Urea melting apparatus

A melting device, urea technology, applied in the direction of fertilization device, urea compound fertilizer, nitrogen fertilizer, etc., can solve the problems of low stirring intensity, high maintenance cost, ammonia bubbling, etc., to speed up the melting speed, prevent the risk of leaking tanks, The effect of preventing local high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

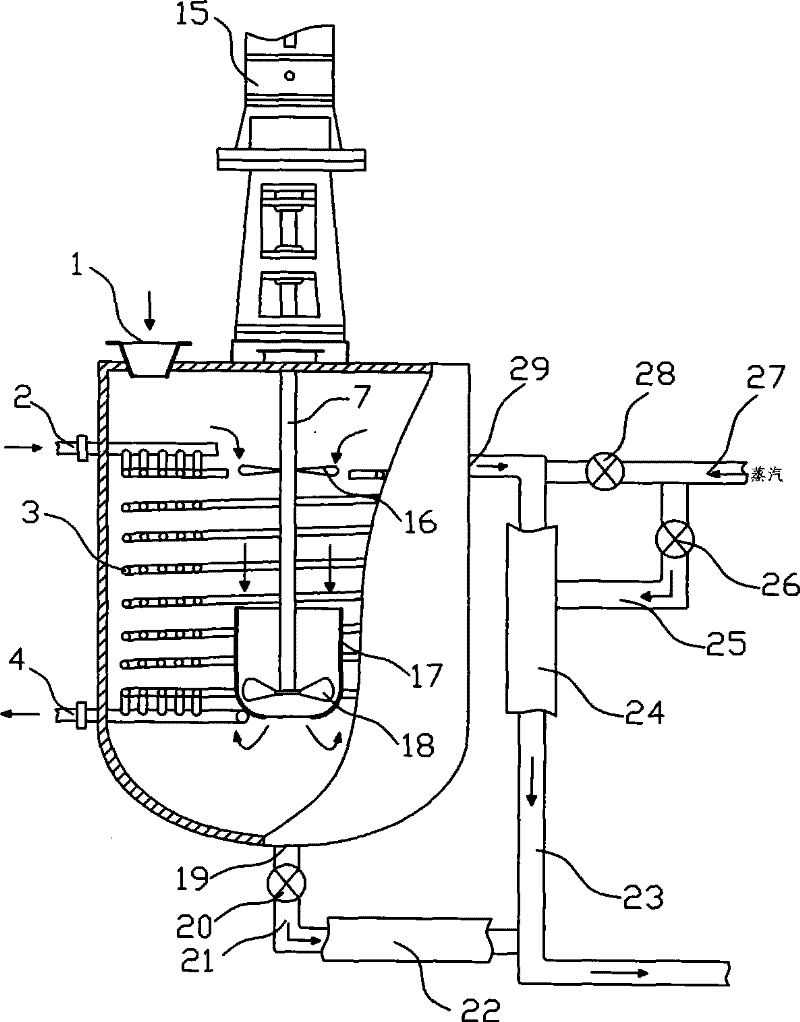

[0030] Example 1 A urea melting device, see figure 2 , Including an ellipsoidal crown bottom melting tank (Φ1800mm, H2200mm), a stirring mechanism, a heating coil 3 set in the melting tank, the stirring mechanism includes a stirring motor 15 (11-15KW, depending on the size of the tank, the speed of the stirring blade It is 85 rpm), the stirring shaft 7 and the upper and lower stirring paddles 16, 18 located in the melting tank, the upper stirring paddle 16 is composed of three inclined blades (inclination angle 30°, width 120mm), The lower stirring paddle 18 is composed of three impeller-type paddles; a drain port 19 is provided at the bottom of the arc bottom surface, and the drain port 19 is connected to the spray pipe 23 by the drain pipe 21; An overflow port 29 connected to the spray pipe 23 is provided at 500mm (filters can be installed at the overflow port). The height difference between the overflow port 29 and the spray outlet of the spray pipe 23 is at least 4m to ensu...

Embodiment 2

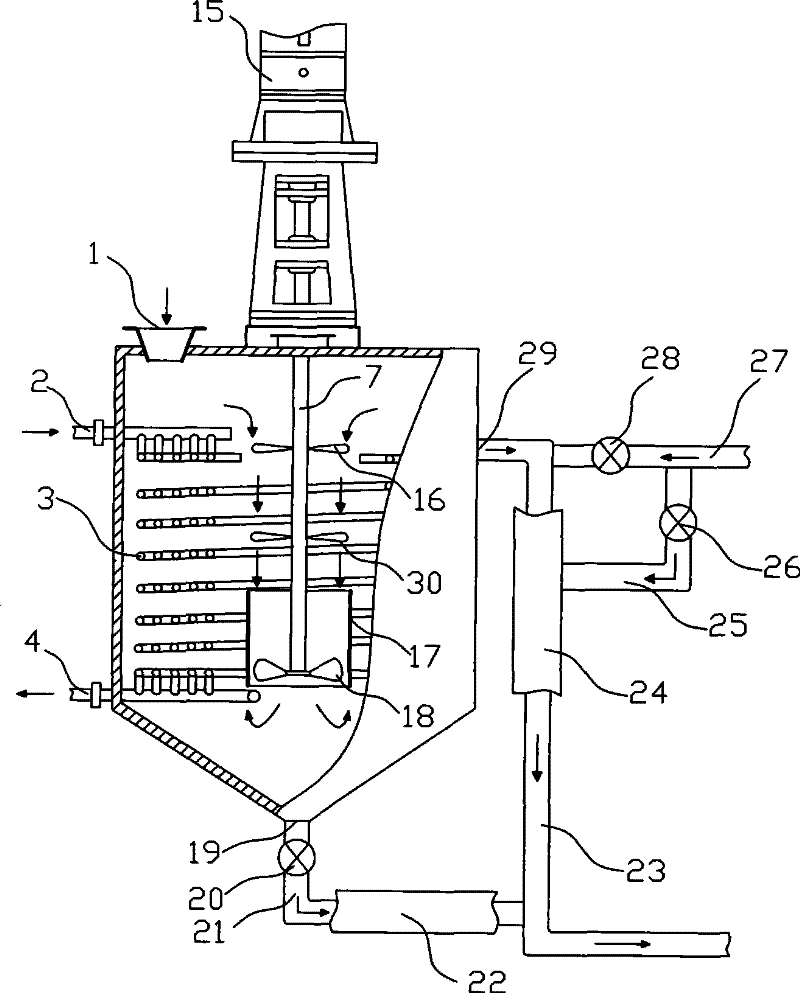

[0033] Example 2 A urea melting device, see image 3 , Including a conical arc-shaped bottom melting tank, a stirring mechanism, and a heating coil 3 arranged in the melting tank. The stirring mechanism includes a drive motor 15, a stirring shaft 7 located in the melting tank, and three upper, middle and lower stirring paddles 16, 30, 18, the upper and middle agitating paddles 16, 30 are both composed of three inclined blades, and the lower agitating paddle 18 is composed of three impeller-type paddles; a drain port 19 is provided at the bottom of the cone bottom. The discharge port 19 is connected to the spray pipe 23 by the discharge pipe 21; an overflow port 29 connected to the spray pipe 23 is provided on the upper part of the side wall of the melting tank, and the height difference between the overflow port 29 and the spray outlet of the spray pipe 23 It is subject to ensuring that there is sufficient pressure at the nozzle; a vertical guide tube 17 is provided in the lowe...

Embodiment 3

[0034] Example 3 is a urea melting device, which is basically the same as Example 1, except that: the upper layer is inclined liquid stirring paddle, the lower layer is the A310 axial flow stirring paddle (Laining); the deflector is a straight tube type .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com