Low temperature tobacco smoking set heated by hot air

A hot air, tobacco technology, applied in the direction of tobacco, smoker's products, applications, etc., can solve the problems of insufficient aroma and active ingredient release, insufficient use of tobacco materials, reducing the user's smoking experience, etc. Hazardous, reasonable and reliable structure, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

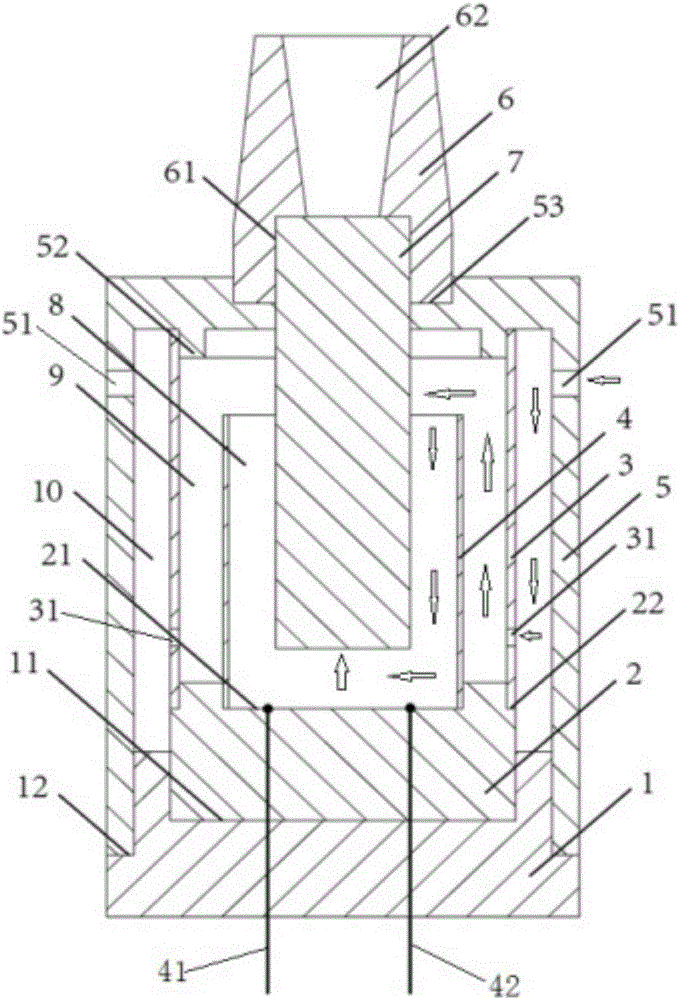

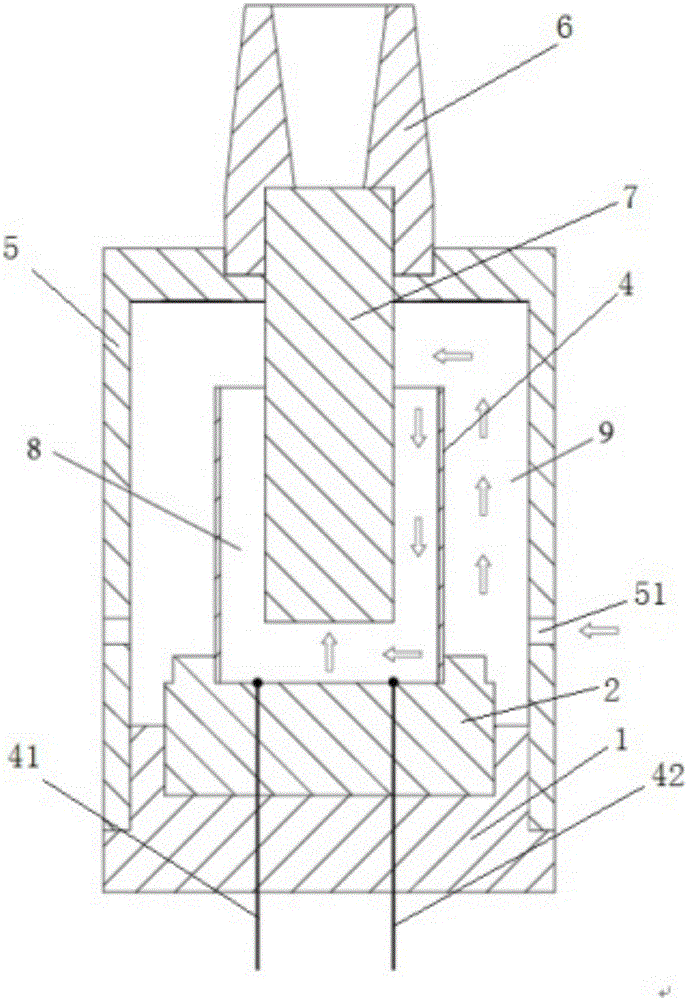

[0012] Such as figure 1 As shown, the smoking set of the present invention is composed of a base 1, an insulating base 2 installed on the base, a sleeve 3 inserted on the insulating base, a tubular heating element 4 fixed in the insulating base, an outer shell 5, and a suction nozzle 6 . The specific structure of the smoking appliance is as follows: the smoking appliance includes a base 1 with a first outer ring platform 12 and a first upper circular central groove 11, the bottom is installed in the first circular central groove 11 and the upper part has a second outer ring The platform 22 and the insulating seat 2 of the second upper circular central groove 21, the casing 3 that is vertically fitted and seated on the second outer ring platform 22, and the bottom is installed in the second upper circular central groove 21 The vertical tubular heating element 4, the shell 5 with a top plate that is vertically set and located on the first outer ring cap 12, the top center of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com