Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Realize automatic pressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

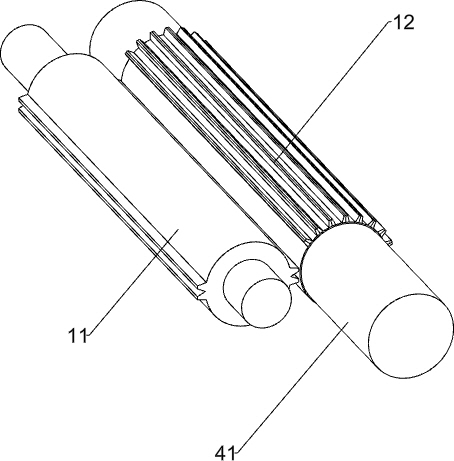

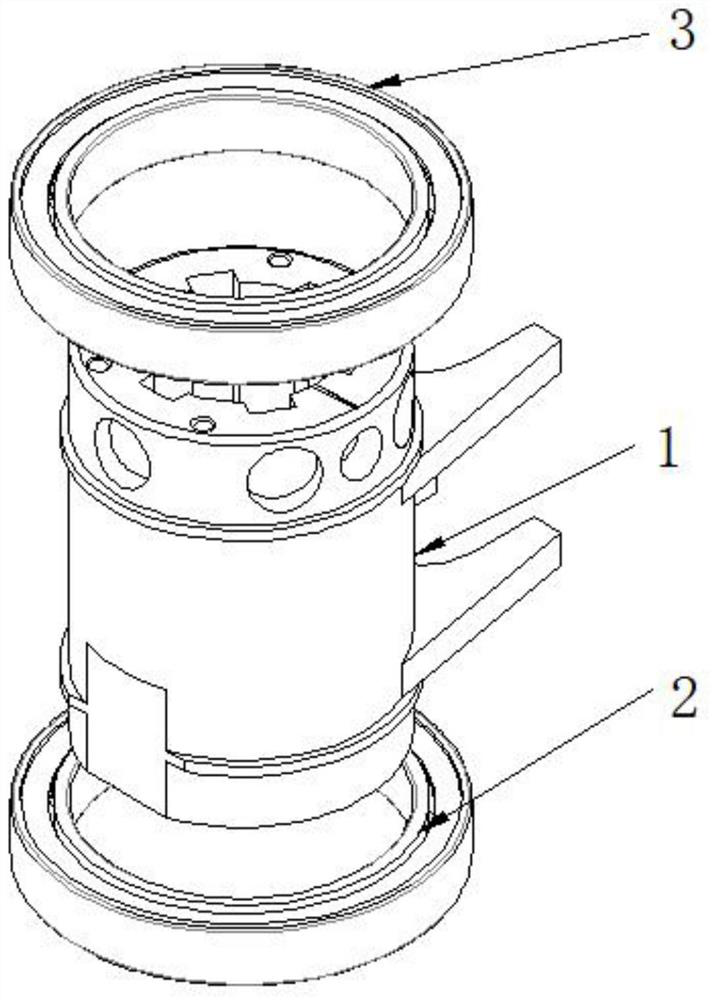

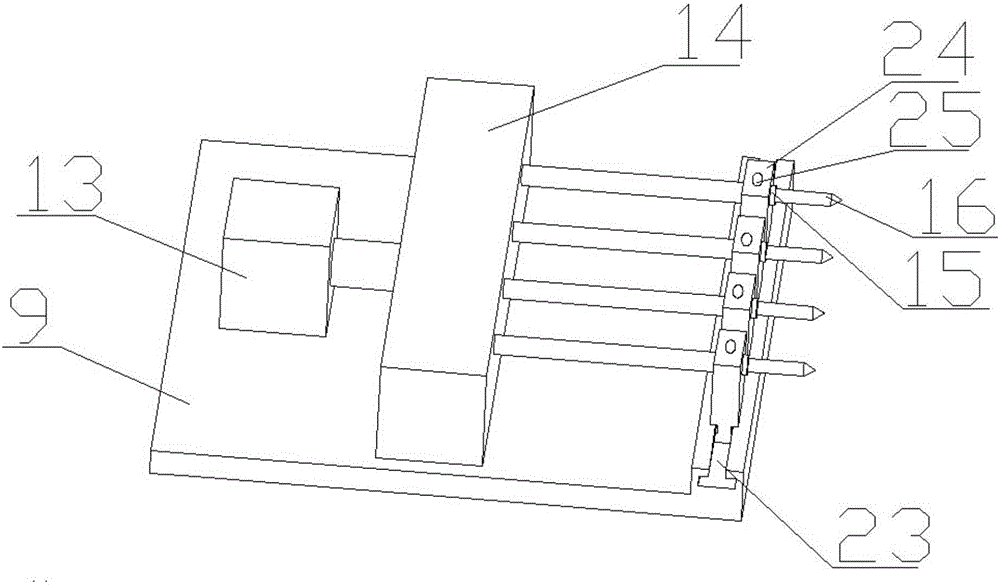

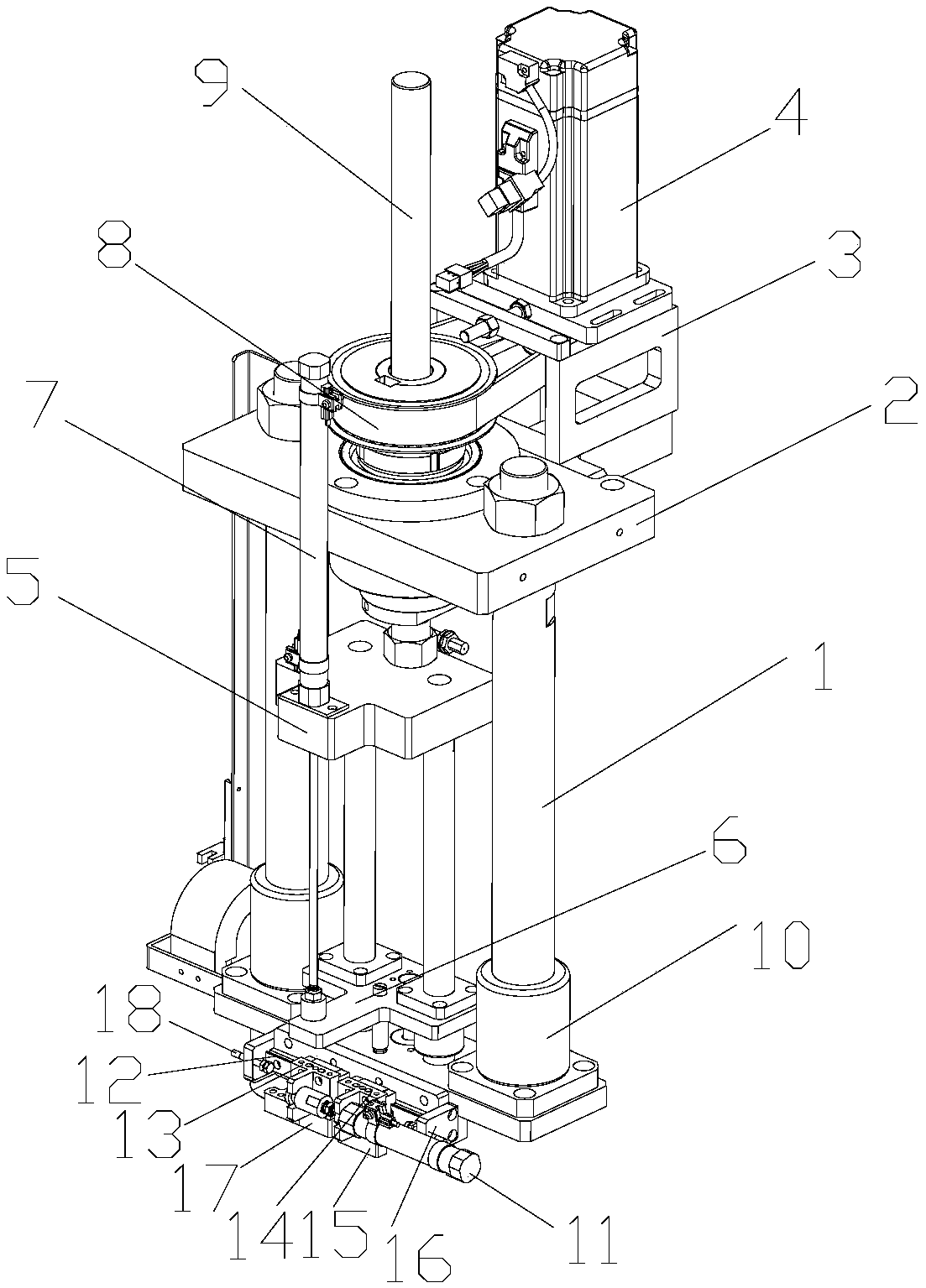

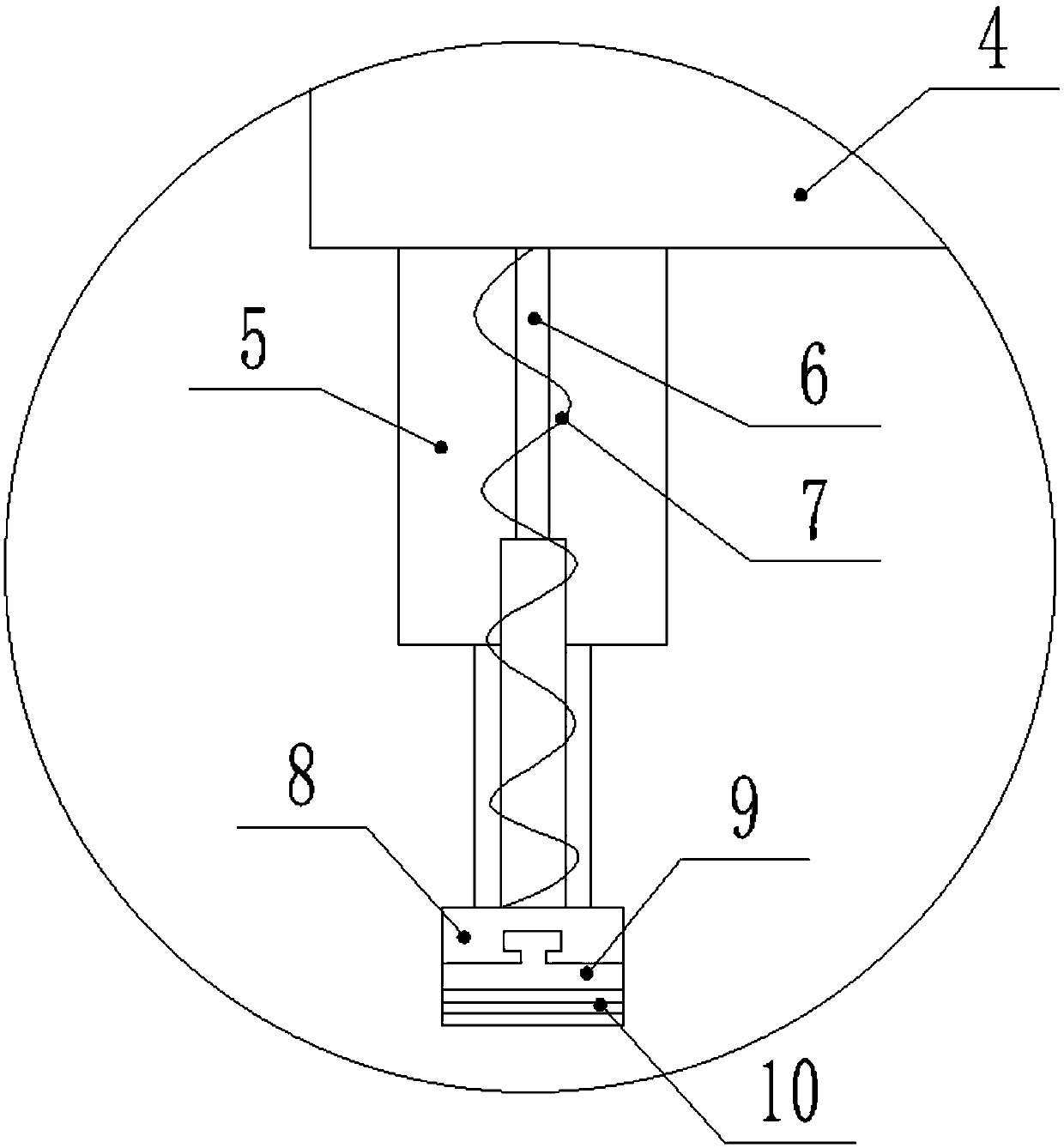

Circlip automatic pressing device and pressing method thereof

InactiveCN101982928AImprove assembly accuracyImprove pressing efficiencyManufacturing stator/rotor bodiesEngineeringCirclip

The invention discloses a circlip automatic pressing device and a pressing method thereof. The device of the invention comprises a pressing main body (1), wherein the pressing main body (1) comprises a Z-shaped base (2); a cylinder (4) is arranged above an upper transverse plate (3) of the base (2); a pressing piece (5) is fixed on a pushing head of the cylinder (4); a pressing piece groove (6) is arranged on the upper transverse plate (3) of the base (2); the pressing piece groove (6) vertically passes through a vertical plate (7) of the base (2); a fixing plate (9) is arranged at the tail end of a lower transverse plate (8) of the base (2); a guide rod (10) passes through the fixing plate (9); a spring (11) is sleeved on the guide rod (10); a pushing plate (12) is fixed at the end part of the guide rod (10); and the pushing plate (12) pushes a circlip to be strung on the pressing piece groove (6). The invention can greatly improve the pressing efficiency of the circlip on a rotor shaft, is suitable for industrialized mass production, improves the assembly accuracy of the circlip, and ensures the quality of finished products of rotors.

Owner:HUZHOU YONGCHANG BEISHITUO ELECTRIC APPLIANCE INDAL

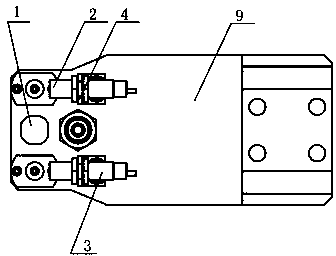

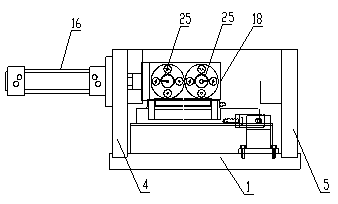

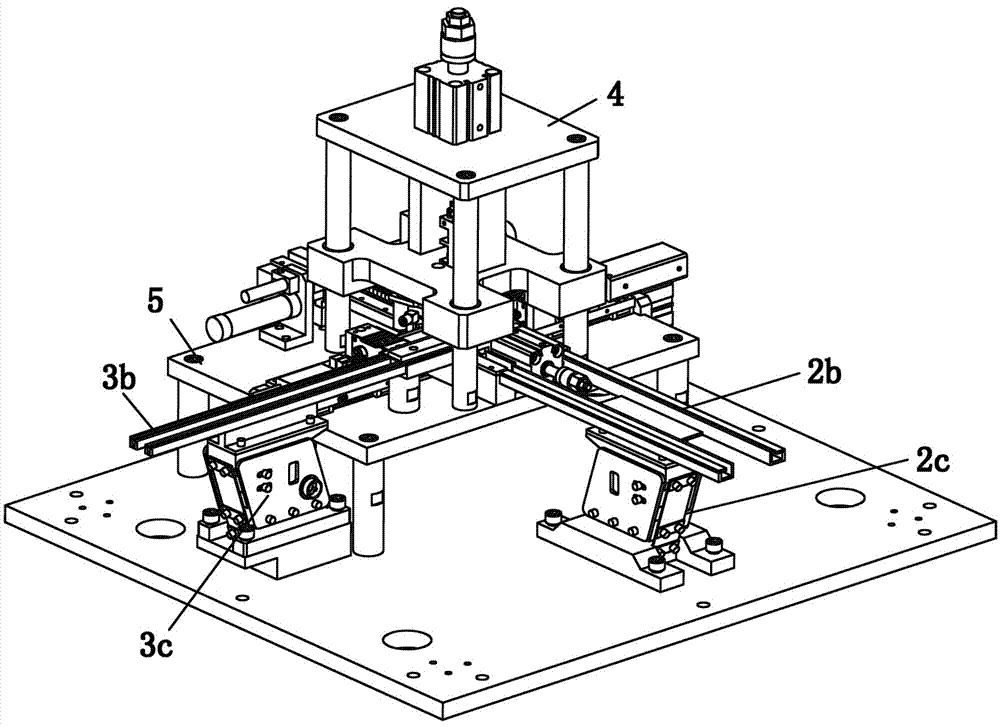

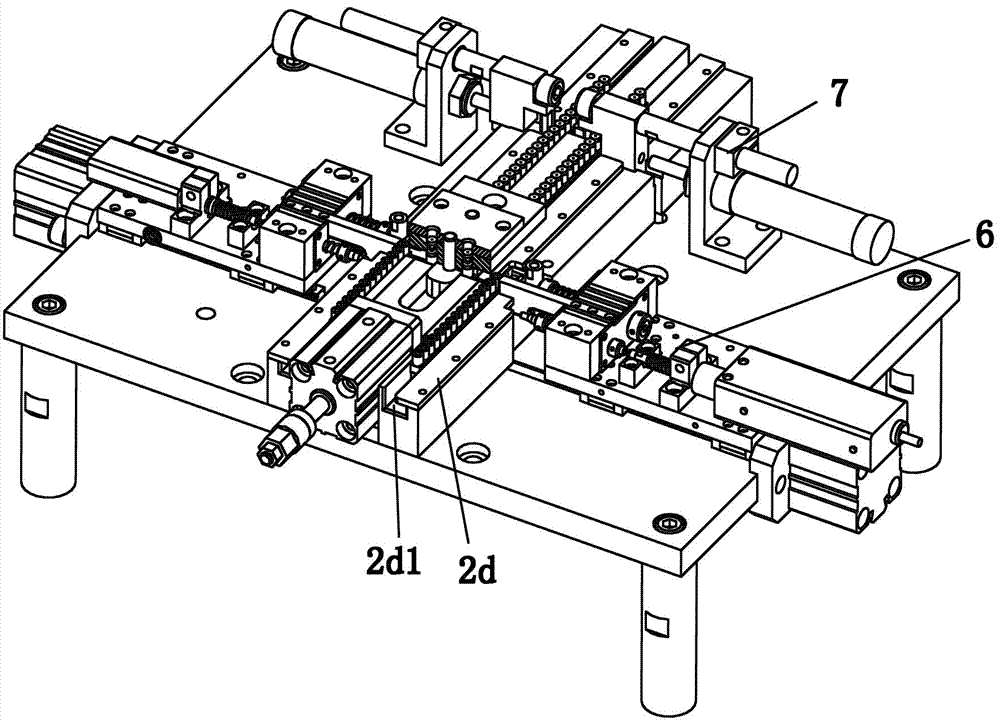

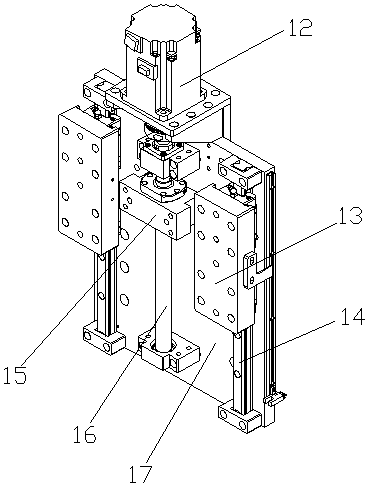

Press fitting mechanism for automatic measurement riveting machine of plunger steel ball

InactiveCN103862270ARealize the monitoring effectRealize automatic pressingMetal working apparatusEngineeringSteel ball

The invention relates to a press fitting mechanism for an automatic measurement riveting machine of a plunger steel ball. The press fitting mechanism comprises a mounting base, wherein a pneumatic lifting unit and a sensing unit are arranged on the mounting base. The press fitting mechanism is simple in structure and easy and convenient to operate; due to the arrangement of a photoelectric sensor, the monitoring performance of a plunger is effectively achieved; due to the arrangement of a proximity switch, displacement of a guide pillar is realized; a floating connector is used for eliminating errors, so that the stability during ascending and descending of the output end of an air cylinder is guaranteed, and the service life of equipment is prolonged. By means of all the units of the press fitting mechanism, automatic press fitting of the steel ball in a plunger is realized, time and labor are saved, the previous machining mode that manual pressing is needed is avoided, and machining efficiency is greatly improved.

Owner:无锡创捷汽车部件有限公司

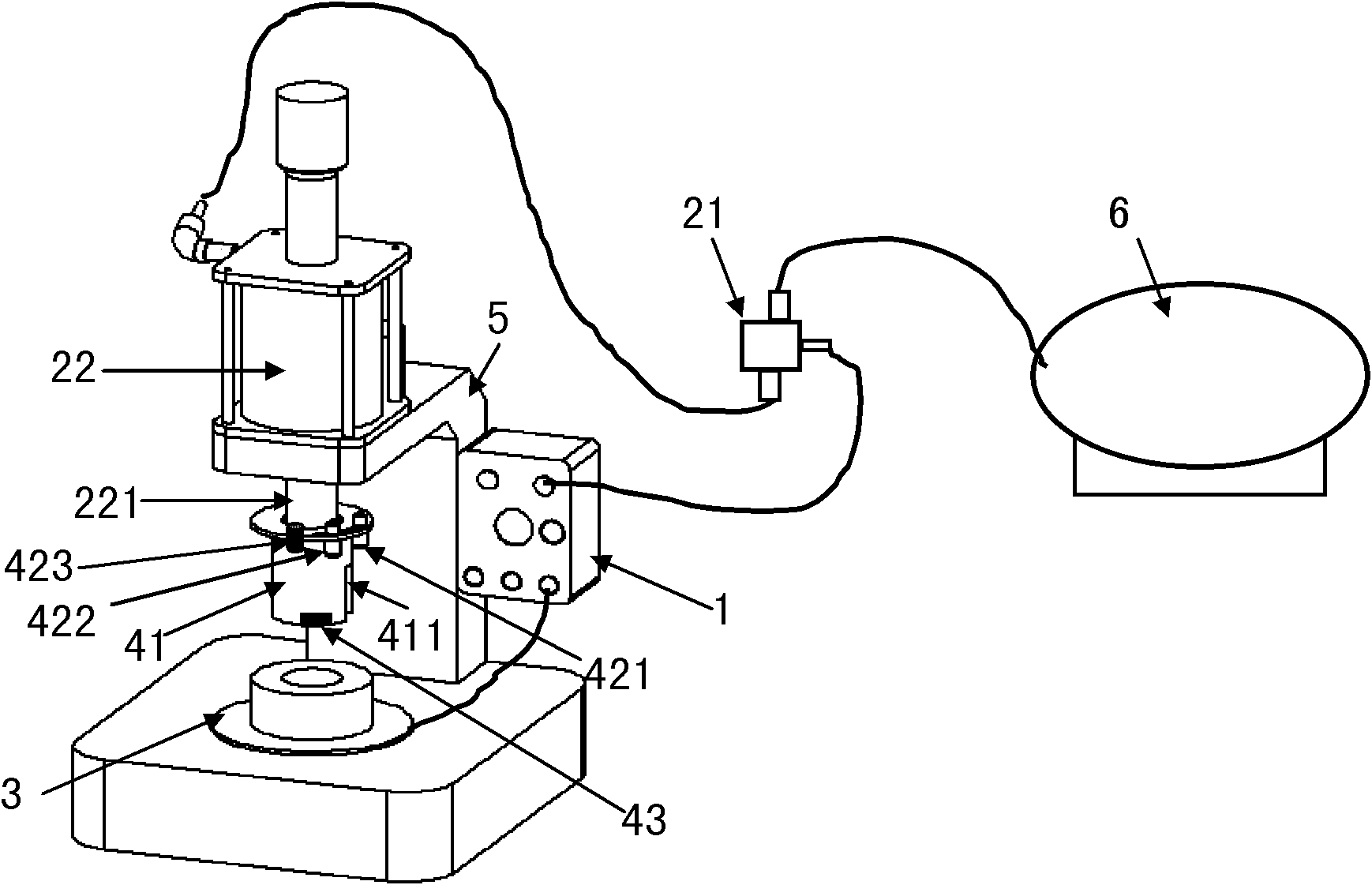

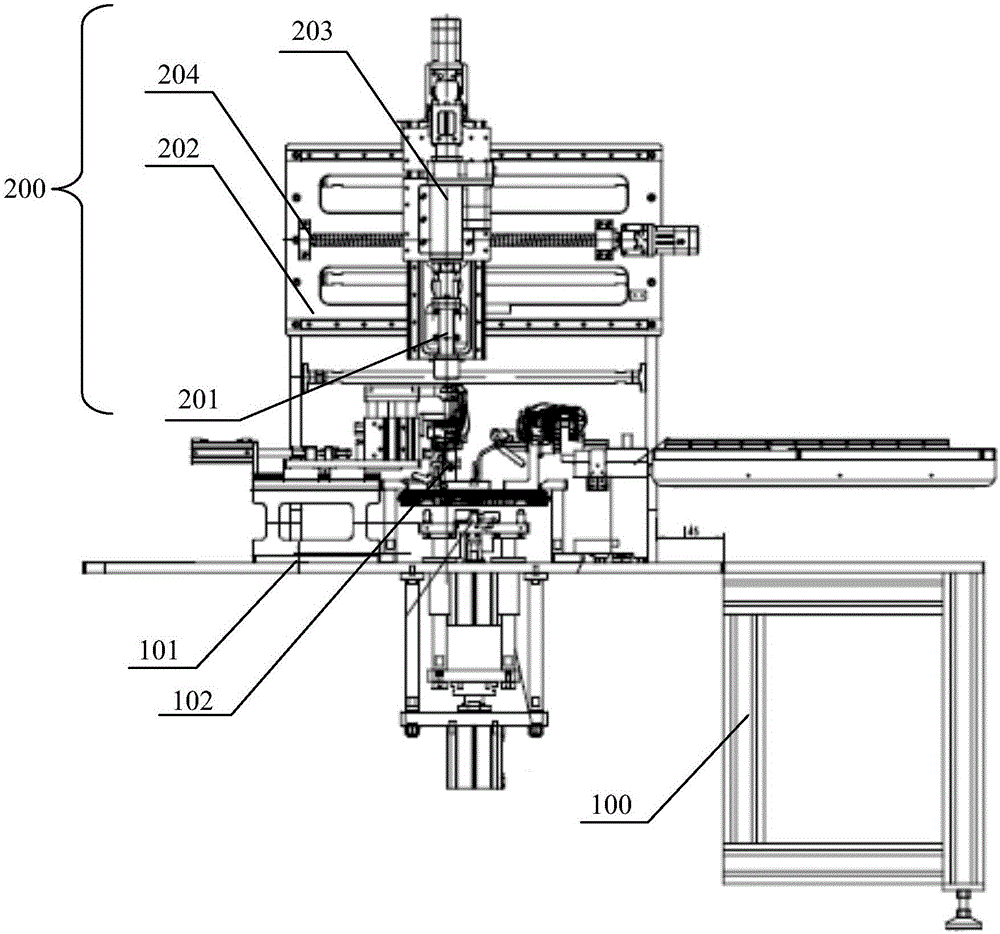

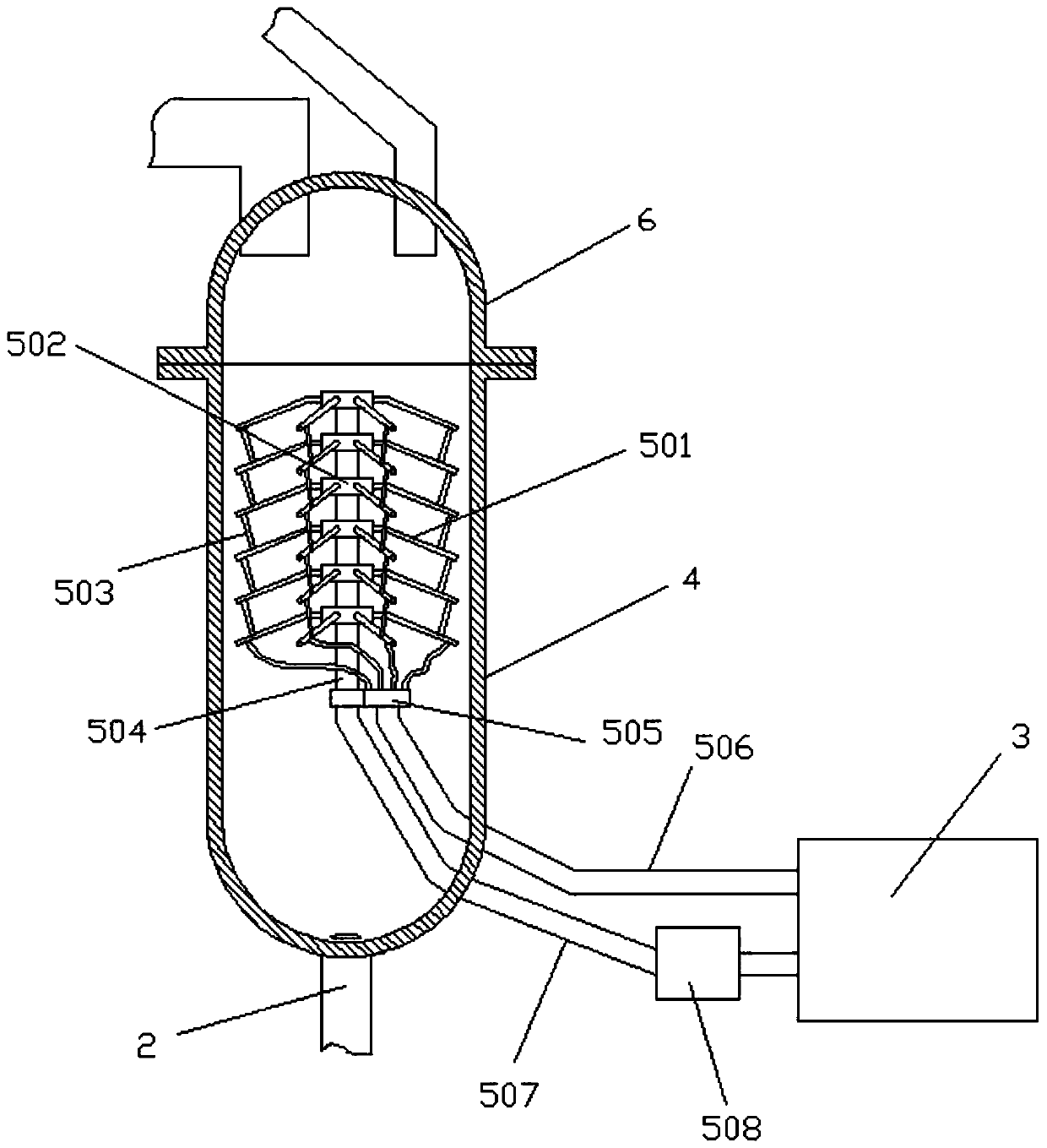

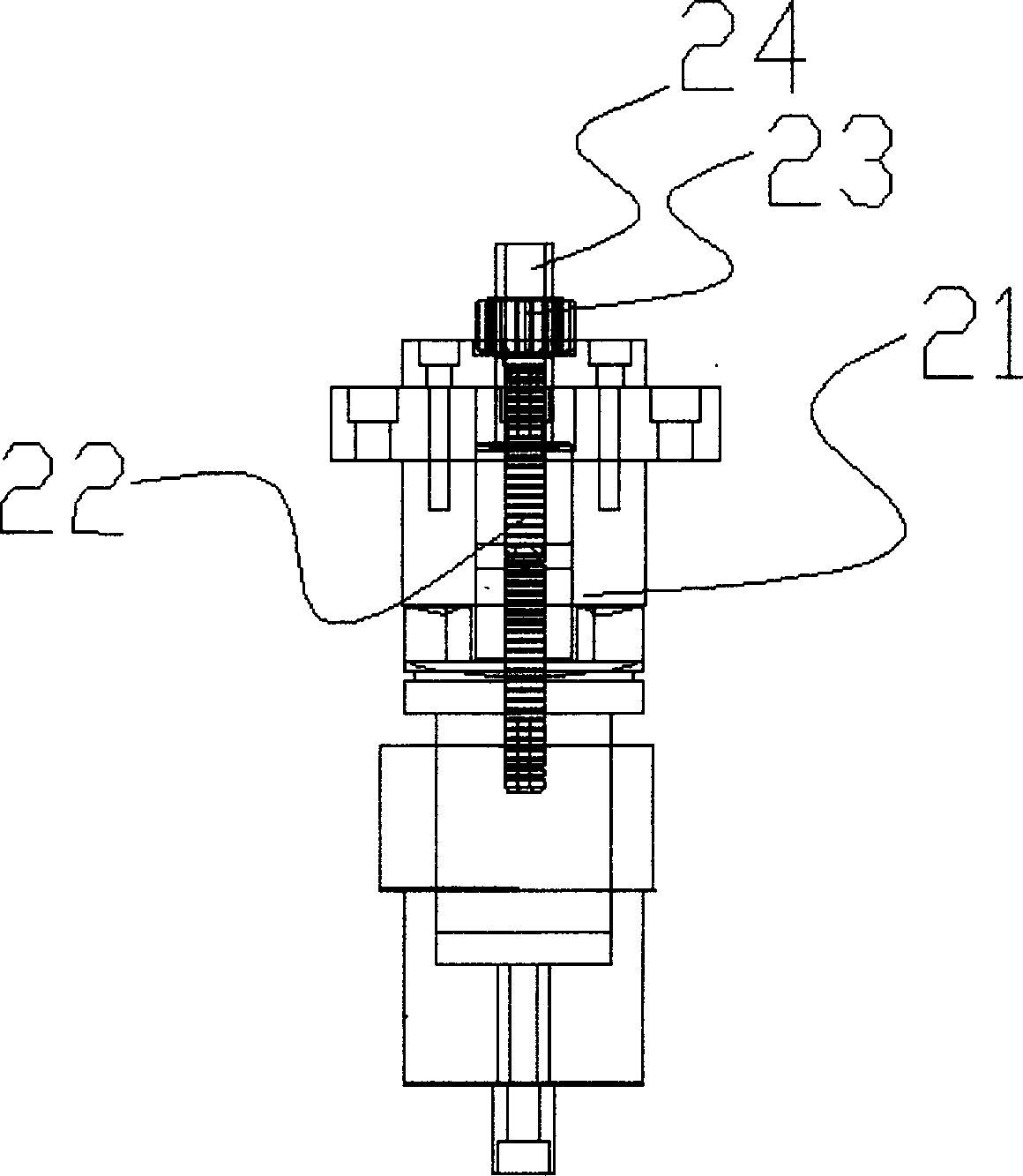

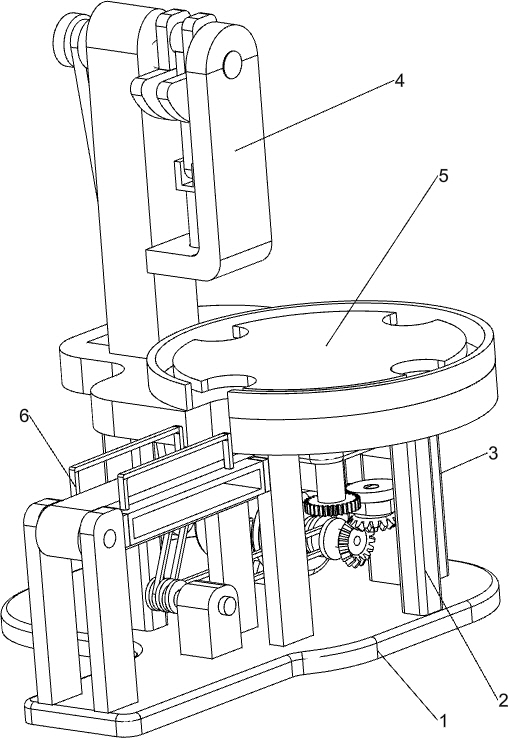

Intelligent pressing device and method of eccentric shaft and bearing

InactiveCN102114593ARealize automatic pressingAutomatically adjust orientationMetal working apparatusRotary stageContact force

The invention relates to an intelligent pressing device and method of an eccentric shaft and a bearing. A microprocessor chip is used as a control core. A pre-compiled eccentric shaft and bearing position identifying unit, a rotary table controlling unit and a pressing disk controlling unit are stored in the microprocessor chip. The microprocessor chip is used for acquiring a distance signal through a sensor and figuring out current positions of the eccentric shaft and the bearing; the microprocessor chip is used for controlling the rotation of a rotary table according to the deviation of the current positions and set positions of the eccentric shaft and the bearing, and automatically regulating positions of the eccentric shaft and the bearing; and then the microprocessor chip is used for automatically regulating a pressing force through detecting a contact force between a pressing disk and the eccentric shaft and automatically realizing the pressing of the eccentric shaft and the bearing. The intelligent pressing device can improve the automation of the eccentric shaft and the bearing during the pressing.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Automatic young fruit bagging machine

ActiveCN105918025AAvoid harmAvoid accidental breakagePlant protective coveringsDrive wheelElectric machinery

The invention discloses an automatic young fruit bagging machine. The automatic young fruit bagging machine comprises an upper press fit frame and a fork plate device, wherein the upper press fit frame comprises a pressing fork; one end of the pressing fork is hinged to a frame; a pressure plate is arranged at the other end of the pressing fork; the pressure plate is arranged above the fork plate device; a bag storing box is arranged below the frame; an automatic bag loading device is arranged in the bag storing box; an automatic bag feeding device is arranged at the upper end of the bag storing box; a handle is arranged above the frame; the handle is provided with a control switch; the fork plate device is provided with two fork plates stretching in a V shape; one end of the pressing fork is fixedly connected with a stay cord; the stay cord is connected to a driving wheel at the back end of the frame after crossing a driven wheel; the driving wheel is driven by a motor; the control switch is used for controlling the motor to rotate forwards or backwards. By adopting the automatic young fruit bagging machine, automatic press fit bagging can be realized, thereby increasing the bagging efficiency, and lowering the labor intensity; a V-shaped opening design is adopted at the front end of the fork plate device, so that the problem of fracture of fruit stems in a bagging process is effectively solved.

Owner:好果子农业科技(北京)有限公司

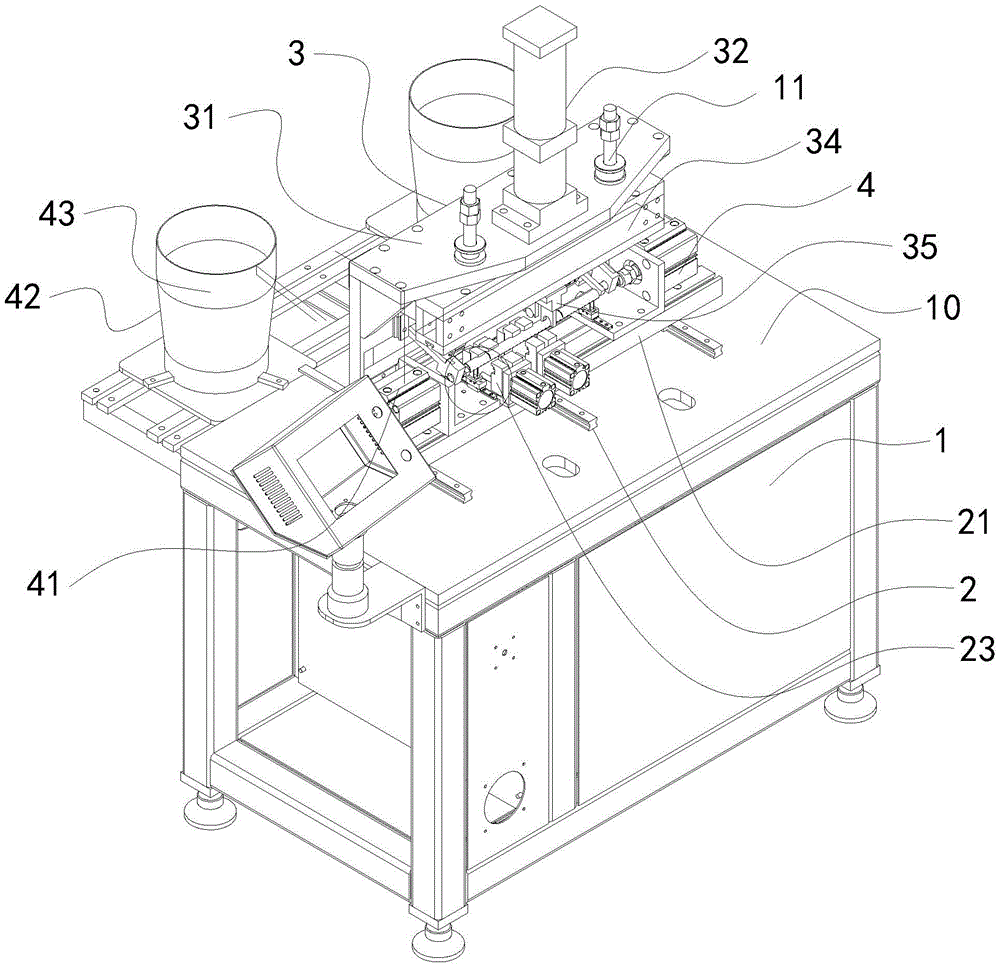

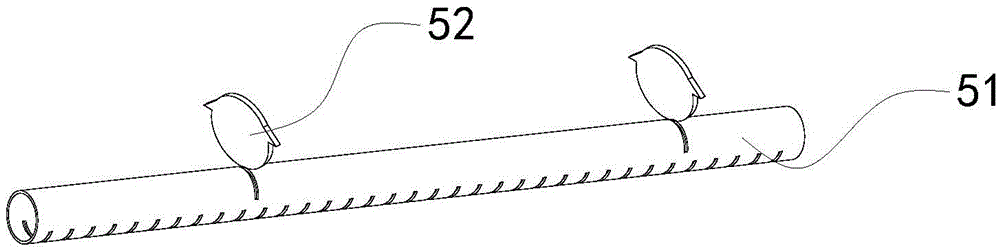

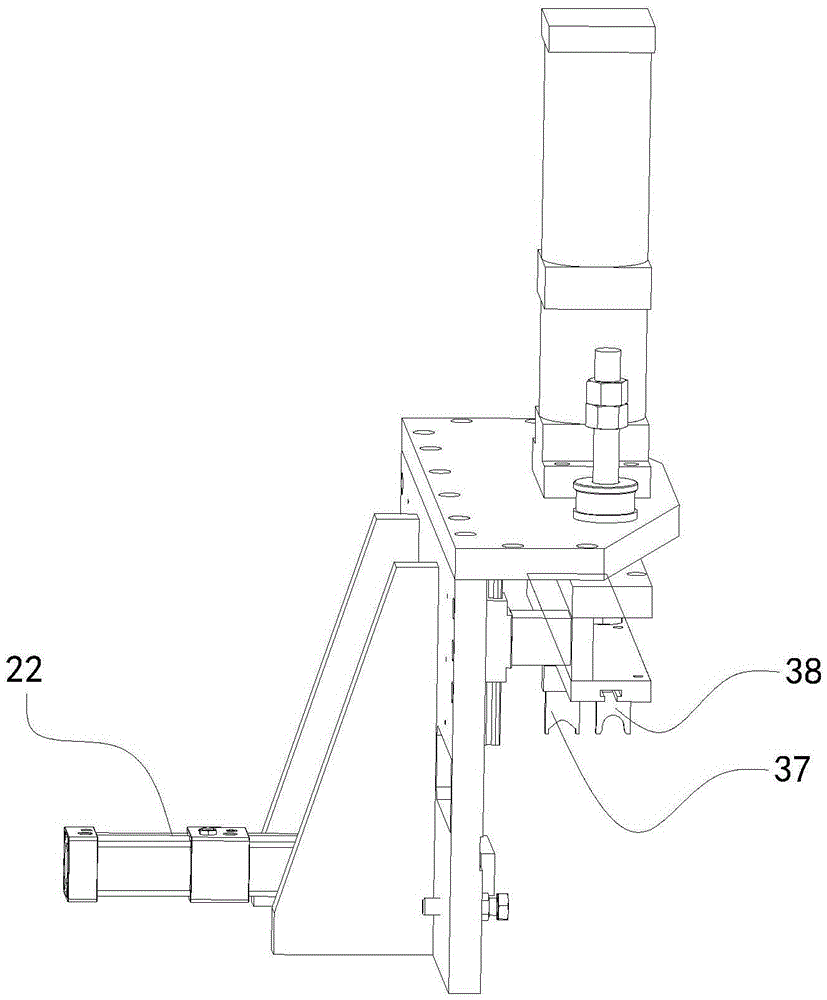

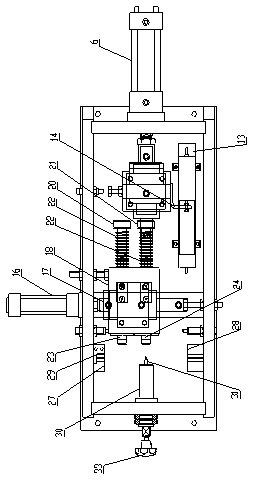

Liquid-collecting-tube assembling machine

ActiveCN105537932ARealize automatic pressingPlay a supporting roleAssembly machinesMetal working apparatusAssembly machineElectrical and Electronics engineering

The invention discloses a liquid-collecting-tube assembling machine. The liquid-collecting-tube assembling machine comprises a machine frame. A workbench is arranged on the machine frame, and a tube fame device for containing a to-be-processed tube and a pressing device for pressing the product are arranged on the workbench; the pressing device comprises an installing base, and a pressing mechanism and a pressing air cylinder for driving the pressing mechanism to press are arranged on the installing base; the pressing mechanism comprises a connecting plate connected with the pressing air cylinder and a pressing mold structure arranged on the connecting plate. Plug installing devices are arranged on the two sides of the tube fame device respectively; the tube frame device is used for containing the to-be-processed tube, partition slice grooves are formed in the tube, to-be-pressed partition slices are arranged in the partition slice grooves, and protrusions are arranged at the two ends of the partition slices; the pressing mold structure is used for pressing the partition slices till the partition slices are completely installed in the partition slice grooves, and then the protrusions at the two ends of the partition slices are pressed to be riveted with the tube. The plug installing devices are arranged on the two sides of the tube frame device respectively and used for installing plugs at one end or the two ends of the tube.

Owner:SUZHOU VEDETTE IND EQUIP CO LTD

Press-in device for internal and external pins of automobile shift shaft assembly

The invention discloses a press-in device for internal and external pins of an automobile shift shaft assembly. The press-in device comprises a main rack, wherein the main rack consists of a bottom plate, a left plate, a right plate, a front plate and a rear plate; the left plate, the right plate, the front plate and the rear plate are respectively fixed to the bottom plate and are fixedly connected to one another. The press-in device is characterized by further comprising a press-in actuator, a press-in mechanism switching device and positioning fixtures; the press-in actuator and the press-in mechanism switching device adopt a pneumohydraulic pressure cylinder and an air cylinder to complete the automatic press-in and switch processes. The press-in device is ingenious in structural design, high in degree of automation and convenient to operate, facilitates standard safety production, greatly improves the work efficiency of the equipment and reduces the labor cost.

Owner:ANHUI WEIJIA EQUIP & TECH

Piston press-fitting device

InactiveCN106514200AReduce labor intensityRealize automatic pressingAssembly machinesMetal working apparatusPistonPumping vacuum

The embodiment of the invention discloses a piston press-fitting device. The piston press-fitting device comprises a rack, a first clamp, a press-fitting mechanism, an air distributing mechanism, an air blowing and a vacuum pumping mechanism, wherein the first clamp is arranged on a worktable of the rack and is used for clamping a tool plate, and the tool plate is used for clamping a brake caliper; the press-fitting mechanism is arranged at the upper part of the worktable; the second clamp for clamping a pre-assembled piston is arranged on the press-fitting mechanism; the air blowing mechanism is used for blowing a dust cover of a piston through the air distributing mechanism; the vacuum pumping mechanism is used for pumping vacuum for the pre-assembled piston and the dust cover of the piston through the air distributing mechanism.

Owner:LIUZHOU WULING MOTORS +1

Press system and control method thereof

ActiveCN107486693ARealize automatic pressingIncrease productivityMetal working apparatusProduction lineEngineering

The embodiment of the invention relates to the technical field of press fit and discloses a press system and a control method thereof. The press system comprises a detection device, a servo press, a grabbing mechanism and a feeding and discharging mechanism; the feeding and discharging mechanism is used for breaking stacked charging trays and stacking empty charging trays; the detection device is used for detecting whether a second workpiece on a conveying belt is conveyed to the press fit station; the grabbing mechanism is used for grabbing the second workpiece conveyed to the press fit station to the servo press and grabbing a first workpiece from the broken charging trays to the servo press; the servo press is used for pressing the first workpiece and the second workpiece; and the grabbing mechanism is further used for grabbing the pressed first workpiece and second workpiece to the conveying belt of a production line. The embodiment of the invention further provides a control method of the press system. According to the press system and the control method thereof, automatic press fit is achieved on the press fit station on the production line, then the production efficiency of products is further improved, and labor cost is reduced.

Owner:DONGGUAN HUABEL ELECTRONICS TECH

Cardio-cerebral resuscitation rescue device for emergency clinic

InactiveCN111494196ARealize automatic pressingReduce labor intensityElectrotherapyHeart stimulationCardiocerebral resuscitationEngineering

The invention discloses a cardio-cerebral resuscitation rescue device for emergency clinic. The cardio-cerebral resuscitation rescue device comprises a cart body, a fixing frame, a moving mechanism, apressing mechanism, a containing frame and a controller. The fixing frame is installed on a right handrail at the top end of the cart body in the vertical direction. The moving mechanism is installedat the top end of the fixing frame in the left-right direction. The pressing mechanism is installed on the rear side of the top end of the moving mechanism in the vertical direction through a support. The placement frame is mounted at the rear end of the right side of the cart main body in the vertical direction, and the controller is arranged at the top end of the front side of the placement frame. According to the cardio-cerebral resuscitation rescue device for emergency clinic, automatic pressing of cardio-cerebral resuscitation on the chest of a patient can be achieved, manual pressing ofmedical staff is avoided, the labor intensity of the medical staff is reduced, pressing can be continuously conducted in the moving process of the patient, and practicability is high.

Owner:张万恒

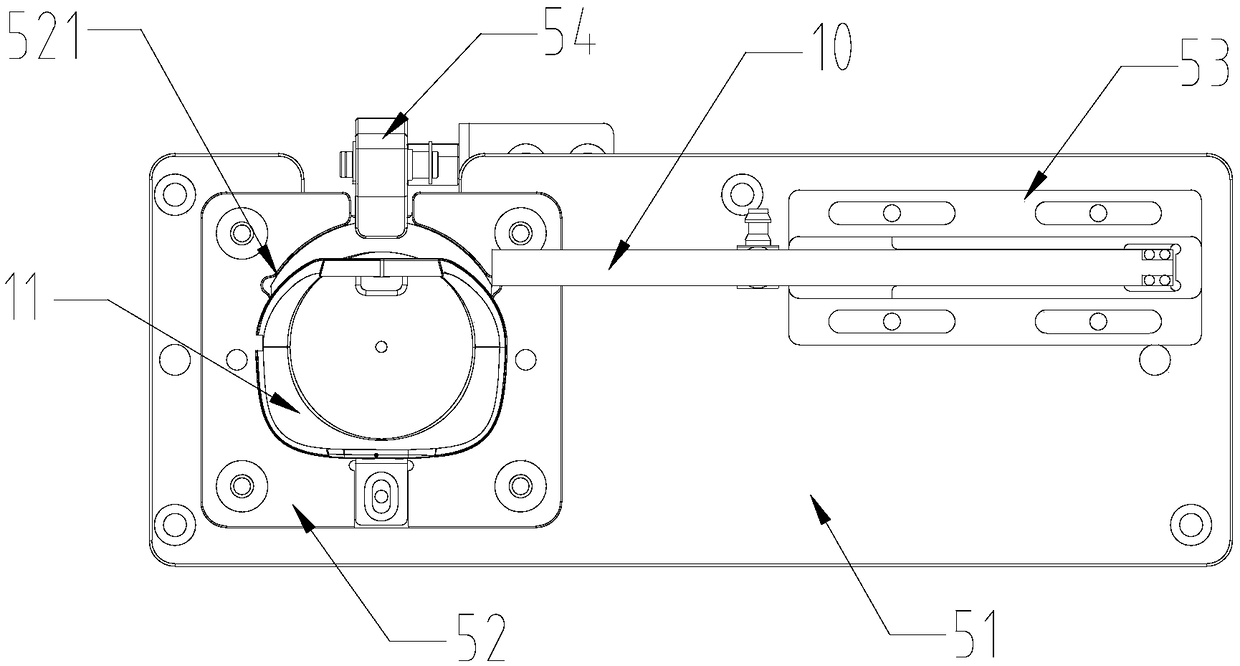

Lens press mounting device

PendingCN110370002ARealize automatic pressingUniform pressing forceMaterial gluingMetal working apparatusMechanical engineering

The invention discloses a lens press mounting device. The lens press mounting device comprises a machine frame, wherein a bearing frame is installed on the surface of the machine frame, a press mounting air cylinder is vertically installed on the surface of the bearing support, an output end of the press mounting air cylinder vertically stretches downward into the bearing support, a press mountinglifting plate is mounted at the output end of the press mounting air cylinder, a rear housing profiling press mounting plate is arranged on the bottom face of the press mounting lifting plate, a press mounting bearing jig and a drive assembly are arranged on the surface of the machine frame, the press mounting bearing jig and the drive assembly are distributed in a straight line mode, a drive endof the drive assembly is connected with the press mounting bearing jig, and used for driving the press mounting bearing jig to slide on the surface of the machine frame, an expansion board is arranged on the outer side of the machine frame, a pasting jig is arranged on the surface of the expansion board, and a heating slice placing groove is formed in the surface of the pasting jig, and used forassist in achieving pasting of a heating slice and a lens. The lens press mounting device has the advantages of being capable of achieving automatic press mounting of the lens, uniform in press mounting force, good in press fitting effect and high in efficiency.

Owner:SUZHOU INST OF INDAL TECH

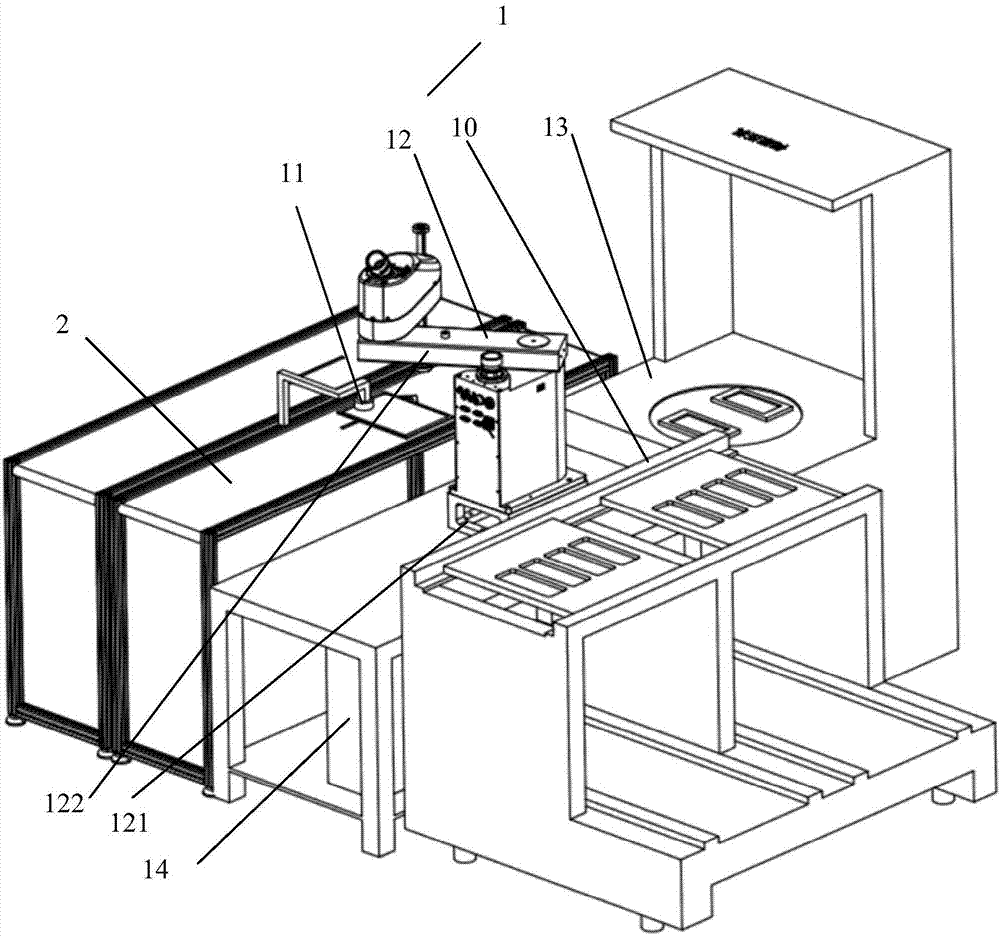

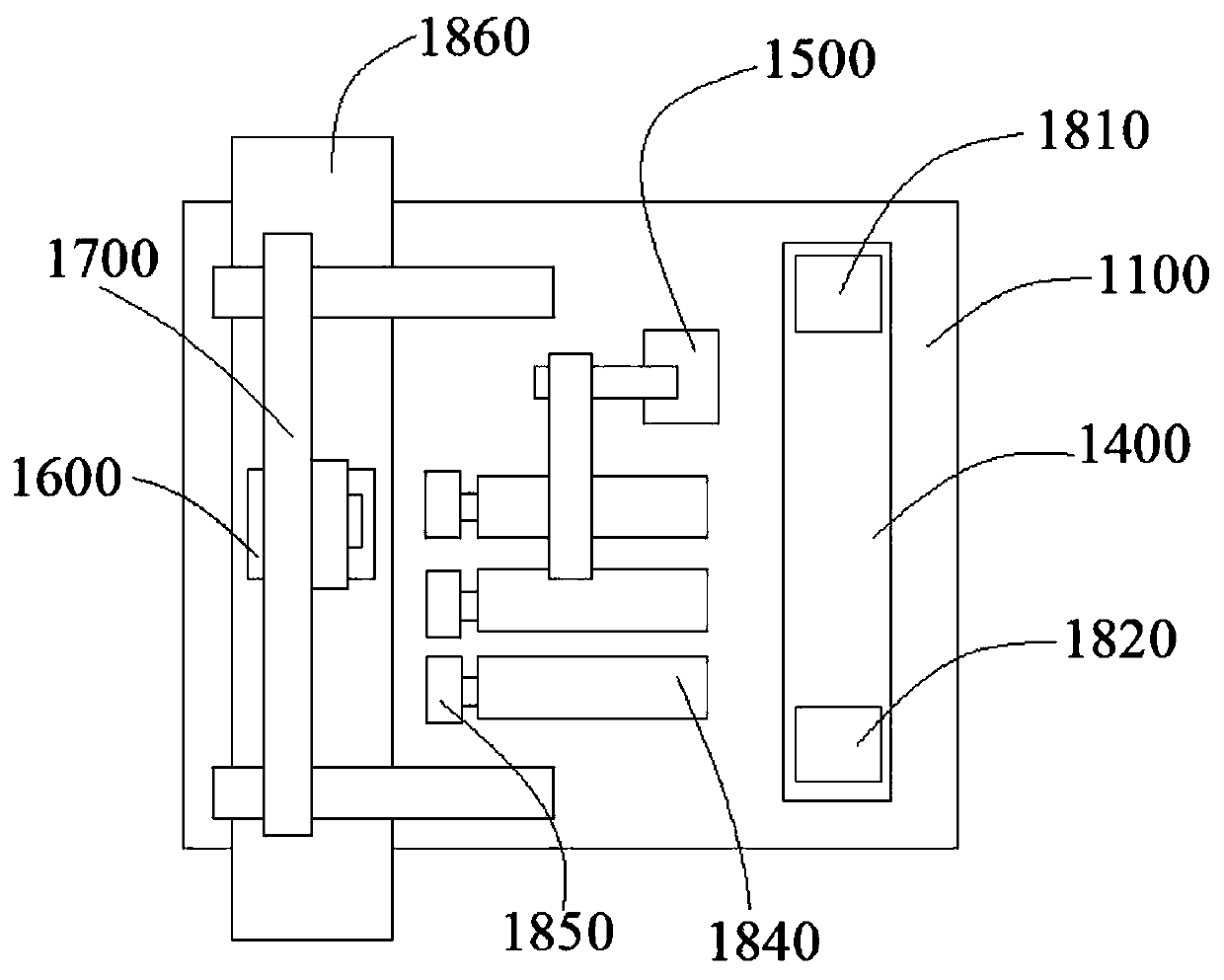

Automatic wire clamp pressing device and wire clamp pressing method

The invention discloses an automatic wire clamp pressing device and a wire clamp pressing method, and belongs to the technical field of automation. The automatic wire clamp pressing device comprises apressing device, wherein the pressing device comprises a plane moving mechanism, a pressing mechanism and a visual guide mechanism, and the pressing mechanism and the visual guide mechanism are arranged on the plane moving mechanism. An upper wire clamp obtaining mechanism is arranged at the lower end of the pressing mechanism and the pressing mechanism can press the obtained upper wire clamp ona lower wire clamp. The visual guide mechanism can photograph the upper wire clamp; the plane moving mechanism drives the pressing mechanism to move to a pressing station according to a photographingresult. The wire clamp pressing method comprises the following steps of S1, acquiring the upper wire clamp through the pressing device, and acquiring guide information of an upper wire clamp 1871 through photographing; and S2, guiding the pressing device to move to a corresponding position according to the guide information to complete wire clamp pressing. The wire clamp automatically-pressing device has the advantages that automation degree of the wire clamp pressing and quality of the wire clamp pressing are improved.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

White asparagus tail cut-away device

InactiveCN111673813AEasy to cutRealize automatic pressingMetal working apparatusEngineeringAsparagus

The invention relates to a cut-away device, in particular to a white asparagus tail cut-away device. The technical aim to be achieved is to provide a white asparagus tail cut-away device which is capable of automatically pressing white asparagus and cutting white asparagus and needs no manual synchronous operation of two hands. According to the technical scheme, the white asparagus tail cut-away device comprises a bottom plate and a lifting mechanism; first mounting plates are mounted on the left side and the right side of the bottom plate, and a fixed plate is arranged between the upper portions of the first mounting plates of the two sides; and the lifting mechanism is arranged on the first mounting plates of the two sides, a containing mechanism is mounted between the first mounting plates of the two sides and is connected with the lifting mechanism, and a cutting mechanism is arranged between the top of the fixed plate and the first mounting plates of the two sides. According to the white asparagus tail cut-away device, through the lifting mechanism, white asparagus can automatically move upwards, and tails of white asparagus can be cut conveniently; and through the containingmechanism, white asparagus can be automatically pressed, white asparagus does not need to be pressed manually, and manual operation is reduced.

Owner:何梦云

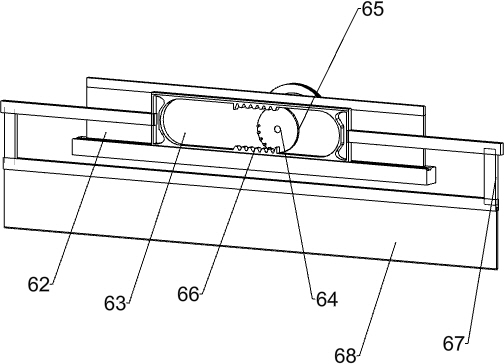

Full-automatic breathing bag pressing device

The invention relates to the field of medical facilities, in particular to a full-automatic breathing bag pressing device. The device comprises a driving part, a base plate and boxes fixed to the twoends of the base plate. Two extrusion plates for extruding a breathing bag are arranged between the two boxes. A connecting rod is fixedly arranged on the extrusion plates. The end, away from the extrusion plates, of the connecting rod penetrates into the boxes and is connected with a movable plate, a stretchable reset rod is connected between the movable plate and the inner walls of the boxes, cams for pushing the movable plate are fixed to the interiors of the boxes, and the cams are driven by the driving part; the device has the advantages that by arranging a cam mechanism, the bag is automatically pressed, and labor amount of nurses is lowered; the relative positions of the cams and the movable plate are adjustable, the single-pressing oxygen output amount is adjustable, and the patient can conveniently use the device; due to the fact that the driving mechanism is low in price and simple in structure, the cost of the device is greatly lowered, and a large number of the devices canbe configured in a hospital conveniently or patients can purchase and use the device conveniently.

Owner:SHAOXING PEOPLES HOSPITAL

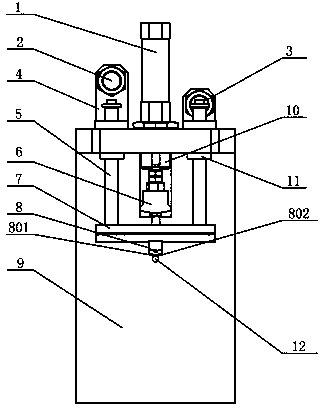

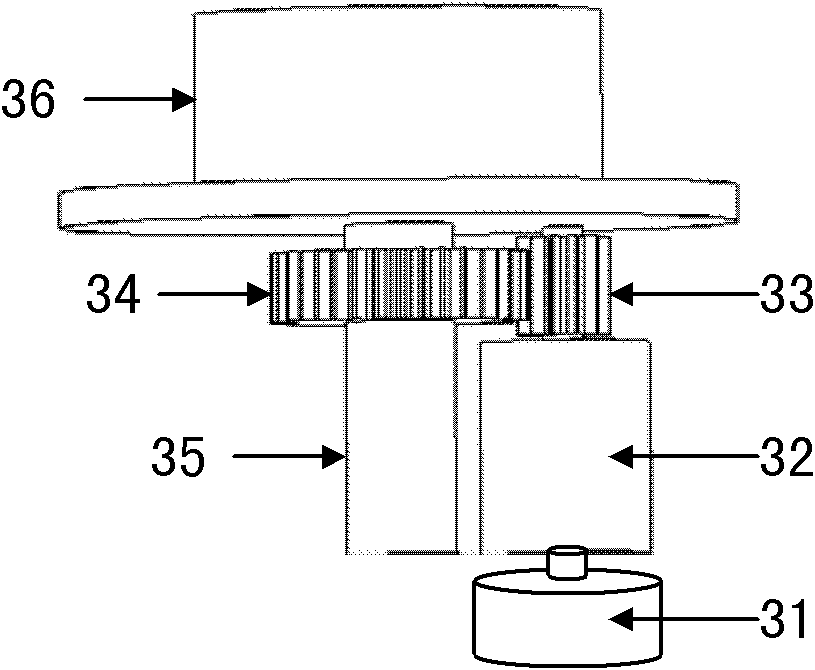

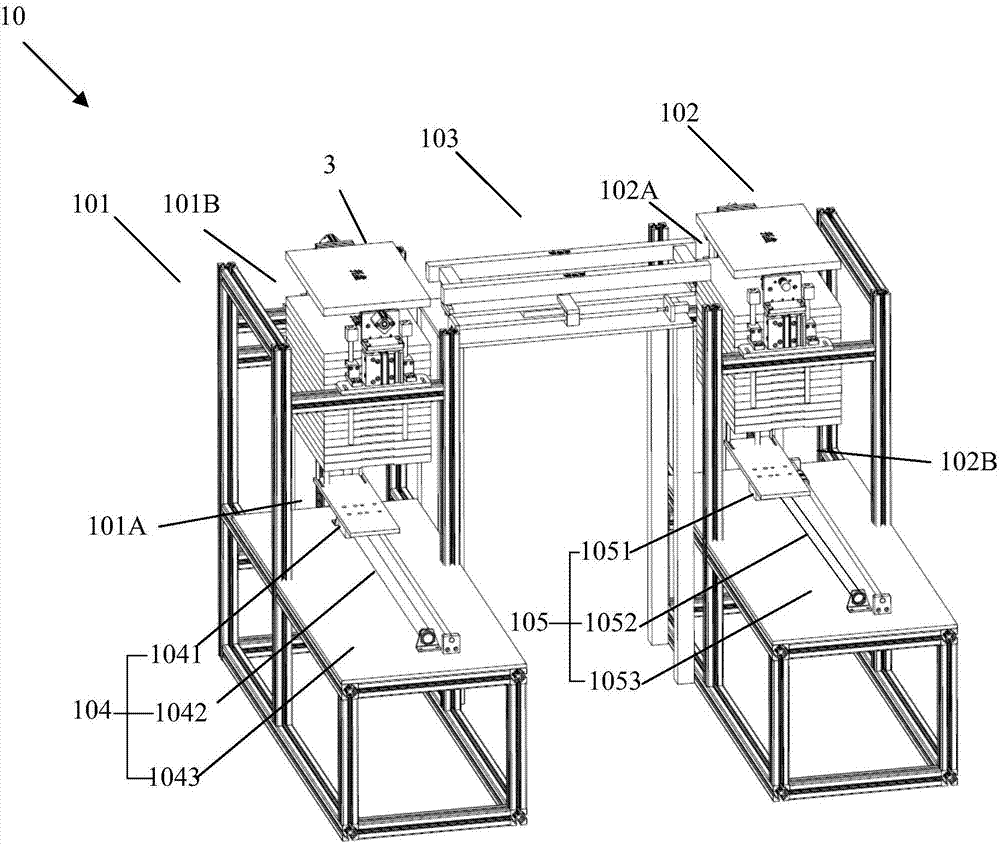

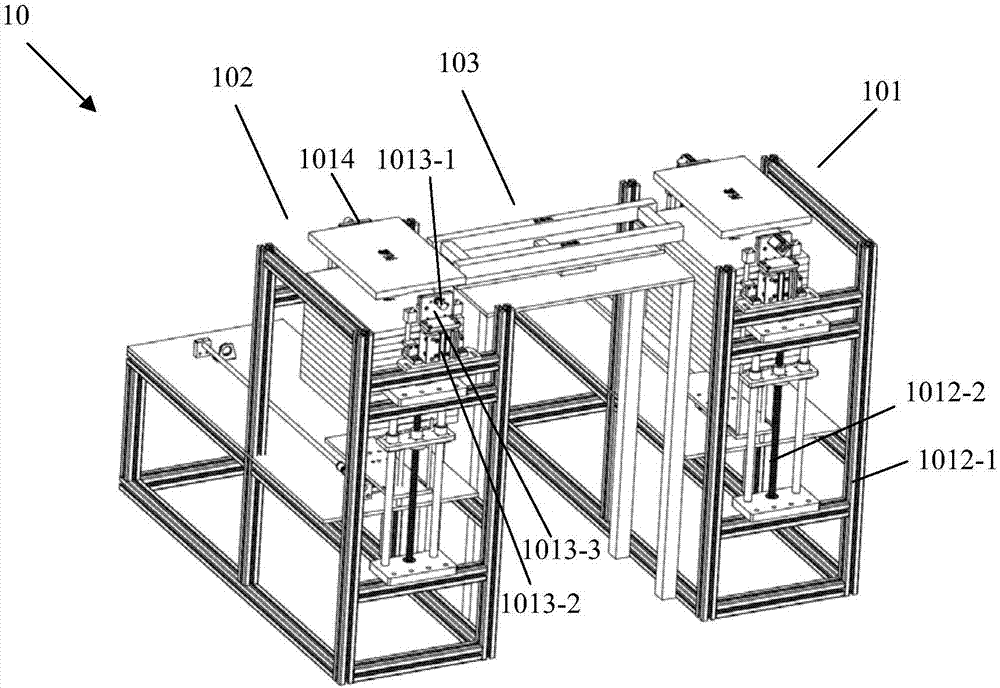

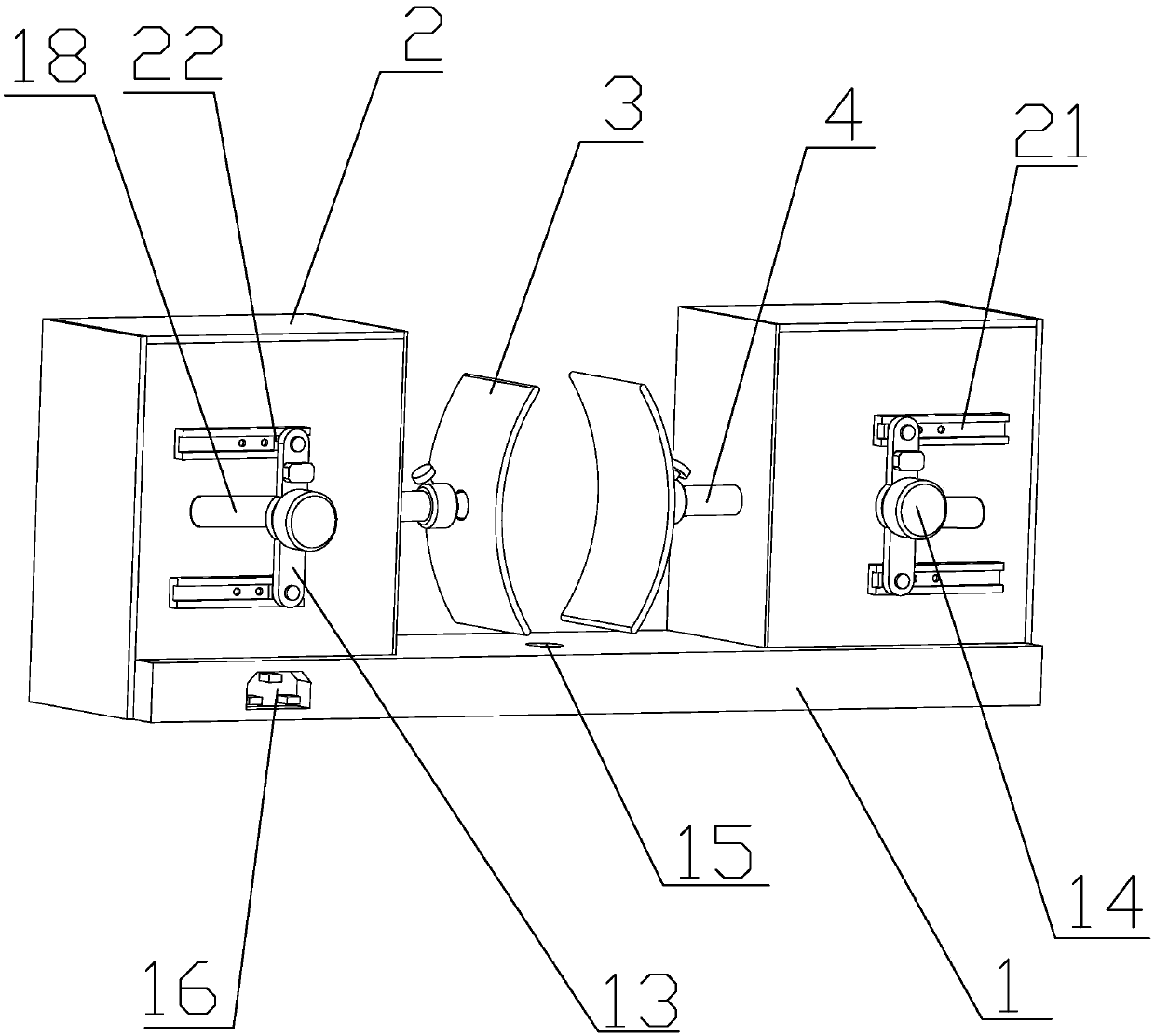

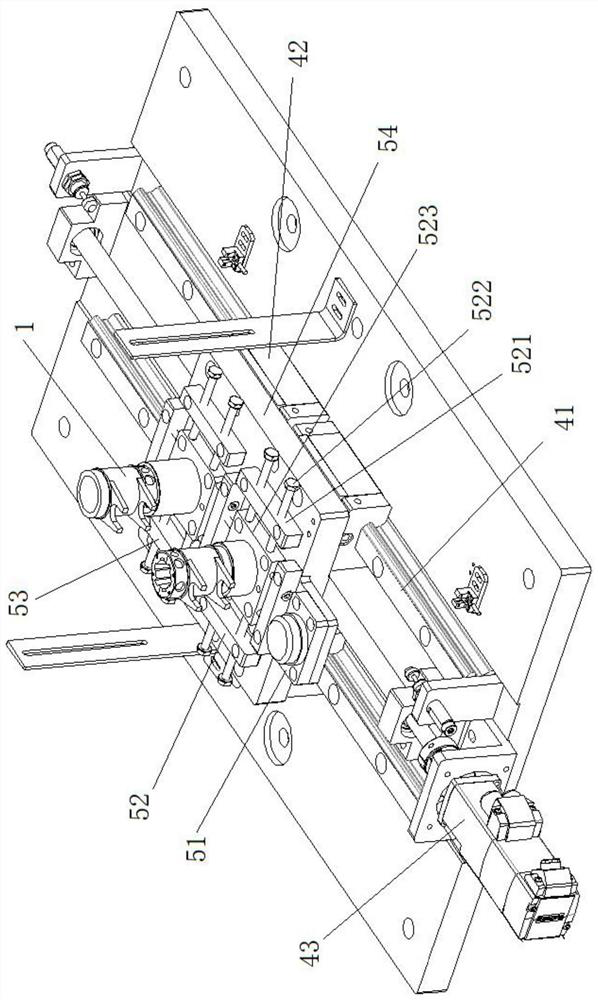

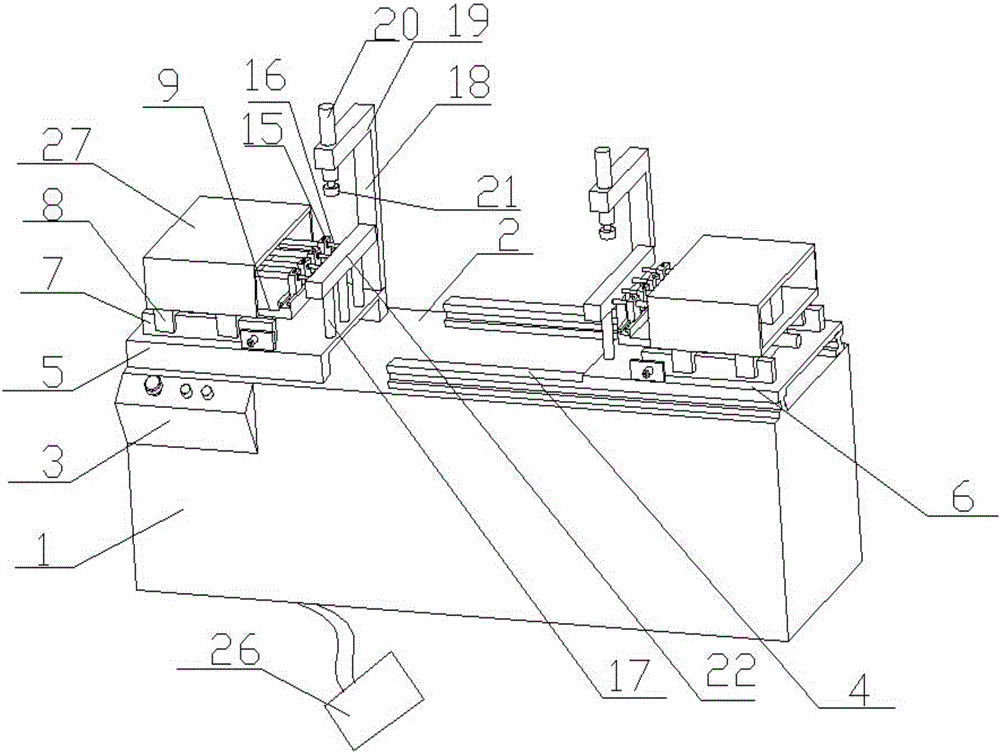

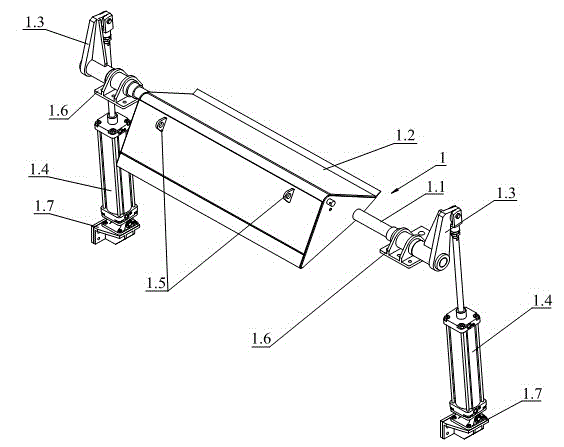

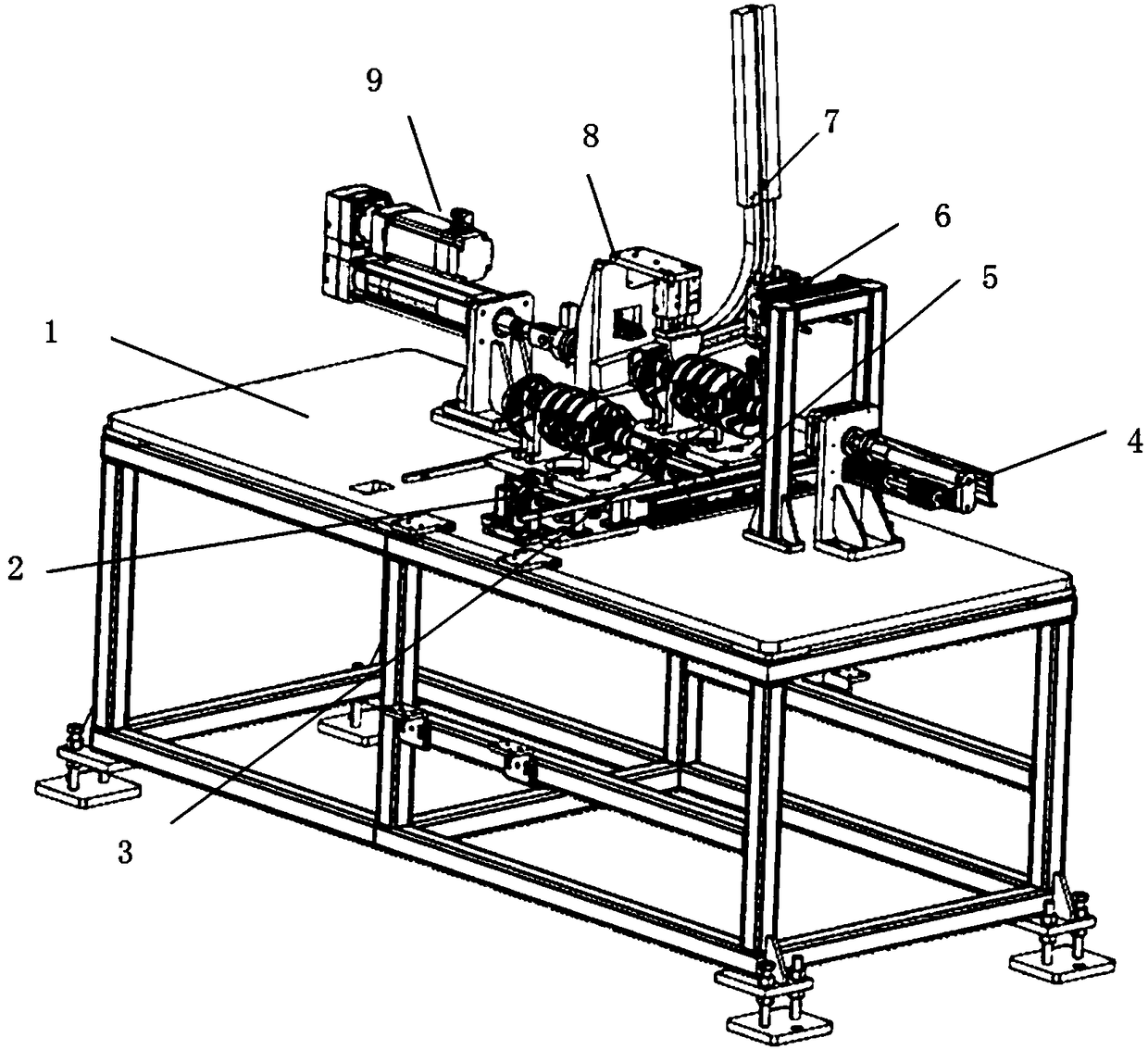

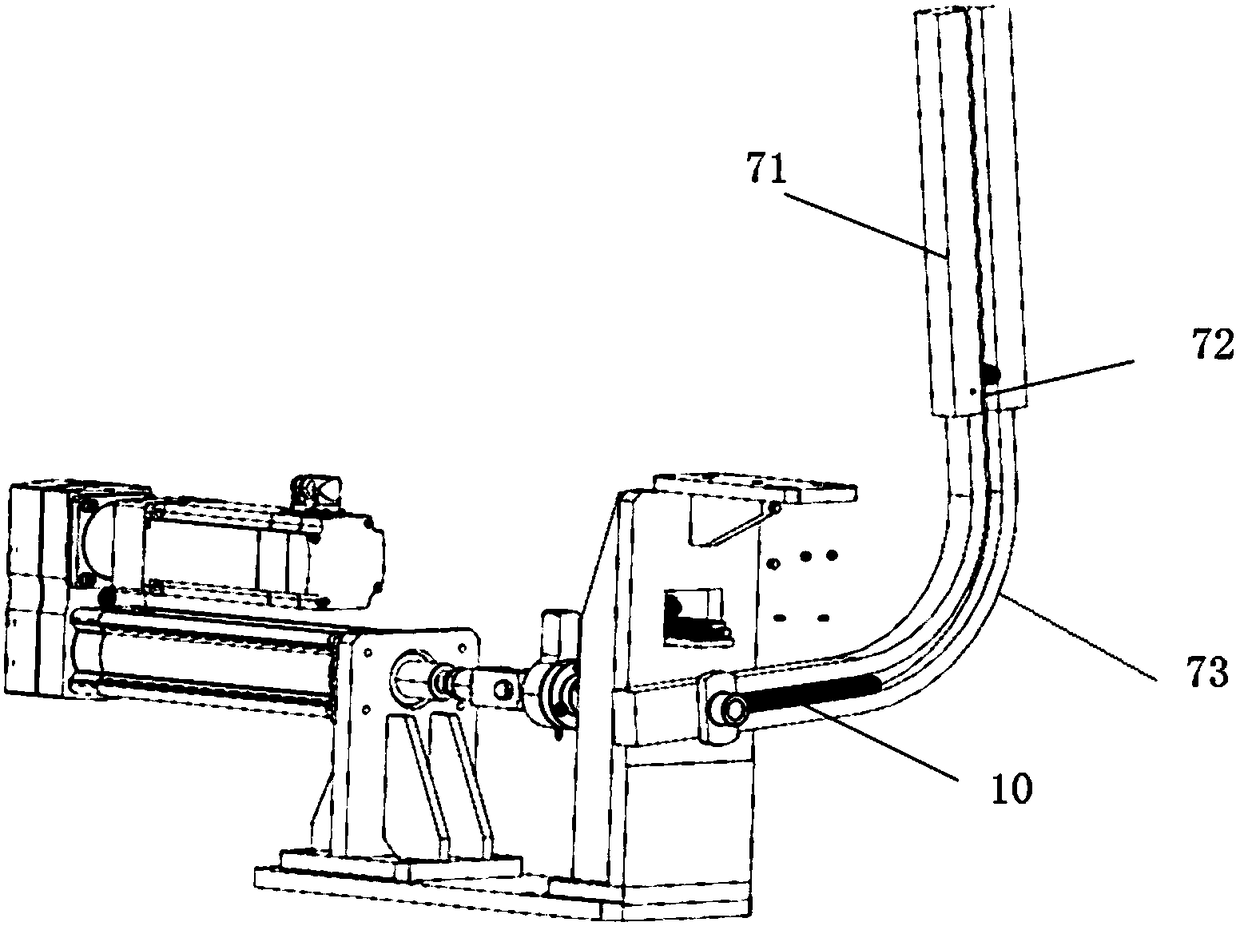

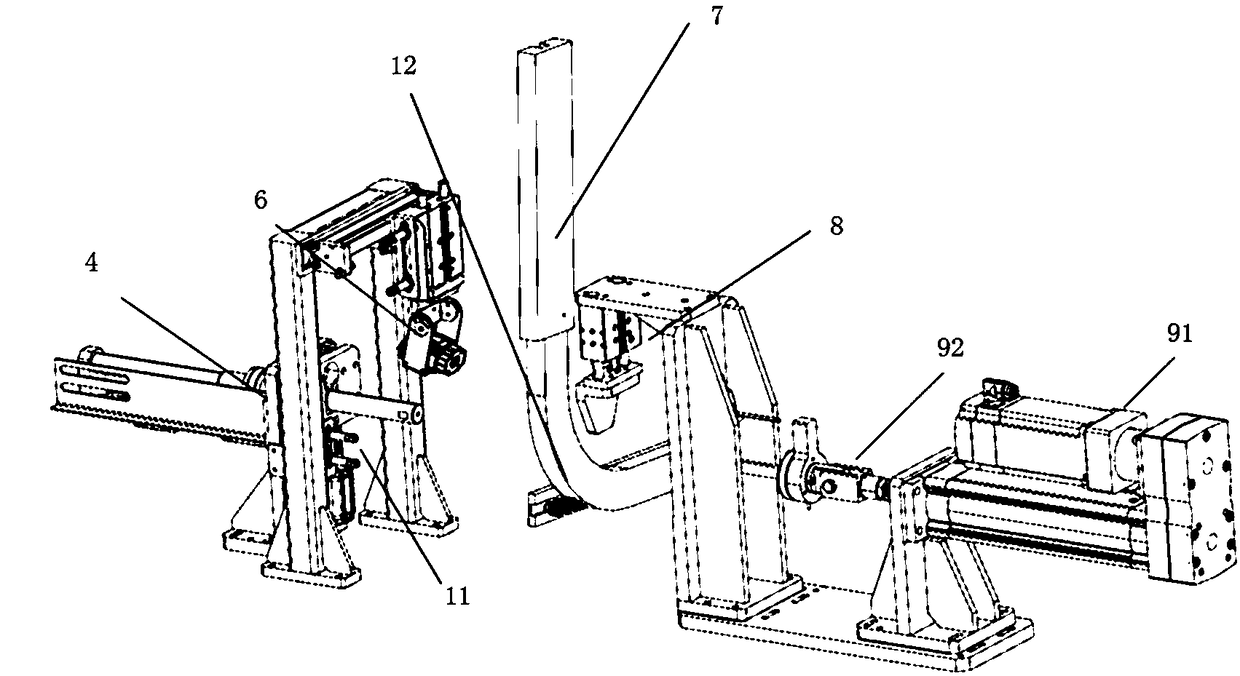

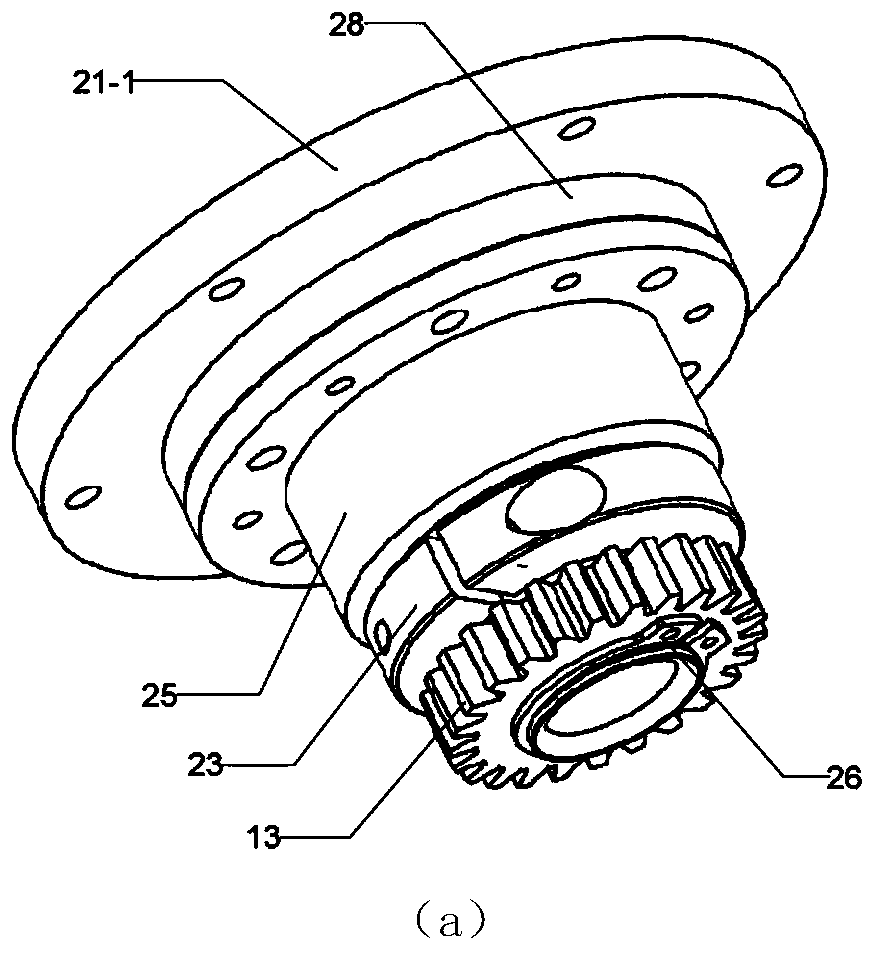

Double-fork shaft sleeve bearing automatic press-fitting system and assembling method

ActiveCN113369864ARealize uniform speed and smooth pressingGuaranteed one-time press fit in placeMetal working apparatusClassical mechanicsStructural engineering

The invention relates to a double-fork shaft sleeve bearing automatic press-fitting system and an assembling method, and belongs to the technical field of automatic assembling. The problems that a bearing is prone to being damaged and the mounting precision is poor during press-fitting of the double-fork shaft sleeve bearing in the prior art are solved. The double-fork shaft sleeve bearing automatic press-fitting system comprises a sliding rail mechanism used for driving a sliding block clamp to move, the sliding block clamp used for positioning the bearing and a double-fork shaft sleeve, a press-fitting mechanism used for press-fitting the bearing on the double-fork shaft sleeve, and an overturning mechanism used for overturning the double-fork shaft sleeve with one end provided with the bearing in a press-fitting mode. After the bearing is pressed at one end of the double-fork shaft sleeve, the double-fork shaft sleeve is overturned through the overturning mechanism, and then the bearing is pressed at the other end of the double-fork shaft sleeve through the press-fitting mechanism. Automatic press fitting of bearings on the two sides of the double-fork shaft sleeve is achieved.

Owner:BEIJING MECHANICAL EQUIP INST

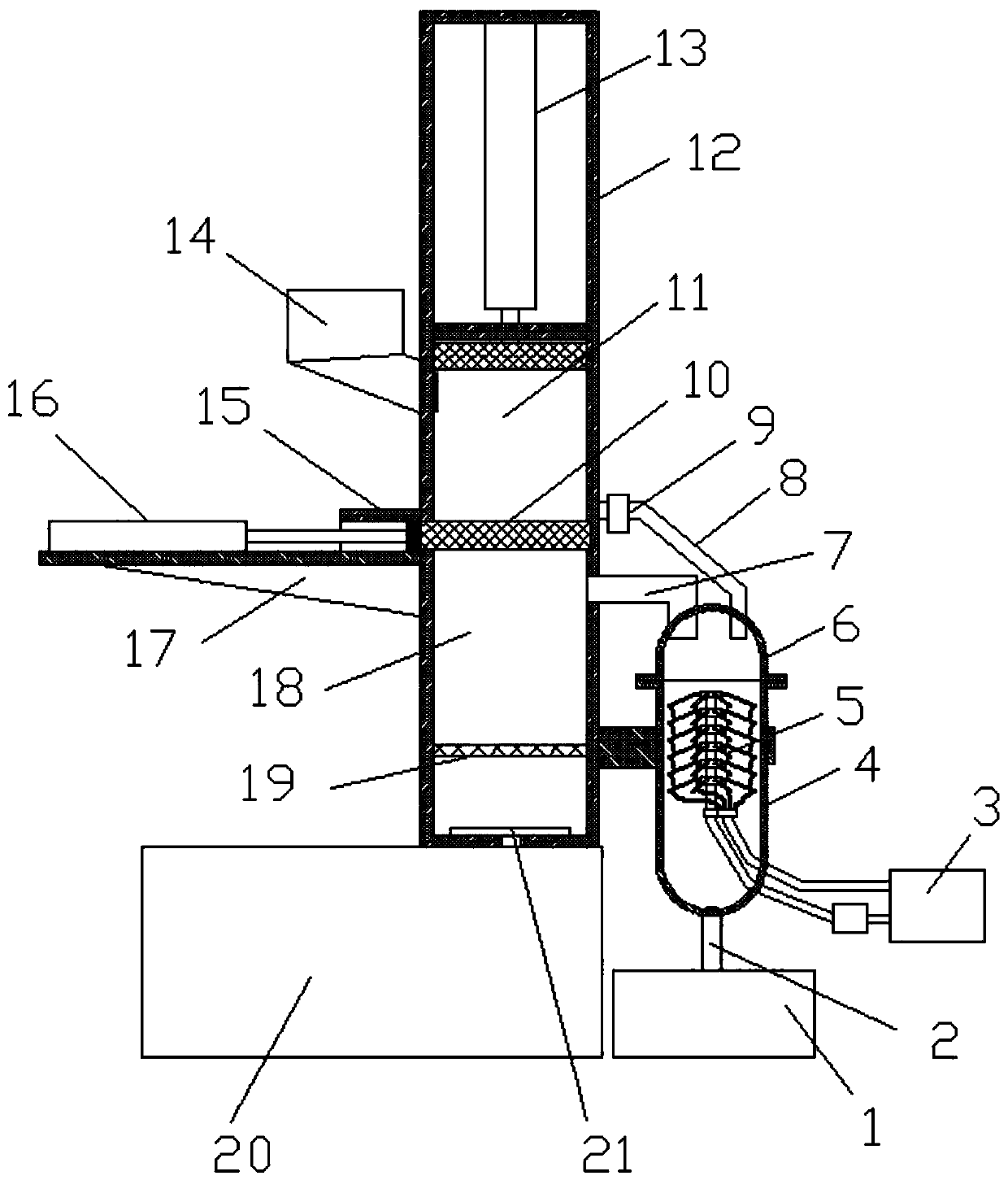

Production system and method for increasing yield of waxberry juice

The invention discloses a production system and method for increasing yield of waxberry juice. The production system comprises a vapor generator, a squeezing and distilling machine body, a juice extraction device, a cooling liquid box and a waxberry juice collecting barrel. The method comprises the steps of selecting waxberries, performing soaking, performing cleaning, performing squeezing, performing distillation and performing condensing. The invention aims to provide the production system and the method for increasing yield of waxberry juice. After the waxberries are subjected to ordinary squeezing, distillation and condensing are performed, so that the yield of the waxberry juice is increased, and waste of nutrient substances in the waxberries is avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Full-automatic aluminum alloy casement window hinge drilling machine

InactiveCN105081389AReduce labor intensityRealize automatic pressingWork clamping meansFeeding apparatusFixed frameDrilling machines

The invention discloses a full-automatic aluminum alloy casement window hinge drilling machine, and relates to the field of drilling machines. The full-automatic aluminum alloy casement window hinge drilling machine comprises a machine frame and a workbench. A left drilling device is arranged at one end of the workbench, and a right drilling device is arranged at the other end of the workbench. A long sliding rail is arranged at one end of the workbench. The left drilling device and the right drilling device comprise a left fixing plate and a right fixing plate respectively. The left fixing plate and the right fixing plate are each provided with a fixing sliding rail. A sliding block is arranged on each fixing sliding rail. A supporting plate is arranged on each sliding block. The left fixing plate and the right fixing plate are each provided with a main motor, a lead screw and a lead screw nut. The lower end of each supporting plate is connected with the corresponding lead screw nut. The left fixing plate and the right fixing plate are each provided with a compressing device. A drilling motor is arranged on each supporting plate. A porous device is arranged on a spindle of each drilling motor. A plurality of universal shafts are arranged on each porous device. A drill bit is arranged on each universal shaft. The left fixing plate and the right fixing plate are each provided with a fixing frame. Due to the design, the structure is simple and reasonable, operation is convenient and rapid, the production cost is lowered, and the working efficiency is improved.

Owner:FOSHAN DEBOKE CNC MACHINERY MFG CO LTD

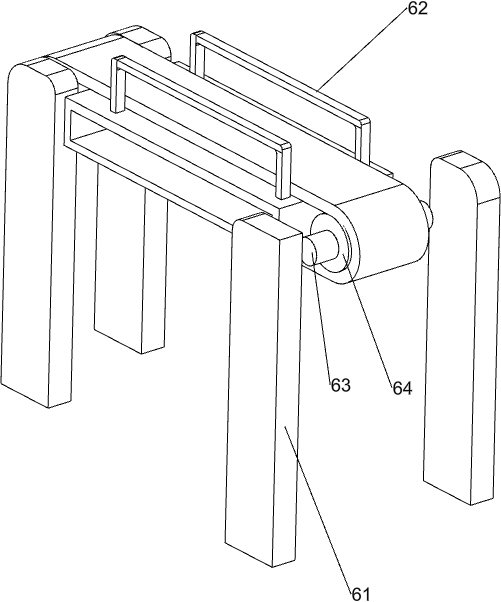

Open mill material pressing mechanism and open mill

InactiveCN104999584ARealize automatic pressingIncrease productivityEngineeringMechanical engineering

The present invention provides an open mill material pressing mechanism and an open mill. With the open mill material pressing mechanism and the open mill, the problem that the bulk and stack-like crushed plastic material with the irregular size and the irregular shape exists in the plastic material and difficultly enters the roller seam between the two roller cylinders can be solved. The open mill material pressing mechanism comprises a rotation shaft and a material pressing weight block for pressing a material into the roller seam between two roller cylinders, wherein at least one end of the rotation shaft is provided with a direction change connection member and a fixedly arranged drive member, the material pressing weight block and the rotation shaft are fixed into the integration, one end of the direction change connection member is fixedly connected with the rotation shaft, and the other end is hinged on the output shaft of the drive member. With the open mill material pressing mechanism and the open mill of the present invention, the automatic material pressing can be achieved, the production efficiency is substantially improved, the security risk is reduced, and the normal production is ensured.

Owner:QINGDAO MESNAC ELECTROMECHANICAL ENG +1

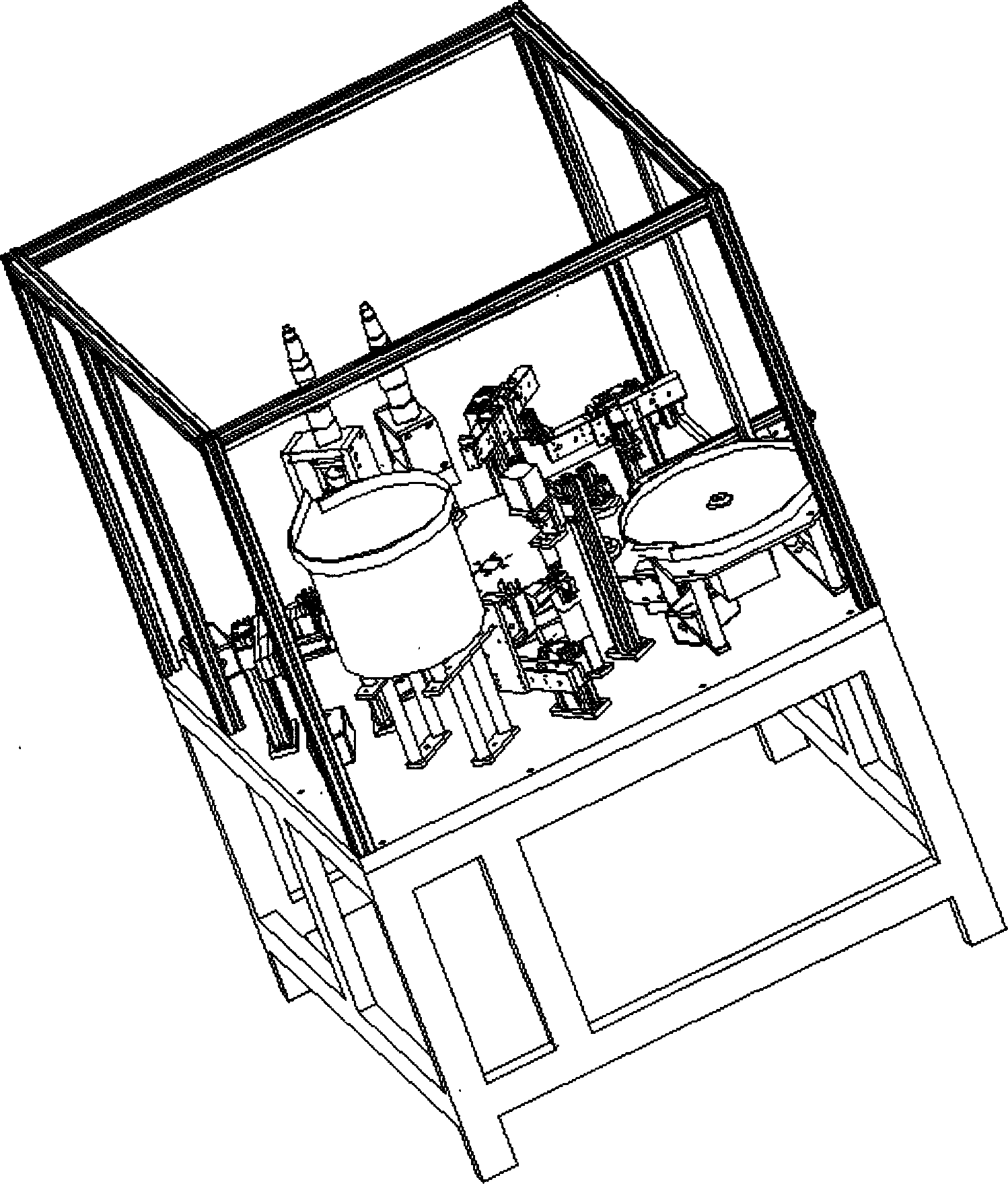

Full-automatic pressing equipment

InactiveCN104227375ARealize automatic pressingRealize the pressing processMetal working apparatusAutomatic test equipmentBiochemical engineering

The invention relates to full-automatic pressing equipment. The full-automatic pressing equipment comprises a turntable, wherein eight bases are arranged on the turntable at equal intervals, and are respectively corresponding to mold 1 feeding equipment, mold 2 feeding equipment, a pressing detecting module, a shaping detecting module, a unqualified product discharge manipulator, a qualified product discharge manipulator, a reset device and a cleaning device. The full-automatic pressing equipment realizes a full-automatic pressing process, is simple in operation, only needs a worker to feed once every one hour, and realizes the production safety; one person can manage four pieces of the equipment, and can produce 40,000 qualified products every day; and the equipment can automatically distinguish qualified products from non-qualified products, so that the labor intensity is largely reduced, the production efficiency is improved, and the equipment is worthy of large-scale promotion.

Owner:NINGBO ZHENHAI XIUCHANG ELECTROMECHANICAL

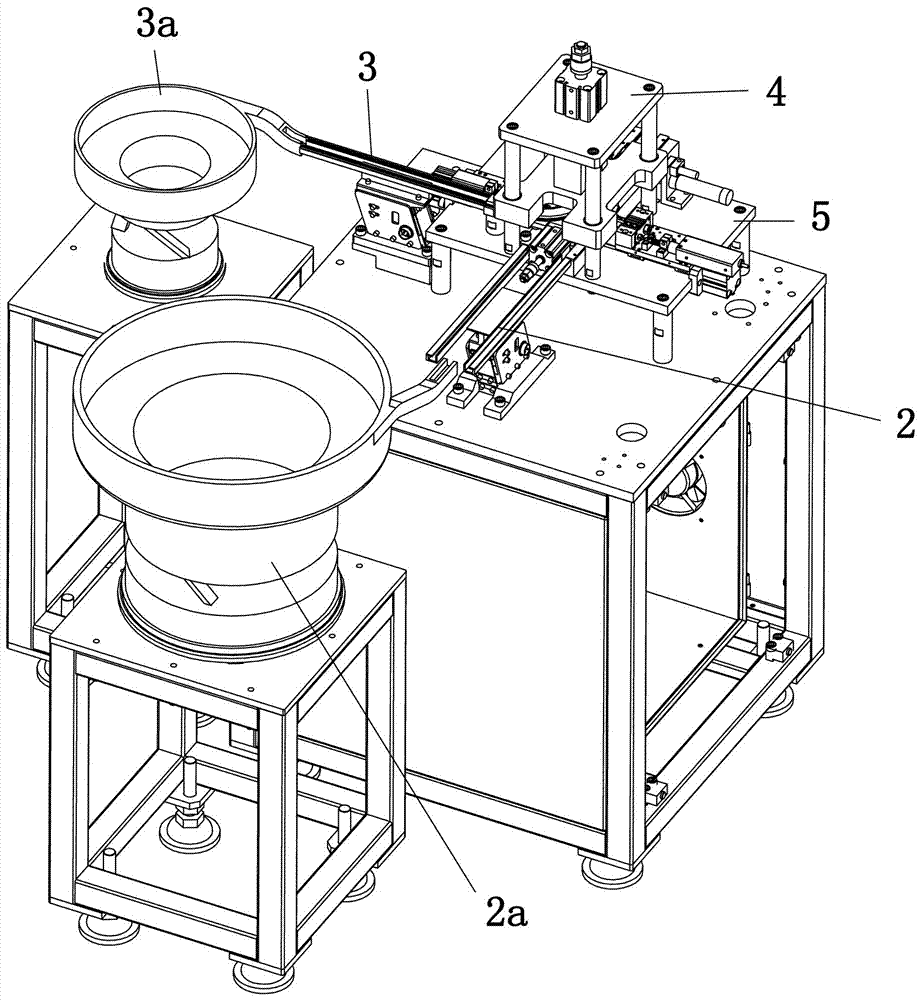

Aluminum alloy support assembling device

PendingCN107932038ARealize automatic pressingHigh precisionMetal working apparatusStructural engineeringBar pressing

The invention discloses an aluminum alloy support assembling device. The device comprises a bottom plate, wherein a positioning unit used for supporting the aluminum alloy support is arranged on the bottom plate, the two sides of the positioning unit are each provided with a guide block, a feeding groove connected with a vibration disc and a discharging groove vertically communicating with the feeding groove are formed in each guide block, outlets of the discharging grooves are formed in the side walls, close to the positioning unit, of the guide blocks, vertical sliding grooves are formed inthe positions, on the two sides of the outlet of the discharging groove, of each guide block, and a movable baffle driven by a baffle lifting air cylinder is arranged in each vertical sliding groove,a pressing rod with the front end facing the outlet is arranged in each discharging groove, the rear end of each pressing rod extends out of the corresponding guide block and is connected with a telescopic air cylinder, and a lifting air cylinder connected with a jacking column is arranged at the position, close to the positioning unit, of the bottom plate. Compared with the prior art, bearings capable of being input into the discharging grooves of the guide blocks through vibration discs are pressed in an aluminum alloy support through the pressing rods driven by the telescopic air cylinders,automatic press-fitting of the bearings is achieved, and the bearing assembling precision and efficiency are improved.

Owner:LIUZHOU JINYUAN MACHINERY MFG

Press-fitting method of bearing press-fitting device

InactiveCN108673100AHeight adjustableRealize automatic pressingMetal working apparatusDrive shaftEngineering

Owner:安徽安元智能科技有限公司

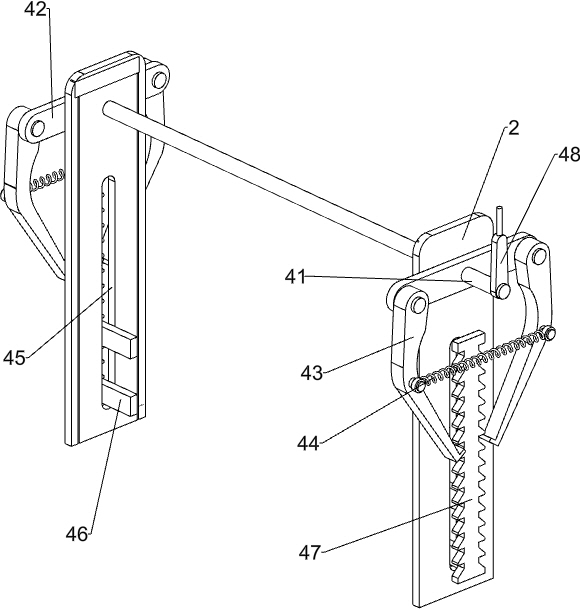

Friction welding fixture

ActiveCN109623131ARealize automatic pressingAchieve looseningNon-electric welding apparatusFriction weldingMechanical engineering

The invention discloses a friction welding fixture, which includes a base and two compressing mechanism arranged symmetrically on both sides of the upper part of the base. The compressing mechanism includes a vertical column, a top compressing assembly for compressing the top of a workpiece and a side face compressing assembly for compressing the side face of the workpiece; the vertical column isinstalled on the upper part of the base, and the top compressing assembly includes a motor, a guide rail, a screw rod, a sliding block, a first lifting part, a top fixing plate, a top moving block, atop flexible pressing plate, a second lifting part and a first spring; the motor is installed in the vertical column, the guide rail is installed horizontally on the upper part of the inner side faceof the vertical column, the screw rod is rotatably connected with the motor, the sliding block is slidably installed on the guide rail, the bottom of the sliding block is connected with a nut, the nutexternally sleeve the screw rod, and the bottom of the inner end of the sliding block is connected with the upper part of the first lifting part; and the lower part of the first lifting part is connected with the top fixing plate, and the sliding block is connected with the top fixing plate through the second lifting part. According to the friction welding fixture, to-be-welded workpieces are conveniently fixed, and the friction welding fixture can be applied to mass production and friction welding of thin plate type workpieces.

Owner:湖南坤鼎数控科技有限公司

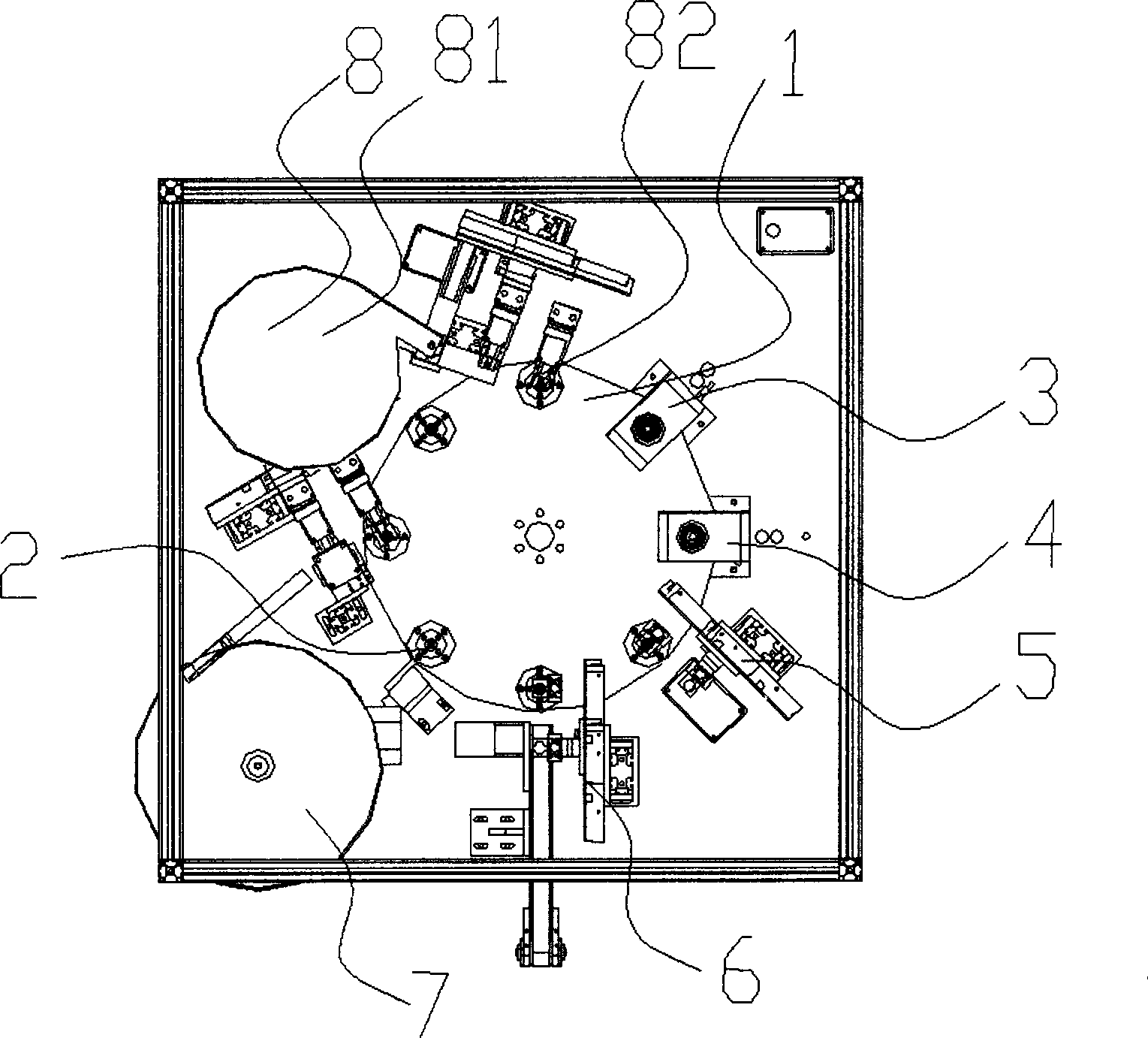

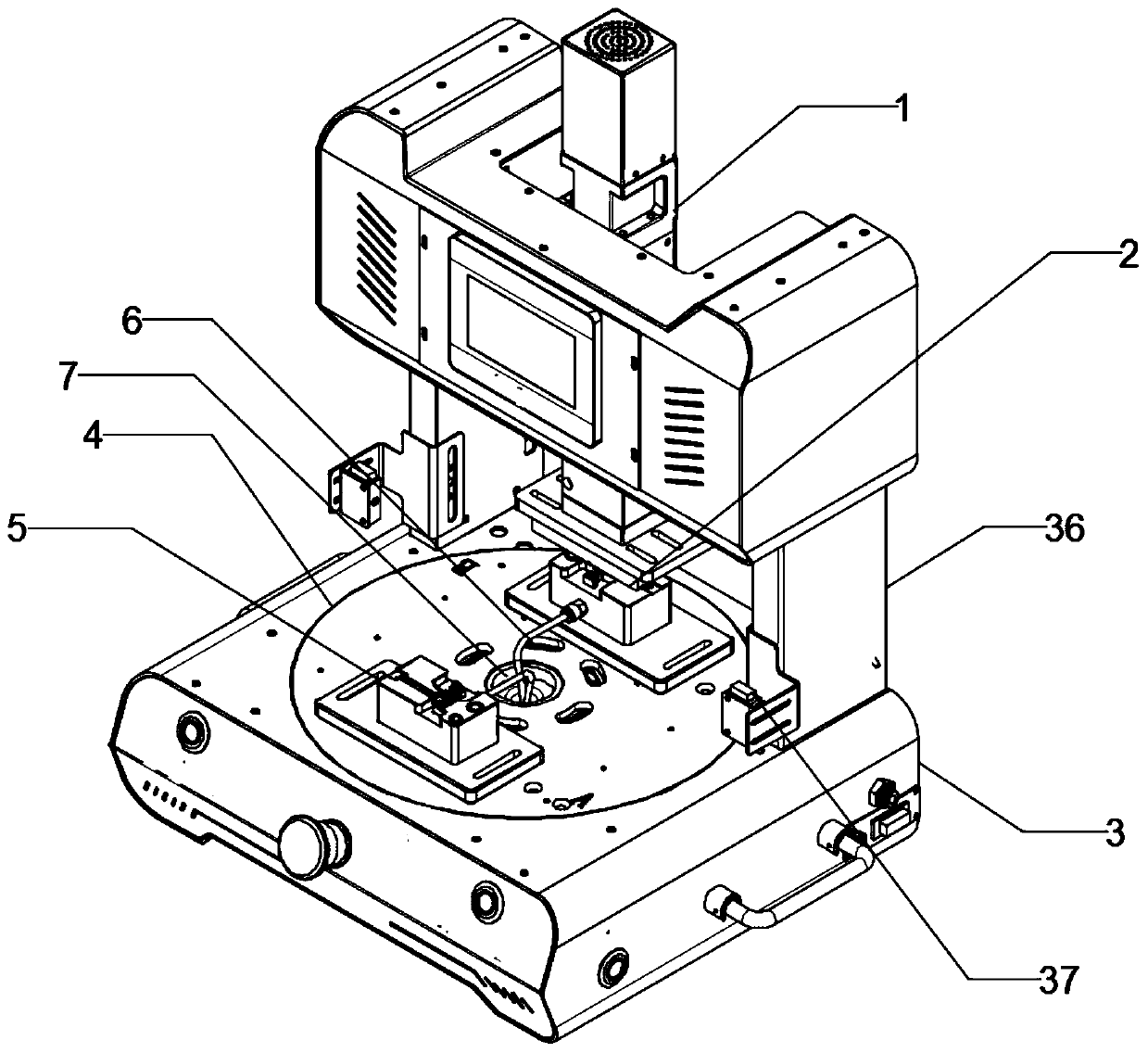

Automatic press-fit detecting device for sensor

PendingCN109061250ASimple structureEasy to operateManufacture of electrical instrumentsTesting equipmentHuman power

The invention discloses an automatic press-fit detecting device for a sensor. The device comprises a lower frame, a worktable disposed on the lower frame, and a rotating disc and a mounting bracket disposed on the worktable, wherein the rotating disc is provided with at least a set of contour positioning mechanisms; the mounting bracket is provided with a clamping pressing mechanism, a performancetesting mechanism and a coding mechanism; the rotating disc drives the contour positioning mechanisms thereon to rotate according to a circular trajectory; the clamping pressing mechanism, the performance testing mechanism and the coding mechanism are located above the circular trajectory, and when the contour positioning mechanism rotates to the position below the clamping pressing mechanism, the performance testing mechanism and the coding mechanism, the press-fit, testing and coding operations are respectively performed. The invention has the advantages of implementation of automatic press-fit, testing and coding of the product, which not only has simple structure and convenient operation, but also realizes automated production, saves manpower and increases the production efficiency.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

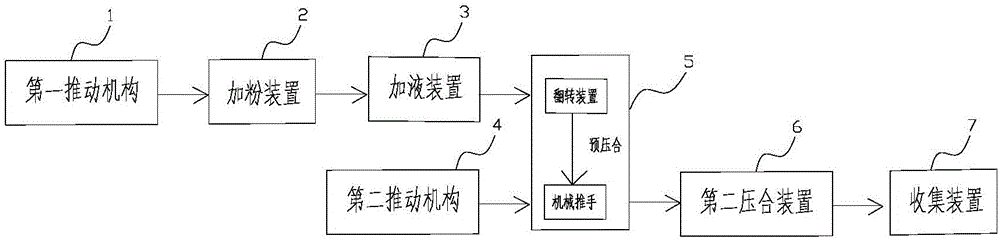

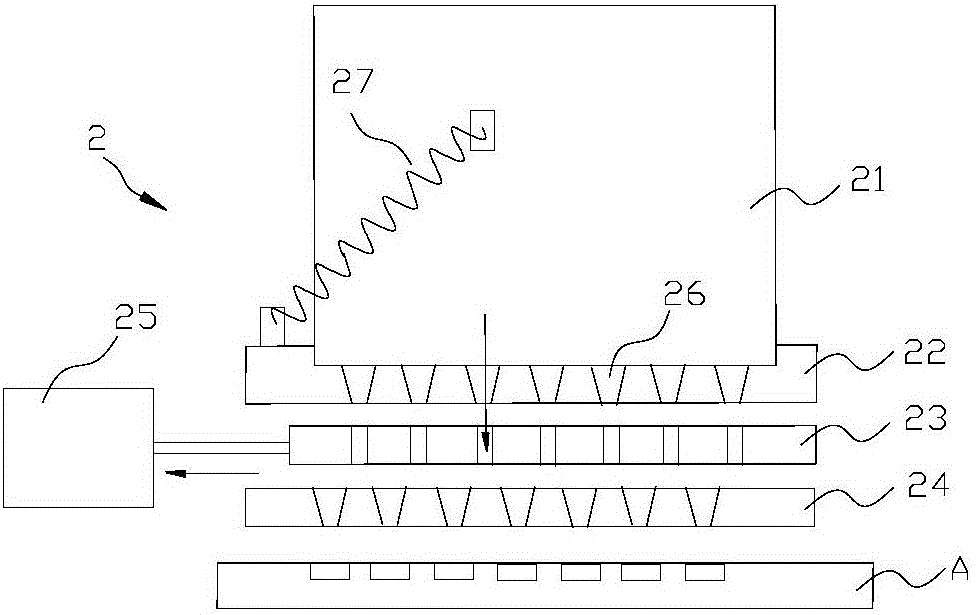

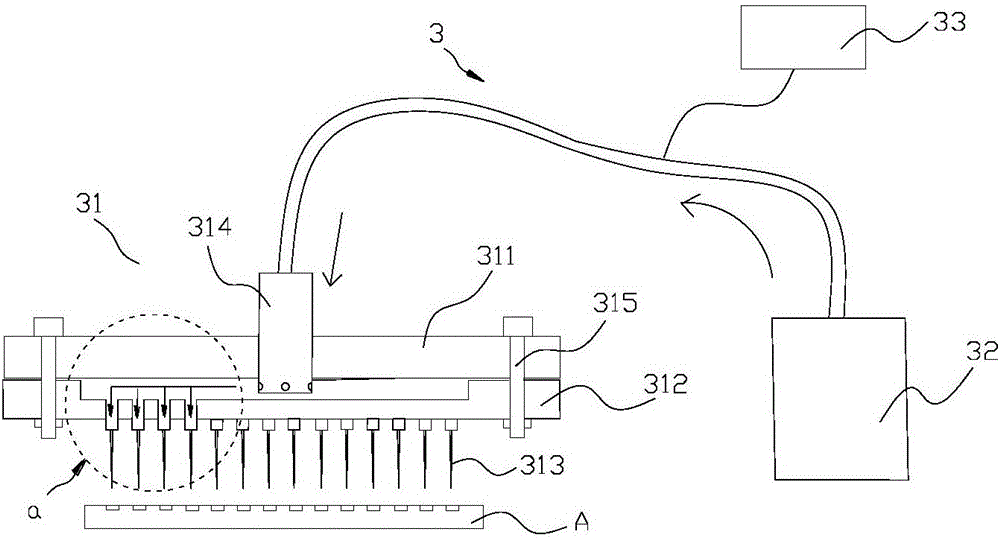

Button cell automatic pressing device

ActiveCN106025305AReduce labor costsImprove powder feeding efficiencyPrimary cell manufactureAssembling battery machinesButton batteryEngineering

The invention discloses a button cell automatic pressing device, which comprises a first pushing mechanism, a powder adding device, an electrolyte adding device, a second pushing device, a first pressing device and a second pressing device, wherein the first pushing mechanism is used for pushing a bottom cover material plate; the powder adding device is used for adding battery powder onto a bottom cover arranged on the bottom cover material plate; the electrolyte adding device is used for adding electrolyte into the bottom cover; the second pushing mechanism is used for pushing a face cover material plate; the first pressing device is used for pre-pressing the bottom cover and a face cover; the second pressing device is used for tightly pressing a pre-pressing button cell; the powder adding device, the electrolyte adding device and the first pressing device are sequentially arranged in the conveying direction of the first pushing mechanism; the second pressing device is arranged in the conveying direction of the second pushing mechanism. Through the arrangement of the fully automatic powder adding device, the electrolyte adding device, the first pressing device and the second pressing device, the automatic powder addition, electrolyte addition and pressing are realized; the work efficiency is improved; the labor cost is reduced.

Owner:佛山市南海区琪德新能源科技有限公司

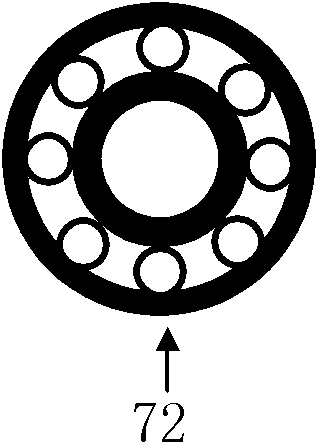

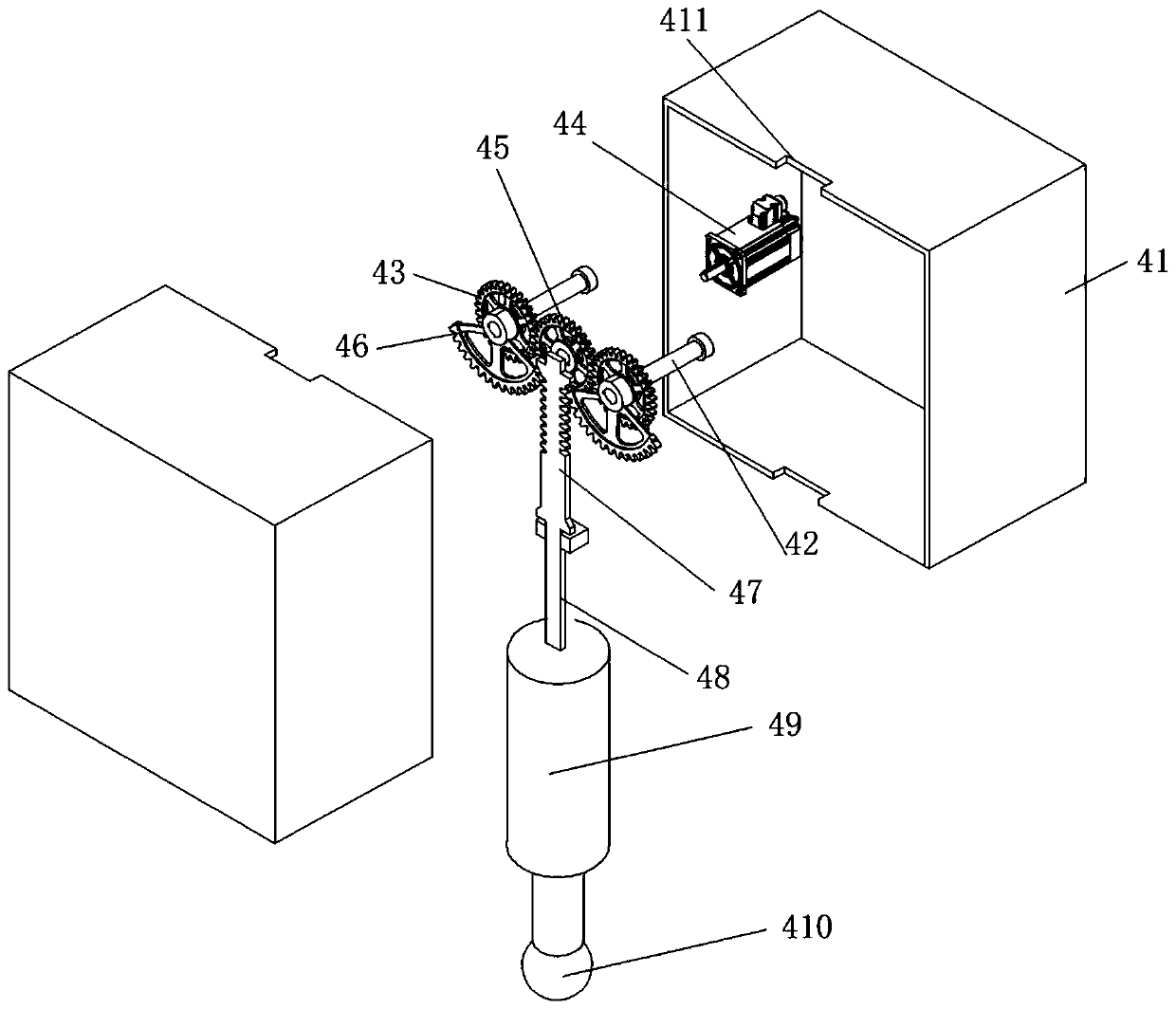

Bearing pressing machine

InactiveCN111702442AAchieve rotationRealize automatic pressingMetal working apparatusEngineeringMachine

The invention relates to a pressing machine, in particular to a bearing pressing machine. According to the bearing pressing machine, workpieces and bearings can be fixed, the bearings can be automatically pressed, the time and labor are saved, and operation is easy. The bearing pressing machine comprises a base, supporting columns, a first supporting frame, a pressing mechanism, a rotating mechanism and a discharging mechanism; the supporting columns are arranged in the middles of the front side and the rear side and the middle of the right side of the top of the base correspondingly; the first supporting frame is arranged on the rear part of the right side of the top of the base; the pressing mechanism is connected between the tops of the supporting columns and the top of the base; and the rotating mechanism is connected between the first supporting frame and the pressing mechanism, and the discharging mechanism is arranged on the front right side of the base. When needing to press the bearings, people place the bearings needing to be pressed into a part of the rotating mechanism, the pressing mechanism is started, under cooperation of the rotating mechanism, the bearings are pressed by the pressing mechanism, when pressing of the bearings is completed, the bearings fall into the discharging mechanism, and people can take out the bearings orderly.

Owner:刘茂椿

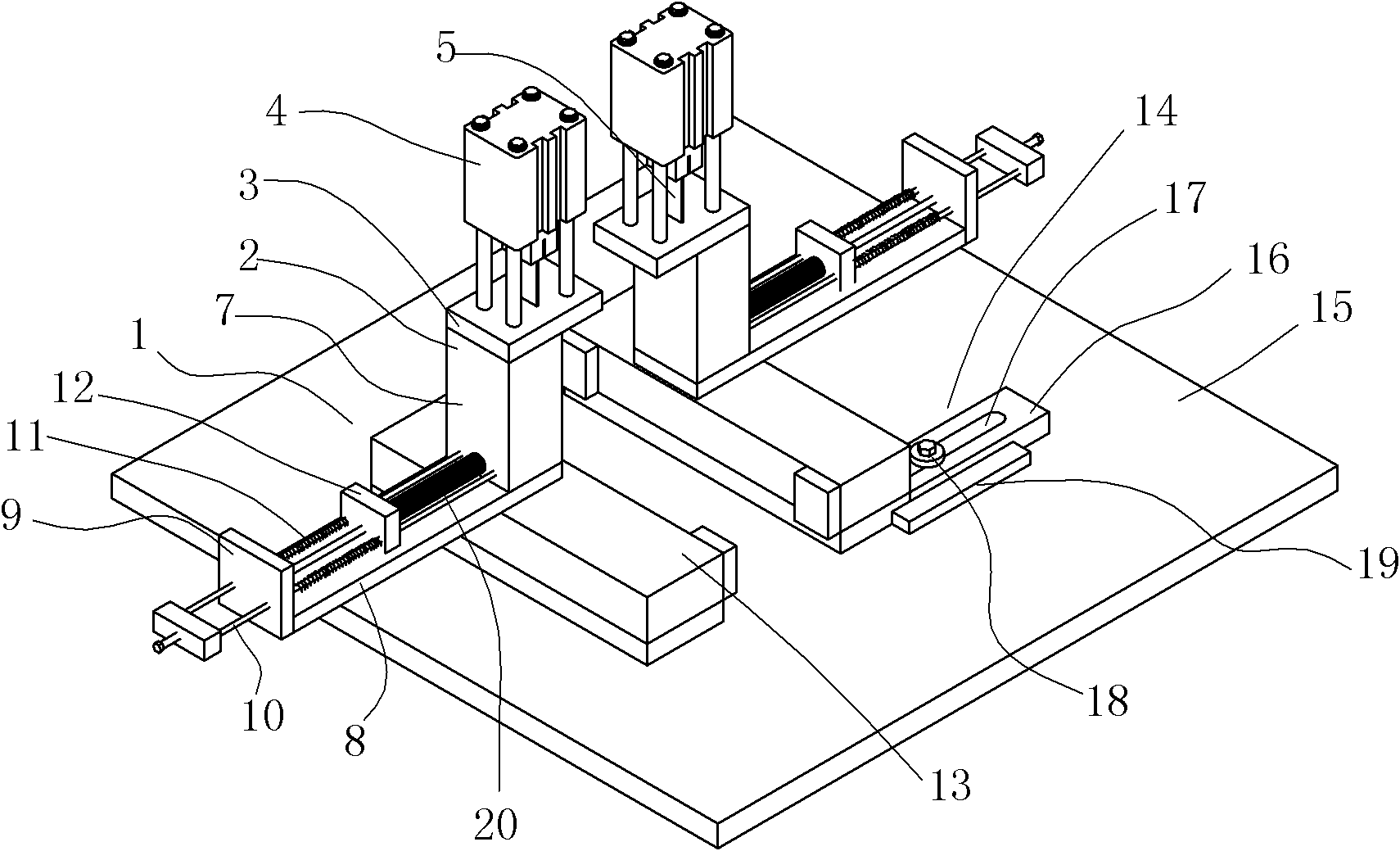

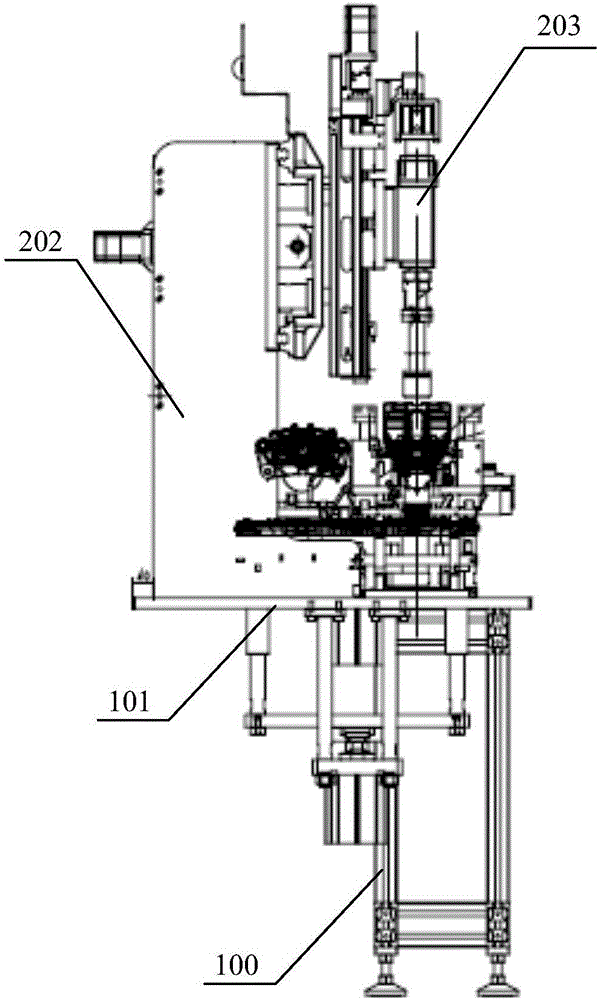

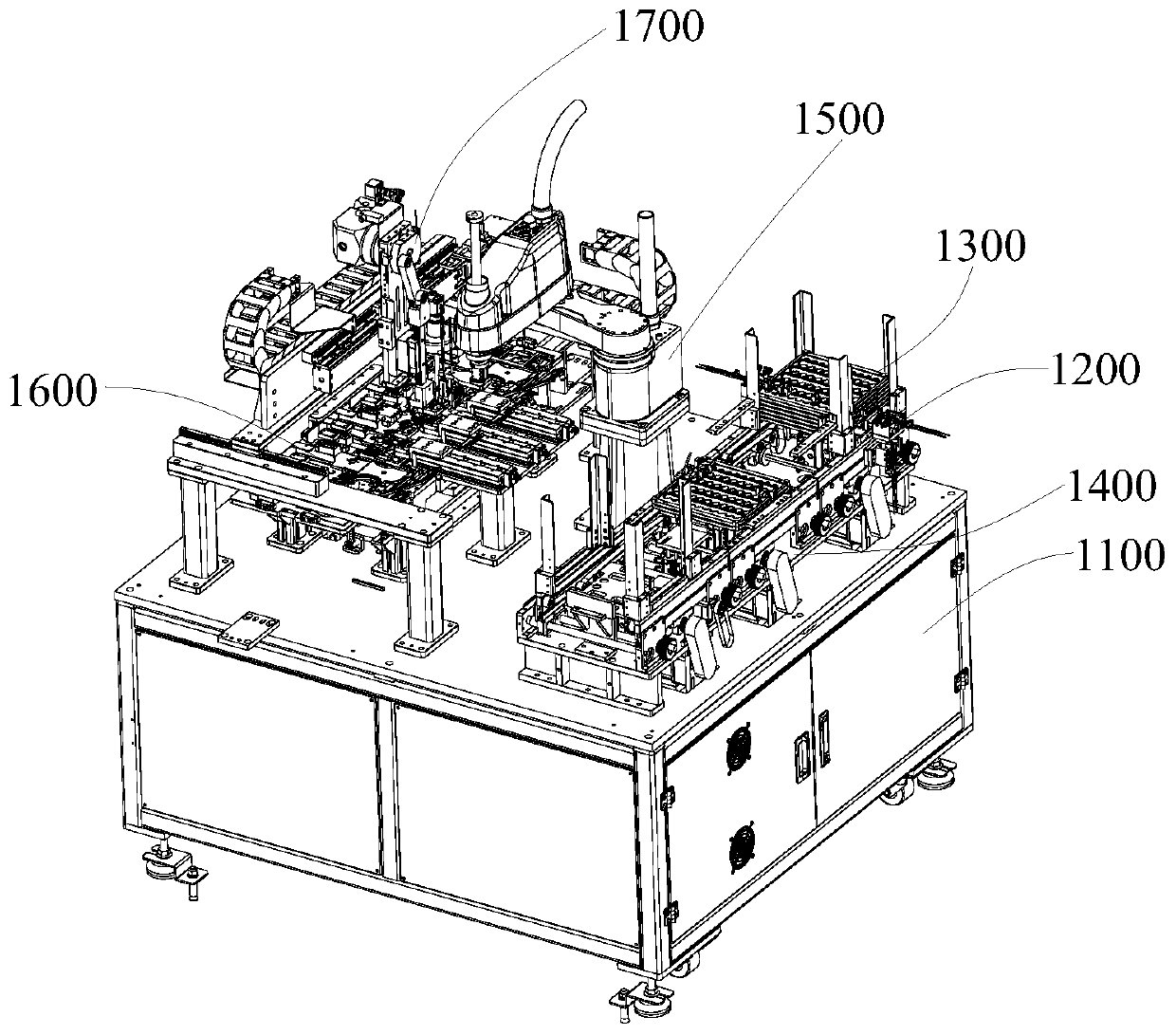

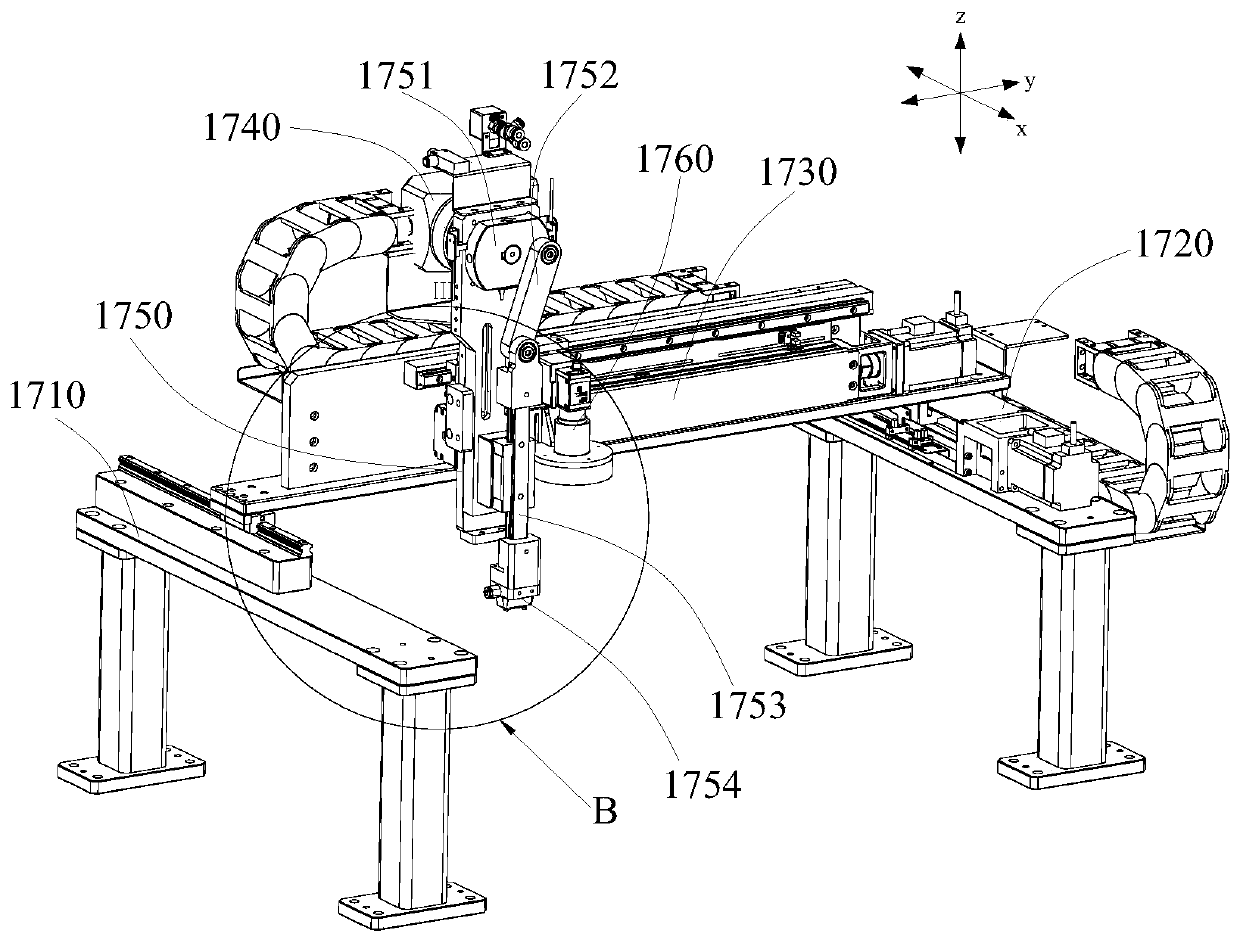

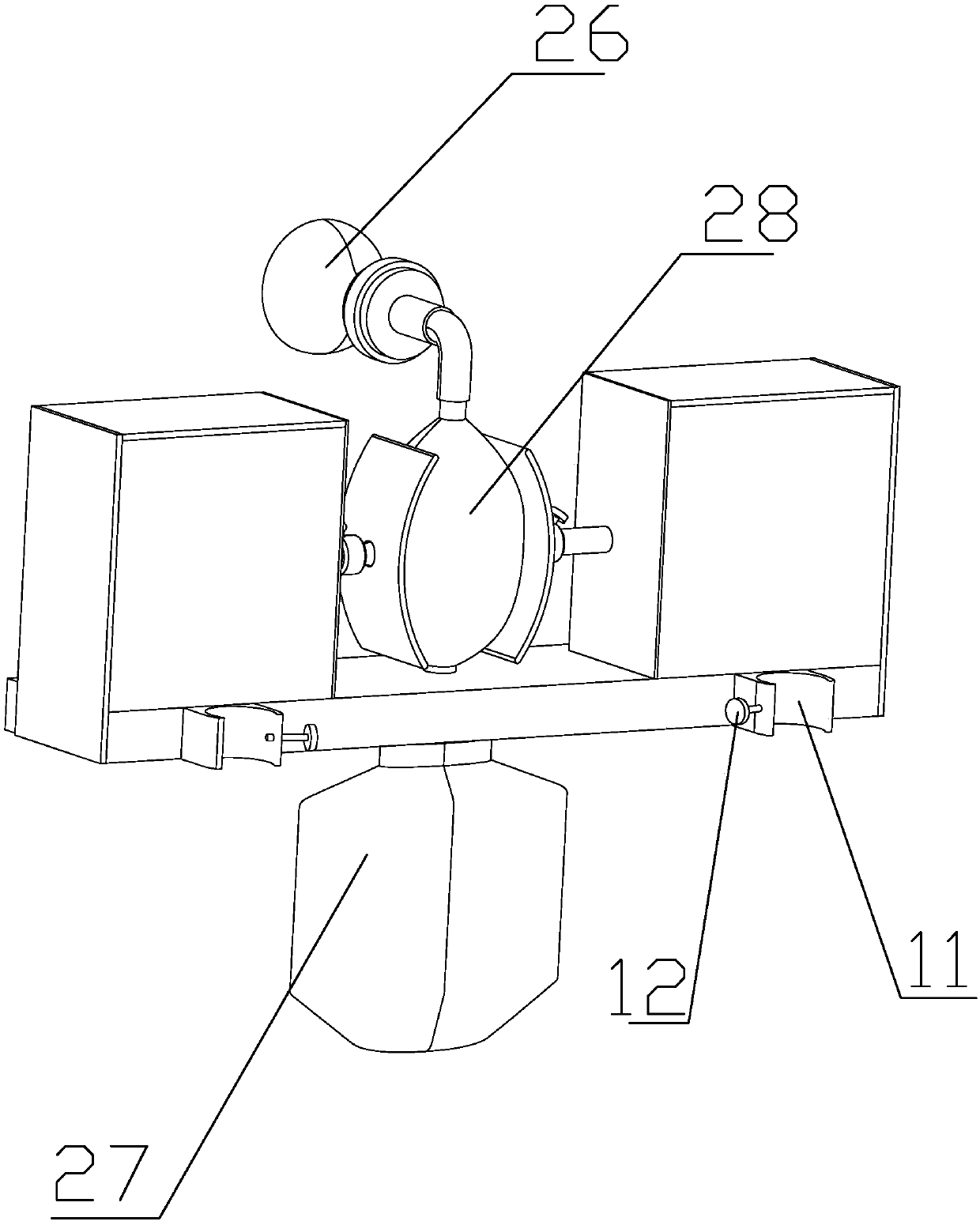

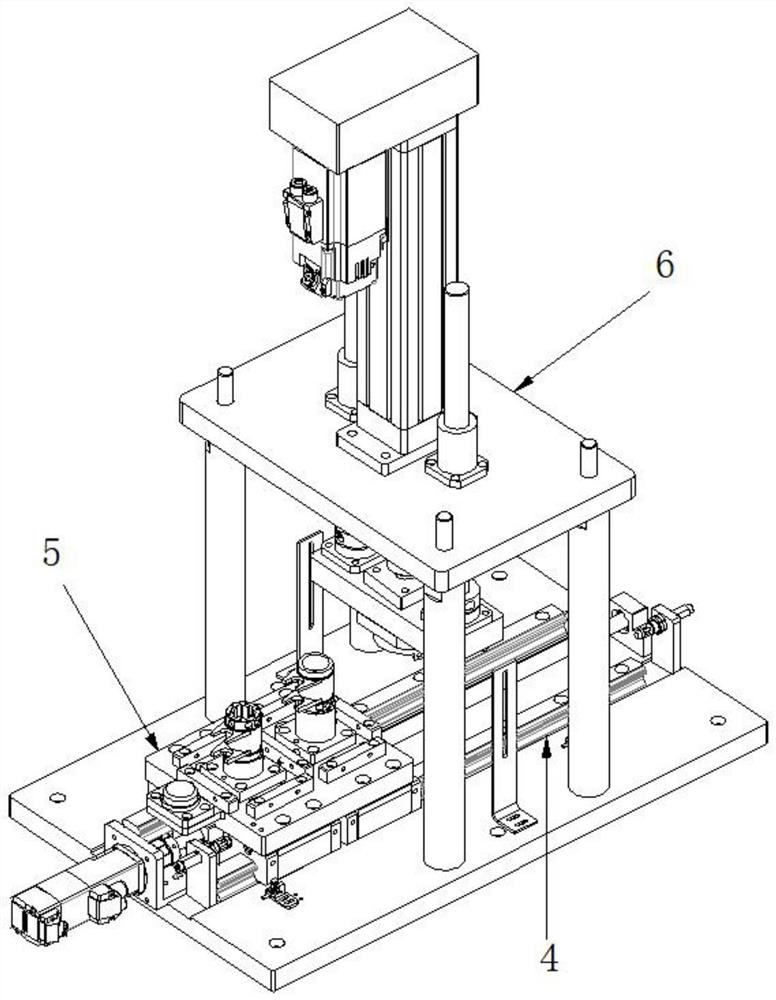

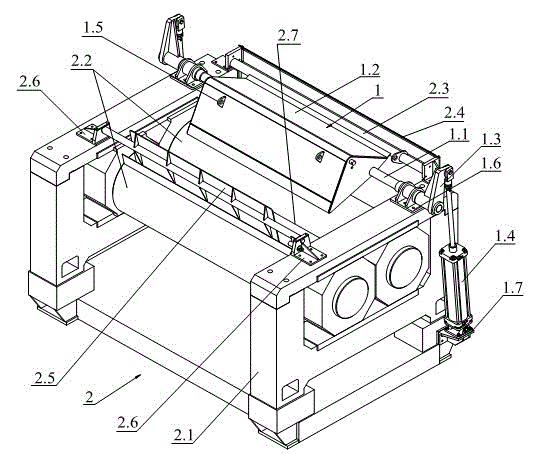

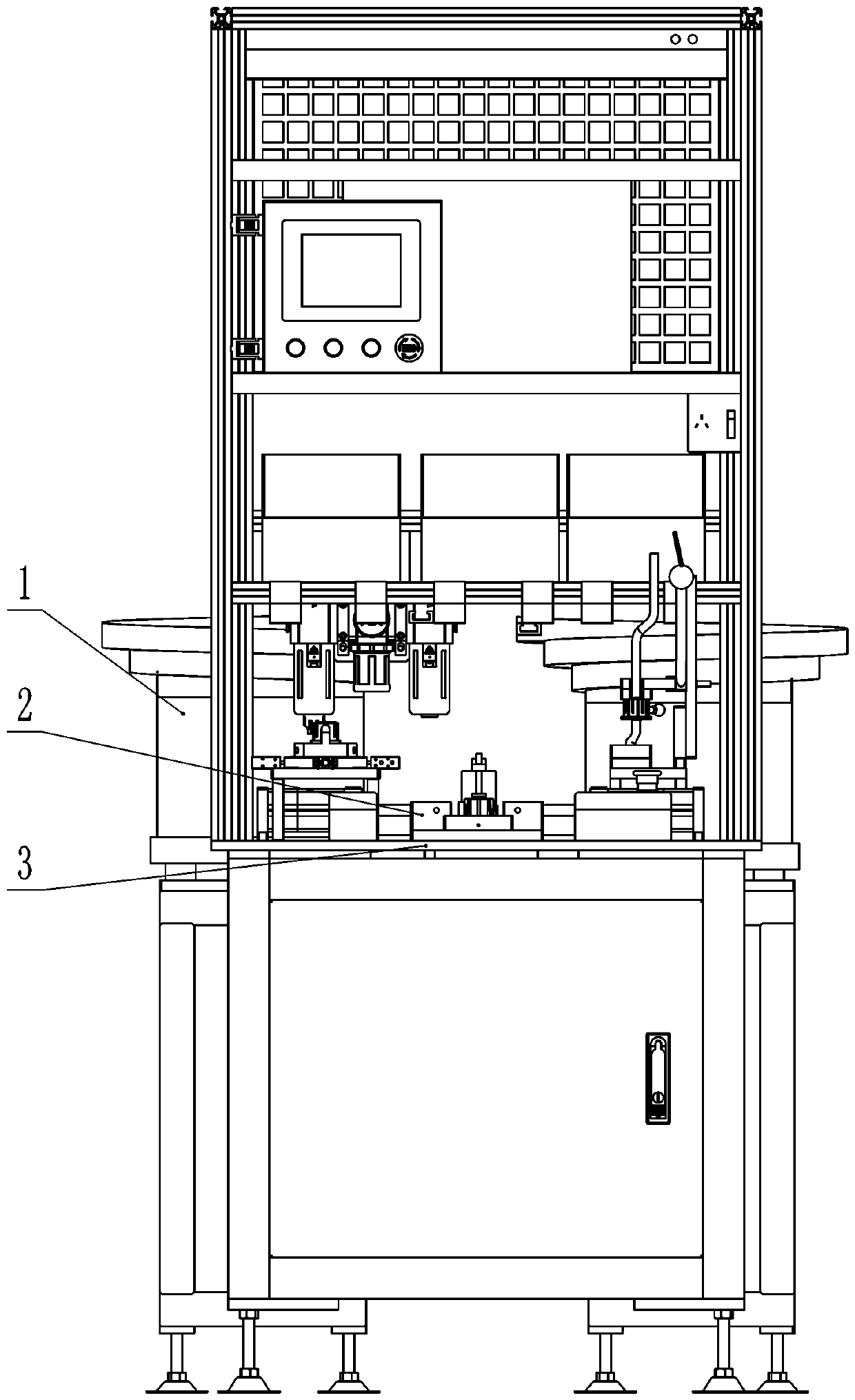

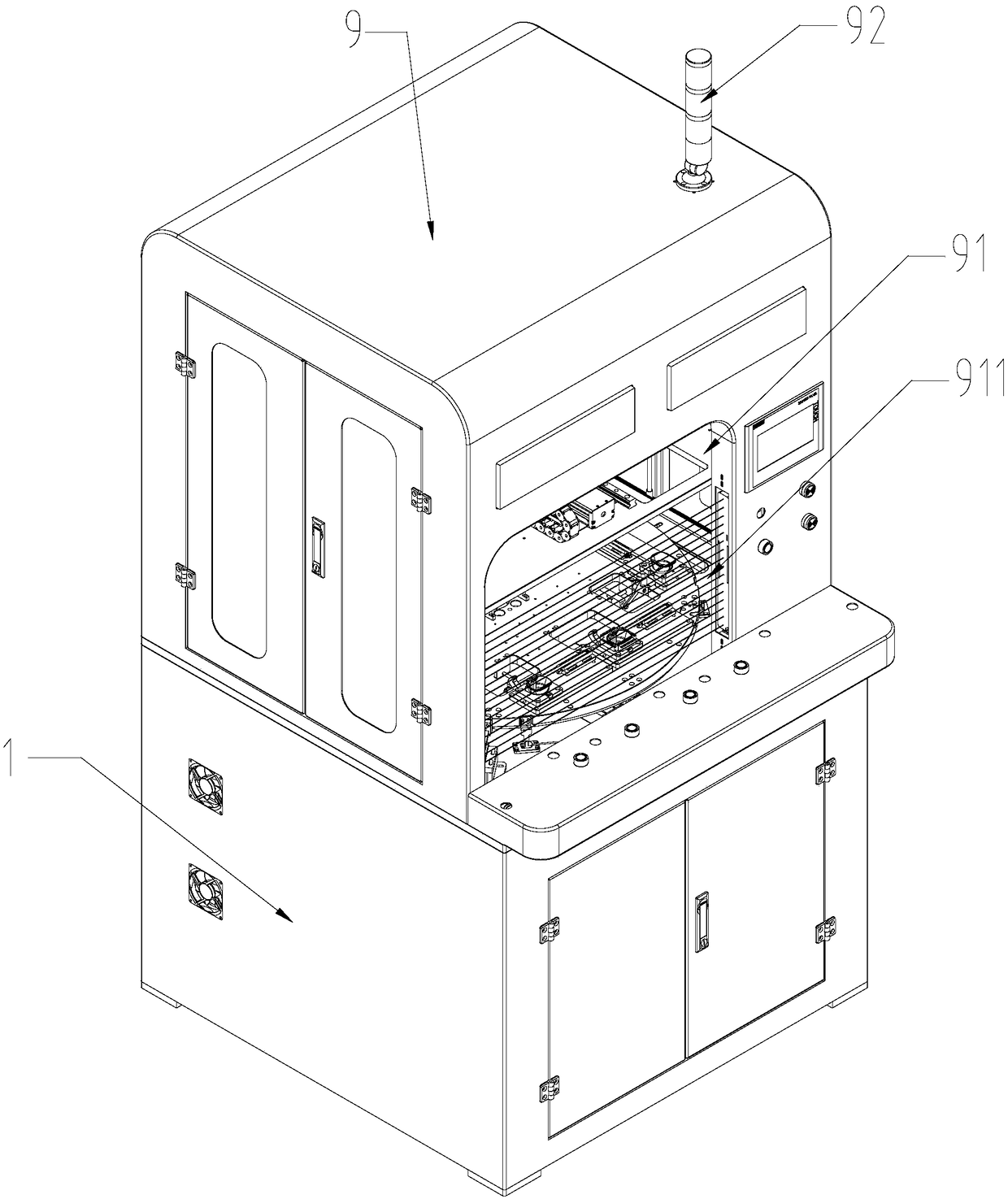

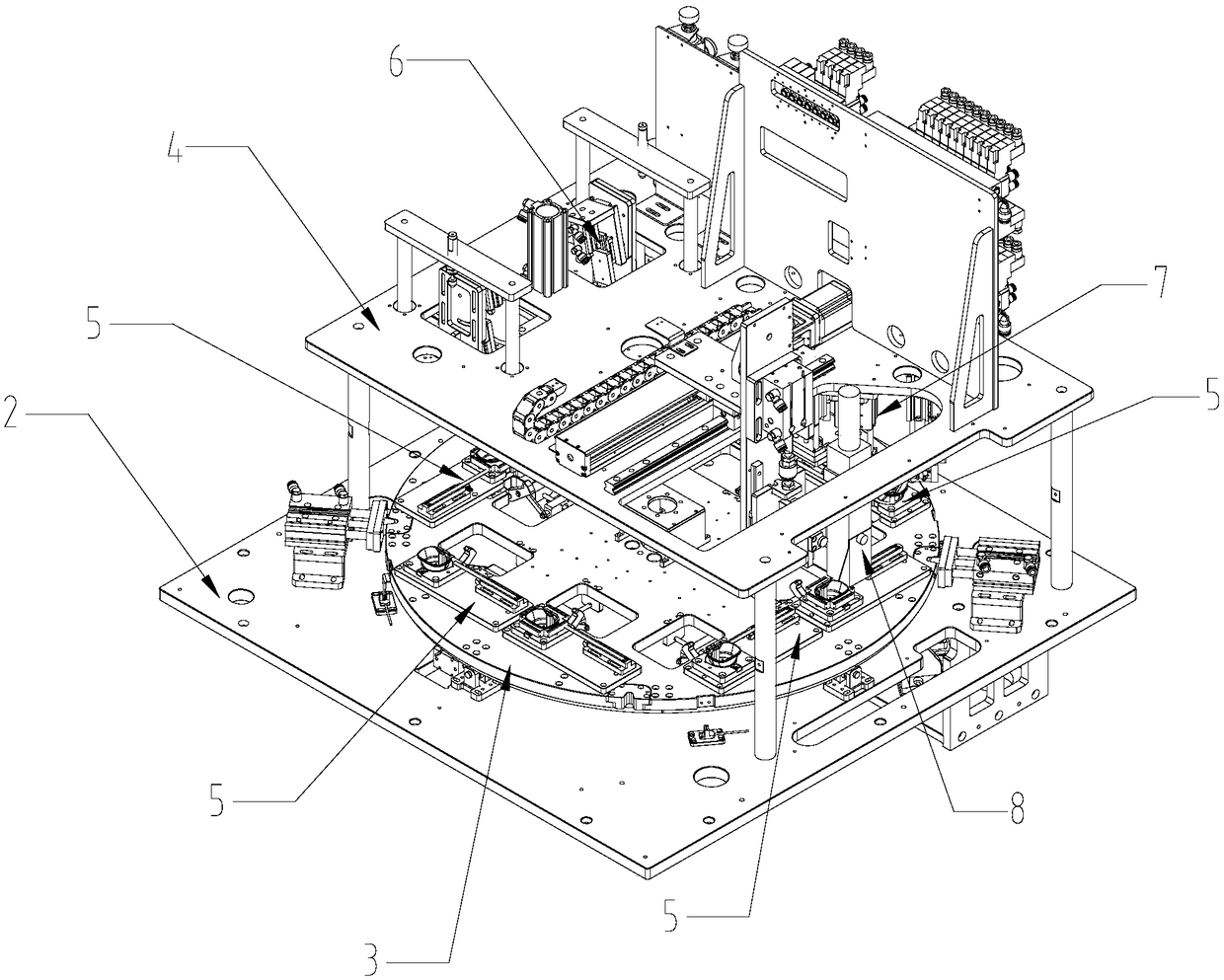

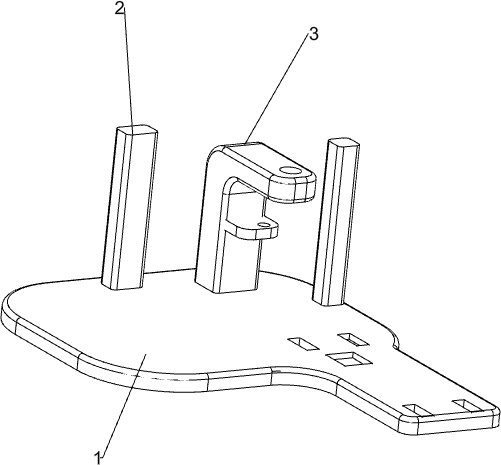

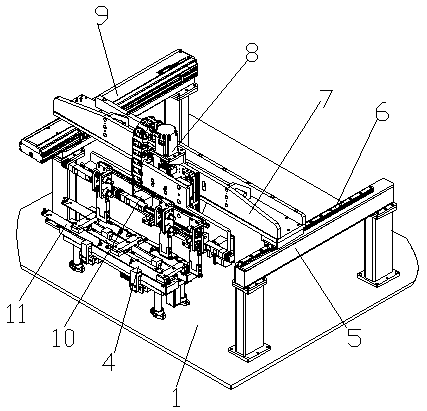

Automatic press-fitting system and assembling method for ball screw pair supporting sleeves

The invention relates to an automatic press-fitting system and assembling method for ball screw pair supporting sleeves, belongs to the technical field of automatic assembly, and solves the problems of low assembly precision and complex operation of a mode of assembling the supporting sleeves by manual press-fitting, hot-fitting or cold-fitting in the prior art. The automatic press-fitting system comprises a sliding rail mechanism, a press fitting mechanism, a sliding clamp, an auxiliary positioning mechanism and a turnover mechanism, wherein the sliding clamp is used for loading the positioning support sleeves and ball screw pairs; the sliding clamp can slide on the sliding rail mechanism; the press-fitting mechanism is provided with a telescopic pressing head, and the supporting sleeves can be clamped into supporting sleeve clamping grooves of the telescopic pressing head and fixed through the auxiliary positioning mechanism; the supporting sleeves comprise a first supporting sleeve and a second supporting sleeve; the press-fitting mechanism can press-fit the first supporting sleeve on ball screw pairs by pressing the telescopic pressing head; the turnover mechanism can turn over the ball screw pairs, and the second supporting sleeve is pressed after the ball screw pairs are turned over. Automatic pressing of the ball screw pair supporting sleeves is achieved.

Owner:BEIJING MECHANICAL EQUIP INST

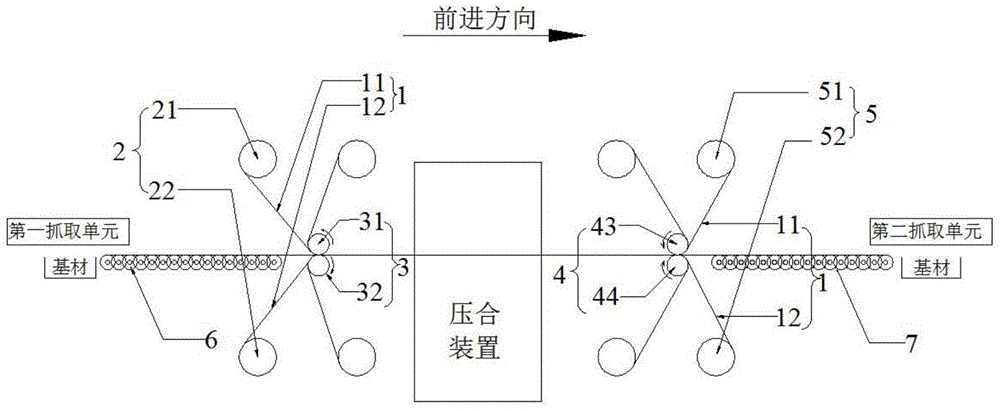

Press-fit system for press-fitting base material and cover film and press-fit technology

ActiveCN105667055ARealize automated productionRealize automatic pressingLaminationLamination apparatusProduction lineEngineering

The invention provides a press-fit system for press-fitting a base material and a cover film. The base material and the cover film undergo press-fit by a press-fit device. The base material is a chip-type base material, and the cover film is a roll-type cover film produced by the utilization of a roll-to-roll technology. The press-fit system comprises a grabbing unit, a transmission unit for transmitting the base material, a roll material feeding unit, a roll-in unit, a press-fit device, a roll-out unit and a roll material receiving unit. According to the press-fit system and the press-fit technology, cost and efficiency are both considered. On one hand, expensive production line for realizing full-automatic press-fit of the base material and the cover film by a roll-to-roll technology is not adopted, and the problem of high cost is overcome; and on the other hand, by the roll-to-chip technology, full-automatic press-fit of the chip-type base material and the roll-type cover film is realized, automatic production of the press-fit technology is realized, and production efficiency is raised.

Owner:SHANGHAI LANGHUA SCI & TRADING

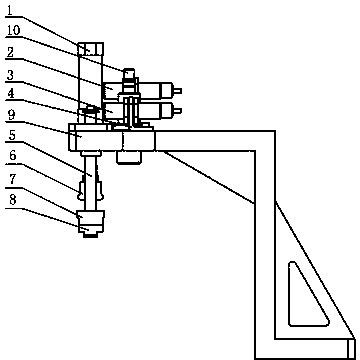

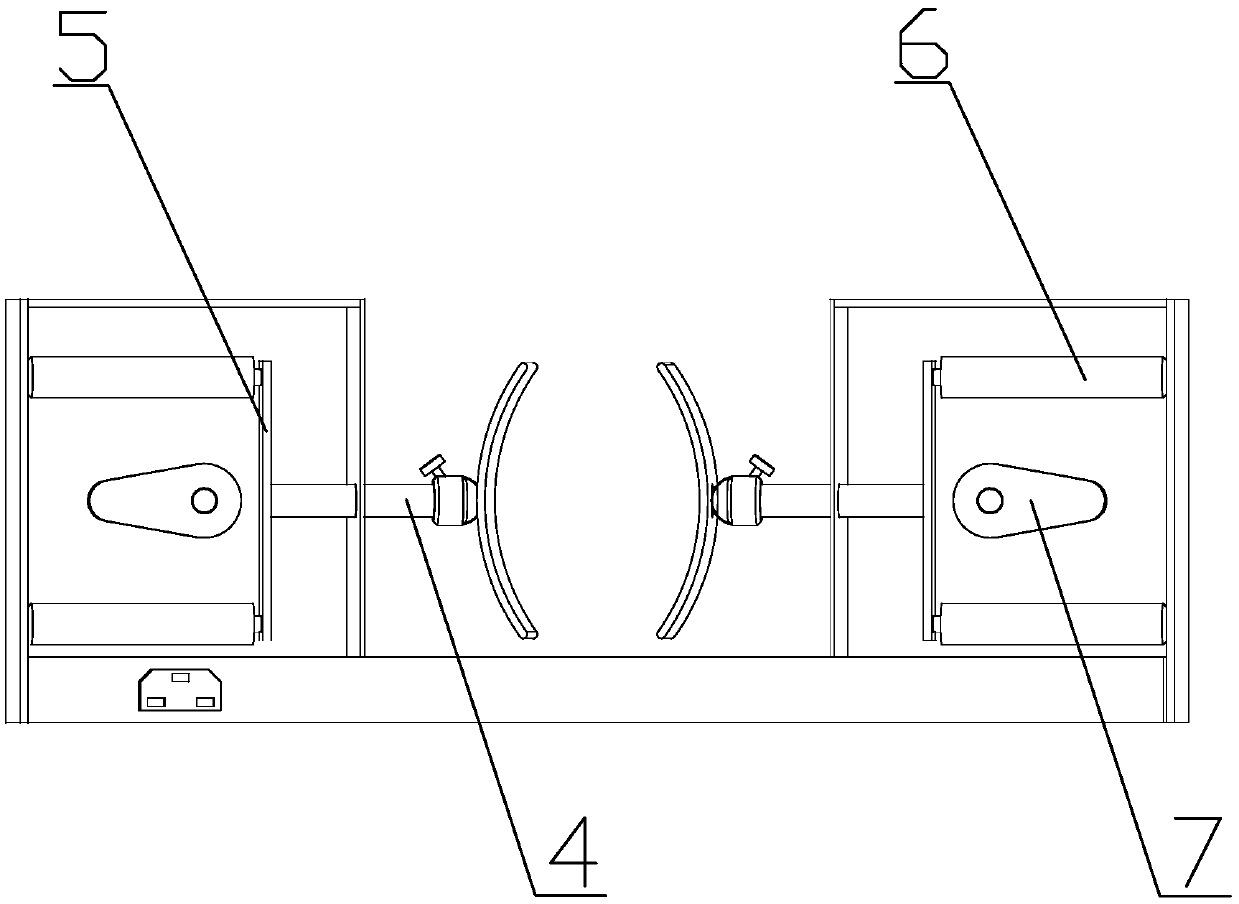

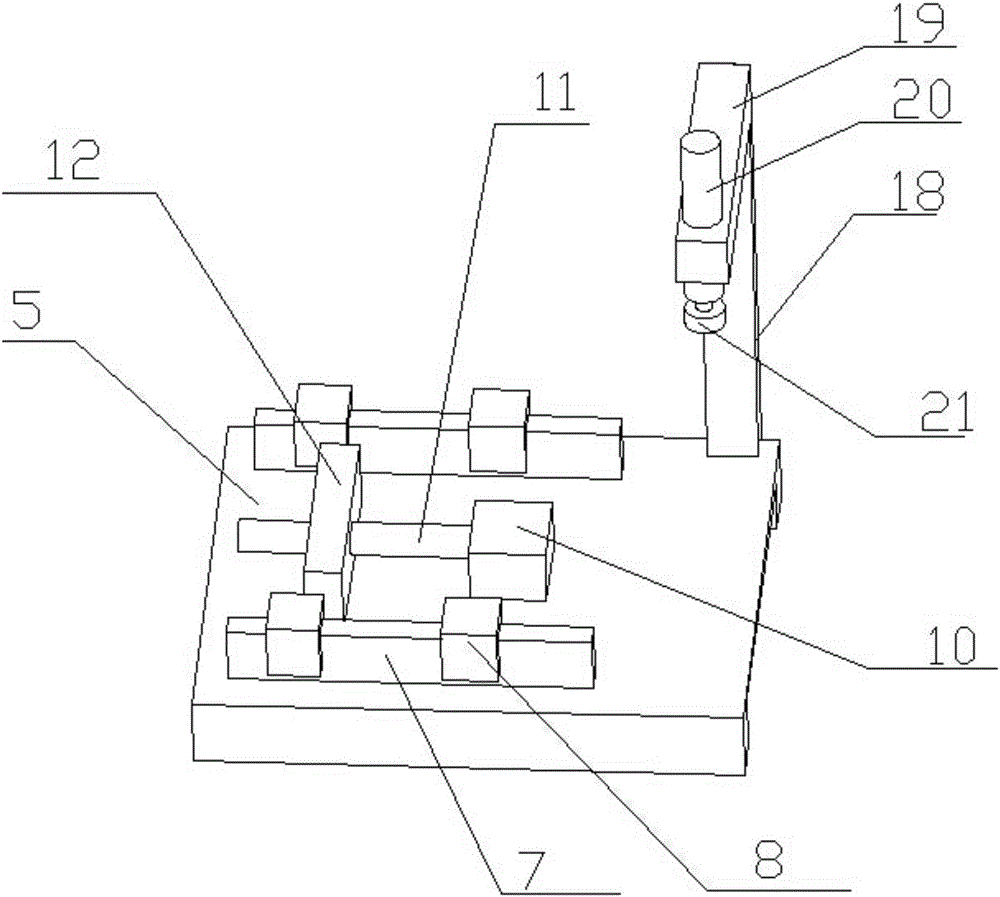

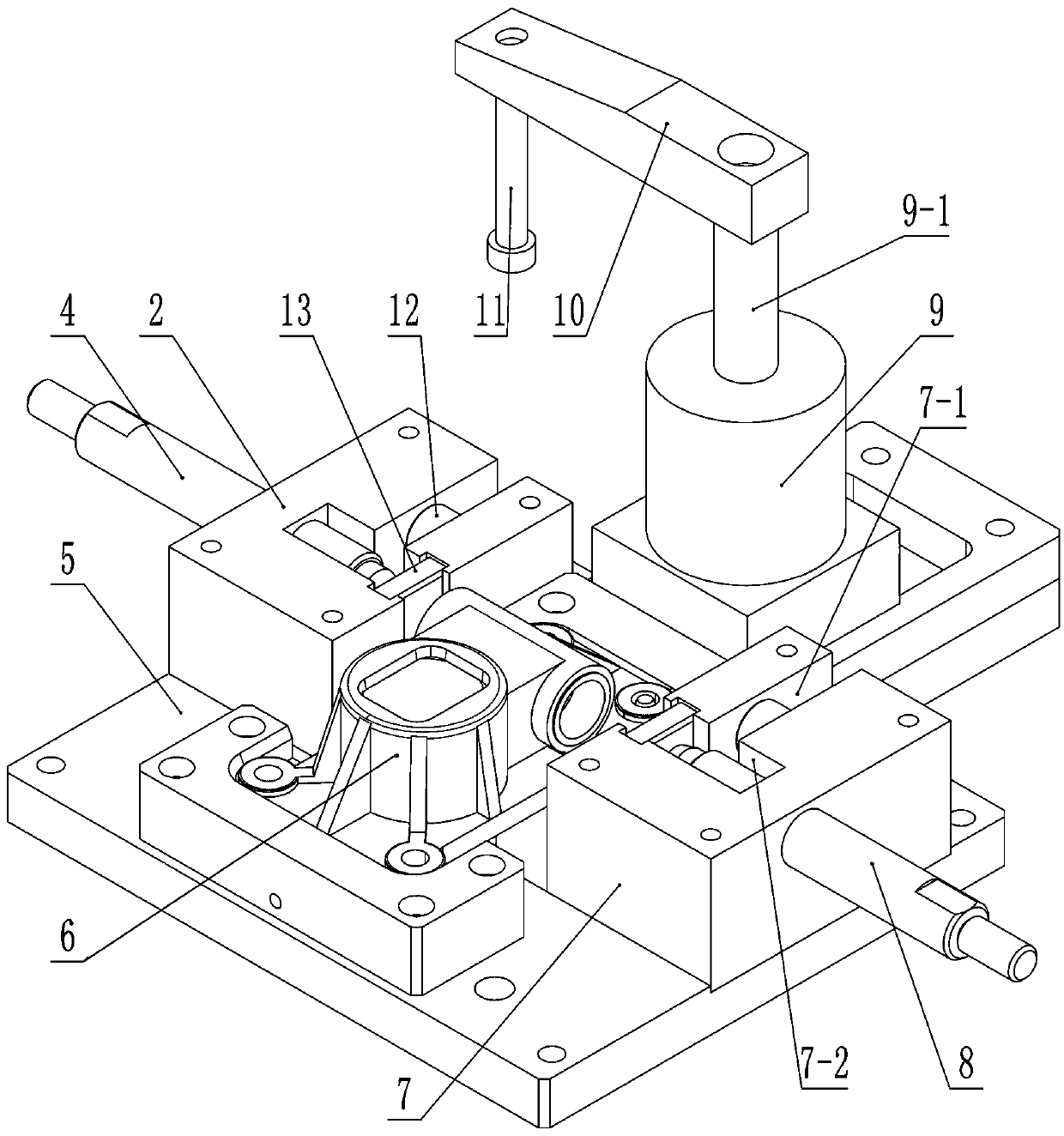

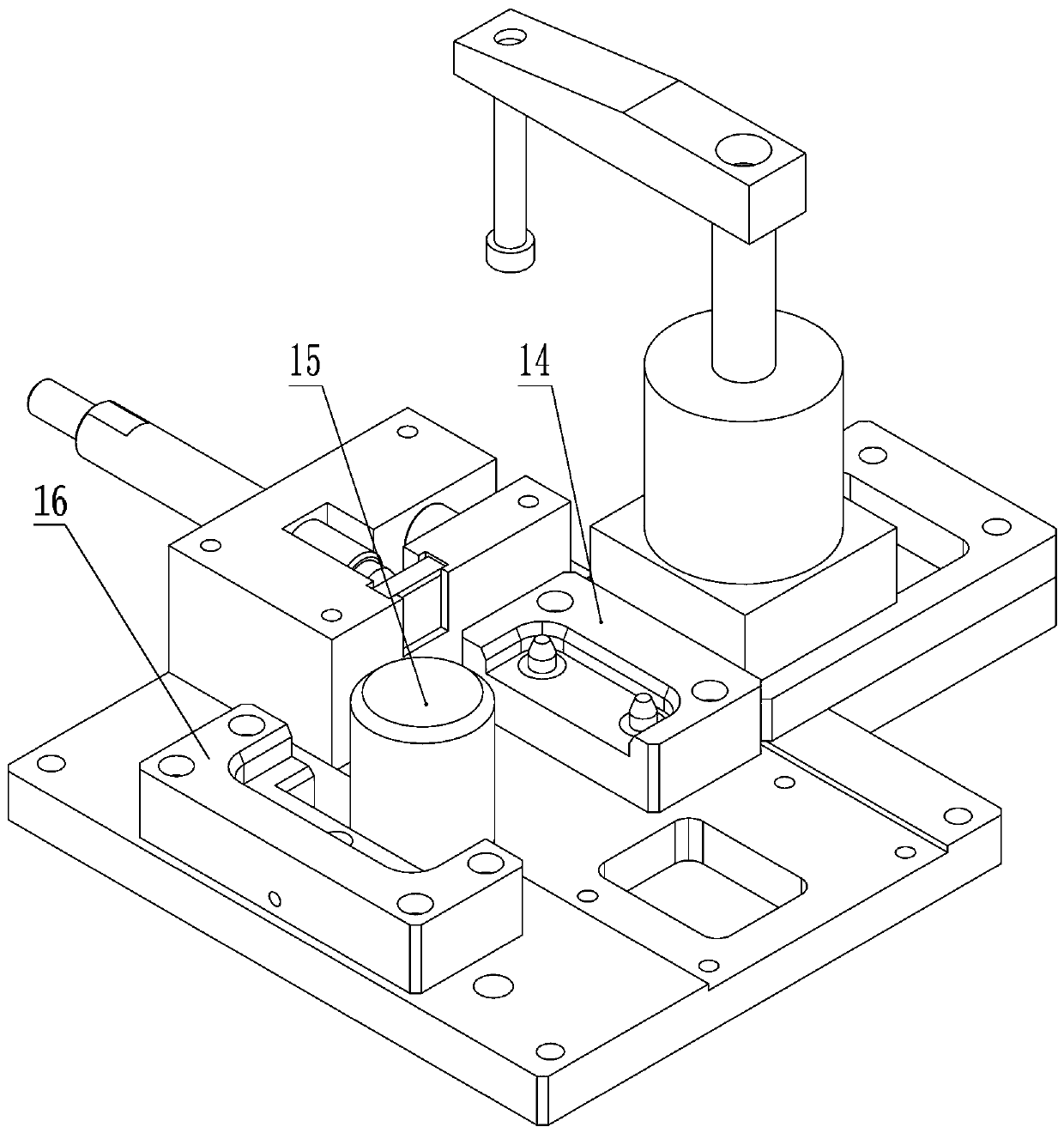

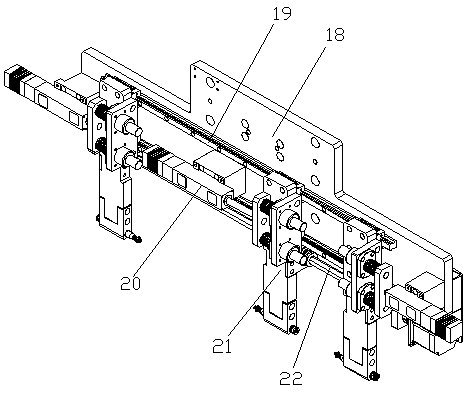

Error-preventing cartridge clip-type feeding bearing automatic press fitting mechanism and method

PendingCN108422380ARealize automatic pressingImprove efficiencyMetal-working hand toolsMechanical engineeringCrankshaft

The invention provides an error-preventing cartridge clip-type feeding bearing automatic press fitting mechanism. The mechanism comprises a working platform, and a blocking and jacking mechanism of apositioning crank shaft, a transportation roller table of a transporting crank shaft, a feeding mechanism, a scanning camera for scanning two-dimensional code information on crank shafts, a side edgepressing mechanism, a top pressing mechanism and a press fitting mechanism are fixed on the working platform; the side edge pressing mechanism and the press fitting mechanism are arranged on two sidesof the working platform respectively, the transportation roller table is suspended above the working platform, and the blocking and jacking mechanism is arranged at the bottom of the transportation roller table. The invention further provides an error-preventing cartridge clip-type feeding bearing automatic press fitting method. The mechanism and the method have the advantages that automatic press fitting of bearings is achieved, the efficiency is improved, the mechanism has an error preventing function, the structure of the mechanism is simple and compact, the cost is lower, and the floor occupation area is smaller.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

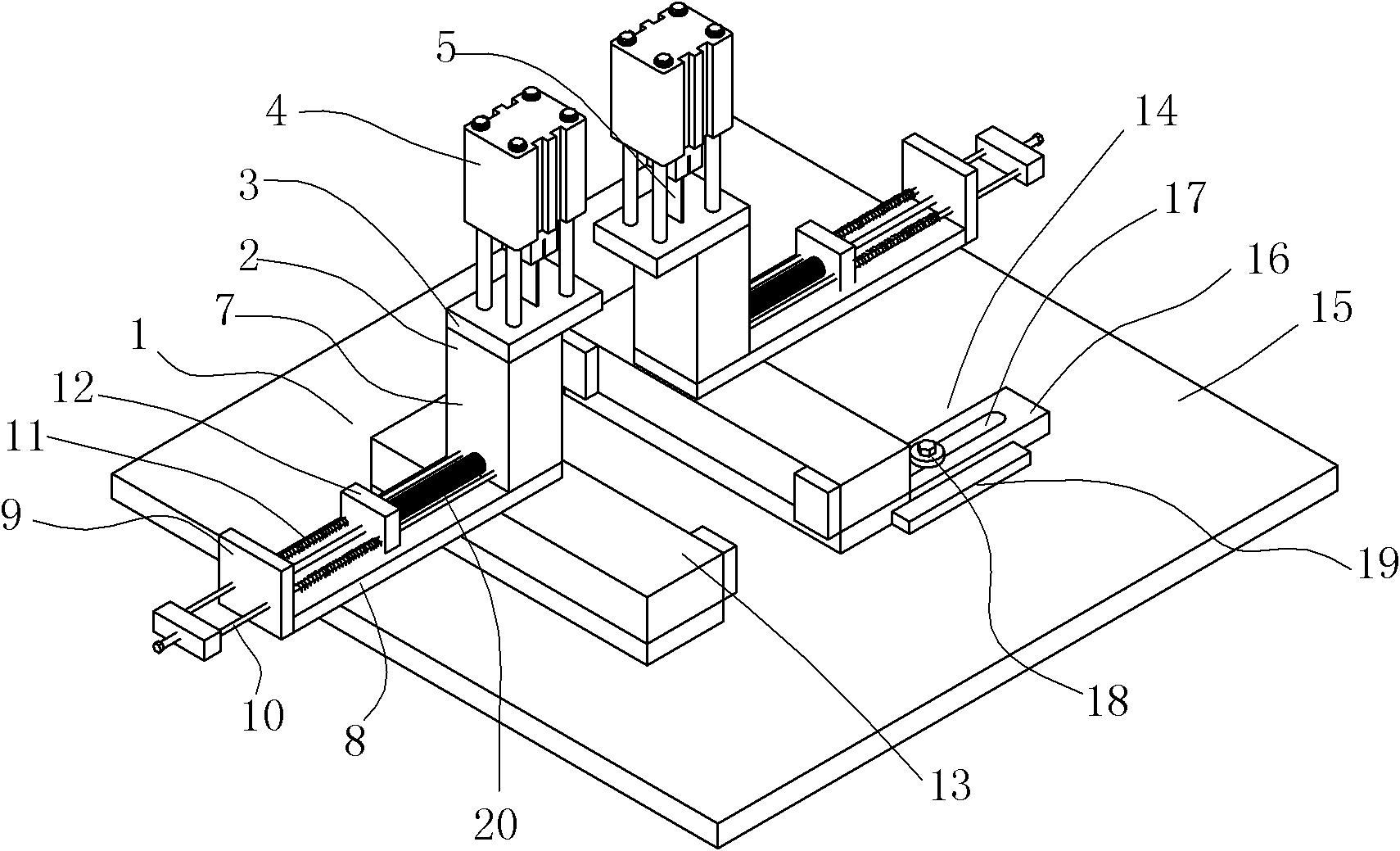

Press fitting mechanism of gas nipple assembly machine

ActiveCN107443051ARealize automatic pressingImprove assembly efficiencyMetal working apparatusAssembly machinePlunger

The invention relates to the field of automation equipment, in particular to a press fitting mechanism of a gas nipple assembly machine, which comprises a fixing plate, wherein the fixing plate is arranged above one assembly platform; four upright poles in rectangular distribution are arranged at the bottom of the fixing plate, bottoms of the four upright poles are fixed on the assembly platform, press plates in up-and-down sliding fit with the four upright poles are arranged on the four upright poles, a press pole is arranged at the bottom of the press plate, a press plate driving cylinder is mounted at the top of the fixing plate, and an output shaft of the press plate driving cylinder passes through the fixing plate and is fixedly connected with the top of the press plate; an arc support is mounted at the top of the press plate, the output shaft of the press plate driving cylinder is connected at the top of the arc support, and a first in-place detection device is mounted on one side inside the arc support; the first in-place detection device comprises a first spring plunger and a first pressure sensor arranged at the top of the first spring plunger. The press fitting mechanism can realize automatic press fitting, has the advantages of high assembly efficiency and good assembly effect, and can effectively reduce labor output.

Owner:惠东达声五金制品有限公司

Shaft sleeve press fitting mechanism of air-conditioning air guiding plate

InactiveCN109014866AFit closelyRealize automatic pressingMetal working apparatusDistribution controlEngineering

The invention relates to a shaft sleeve press fitting mechanism of an air-conditioning air guiding plate. The shaft sleeve press fitting mechanism comprises a rack and a power distribution control box, the middle portion of the rack is provided with a workpiece jig matched with the air-conditioning air guiding plate, the portions, on the left and right sides of the workpiece jig, of the rack are symmetrically provided with shaft pressing support frames, the left and right shaft pressing support frames are provided with a front and rear slide rail and a front and rear slide table cylinder, theoutput end of the front and rear slide table cylinder is fixedly connected with a support horizontal plate in sliding fit with the front and rear slide rail, the middle portion of the support horizontal plate is provided with an alignment device, and a pushing device matched with a supporting member on the air-conditioning air guiding plate is arranged below the alignment device. The air-conditioning air guiding plate is fixed through the workpiece jig, a shaft sleeve transversely moves to the position above the workpiece jig through the front and rear sliding table cylinder, then the shaft sleeve and the supporting member are accurately positioned through the alignment device, then the shaft sleeve is pressed into the supporting member through the pushing device, and therefore automatic press fitting of the shaft sleeve of the air guiding plate is achieved, the production efficiency is high, and the shaft sleeve and the supporting member are closely matched with each other.

Owner:DONGGUAN UNIV OF TECH

Multifunctional assembling rotary pressing machine and pressing method thereof

PendingCN111590297ASolve the problem of unstable pressing force and large fluctuation of pressing qualityRealize automatic pressingMaterial gluingMetal working apparatusReciprocating motionEngineering

The invention discloses a multifunctional assembling rotary pressing machine and a pressing method thereof. The rotary pressing machine comprises a feeding part and a pressing part located directly above the feeding part, wherein the pressing part comprises a Z-axis linear lifting device and a pressing heat fixed to a driving end of the Z-axis linear lifting device; and the feeding part comprisesa base, a rotating table assembled on the base through a shaft sleeve part, two positioning tooling symmetrically fixed to the rotating table, a driving device for driving a connecting shaft of the shaft sleeve part to rotate and move back and forth, and a vacuum pipeline penetrating through a hollow cavity of the connecting shaft and communicating with adsorption holes in the positioning tooling,and the rotating table is fixed to the top of the connecting shaft. According to the multifunctional assembling rotary pressing machine, continuous operation is achieved through a rotating mode, andthe pressing efficiency is high.

Owner:TIANJIN JINYA ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com