Press-in device for internal and external pins of automobile shift shaft assembly

A press-in device and automobile gear shifting technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of uncontrollable assembly quality, large human resource occupation, and low degree of automation, so as to avoid personal injury and improve Production efficiency, pollution avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

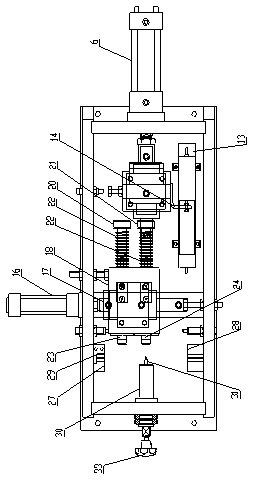

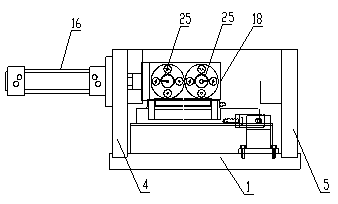

[0020] Such as Figure 1-3 As shown, a device for pressing the inner and outer pins of an automobile shift shaft assembly, the device includes a main body frame, and the main body frame is composed of a bottom plate 1, a left side plate 2, a right side plate 3, a front plate 4, and a rear plate 5 , the left side plate 2, the right side plate 3, the front plate 4, and the rear plate 5 are respectively fixed on the bottom plate 1, wherein the left side plate 2, the right side plate 3, the front plate 4, and the rear plate 5 are fixedly connected to each other, and the inner , The export pin press-in device also includes a press-in actuator, a press-in mechanism switching device and a positioning fixture. The press-in actuator is composed of a gas-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com