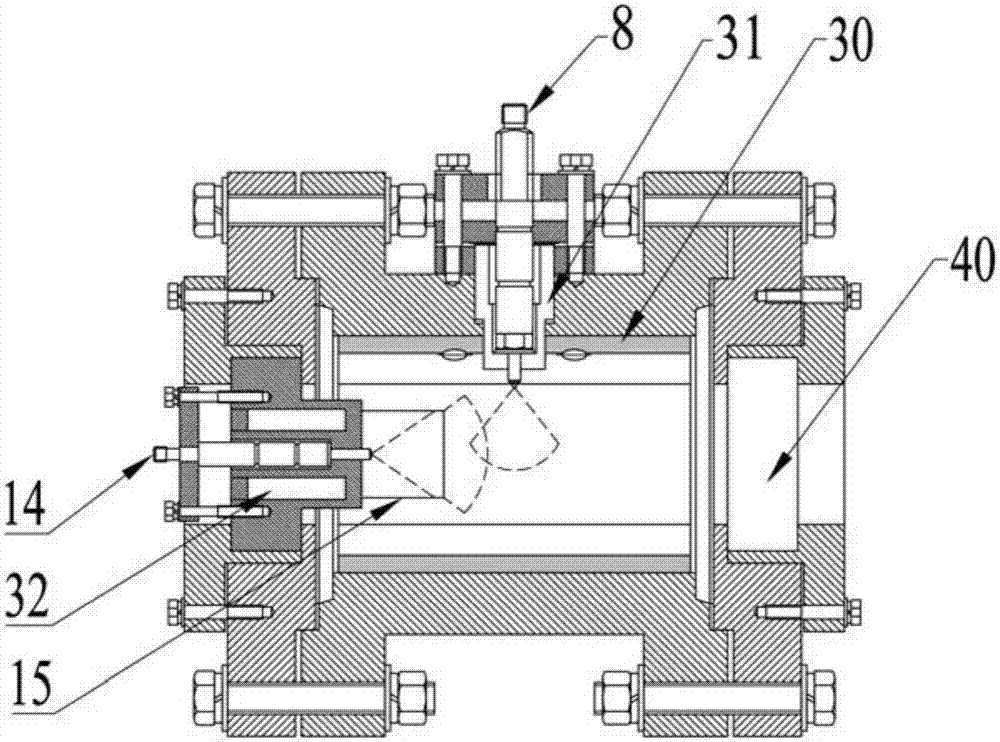

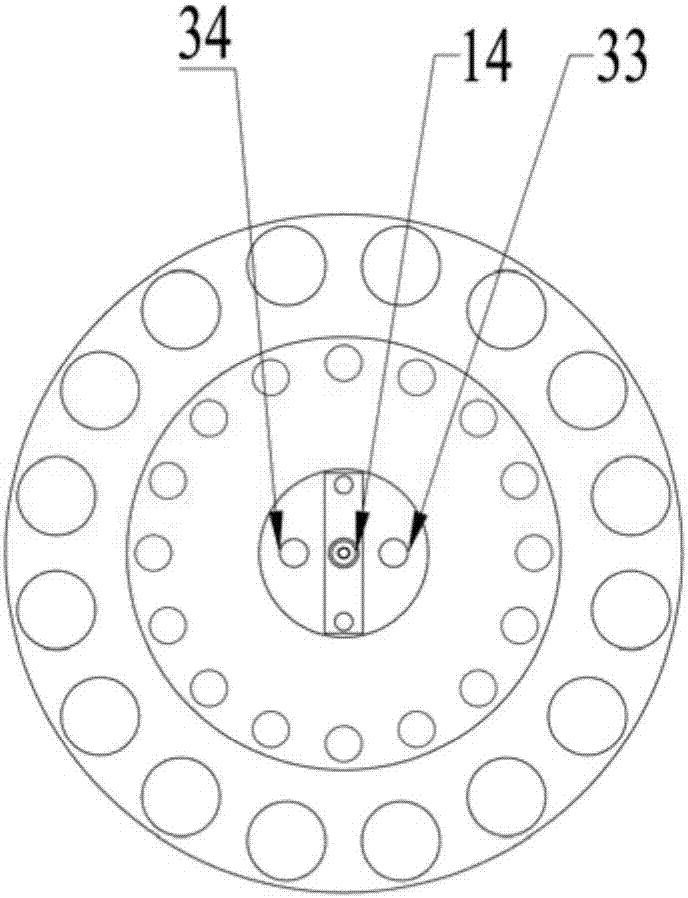

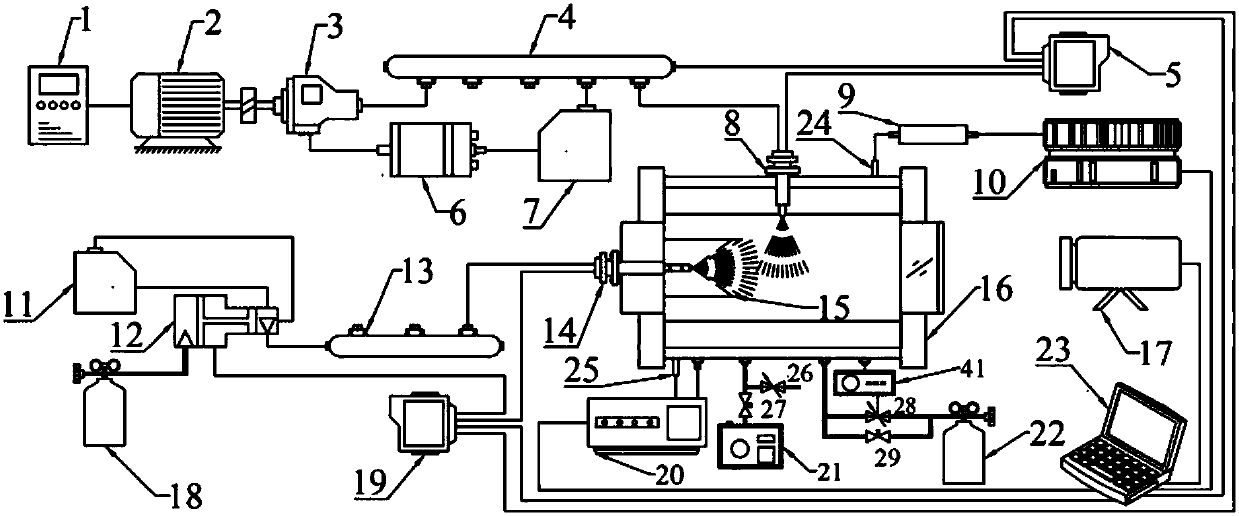

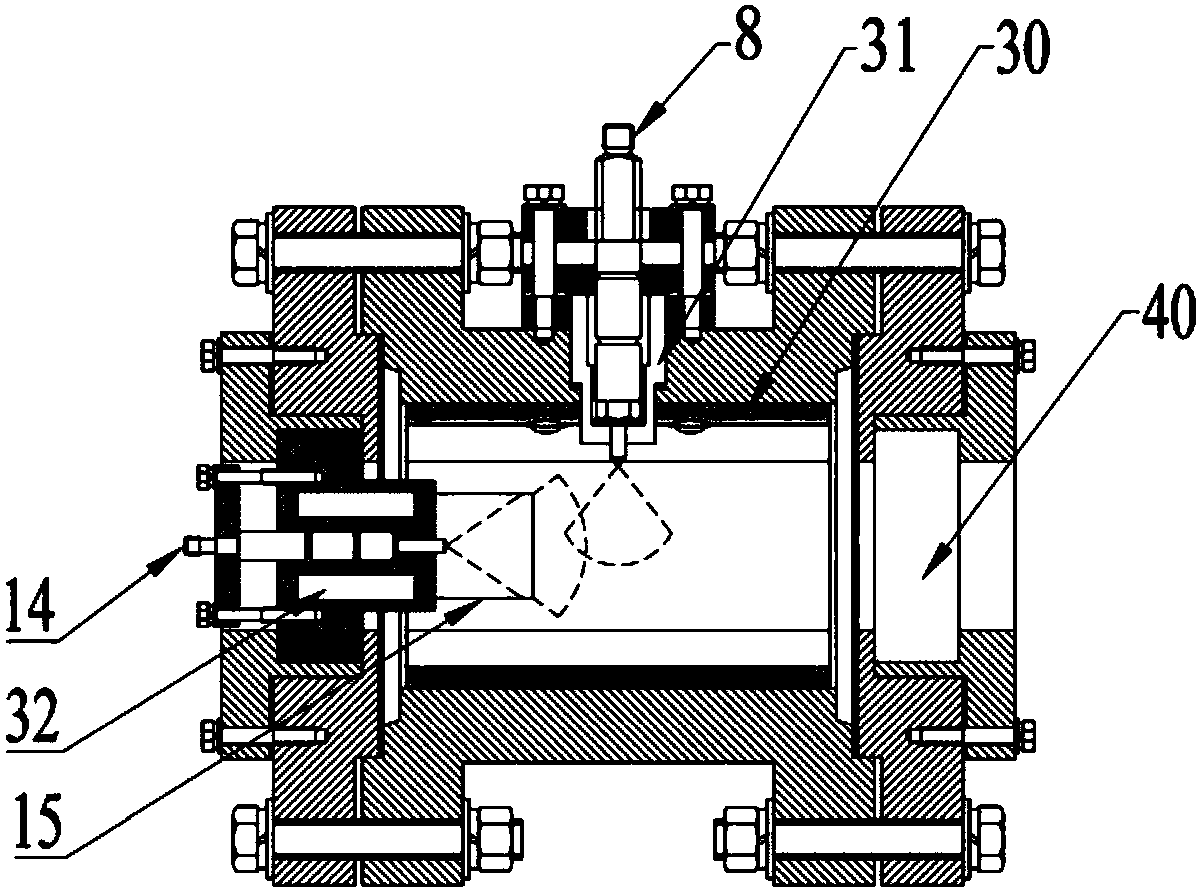

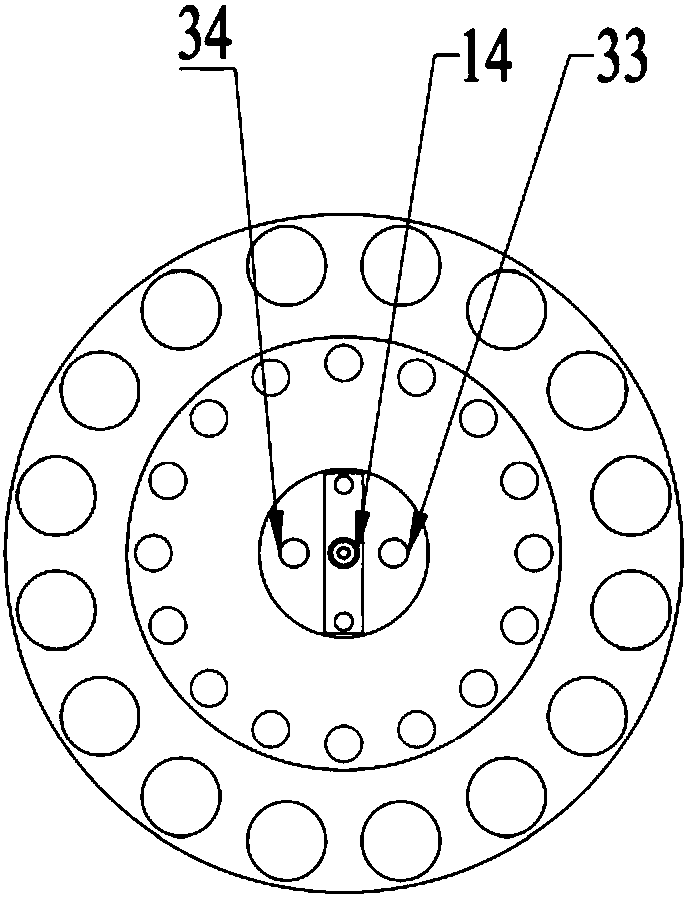

Constant volume combustion bomb system for simulating multiple combustion modes of methanol/diesel oil dual-fuel engine and method thereof

PendingCN107271193AWith heating functionHeating fully and evenlyInternal-combustion engine testingControllers with particular characteristicsOil canSystem pressure

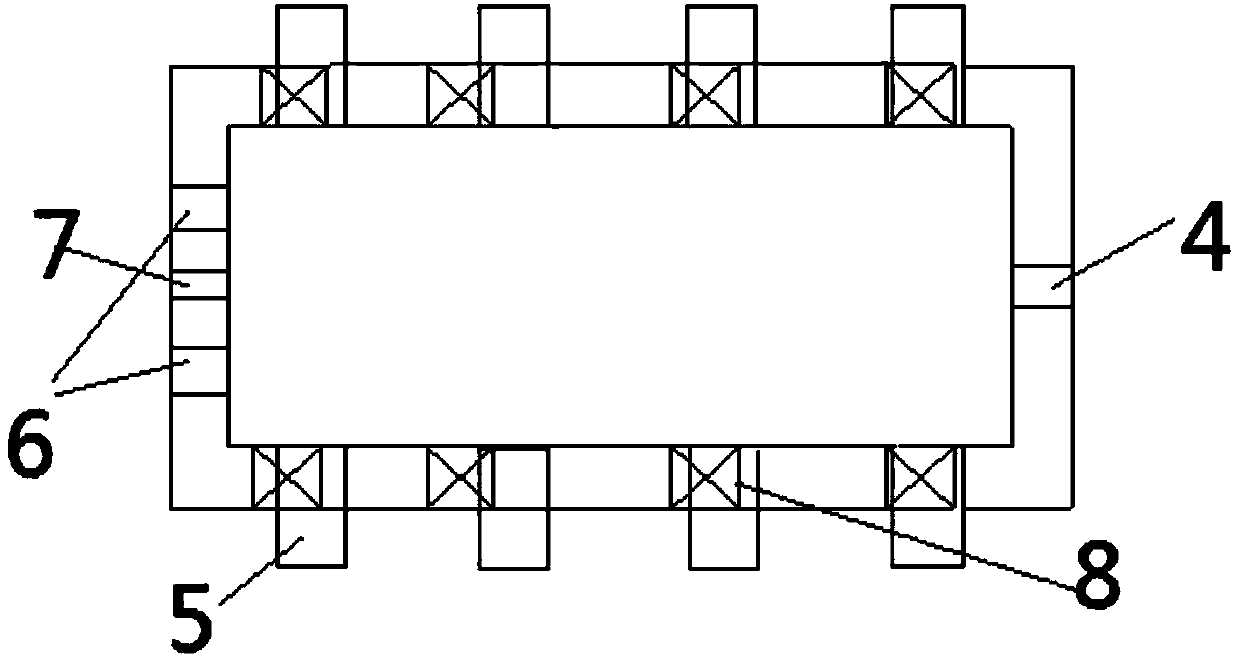

The invention relates to a constant volume combustion bomb system for simulating multiple combustion modes of a methanol / diesel oil dual-fuel engine and a method thereof. The constant volume combustion bomb system for simulating multiple combustion modes of the dual-fuel engine comprises a constant volume combustion bomb, a diesel oil injector, a diesel oil injection system connected with the diesel oil injector, a methanol injector, a methanol injection system connected with the methanol injector, a gas inlet system, a gas exhaust system, a pressure sensor, a synchronous data acquisition card, a high-speed camera and an upper computer. Multiple combustion modes that the diesel oil ignites the methanol, the diesel oil and the methanol are on fire simultaneously and the methanol is self-ignited before the diesel oil can be realized by adjusting the injection moment of the methanol relative to the diesel oil, uniform premixing and concentration stratification of the methanol in the constant volume combustion bomb can also be realized and the injection pressure of the methanol is flexible and adjustable.

Owner:TIANJIN UNIV

Guardrail bending device

The invention belongs to the technical field of guardrail machining, and particular discloses a guardrail bending device. The guardrail bending device sequentially comprises a horizontally-placed positioning frame, a bending roll and a first power mechanism; sliding seats are symmetrically arranged on the two sides of the positioning frame, sliding plates are horizontally and slidably connected into the sliding seats, and the positioning frame is internally provided with two supporting plates and a second power mechanism; rotating plates are connected between the supporting plates and the sliding plates, one ends of the rotating plates are hinged to the supporting plates, and the other ends of the rotating plates are hinged to the sliding plates; and the bending roll is fixedly connected with the first power mechanism and is internally provided with a horizontal sliding chute and two oblique grooves, openings of the horizontal sliding chute and the oblique grooves face the positioningframe, and the horizontal sliding chute is internally provided with a heating mechanism. When a guardrail is extruded by the bending roll, the heating mechanism heats the to-be-bent position of the guardrail, and oblique plates are slidably connected into the oblique grooves. According to the guardrail bending device, the bending angle is easily controlled, and breaking does not easily occur in the bending process.

Owner:临沂经济开发有限公司

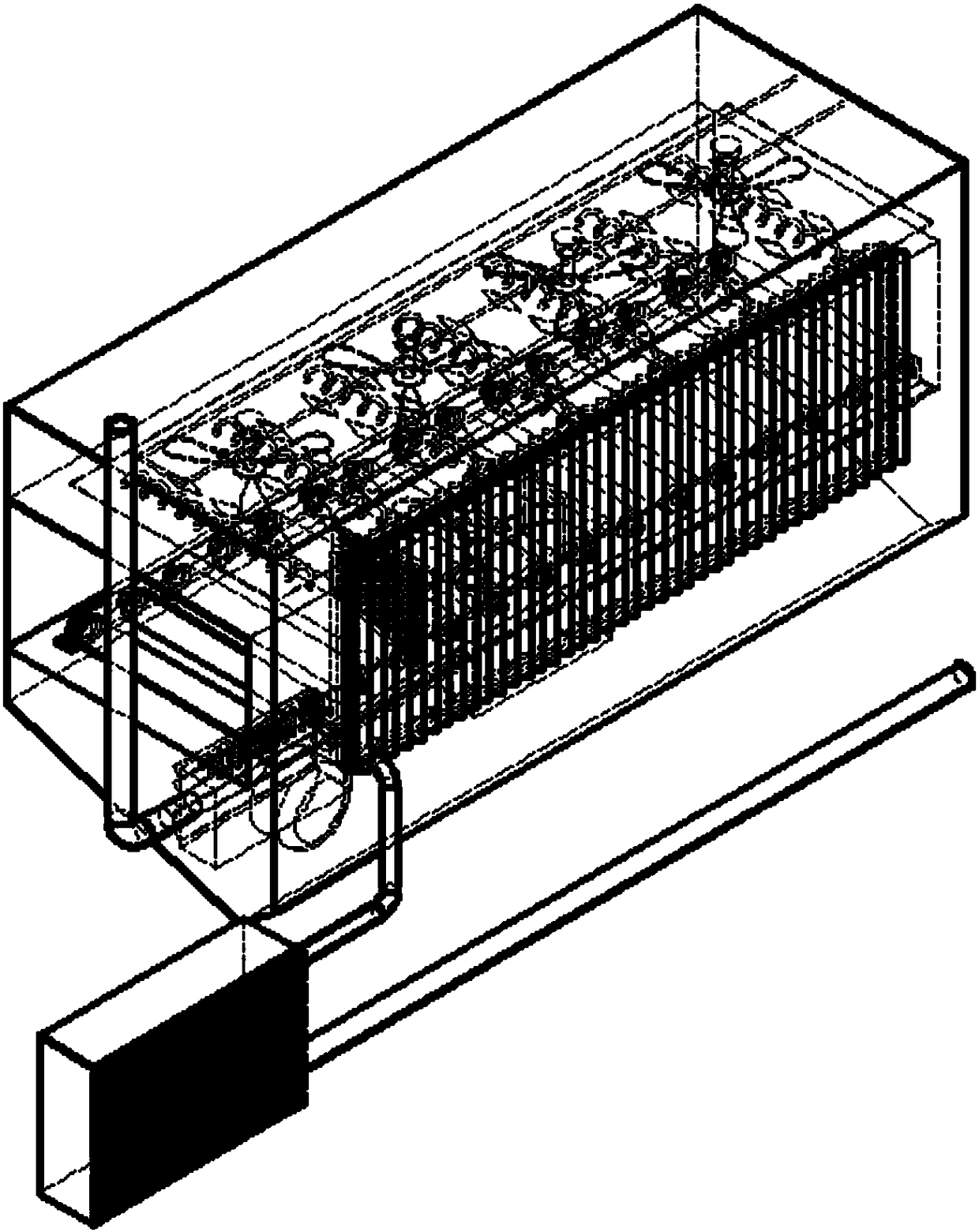

Energy-saving tunnel drying oven

ActiveCN108131930AHeating evenlyFully heatedDrying gas arrangementsDrying chambers/containersWorking environmentEngineering

The invention relates to an energy-saving tunnel drying oven. The energy-saving tunnel drying oven comprises an outer shell, an inner shell, an air channel, a conveyor belt, a heat exchanger, an air inlet, a heat pump system, fans, heating devices, an air flow distributor, an air exhaust pipe and the like. Outside air enters the air channel through the air inlet, the air is preheated by the heat exchanger, heated by the heat pump system and subjected to auxiliary constant temperature keeping by the heating devices, and the air heats and dries heated objects on the conveyor belt; and through distributing of the air flow distributor, the part of hot air is subjected to heat exchanging by the heat exchanger and then exhausted through the air exhaust pipe, and the other part of hot air is mixed with new air preheated by the heat exchanger, heated by the heat pump system and heated by the heating devices, then heats and dries the heated objects, and is distributed by the air flow distributor, in this way, heat energy in the air is circularly utilized, the energy is saved, and the heating efficiency is improved. When the working environment temperature is high, the heat pump system can further be used for cooling the working environment while being used for heating the air.

Owner:GUANGZHOU HENGXINCHUANGZHAN TECH CO LTD

Convection current radiation heated flue-cured tobacco type electronic cigarette

The invention discloses a convection current radiation heated flue-cured tobacco type electronic cigarette. The convection current radiation heated flue-cured tobacco type electronic cigarette comprises a heater main body and a gas guide sleeve; the heater main body is provided with an accommodation cavity and a heating part facing the accommodation cavity for heating; the gas guide sleeve is detachably installed in the accommodation cavity; the gas guide sleeve is provided with a tobacco placing cavity and an internal forced gas guide needle tubing located in the tobacco placing cavity; a first breathing hole penetrating through a convection current gap and the tobacco placing cavity is formed in the bottom of the tobacco placing cavity; the internal forced gas guide needle tubing is provided with a gas guide cavity, and several second breathing holes penetrating through the gas guide cavity and a cigarette accommodation gap are formed in the side wall of the internal forced gas guideneedle tubing; the bottom of the gas guide cavity is communicated with the convection current gap. In this way, the convection current radiation heated flue-cured tobacco type electronic cigarette achieves a tobacco flue-curing mode of convection current heating, direct contact of the heating part and tobacco is avoided, omnibearing dead-angle-free heating is achieved, so that heating is fuller and more uniform, and the situations that naked light occurs to tobacco shreds when local temperature is too high, and the mouthfeel is influenced and the tobacco shreds are wasted when the local temperature is relatively low are avoided.

Owner:肖鑫

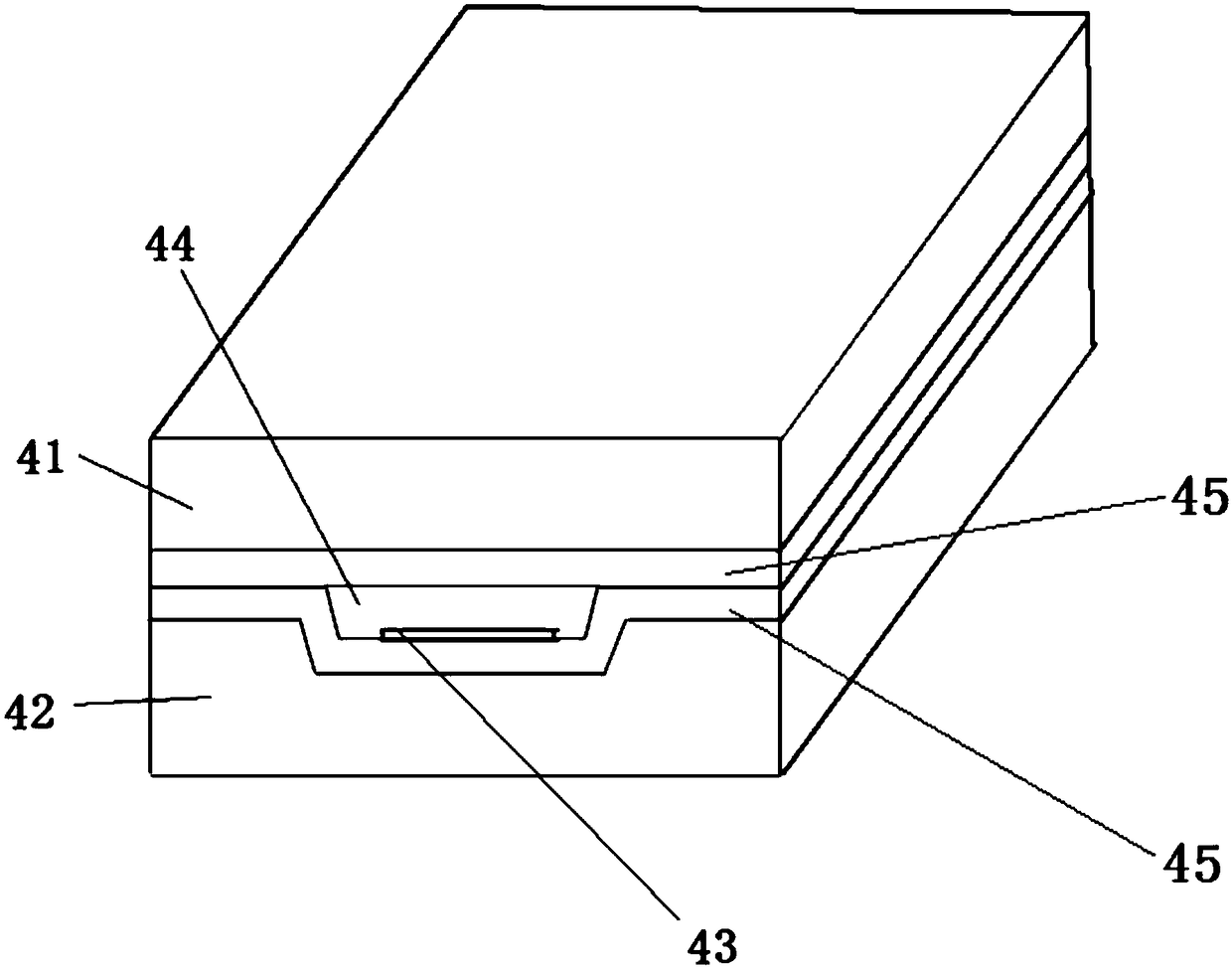

Plasma synthetic jet exciter suitable for high-pressure condition

InactiveCN111787680AHigh electrode spacingLong electrode spacingPlasma techniqueCombustion chamberJet flow

A plasma synthetic jet exciter used under a high air pressure condition comprises an exciter body and a sheet-shaped rectangular cover plate; the exciter body comprises an anode discharge electrode, acathode discharge electrode, a semiconductor coating and an exciter shell. The top of the exciter shell is connected with the lower surface of the cover plate in a sealing manner, the cover plate isprovided with inclined straight-through jet holes from top to bottom, the left end panel and the right end panel of the exciter shell are provided with through holes, and the anode discharge electrodeand the cathode discharge electrode extend into the exciter shell through the through holes. Aiming at a working environment with high flow pressure in a combustion chamber, the discharge voltage between the cathode and the anode is greatly reduced by utilizing the semiconductor coating; therefore, the exciter can still maintain a large electrode distance under high air pressure; meanwhile, the conversion efficiency of discharge energy is improved and the jet flow effect of the exciter is improved by utilizing a large discharge cavity volume and the geometric structure of the vertically-cut cylinder, thereby solving the problem that the exciter is not suitable for a ramjet combustion chamber in the prior art.

Owner:AIR FORCE UNIV PLA

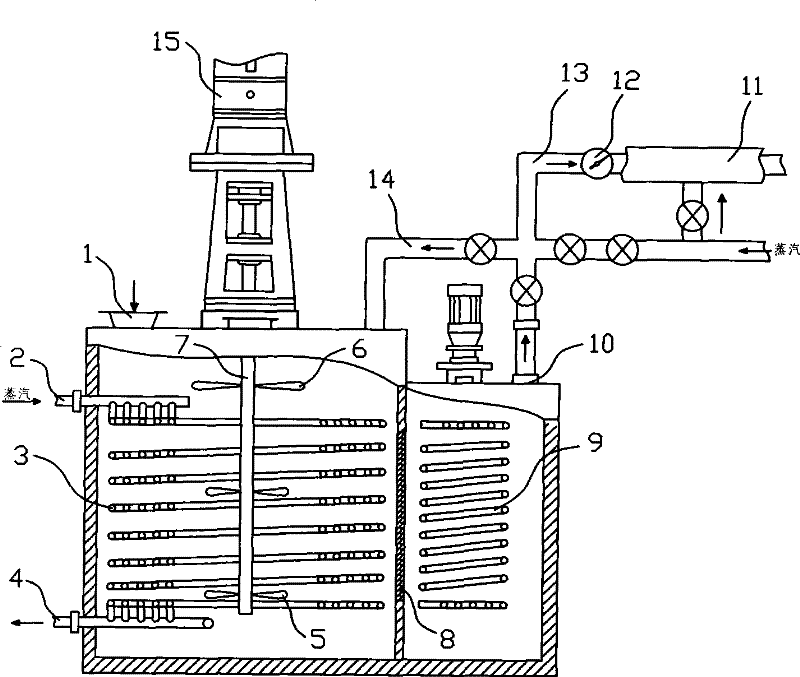

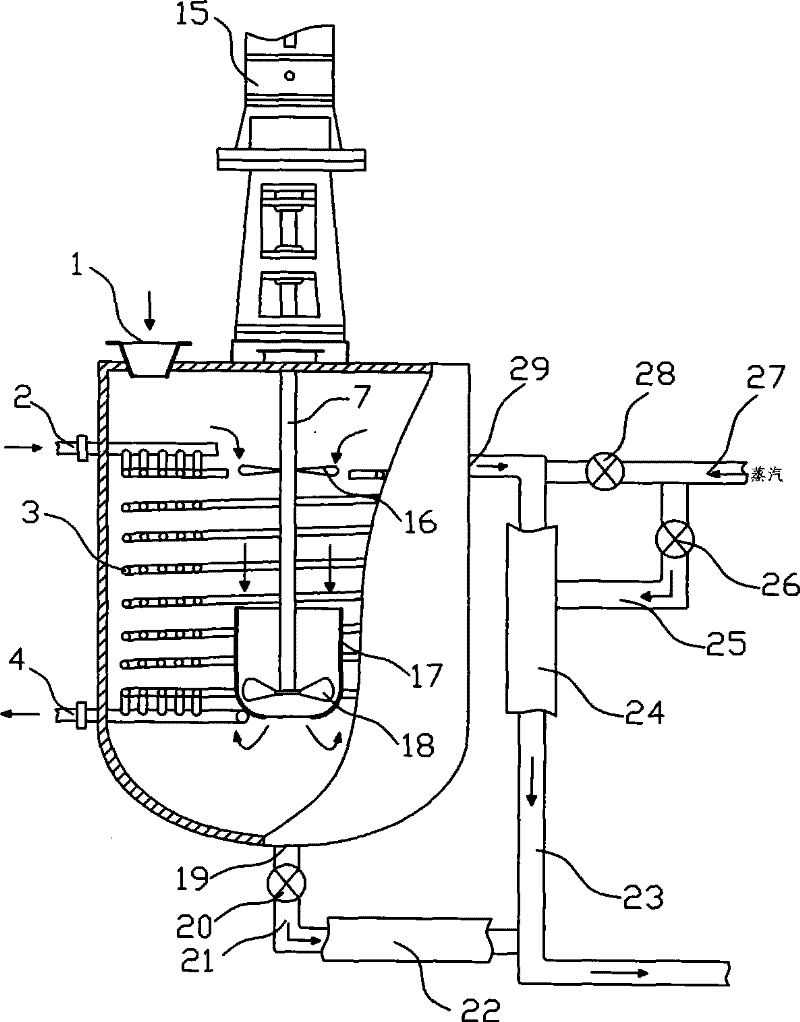

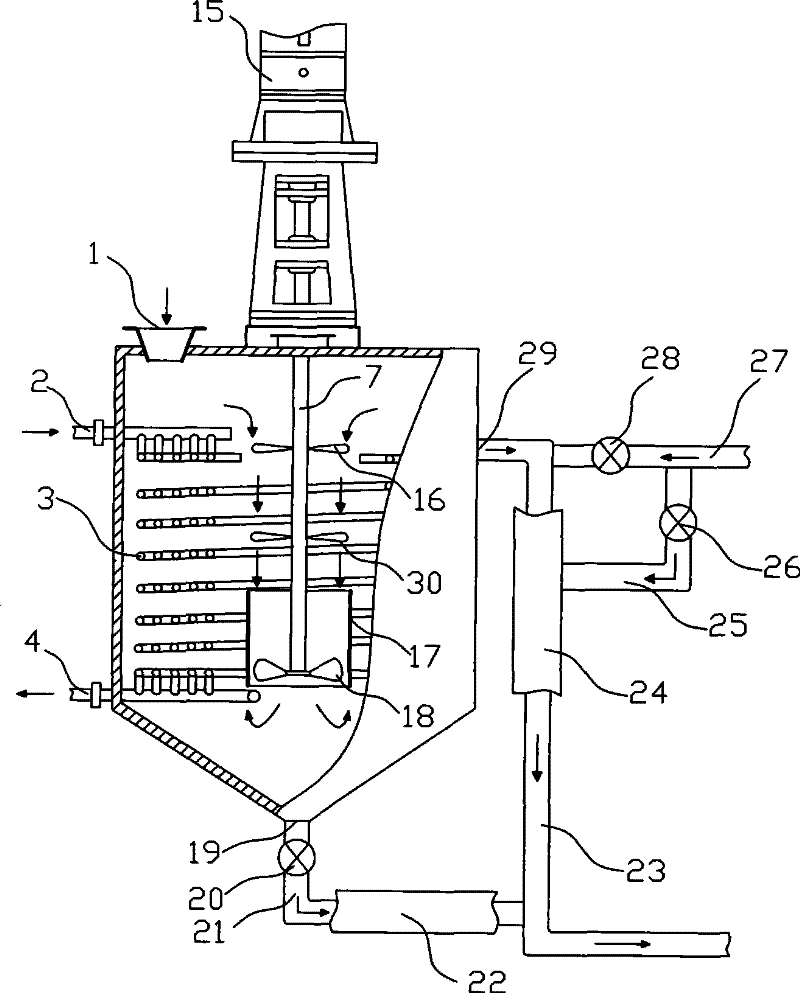

Urea melting apparatus

The invention relates to a solid urea melting device, aiming at solving the technical problems of low melting efficiency, easy generation of biuret, difficult clearing and maintaining, as well as high operating cost in the existing similar devices. The device comprises a melting tank, a stirring mechanism and a heating coil arranged in the melting tank, wherein, a stirring shaft and stirring paddles of the stirring mechanism are arranged in the melting tank; the device is characterized in that: the bottom surface of the melting tank is a curved surface, and a purging port is arranged at the bottom of the curved surface; an overflow port communicated with a guniting pipe is arranged at the upper part of the side wall of the melting tank; at least two upper and lower layers of stirring paddles are laid out on the stirring shaft; and a guide flow cylinder is arranged at the lower area of the inside of the heating coil, and the lower layer of stirring paddles is matched with and arranged in the guide flow cylinder. The device can be widely applied in the field of compound fertilizer production for the fast melting of solid urea.

Owner:JIANGSU ABOLUO COMPOUND FERTILIZER +1

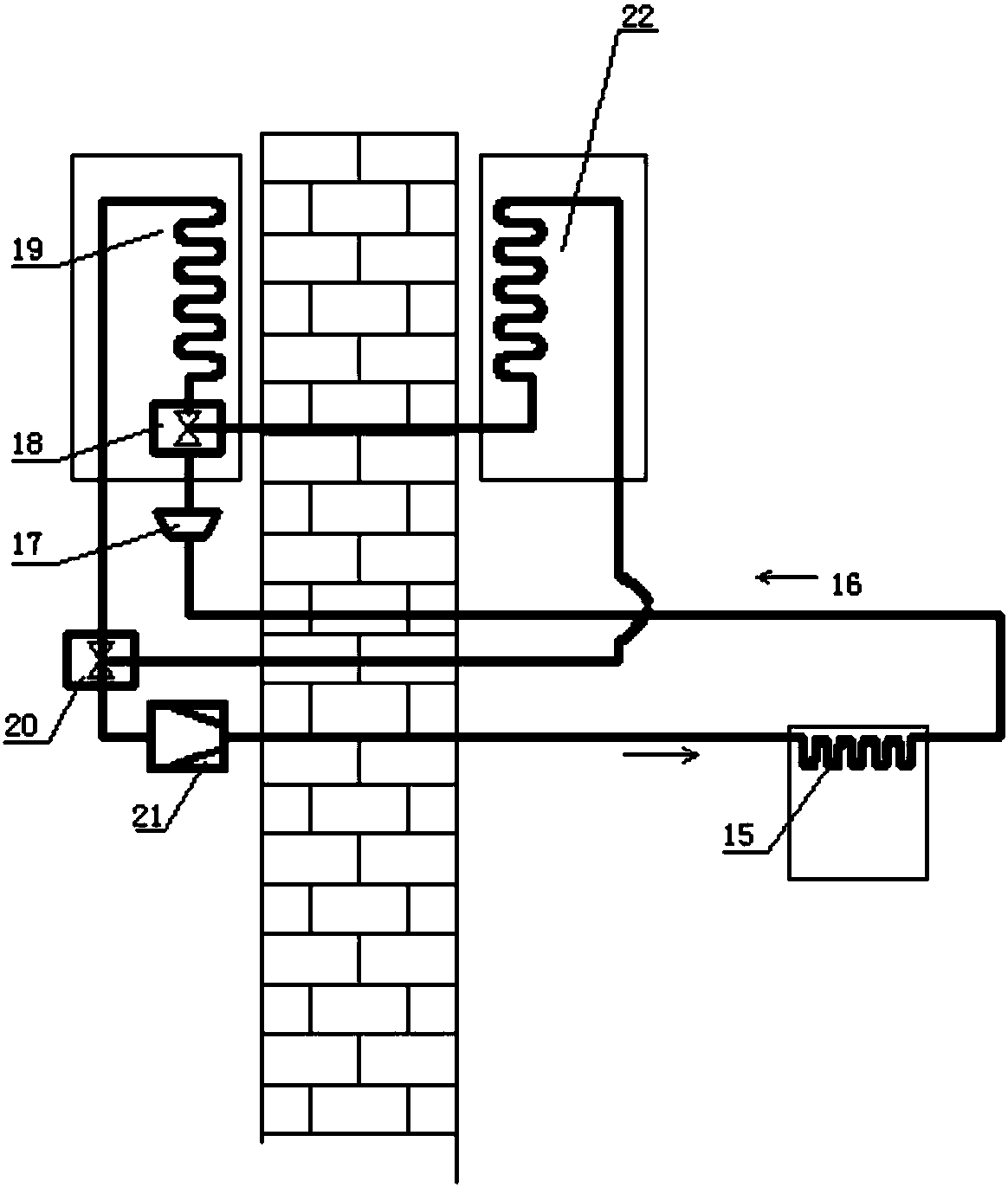

Constant-volume combustion bomb system and method with simulation of various combustion modes of methanol/diesel dual-fuel engine

ActiveCN107796629AWith heating functionHeating fully and evenlyInternal-combustion engine testingDiesel injectorData acquisition

The invention relates to a constant-volume combustion bomb system and method with simulation of various combustion modes of a methanol / diesel dual-fuel engine. The system is composed of a constant-volume combustion bomb, a diesel injector, a diesel injection system connected to the diesel injector, a methanol injector, a methanol injector system connected to the methanol injector, an air intake system, an exhaust system, a pressure sensor, a synchronous data acquisition card, a high-speed camera, and an upper computer. According to the invention, with adjustment on the injection time of methanol relative to the diesel, several kinds of different combustion modes such as methanol ignition by diesel, simultaneous ignition of diesel and methanol, and autoignition of methanol earlier than diesel are realized; uniform premixing and concentration layering of methanol in the constant-volume combustion bomb are realized respectively; and the injection pressure of methanol is adjusted flexibly.

Owner:TIANJIN UNIV

Cover plate glass electric melting furnace and heating method thereof

InactiveCN107673584AStable lengthHigh strengthGlass furnace apparatusElectric furnaceCombustionTemperature difference

The invention discloses a cover plate glass electric melting furnace and a heating method thereof. An upper heating furnace body and a lower liquid storage furnace body form a melting furnace pool body; a plurality of heating electrode grooves are formed in the side wall of the lower liquid storage furnace body uniformly; the heating electrode grooves are communicated with an inner cavity of the lower liquid storage furnace body; heating electrodes are arranged in the heating electrode grooves; a feeding opening and a flue opening are formed in the side wall of the upper heating furnace body;the feeding opening and the flue opening are communicated with an inner cavity of the upper heating furnace body; a plurality of heating combustion guns are distributed on the side wall of the upper heating furnace body uniformly; the heating electrodes on the side wall of the lower liquid storage furnace body and the heating combustion guns on the side wall of the upper heating furnace body perform heating simultaneously, so that the temperature difference between the surface temperature of cover plate glass liquid and the internal temperature of the glass liquid is reduced, the glass materials are melted in the melting pool completely and uniformly, the temperature of the glass liquid in the melting process can keep high enough, excessive temperature difference between the surface temperature of cover plate glass liquid and the internal temperature of the glass liquid can be avoided, and the production efficiency of glass melting is greatly improved.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

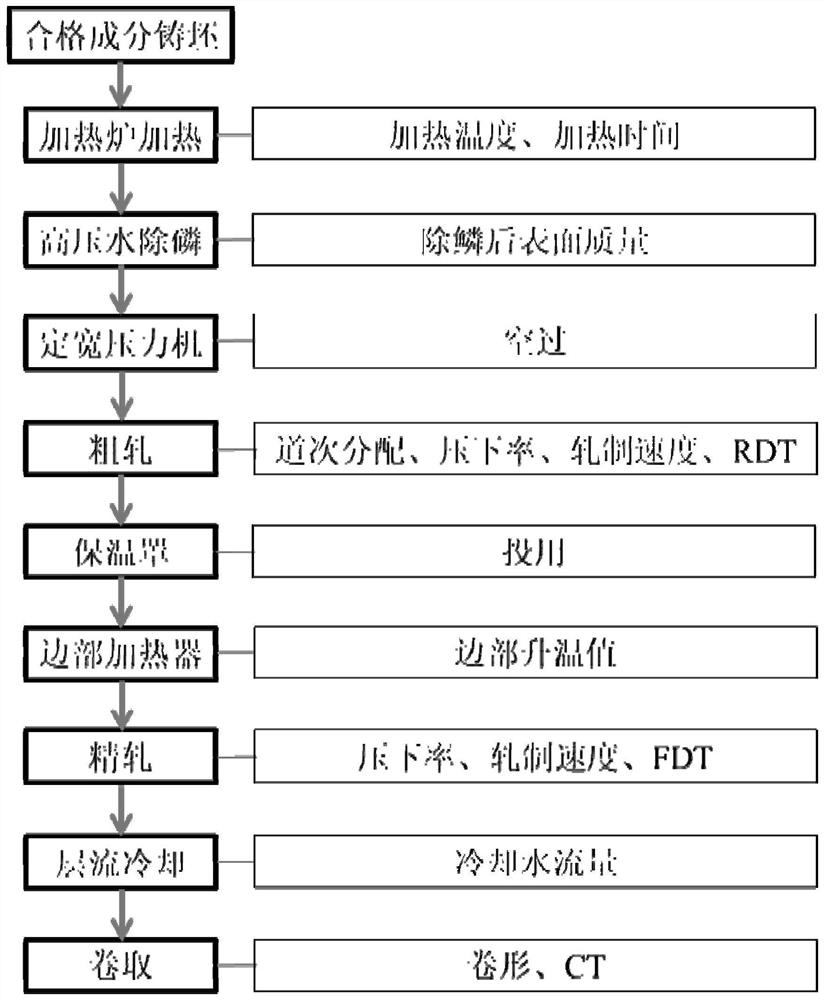

Control method of excellent hot-rolled oriented silicon steel plate shape

ActiveCN112246869AEasy to shapeFulfil requirementsTemperature control deviceWork treatment devicesLaminar coolingStrip steel

The invention discloses a control method of an excellent hot-rolled oriented silicon steel plate shape, and belongs to the field of hot-rolled oriented silicon steel manufacturing. The method comprises the following steps that S1, a heating furnace is used for heating, specifically, the temperature of a soaking section of the heating furnace is 1250-1320 DEG C, and the soaking time is longer thanor equal to 60 min; S2, rough rolling is conducted, specifically, rough rolling is conducted on an E1 / R1 reversible rough rolling machine and an E2 / R2 reversible rough rolling machine in sequence, andthe temperature of an intermediate billet is larger than or equal to 1120 DEG C after rough rolling is finished on the E2 / R2 reversible rough rolling machine; S3, finish rolling is conducted, specifically, seven-rack continuous rolling is adopted, the pass reduction rate in the F1-F7 continuous rolling process is sequentially reduced, the finish rolling F1 reduction rate is 45-50%, and the F7 reduction rate is 5-10%; and S4, laminar cooling is conducted, specifically, the cooling water amount of a nozzle at the edge of strip steel is smaller than that in the middle. According to the method, the defect that in the prior art, the requirements of a hot-rolled oriented silicon steel raw material for performance and plate shape cannot be considered is overcome, the hot-rolled oriented siliconsteel plate with the excellent plate shape is obtained under the condition that it is guaranteed that all key temperature parameters reach the standard, and the obtained plate shape can guarantee thatthe comprehensive yield from the oriented silicon steel raw material to a finished product is larger than or equal to 91%.

Owner:MAANSHAN IRON & STEEL CO LTD

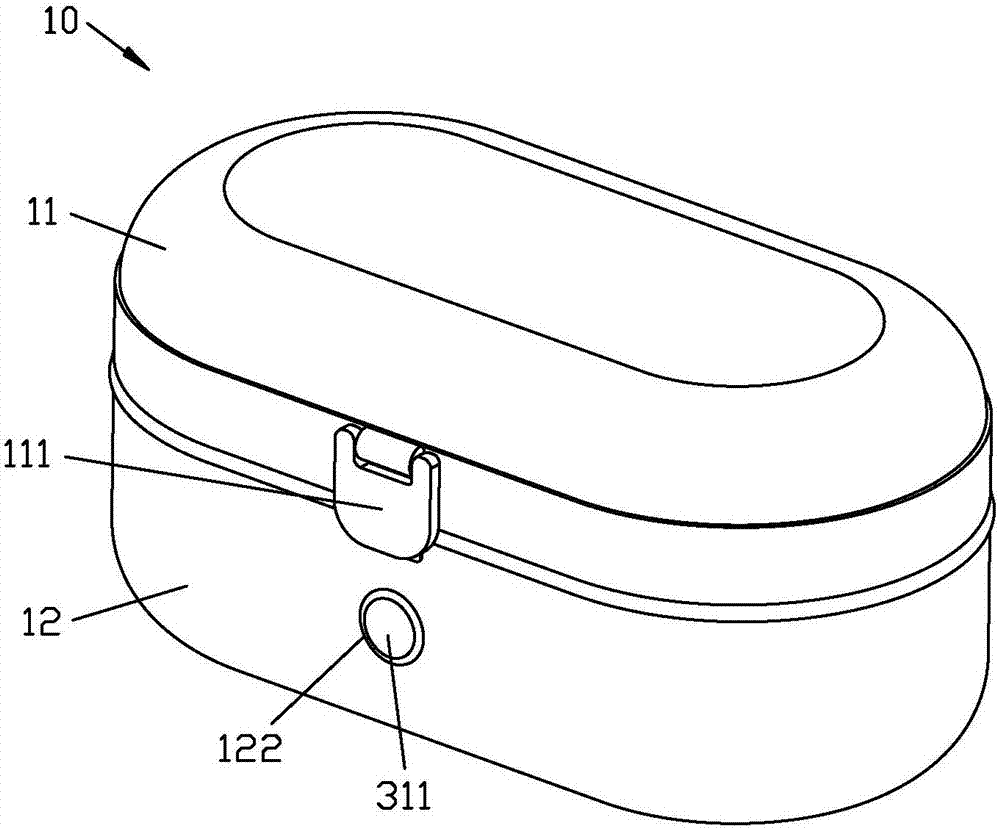

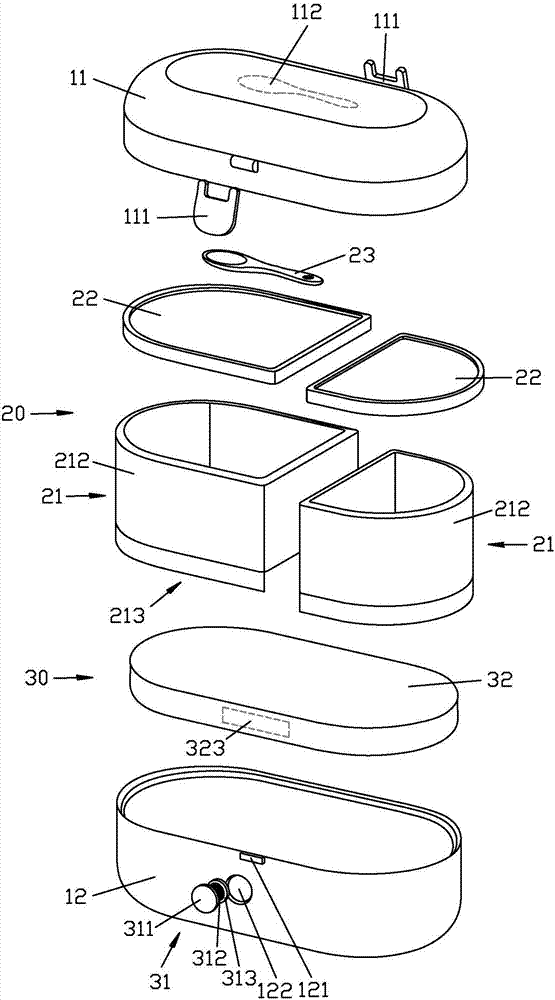

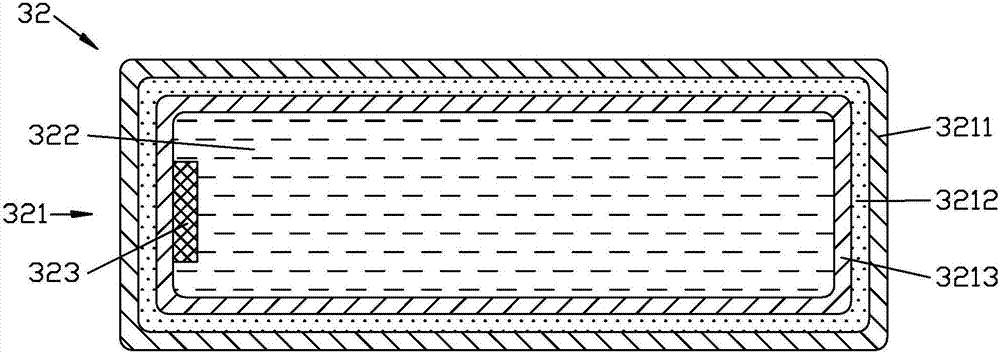

Power-supply-free re-heatable lunch box

ActiveCN107048655AReduce cooling rateThere will be no difficult heat penetrationOther accessoriesWarming devicesPolyesterSodium acetate

The invention discloses a power-supply-free re-heatable lunch box, comprising a shell, a lunch box component and a heating component; the lunch box comprises a box body and a box cover; the bottom of the box body is of single-layer aluminum structure, the sidewall of the box body is of double-layer aluminum hollow structure, the sidewall is at least partially extended down out of the bottom wall to form extension portions which cooperate to form a circular raised edge; the heating component comprises a startup module and a heating module; the heating module is mounted within the circular raised edge and is in contact with the bottom wall of the box body; the heating module comprises a sealed bag that is formed by combining a polyester film layer, an aluminum foil layer and a tinfoil layer, and oversaturated sodium acetate solution and a memory alloy sheet are arranged in the sealed bag; by extruding the memory alloy sheet through the startup module and deforming the memory alloy sheet, the oversaturated sodium acetate solution in the sealed bag is caused to release heat through phase change, and a meal in the box body is heated. The power-supply-free re-heatable lunch box has the advantages of good portability, high heating efficiency and reusability.

Owner:林昌坤

Wheat drying equipment for vital gluten processing

PendingCN112728899AHeating fully and evenlyEvenly heatedSievingScreeningElectric machineryAgricultural engineering

The invention discloses wheat drying equipment for vital gluten processing. The wheat drying equipment comprises a drying box, a first discharging device and a second discharging device, a feeding hopper is fixedly connected to the upper end of the drying box, a motor is arranged inside the drying box, the outer side of the motor is sleeved with a transmission wheel, the outer side of the transmission wheel is sleeved with a transmission belt, the motor is in transmission connection with a first stirring shaft and a worm through the transmission wheel and the transmission belt, and the first stirring shaft is fixedly connected with a heat-conducting plate. When the wheat drying equipment is used, the heat-conducting plate and first stirring blades are heated through a heating device, then wheat is heated, the first stirring shaft is driven by the motor, the first stirring shaft drives the heat-conducting plate and the first stirring blades to rotate and stir the wheat to enable all parts of the wheat to be heated evenly, and a plurality of second stirring shafts and second stirring blades are driven to rotate and stir the wheat through the mutual matching of a stirring frame, a first connecting gear, a second connecting gear, the second stirring shafts and the second stirring blades while the heat-conducting plate rotates, so that the wheat is heated more sufficiently and uniformly.

Owner:安徽省碧绿春生物科技有限公司

Indirect Thermal Desorption Unit

Owner:ZHEJIANG EASYCLEAN ENVIRONMENTAL TECH CO LTD

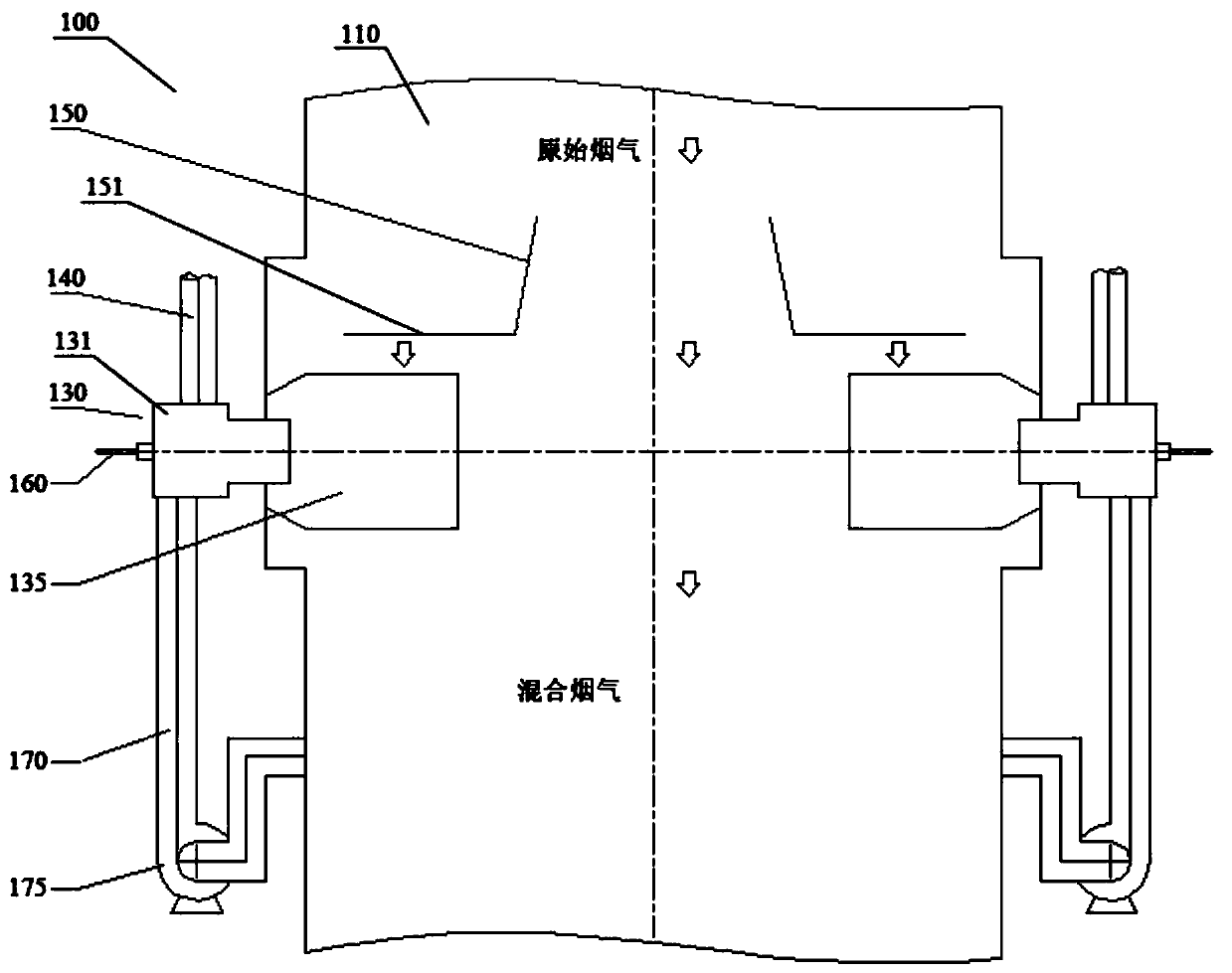

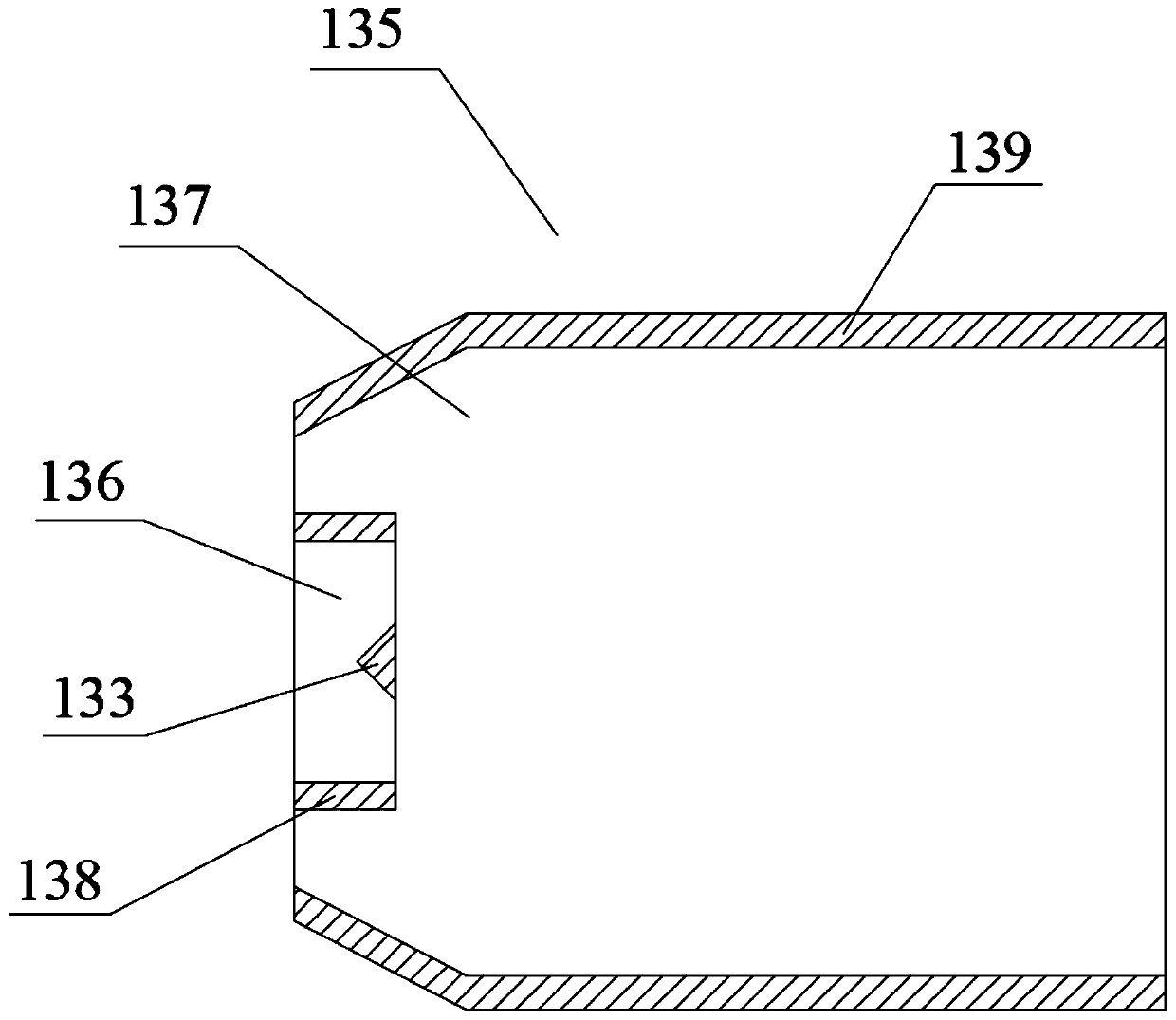

Flue gas heating system

PendingCN110160066AEnsure negative pressure environmentStable and safe heating processIncinerator apparatusCombustorCombustion chamber

The invention discloses a flue gas heating system. The flue gas heating system is suitable for heating raw flue gas. The flue gas heating system comprises a flue, at least two burners and a combustion-supporting air system, wherein the flue is suitable for inletting raw flue gas, the burners are arranged at the opposite two sides of the flue, the burners are provided with combustion chambers, thecombustion chambers are arranged in the flue and used to combust fuel gas, the raw flue gas is mixed after being heated by the combustion chambers to form mixed flue gas, the combustion-supporting airsystem is connected to the burners and the flue, the combustion-supporting air system comprises a combustion-supporting fan, and the combustion-supporting fan communicates with the flue at the downstream of the burners so as to extract partial mixed flue gas in the flue or air in the atmosphere into the burners. The flue gas heating system can prevent the amount of the mixed flue gas in the fluefrom increasing too fast, ensures the negative pressure environment in the flue, and makes the flue gas heating process more stable and safer.

Owner:北京永博洁净科技有限公司

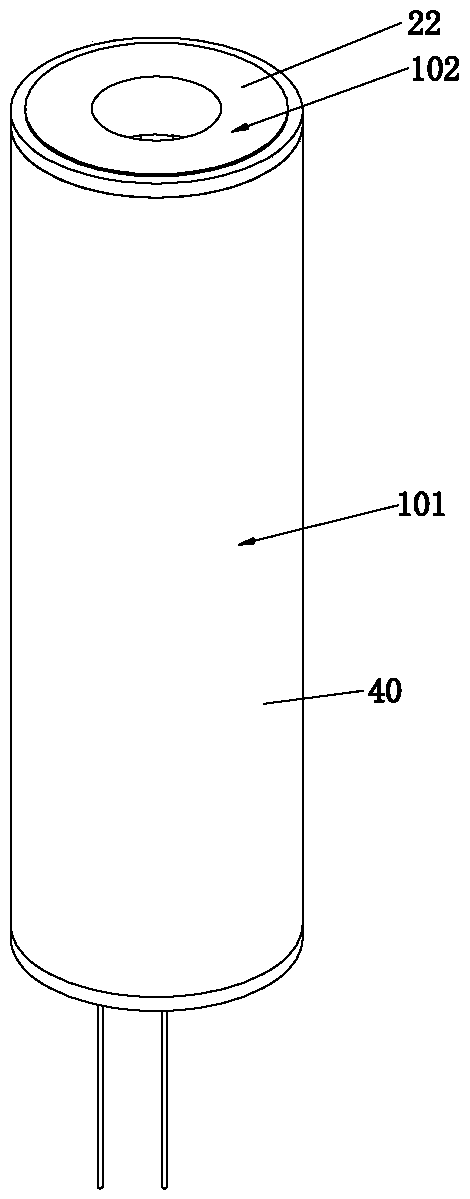

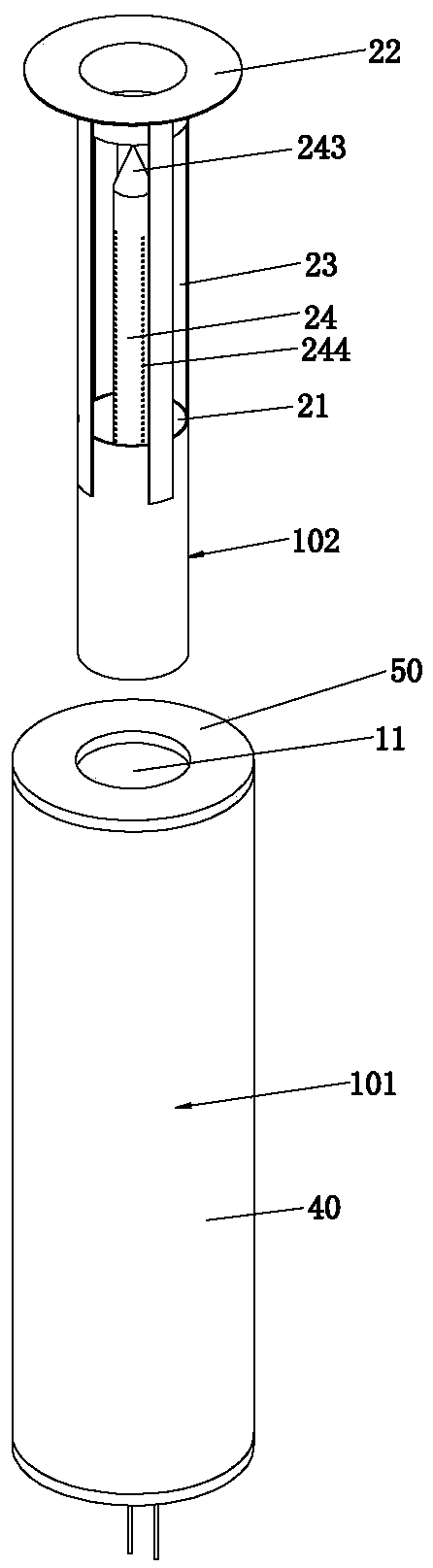

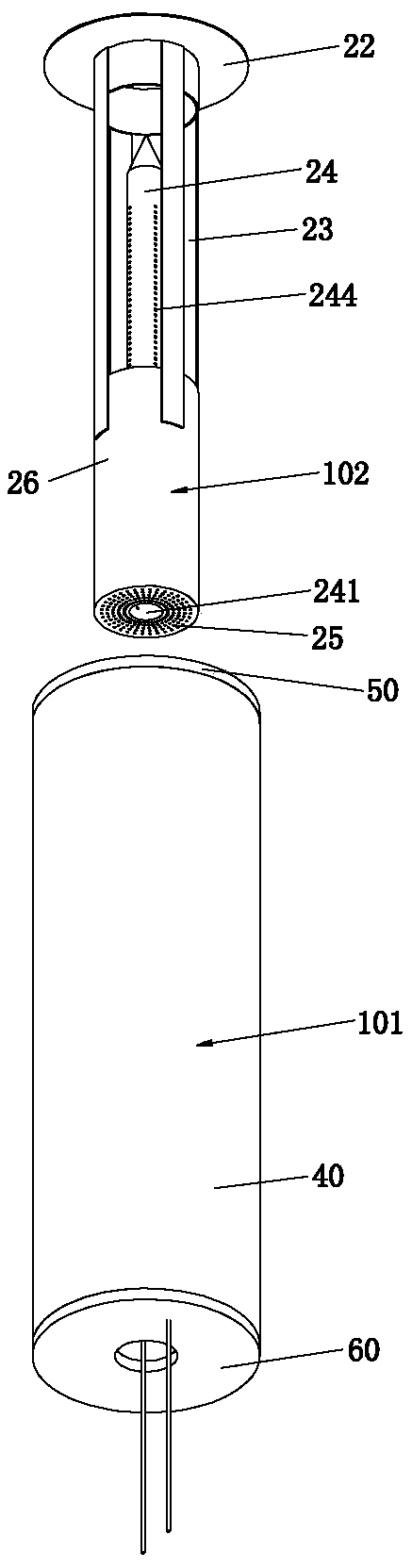

Heat-not-burn device

The invention provides a heat-not-burn device. The device comprises a heating cavity and an infrared heater, wherein an inserting hole is formed in the bottom wall of the heating cavity, and the inserting hole is located in the middle area of the bottom wall; and the infrared heater comprises a columnar carrier, an infrared coating located on the outer side face of the carrier and an electrode electrically connected with the infrared coating. The top surface of the carrier is closed, and the top surface of the carrier and the part, opposite to the infrared coating, of the carrier are insertedinto the heating cavity from the inserting hole; and an electrode electrically connected with the infrared coating is led out of the heating cavity. By using the device, the tobacco materials are heated more uniformly and fully, and the generated smoke is more sufficient.

Owner:HUBEI CHINA TOBACCO IND

Friction welding fixture

ActiveCN109623131ARealize automatic pressingAchieve looseningNon-electric welding apparatusFriction weldingMechanical engineering

The invention discloses a friction welding fixture, which includes a base and two compressing mechanism arranged symmetrically on both sides of the upper part of the base. The compressing mechanism includes a vertical column, a top compressing assembly for compressing the top of a workpiece and a side face compressing assembly for compressing the side face of the workpiece; the vertical column isinstalled on the upper part of the base, and the top compressing assembly includes a motor, a guide rail, a screw rod, a sliding block, a first lifting part, a top fixing plate, a top moving block, atop flexible pressing plate, a second lifting part and a first spring; the motor is installed in the vertical column, the guide rail is installed horizontally on the upper part of the inner side faceof the vertical column, the screw rod is rotatably connected with the motor, the sliding block is slidably installed on the guide rail, the bottom of the sliding block is connected with a nut, the nutexternally sleeve the screw rod, and the bottom of the inner end of the sliding block is connected with the upper part of the first lifting part; and the lower part of the first lifting part is connected with the top fixing plate, and the sliding block is connected with the top fixing plate through the second lifting part. According to the friction welding fixture, to-be-welded workpieces are conveniently fixed, and the friction welding fixture can be applied to mass production and friction welding of thin plate type workpieces.

Owner:湖南坤鼎数控科技有限公司

Combined smear dyeing device table

ActiveCN105158045AReduce labor intensityEasy to storePreparing sample for investigationPulp and paper industrySupport plane

The invention belongs to the field of medical apparatus and instruments, and discloses a combined smear dyeing device table. The combined smear dyeing device table comprises a dyeing table, a support frame, a plurality of baffles, and a waste liquor groove, a dyeing platform and a placing platform which are sequentially arranged on the support frame from bottom to top, wherein the dyeing platform comprises a plurality of first sliding grooves formed in the support frame; the placing platform comprises a plurality of second sliding grooves which are sequentially formed in the support frame from top to bottom; the baffles are arranged on the support frame in a sliding manner through the first sliding grooves or the second sliding grooves, and are hollowed-out baffles; a mounting groove is formed in the upper surface of the dyeing table; the waste liquor groove is formed in the mounting groove. According to the combined smear dyeing device table, the dyeing platform and the placing platform are arranged on the support frame, so that dyeing, airing and other steps can be carried out at the same time; residual liquid generated from smear flushing during airing can smoothly flow into the waste liquor groove without directly dropping, and after flushing, next batch of smears can be directly dyed, so that the time for waiting airing is further shortened.

Owner:TARIM UNIV

Food cooking device

InactiveCN109527984AAvoid undercookedAvoid the situationCooking insertsFood scienceHelical bladeProcess engineering

The invention relates to the technical field of food cooking equipment, and discloses a food cooking device, which comprises a cooking container, a driving mechanism and a stirring mechanism arrangedin the cooking container, wherein one end of the cooking container is provided with a feeding port, and the other end of the cooking container is provided with a discharging port; the bottom of the cooking container is provided with a heating jacket for heating a cooking area; the stirring mechanism comprises a rotating shaft rotatably connected with the cooking container, and the periphery of therotating shaft is provided with spiral blades extending in the axial direction of the rotating shaft; and the driving mechanism is connected with the rotating shaft to drive the rotating shaft to rotate. The food cooking device ensures sufficient and uniform heating, is favorable for controlling cooking temperature and cooking time, is also favorable for forming continuous production line food production, improves food cooking efficiency, is particularly suitable for central kitchens, chain restaurants and restaurant canteens, food processing plates and other units to carry out dish engineering production.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

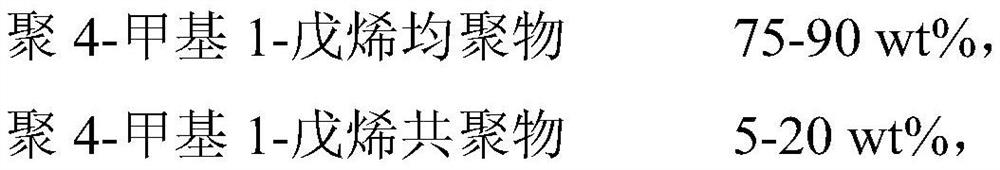

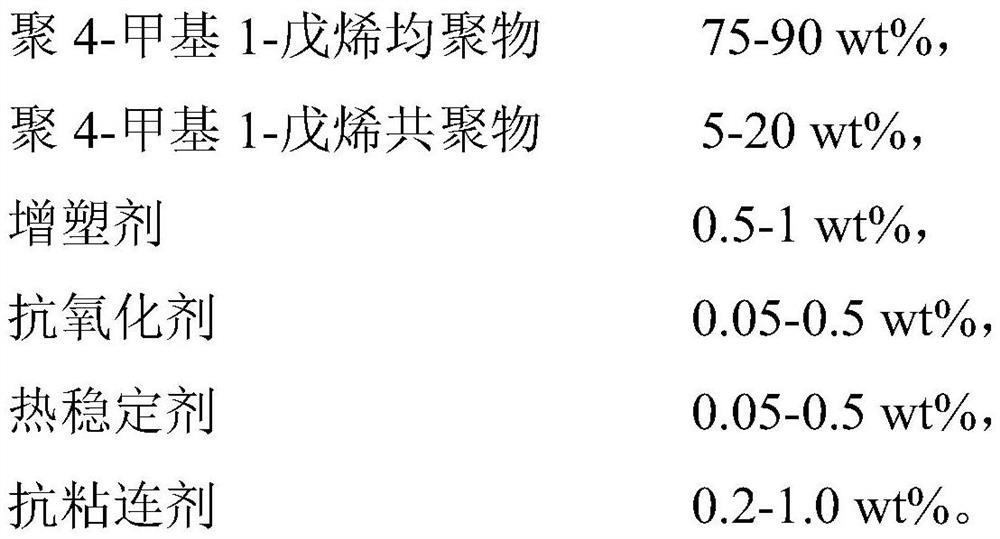

Biaxially oriented poly (4-methyl-1-pentene) film and preparation method thereof

The invention relates to a biaxially oriented poly (4-methyl-1-pentene) film and a preparation method thereof, and particularly belongs to the technical field of high polymer materials. The film belongs to crystalline olefin resin, and is high in heat resistance, the melting point reaches up to 240 DEG C, and the working temperature can reach 140-160 DEG C. According to the preparation method of the poly (4-methyl-1-pentene) film, by setting temperature parameters of all sections in a production line, main factors influencing crystallization, stretching orientation and shaping processes of poly (4-methyl-1-pentene) molecules are controlled, and it is guaranteed that the product performance suitable for capacitor films is obtained; in the processing course, poly (4-methyl-1-pentene) resin with the optimal molecular weight is selected, the crystallization degree of the film is controlled and material degradation is prevented according to the temperature and stretching ratio suitable forprocessing, and the biaxially oriented poly (4-methyl-1-pentene) film which is resistant to high temperature and good in thickness uniformity is continuously produced.

Owner:ANHUI TONGFENG ELECTRONICS

Accelerated-heat-aging test device used for inspection of automobile parts

ActiveCN109297893AImprove flexibility and applicabilityImprove heating efficiencyWeather/light/corrosion resistanceAging testEngineering

The invention provides an accelerated-heat-aging test device used for inspection of automobile parts. The device comprises wind guiding plates, a screw cap, support hanging rods, a positioning suspending rod, a sliding top cover, positioning insertion rods, an upper positioning ring and a lower positioning ring. An insertion ring is supported and disposed at the center of a top end of the screw cap. The five support hanging rods are also supported and disposed on an end face of a periphery of the insertion ring in a manner of an annular array. Each of top ends of the five support hanging rodssupports a seizing piece with a positioning hole inwards. A sliding top cover is disposed on the positioning suspending rod in a sleeving manner. The sliding top cover is located above the upper positioning ring. The five positioning insertion rods are supported and disposed on a bottom ring plate of the sliding top cover in a manner of an annular array. According to disposing of a packing-auger wind guiding vane of the invention, the packing-auger wind guiding vane has a spiral guiding function, and spiral eddy currents are more easily formed inside a cyclone cylinder 10 under auxiliary guiding thereof.

Owner:竹田(无锡)汽配制造有限公司

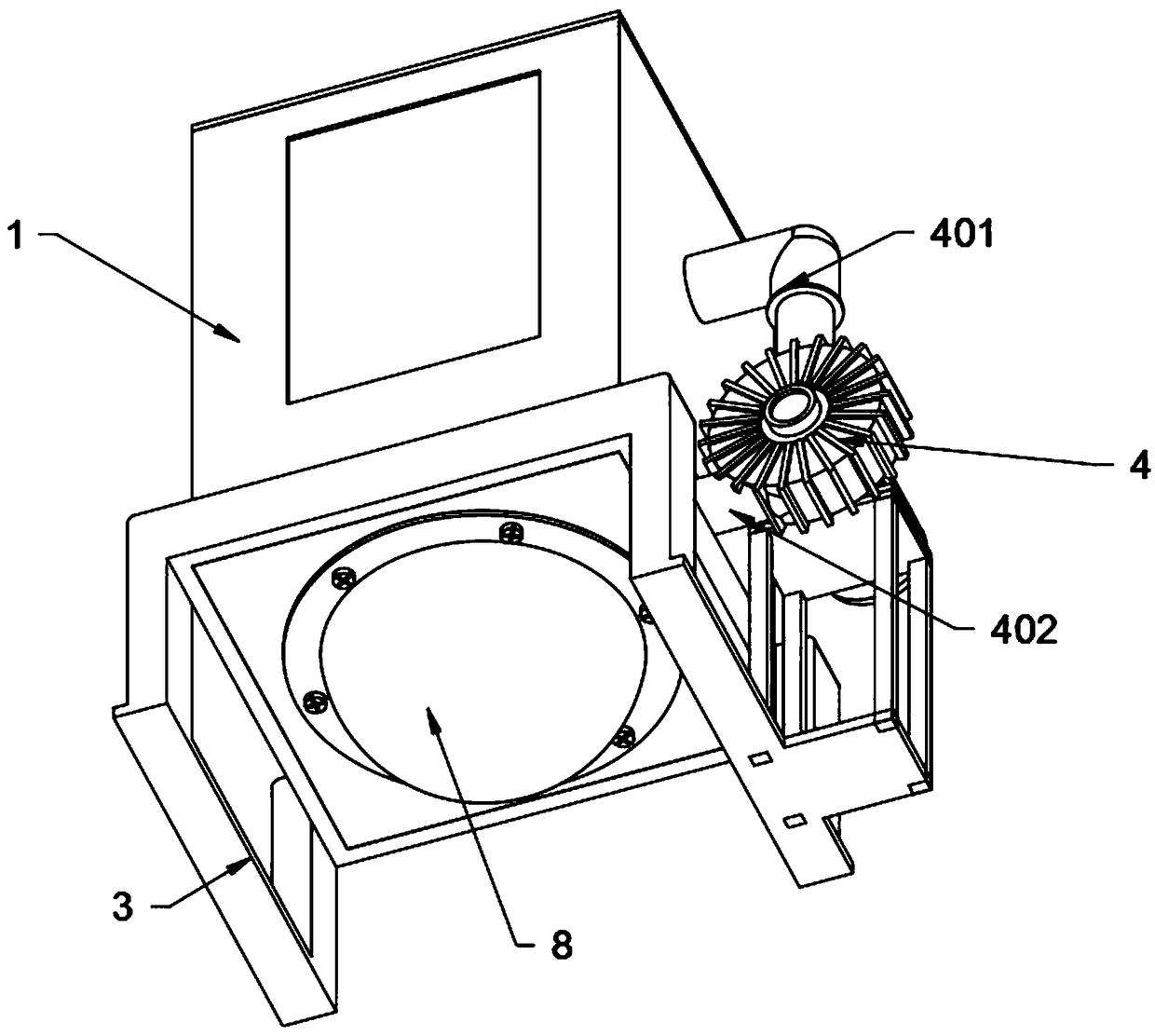

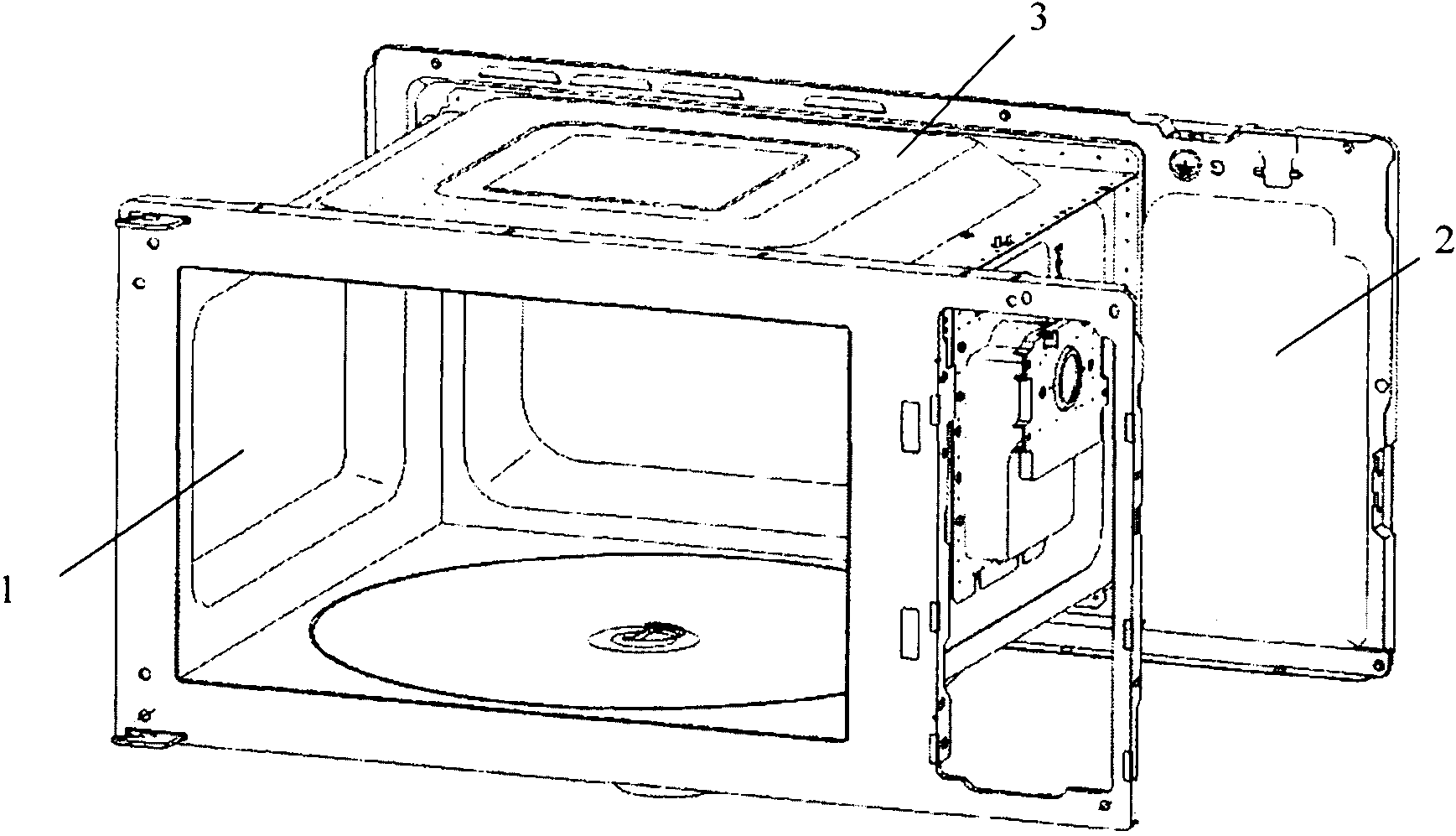

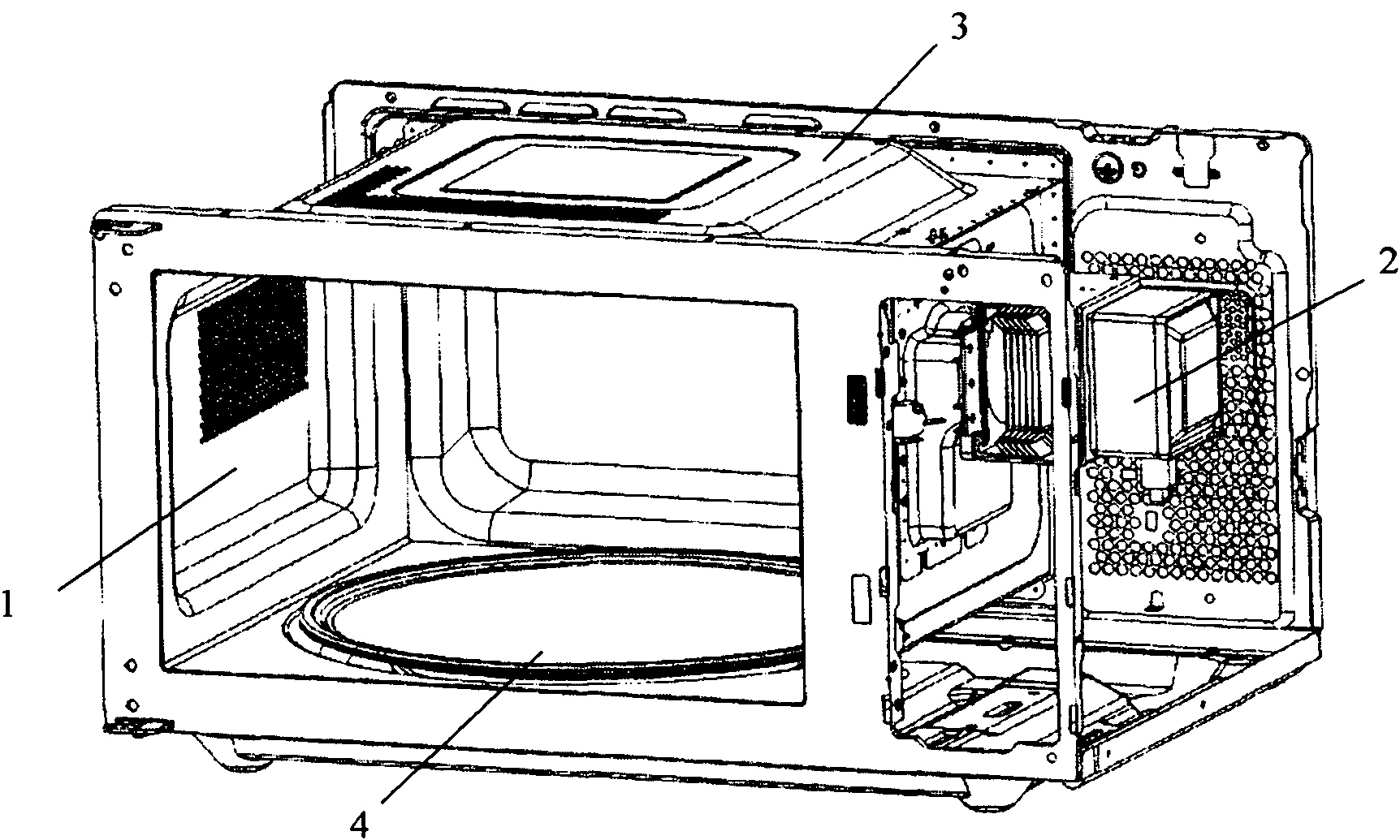

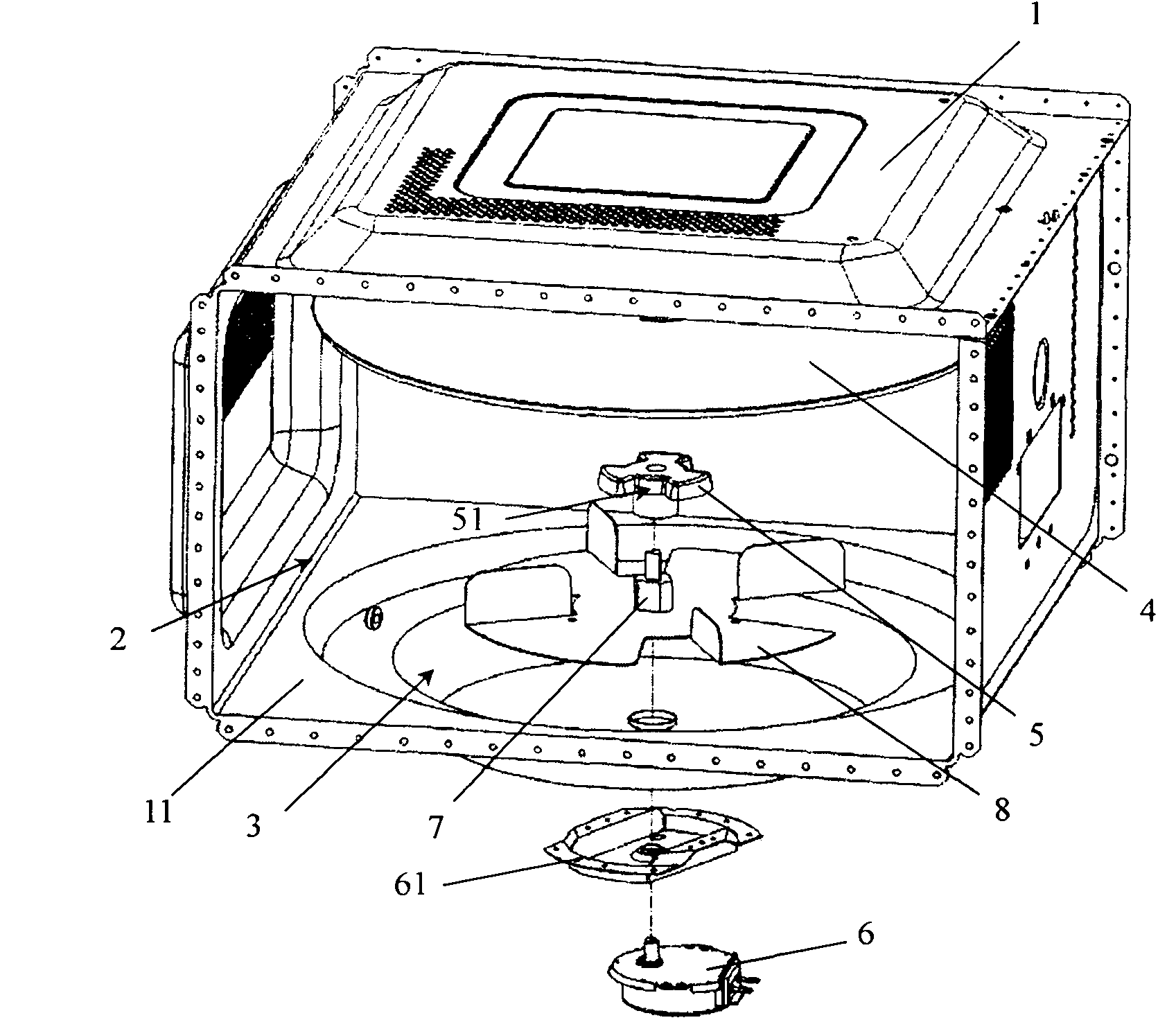

Microwave oven with novel rotating disk structure

InactiveCN102168863AImprove work efficiencyDoes not affect utilizationDomestic stoves or rangesStoves/ranges shelves or racksMicrowave ovenEngineering

The invention discloses a microwave oven with a novel rotating disk structure, comprising an oven body(1). A groove (3) is arranged in a bottom panel (11) of the oven body (1); the rotating disk (4) can be rotatably arranged in the groove (3); and the top of the rotating disk (4) and the top of the bottom panel (11) of the oven body (1) are on the same horizontal surface. The microwave oven disclosed by the invention can rotatably cook various food placed in the oven chamber to achieve the effect of fully and evenly heating the food within the oven chamber, with the prerequisite of the space within the oven chamber not being influenced, so as to guarantee good mouthfeel of the food cooked within the microwave oven. Besides, because of the utilization rate of the space within the oven chamber not being influenced, a big amount of food can be placed in the oven chamber, so as to increase working efficiency of the microwave oven, thereby substantially enhancing product usage feeling of users of the microwave oven, expanding market application prospect of the microwave oven and having important production practice meaning.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com