Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

139results about How to "Uniform pressing force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

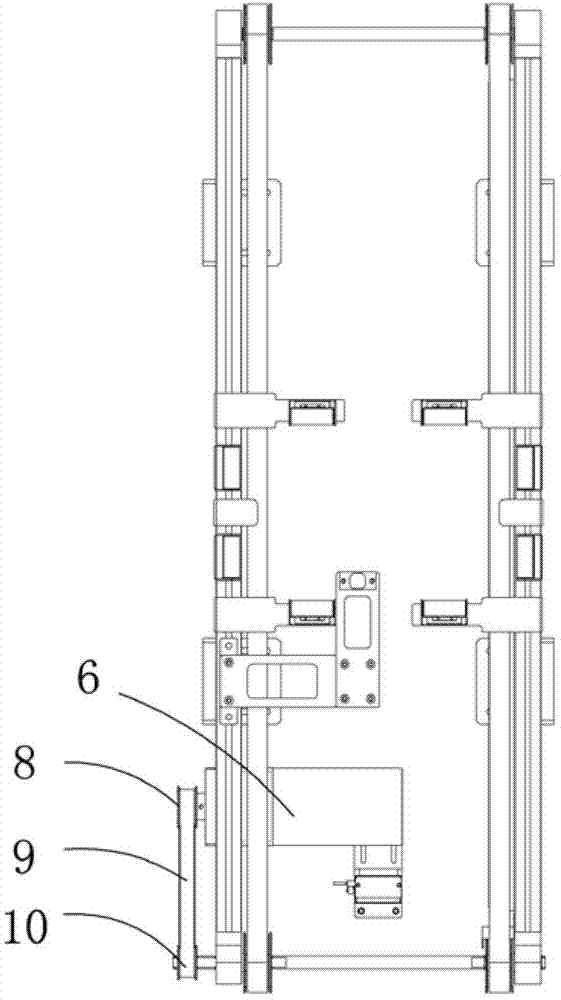

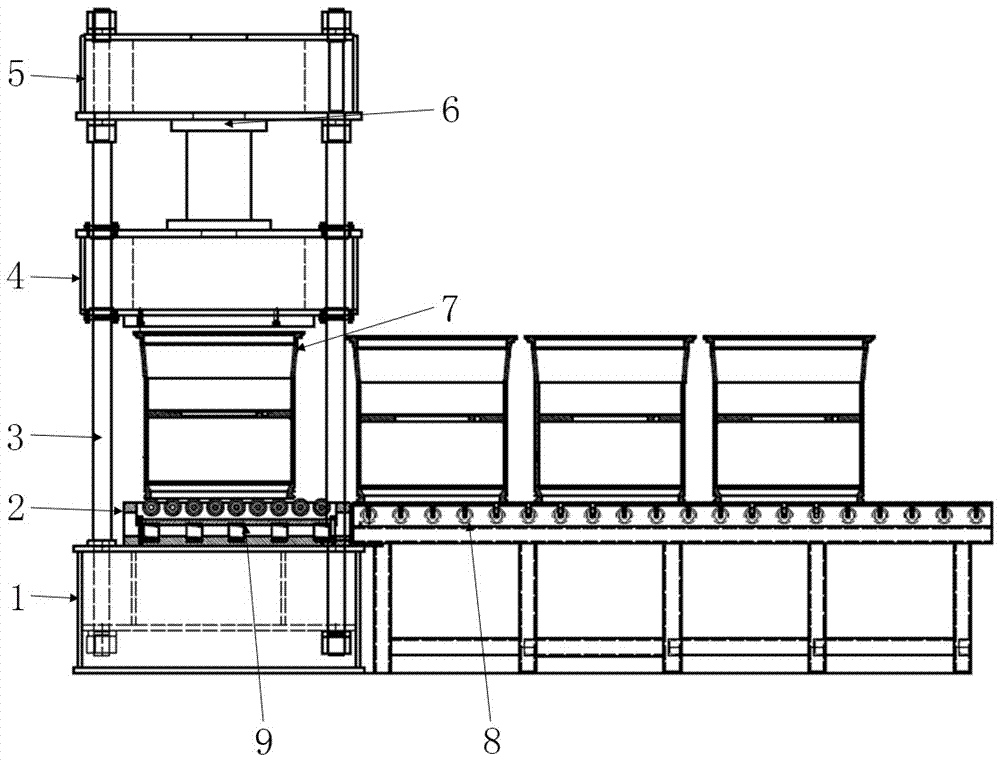

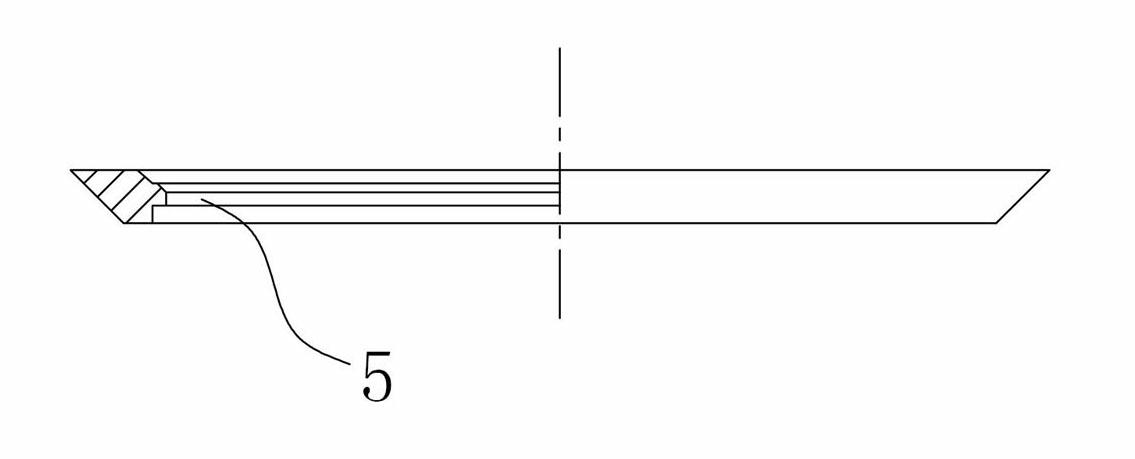

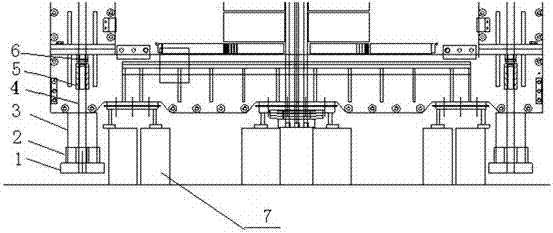

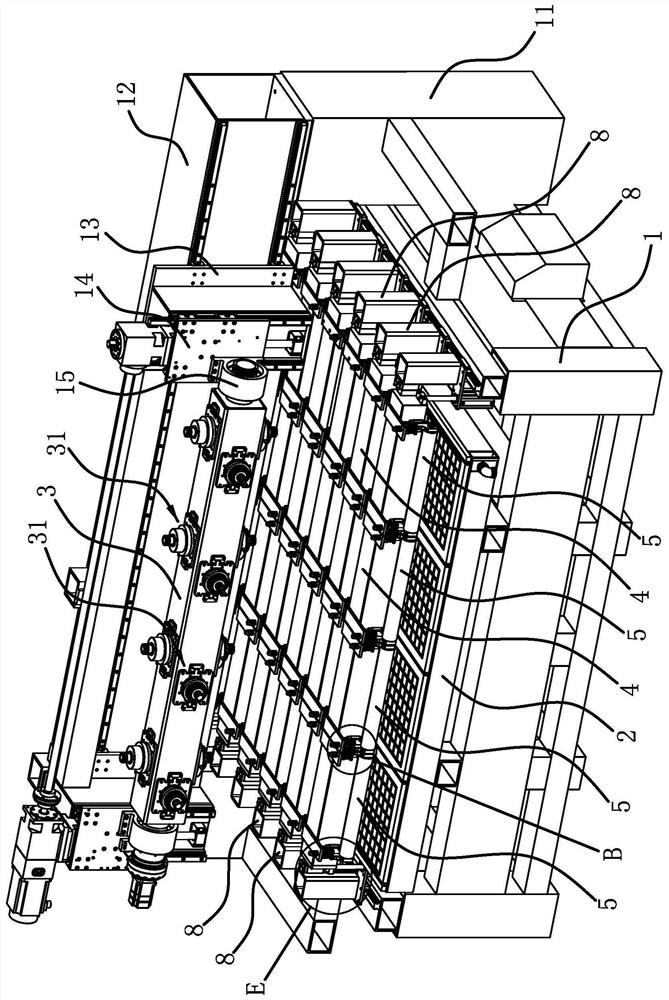

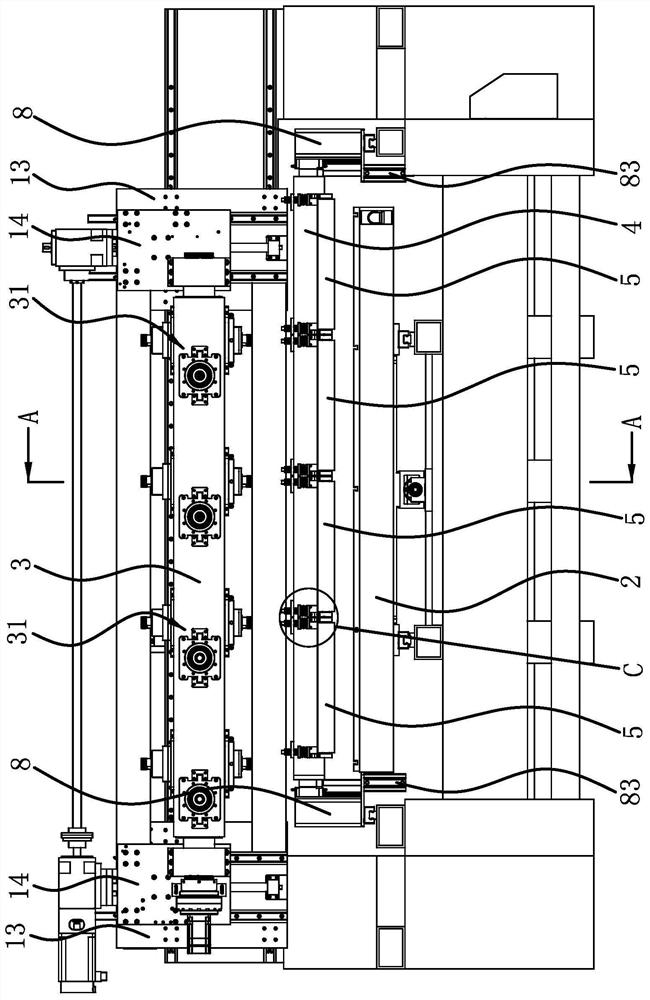

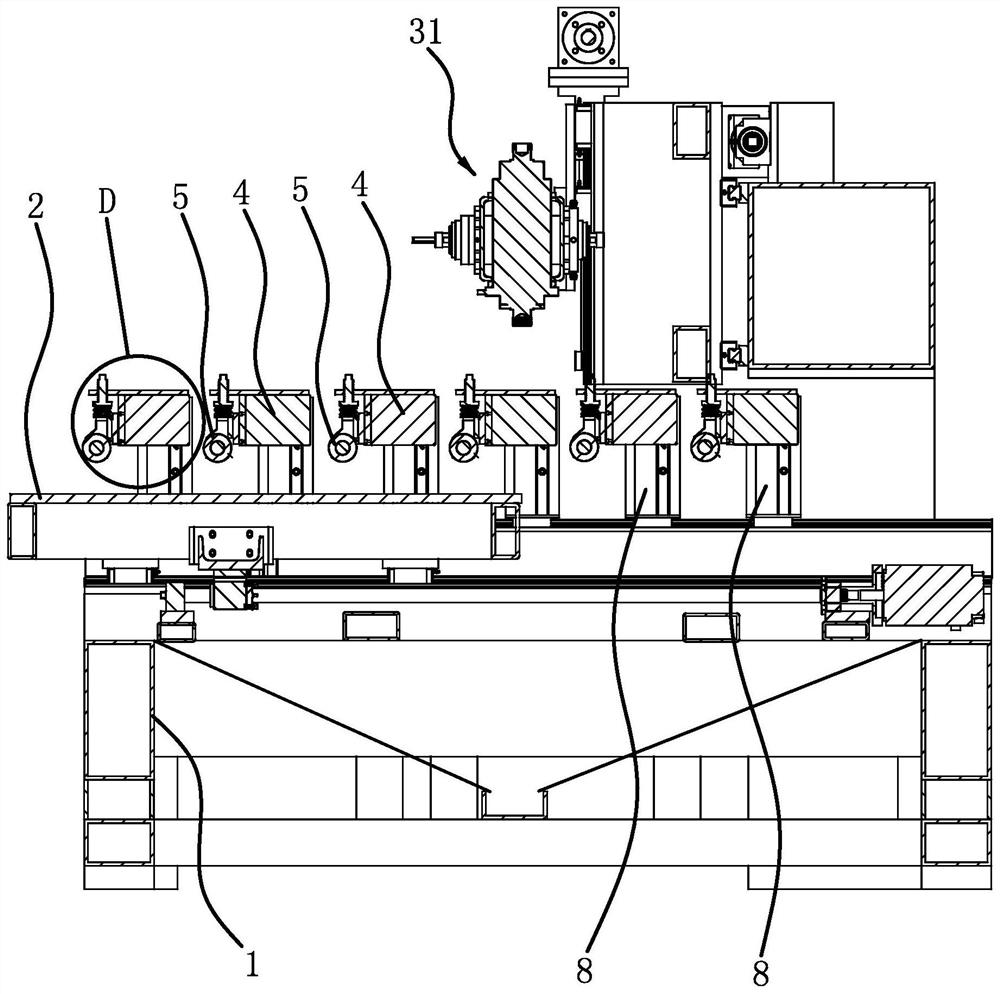

Pipeline type LCD (Liquid Crystal Display) mounting equipment

ActiveCN103698916AConvenient lifting controlReduce in quantityNon-linear opticsConveyor partsLiquid-crystal displayEngineering

The invention relates to pipeline LCD (Liquid Crystal Display) mounting equipment. Products are placed on a vehicle of the equipment, the vehicle completes the operation to flow in a pipeline from the pervious station, a baffle block of an upper pipeline mechanism is driven to descend by a lifting cylinder, so that the vehicle enters the upper part of a jacking correcting mechanism, a limiting baffle block of the jacking correcting mechanism is driven to ascend by the limiting cylinder, after the vehicle is blocked, the product is jacked by a jacking cylinder, CCD of an aligning pressing mechanism begins to shoot and align the product, then the product is sucked and turned over by an overturning mechanism, the product is shot and aligned again by the CCD on the aligning pressing mechanism so as to obtain a compensation value through calculation, then the correction is completed through motion of the jacking correcting mechanism so as to find out an accurate position, the product is put down by the overturning mechanism, at that time the product is pressed by a pressing block of the aligning pressing mechanism and the pressure is kept for a few seconds so as to complete pressing, then the jacking cylinder is descended, and the product is flown away from the pipeline so as to complete the whole operation process of the equipment, and the equipment works in a circulating manner.

Owner:BOZHON PRECISION IND TECH CO LTD

Protective sealing door for underground refuge chamber

ActiveCN102900335AImprove toughnessImprove bindingFireproof doorsConstruction fastening devicesLocking mechanismEngineering

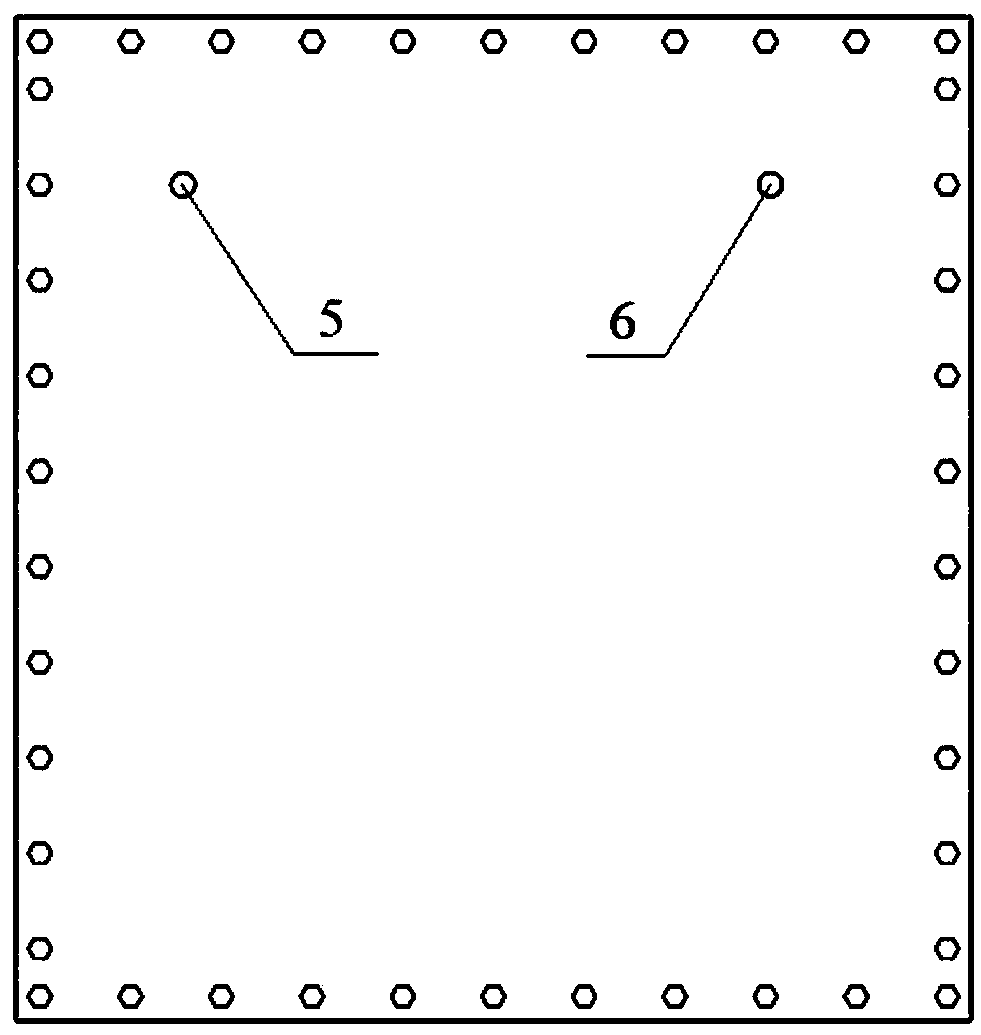

The invention discloses a protective sealing door for an underground refuge chamber. The protective sealing door comprises a door frame and a door plate, wherein the door plate is arranged on the door frame through a rotation shaft; a locking mechanism for locking the door plate on the door frame is arranged on the door plate, a plurality of first reinforcing ribs for reinforcing the strength of the door plate are arranged in the door plate; heat-insulating materials, namely aerogel heat-insulating felts are filled among the reinforcing ribs; at least two annular sealing rings, namely flame-resisting sealing rings are arranged at the joint of the door plate and the door frame; and the periphery of the door plate is locked by the locking mechanism. According to the protective sealing door, the aerogel heat-insulating felts which can bear the temperature of 1,400 DEG C to the maximum are filled in the door plate, so that the door plate can resist high temperature generated during explosion, and the high temperature is insulated out of the refuge chamber; at least two sealing rings which are made of flame-resisting, anti-static, high temperature-resisting and oil-resisting materials are arranged on the contact surface of the door plate and the door frame, so that the protective sealing door has a good sealing effect.

Owner:CCTEG CHINA COAL RES INST

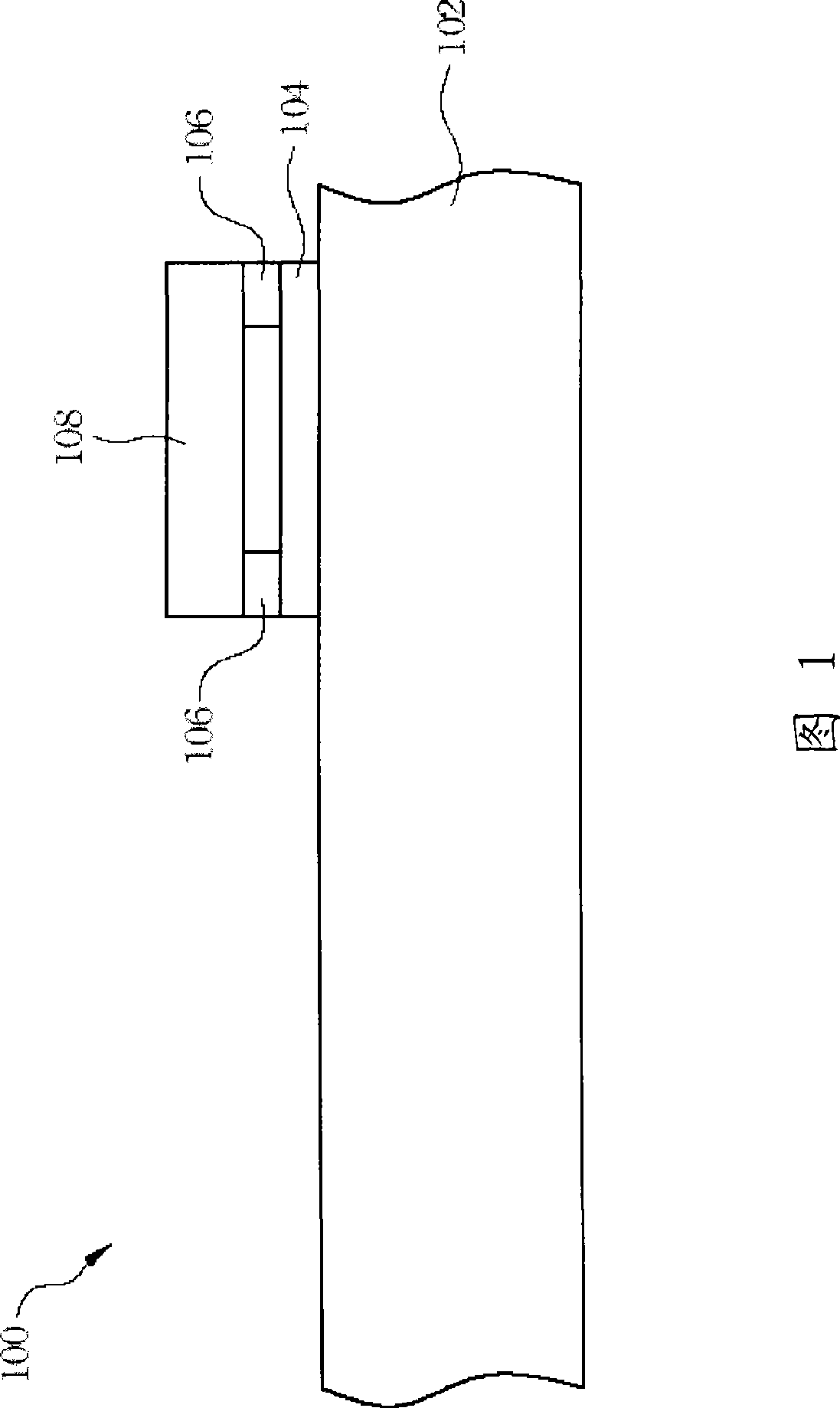

Packaging method and display device

InactiveCN103715371AUniform pressing forceFit tightlySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceIrradiation

The embodiment of the invention provides a packaging method and a display device and relates to the field of display device packaging preparation. The process of the packaging method can be simplified, and the occurrence of the phenomenon that stress is generated inside glass glue when laser beams are irradiated on the glass glue so as to cause poor packaging such as packaging glass cracking or peeling-off can be reduced. The packaging method comprises the following steps: forming a glass glue pattern layer in a packaging area of a first glass substrate; fitting the packaging substrate on which the glass glue is formed onto a device substrate to enable the packaging area of the packaging substrate to be aligned with a packaging area of the device substrate; and irradiating laser on the packaging areas, sintering the glass glue and applying uniform pressing force to the packaging areas during laser irradiation. The packaging method is used in packaging preparation of a display device needing to be isolated from the surrounding environment during packaging.

Owner:BOE TECH GRP CO LTD

Rapidly-and-evenly-pressing pressing plate

InactiveCN104440296AUniform pressing forceReliable compressionPositioning apparatusMetal-working holdersHydraulic cylinderMechanical engineering

The invention relates to the technical field of clamps, in particular to a rapidly-and-evenly-pressing pressing plate. The pressing plate comprises a base, pressing plate bodies, an identical arm lever and a hydraulic cylinder; the hydraulic cylinder is vertically arranged, a piston rod of the hydraulic cylinder upwards extends into the portion, inside the base, of the top end of the hydraulic cylinder, the middle of the identical arm lever is connected with the piston rod of the hydraulic cylinder, the number of the connecting rods and the number of the pressing plate bodies are two, the connecting rods are symmetrically arranged in the base, the bottom ends of the connecting rods are hinged to the end of the identical arm lever, and the top ends of the connecting rods extend out of the upper portion of the base to be hinged to the middles of the pressing plate bodies arranged at the top of the base, the pressing plate bodies are symmetrically arranged at the top of the base and correspond to the connecting rods, the back ends, close to the edge of the top of the base, of the pressing plate bodies are hinged to a seat, a cavity is formed in the portion, corresponding to the identical arm lever, of the interior of the base, hydraulic drive is achieved, the pressing plate bodies run at the same time to press workpieces, operation is convenient, and even pressing is achieved.

Owner:CHANGZHOU JINGYUAN NOISE CONTROL MATERIALS

Substrate holding apparatus and polishing apparatus

ActiveUS20060199479A1Uniform pressing forceUniform polishing ratePolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

The present invention relates to a substrate holding apparatus for holding a substrate (W) such as a semiconductor wafer in a polishing apparatus for polishing the substrate to a flat finish. A substrate holding apparatus comprises a vertically movable member (6), and an elastic member (7) for defining a chamber (22). The elastic member (7) comprises a contact portion (8) which is brought into contact with the substrate (W), and a circumferential wall (9) extending upwardly from the contact portion (8) and connected to the vertically movable member (6). The circumferential wall (9) has a stretchable and contractible portion (40) which is stretchable and contractible vertically.

Owner:EBARA CORP

Single-axis yaw electric bolt tightening machine

ActiveCN102451993ATighten to achieveHigh precisionWind motor assemblySpannersCounterforceTorque sensor

The invention discloses a single-axis yaw electric bolt tightening machine, which comprises a base, a bracket, a revolving servo motor, an encoder, an output revolving shaft, a small belt wheel, a cog belt, a large belt wheel, a revolving shaft, a swiveling jib, a shaft sleeve, a guide post, a housing plate bracket, an electric tightening shaft assembly, a sleeve, a counterforce support plate, a special sleeve, a counterforce sleeve, a servo motor, a torque sensor, an angle sensor and a connecting shaft, wherein the bracket is fixed on the base, and is provided with the revolving servo motor and the encoder; the revolving servo motor is connected with the output revolving shaft; the output revolving shaft is provided with the small belt wheel; the small belt wheel is matched with the large belt wheel through the cog belt; the large belt wheel is connected with the revolving shaft; the guide post is connected with the swiveling jib through the shaft sleeve, and is fixed on the housing plate bracket; and the electric tightening shaft assembly is fixed in the housing plate bracket.

Owner:DALIAN DEXIN M&E TECH ENG

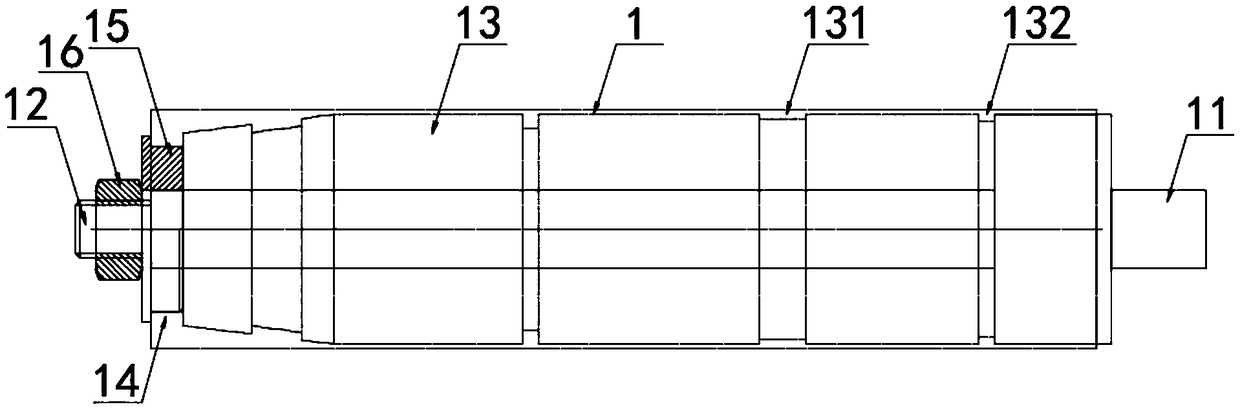

Thin-wall shell processing method

ActiveCN109396766ARestricted degrees of freedomGuarantee quality requirementsWork clamping meansPositioning apparatusEngineeringThermal treatment

The invention discloses a thin-wall shell processing method which comprises a tool clamp, wherein the tool clamp comprises a mandrel; one end of the mandrel is equipped with a mounting column; the outer part of the mandrel is fixedly equipped with an outer ring body in a sleeving mode; a wide ring-shaped slot and a narrow ring-shaped slot are formed in the outer ring body; a step is arranged between one end of the outer ring-shaped body and the mandrel; an auxiliary pressure plate is arranged on the outer part of the step in the sleeving mode; one side of the auxiliary pressure plate is equipped with a nut; and the nut is in threaded connection with the mounting column. The thin-wall shell processing method comprises the following specific steps: step I, outer wall rough turning; step II,high-temperature tempering; step III, left end surface turning; step IV, right end surface turning; step V, clamp mounting; step VI, outer wall fine turning; and step VII, appearance processing. The thin-wall shell processing method performs processing through a high-efficiency machine tool, and a thermal-treatment tempering distressing process is added to release part processing inner stress; andthe necessity of designing a special clamp is combined, so that processing deformation is prevented, and part processing quality requirements are guaranteed.

Owner:河南红宇精密机械有限公司

Press mounting device for locating pin of fly wheel clutch

The invention discloses a press mounting device for a locating pin of a fly wheel clutch. A base is fixedly provided with four vertical posts, the top ends of the four vertical posts are fixed with a top plate, a servo motor is arranged on the top plate, the lower end of an output shaft of the servo motor is connected with the upper end of the lead screw and a feed screw nut on the lead screw is simultaneously fixed with a lifting plate; the lower plate surface of the lifting plate is fixed with a support plate, and the lower end of the vertical section of the support plate is horizontally welded with a press mounting disk; the edge of the press mounting disk is provided with vertical threaded holes, each vertical threaded hole is connected with an outer threaded section of a press mounting rod, and a falling-prevention sleeve is fixed in a blind hole in the lower end of the press mounting rod; a proximity switch is fixedly arranged at a certain side of the press mounting disk, a position detection block matched with the proximity switch is fixed on a cushion plate, a central locating post and 4 locating cushion blocks are arranged at the top surface of the cushion plate and a fly wheel pressing device is arranged at the top surface of the cushion plate. According to the press mounting device for the locating pin of the fly wheel clutch, the locating pin of the clutch can be accurately and quickly pressed in a pin hole of a fly wheel; furthermore, the press mounting device is high in degree of automation and good in reliability; in addition, the press mounting depth can be precisely controlled.

Owner:CHONGQING MINFA AUTOMOBILE FITTINGS

Twin-shaft pitch electric bolt screwing machine

ActiveCN102451994AGuaranteed installation accuracy requirementsNo deformationWind motor assemblyMachines/enginesEngineeringMachine

The invention relates to a twin-shaft pitch electric bolt screwing machine, comprising a substrate front end, a substrate back end, a servomotor, a servo revolving table, a servo feeding sliding table, a pneumatic device, a main machine base, a lifter, a lift adjusting guide post, a support upright post, a lifting platform, an angular adjuster, a bearing platform, a revolving servomotor, an output rotating shaft, a centering device, a rotating arm, a sliding lead screw, a screwing servomotor and an automatic nut fitting and counterforce device. The low-noise vibration-free full automatic twin-shaft pitch electric bolt screwing machine has the advantages of simplicity of operation, high screwing accuracy and equalized pressing force, can remember the position of a rejected product, simultaneously performs screwing operation on diagonal bolts on a pitch instrument, saves time and labor, ensures the installation accuracy of the pitch instrument, and can not cause deformation of the pitch instrument.

Owner:DALIAN DEXIN M&E TECH ENG

Wet type double-clutch unit

ActiveCN104879397AReduce machining tolerancesEasy to processFluid actuated clutchesTransmitted powerEngineering

The invention discloses a wet type double-clutch unit which comprises an odd-numbered shaft clutch and an even-numbered shaft clutch, wherein the two clutches work independently; each clutch comprises a diaphragm spring which is contacted with a hill-like supporting bulge of an axial pressing disc, and the axial pressing disc is forced by deformation of the diaphragm spring to move axially, so that a friction plate below the axial pressing disc is compressed to transmit power to dual discs. The wet type double-clutch unit has the advantages as follows: compression force is transmitted through deformation of the diaphragm springs, and compared with the conventional compression force transmission under hydraulic control, higher response speed is provided during gear shifting; the structure facilitates mounting, and the wet type double-clutch unit has good reliability and fatigue durability.

Owner:华域动力总成部件系统(上海)有限公司

Automatic filling sealing structure for high-pressure valve

The invention relates to an automatic filling sealing structure for a high-pressure valve, which comprises a valve rod filling box body, a valve rod, a filling assembly and a support plate, wherein a difference pressure ring block in a step shaft sleeve structure is coaxially arranged on the valve rod arranged between the support plate and the filling assembly in the filling box body, a gap is formed between the upper plane of the step of the difference pressure ring block and the radial matched surface made in the filling box body, a waveform elastic element is coaxially pressed on the valverod arranged between the difference pressure ring block and the support plate, the filling assembly is coaxially arranged on the valve rod arranged in the filling box body at the inner side of the difference pressure ring block and sequentially comprises a filling pad, woven forming fillings, a filling separation sleeve and forming press ring fillings from top to bottom, the woven forming fillings, the filling separation sleeve and the forming press ring fillings are fixedly assembled. The sealing can be automatically formed under the medium pressure effect, the structure is simple, the effect is obvious, the sealing reliability of the movable sealing position of the valve rod is greatly improved, the filling abrasion can be automatically compensated through the structure, and the sealingpressure of the fillings in the use process is maintained.

Owner:TIANJIN BAILIZHANFA GRP

Boring clamp and operation method thereof

ActiveCN110774027AQuick clampingEffective clampingPositioning apparatusMetal-working holdersStructural engineeringRabbet

The invention discloses a boring clamp and an operation method thereof. The boring clamp includes a clamp body and a pressing ring; the clamp body is provided with a base, and a semi-cylinder structure is fixed and supported on the base; the semi-circular cylinder structure includes an upper end surface, an arc surface and a side end surface; the upper end surface is a workpiece mounting surface;the side end surface is a straightening datum surface; a datum hole is formed in the clamp body; a semi-circular clamp rabbet is machined in the upper end surface; a positioning block on the left sideand a positioning block on the right side are slidably mounted on the upper end surface; the positioning block on the left side and the positioning block on the right side are symmetrical about the center of the clamp rabbet; a plurality of pressing plates are slidably arranged on the upper end surface in the circumferential direction; and the pressing ring is in a semi-circular shape, is mountedon the clamp body through a connecting device and used for clamping the upper end of a workpiece on the clamp body. The boring clamp can realize the quick alignment of the workpiece, and the alignment efficiency is high; and the force of the workpiece is uniform, so that the machining precision is not affected.

Owner:AECC AVIATION POWER CO LTD

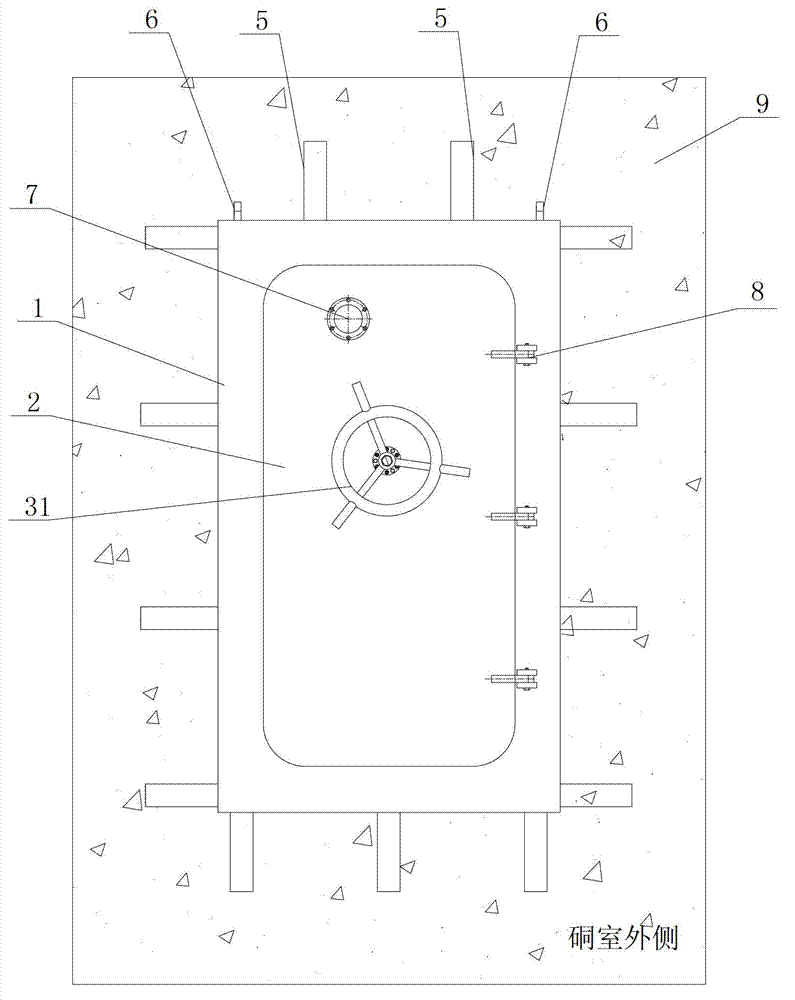

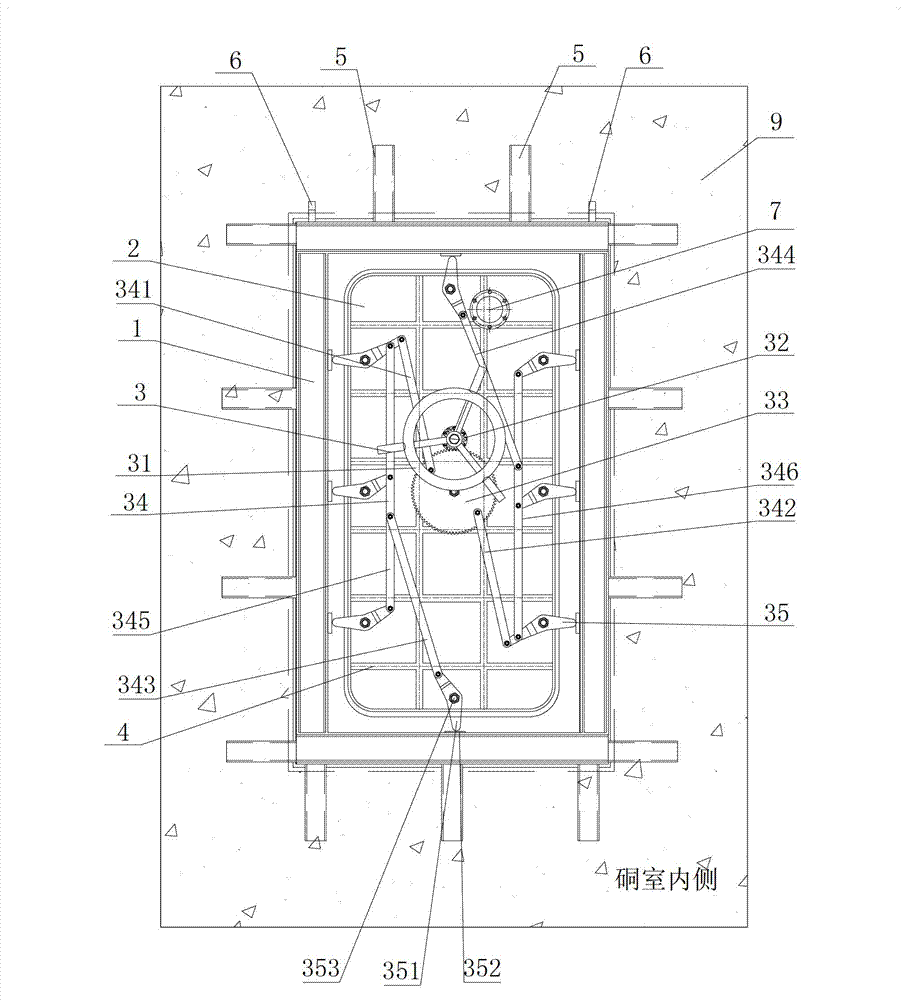

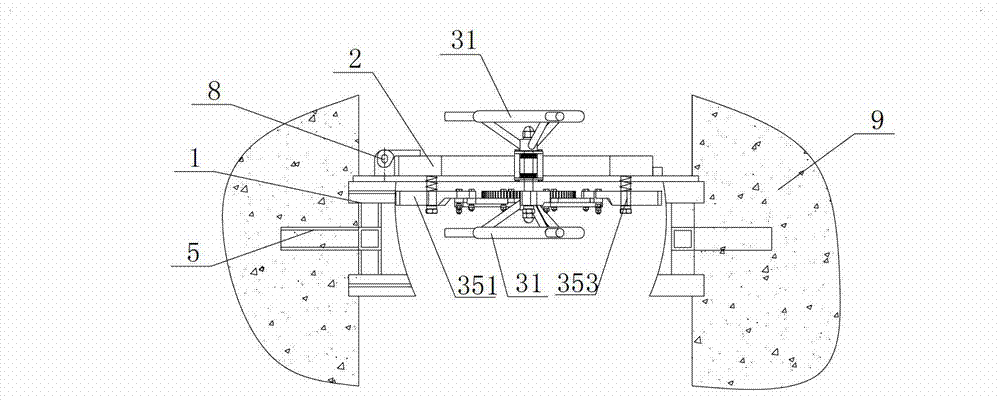

Hand-operated tunnel door structure of test section

InactiveCN104453496APrevent looseningPrevent exitConstruction fastening devicesLocking mechanismEngineering

The invention provides a hand-operated tunnel door structure of a test section. The hand-operated tunnel door structure comprises a door body, a door-spindle connecting rod, a self-locking mechanism base, a handle, a door frame, sealing strips, an inserting pin mechanism and a ratchet self-locking mechanism, wherein the inserting pin mechanism and the ratchet self-locking mechanism are arranged on the frontage of the door body; the inserting pin mechanism comprises first pin-hole bases, second pin-hole bases, inserting pins, connecting rods and a rotating disc; the rotary disc is arranged in the center of the door body; the first pin-hole bases, the second pin-hole bases, the inserting pins and the connecting rods in six groups are uniformly distributed around the door body, wherein each group comprises one first pin-hole bases, one second pin-hole bases, one inserting pins and one connecting rod; one end of each connection rod is connected with the rotating disc, and the other end is articulated with each inserting pin; the inserting pins are arranged in the corresponding first pin-hole base and the corresponding second pin-hole bases and can slide in pin holes of the first pin-hole base and the second pin-hole bases; the first pin-hole bases are fixed on the door body, and the second pin-hole bases are fixed on a tunnel body. The hand-operated tunnel door structure of the test section has a good sealing performance, can be used for sealing the tunnel door easily, conveniently and reliably and has the characteristics of simple structure, low cost, convenience for maintenance and high reliability.

Owner:BEIJING AEROSPACE YISEN WIND TUNNEL ENG TECH

Low-pressure injection molding mold

ActiveCN102975335AReduce manufacturing costSimple structureCoatingsEngineeringElectrical and Electronics engineering

The invention discloses a low-pressure injection molding mold comprising a fixed mold, a mold core, and a surface material pressing mechanism. The mold core is arranged on the fixed mold. The surface pressing mechanism is composed of a plurality of pressing devices. A plurality of recesses are provided around the mold core. The pressing devices are fixedly arranged in the recesses. The pressing devices are composed of limiting blocks, pins, and elastic elements. The limiting blocks are fixedly arranged on the fixed mold. At least one limiting hole is arranged on each limiting block. The pins and the elastic elements are arranged in the limiting holes. One part of the pin extends out of the limiting hole. The elastic elements are arranged below the pins. The other ends of the elastic elements bear against the fixed mold. The mold has the advantages of simple structure, low cost, high product molding qualification rate, and stable and reliable application.

Owner:CHENGDU AEROSPACE MOLD & PLASTIC CO LTD

Lens press mounting device

PendingCN110370002ARealize automatic pressingUniform pressing forceMaterial gluingMetal working apparatusMechanical engineering

The invention discloses a lens press mounting device. The lens press mounting device comprises a machine frame, wherein a bearing frame is installed on the surface of the machine frame, a press mounting air cylinder is vertically installed on the surface of the bearing support, an output end of the press mounting air cylinder vertically stretches downward into the bearing support, a press mountinglifting plate is mounted at the output end of the press mounting air cylinder, a rear housing profiling press mounting plate is arranged on the bottom face of the press mounting lifting plate, a press mounting bearing jig and a drive assembly are arranged on the surface of the machine frame, the press mounting bearing jig and the drive assembly are distributed in a straight line mode, a drive endof the drive assembly is connected with the press mounting bearing jig, and used for driving the press mounting bearing jig to slide on the surface of the machine frame, an expansion board is arranged on the outer side of the machine frame, a pasting jig is arranged on the surface of the expansion board, and a heating slice placing groove is formed in the surface of the pasting jig, and used forassist in achieving pasting of a heating slice and a lens. The lens press mounting device has the advantages of being capable of achieving automatic press mounting of the lens, uniform in press mounting force, good in press fitting effect and high in efficiency.

Owner:SUZHOU INST OF INDAL TECH

Pressing machine

ActiveCN107160153AUniform pressing forcePress-fit quality is reliableVehicle componentsMetal working apparatusEngineeringMechanical engineering

The invention discloses a pressing machine, and relates to the technical field of assembly equipment. The pressing machine comprises an upper beam and a base connected through a guide stand column; a pressing slide table slidingly matched with the guide stand column is arranged between the upper beam and the base; a hydropress is mounted on the upper beam; a piston rod of the hydropress is connected with the pressing slide table; and a positioning tool is mounted on the base. The pressing machine solves the problems of low pressing quality and low production efficiency of steel ring parts in traditional engineering.

Owner:广西泰坦宇翔钢圈股份公司

Pair punching seal sleeve for penetration and connection of tubular product

ActiveCN102121534ASimple structureEasy to manufactureEngine sealsDoor/window protective devicesPunchingMaterial Perforation

The invention discloses a pair punching-hole seal sleeve for penetration and connection of a tubular product. The seal sleeve comprises a seal sleeve body which is of a cylinder shape, wherein the upper end and the lower end of the seal sleeve body are provided with clamping edges which are matched with a pair punching hole; the clamping edge on the upper end of the seal sleeve body is provided with a first pressing block; and the lower end surface of the first pressing block is provided with a soft seal ring which can be pressed to the opening of the upper end of the pair punching hole. The pair punching-hole seal sleeve for penetration and connection of the tubular product has the advantages of good sealing property, simple structure and low cost, and is convenient to manufacture, and is convenient and rapid to install.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

Glass fiber reinforced plastic sandwich laminated board production equipment

PendingCN114274651APrevent springbackUniform pressing forceLamination ancillary operationsLaminationGlass fiberCeramic materials

The invention relates to the field of glass fiber reinforced plastic sandwich boards, in particular to glass fiber reinforced plastic sandwich laminated board production equipment. The technical problem is that after glass fiber fabrics are pressed on a trapezoidal polyurethane plate, due to the fact that the glass fiber fabrics can rebound to a certain extent, after a vacuum film covers the trapezoidal polyurethane plate, air exhaust and pressure reduction are conducted, the fitting degree of the three layers of glass fiber fabrics and the trapezoidal polyurethane plate is poor, and the quality of a finished product is affected. According to the technical scheme, the glass fiber reinforced plastic sandwich laminated board production equipment comprises a bottom frame, a mounting frame, a first fixing frame and the like; a mounting frame and a first fixing frame are fixedly connected to the middle of the upper side of the underframe. When the device is used, glass fiber fabric is automatically laid and pressed, pressing force application is uniform through a first round rod, the quality of a finished product is guaranteed, when the glass fiber fabric is pressed to a trapezoidal polyurethane plate, pre-shaping is conducted by coating resin liquid, the glass fiber fabric is prevented from rebounding, then vacuum film covering is not needed, and the production efficiency is improved. The quality is ensured; meanwhile, the subsequent treatment steps and the production cost are reduced.

Owner:廖广寿

Composite rotary kiln sealing device

ActiveCN105910427AUniform pressing forceGuaranteed uptimeRotary drum furnacesEngineeringConductor Coil

The invention discloses a composite rotary kiln sealing device. The composite rotary kiln sealing device comprises a packing arranged at the joint position of a rotary barrel and the outer wall of a cover in a winding manner. The upper end face of the packing is pressed through a sealing race I, and the outer end face of the packing is pressed through a sealing race II. A pressing plate I is arranged between the sealing race I and the upper end face of the packing. A plate spring I of an arc structure is arranged in an annular cavity between the pressing plate I and the sealing race I. The middle portion of the plate spring I is fixed to the sealing race I, and the two ends of the plate spring I are pressed on the pressing plate I. The sealing race II presses the outer end face of the packing through the side wall connected by one side, a gland is arranged on the other side of the sealing race II, and a rubber sealing ring is arranged in an annular cavity between the side wall of the sealing race II and the gland. A pressing plate II is arranged on the rubber sealing ring in a pressed manner. An arc plate spring II is arranged in an annular cavity between the pressing plate II and the sealing race II. The composite rotary kiln sealing device is high in air tightness, capable of adapting to barrel roundness and radial run-out of a rotary kiln, safe and reliable, and long-term efficient running of the device can be guaranteed.

Owner:CITIC HEAVY INDUSTRIES CO LTD

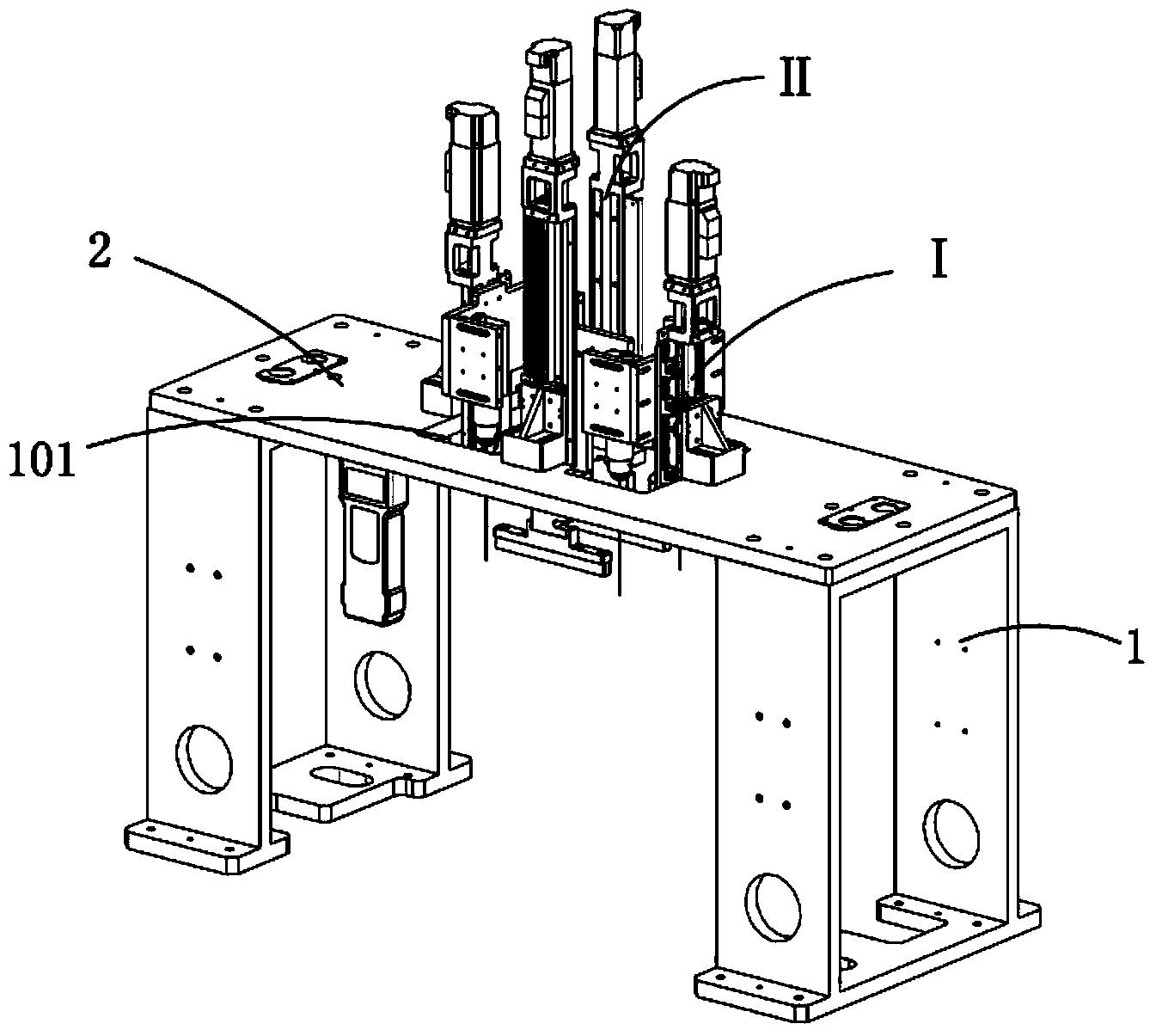

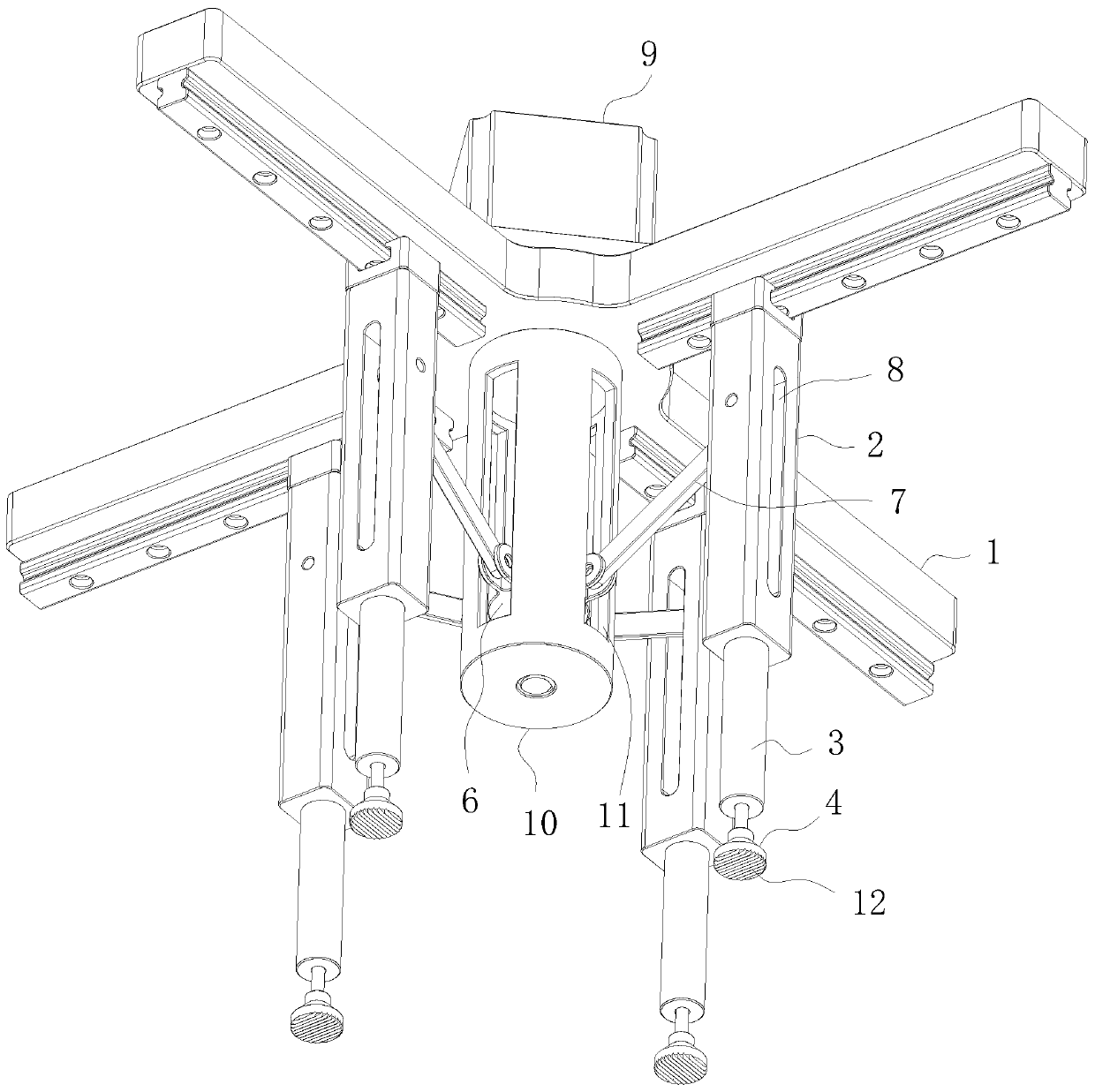

Alignment press-fit mechanism

ActiveCN103706722AAccurate CalibrationUniform pressing forceMetal-working feeding devicesPositioning devicesEngineeringPressure sensor

Owner:BOZHON PRECISION IND TECH CO LTD

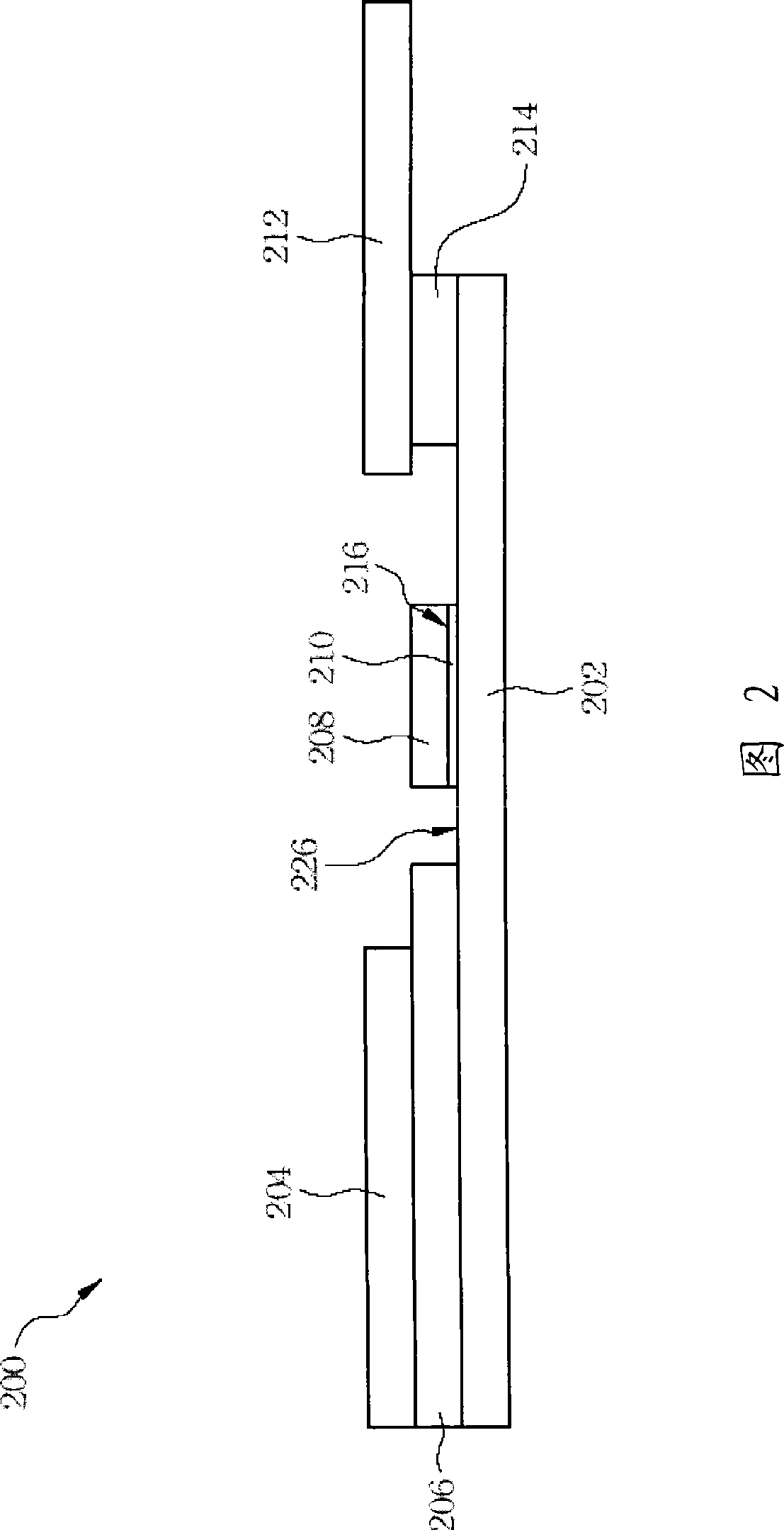

Display device with flip-chip structure

InactiveCN101414583APrevent bad fitImprove uniformitySemiconductor/solid-state device detailsSolid-state devicesDisplay deviceEngineering

The invention discloses a display device with a flip-chip structure, the display device at least comprises a first substrate and at least one integrated circuit chip which is arranged on the first substrate, wherein, a plurality of connecting bumps are arranged on one surface of the integrated circuit chip, the connecting bumps are connected between the integrated circuit chip and the first substrate; and the display device also comprises at least one Dummy Bump which is clamped between the integrated circuit chip and the first substrate for balancing the distribution of the connecting bumps on the surface of the integrated circuit chip.

Owner:INNOLUX CORP +1

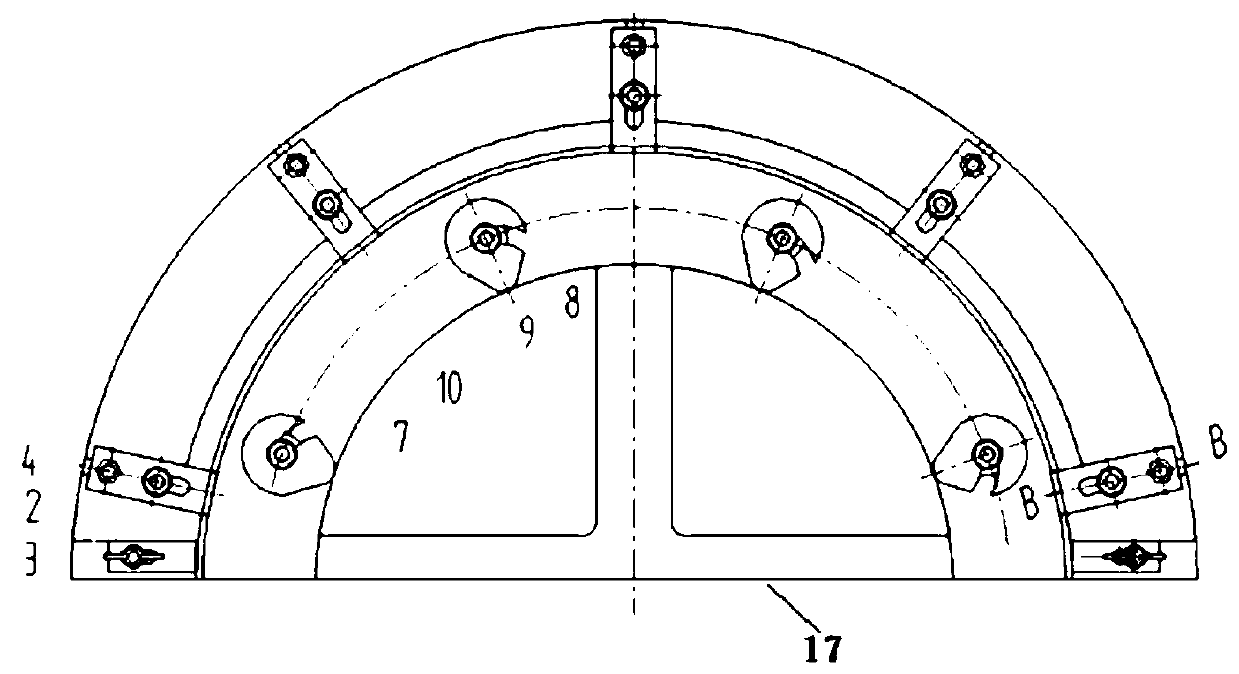

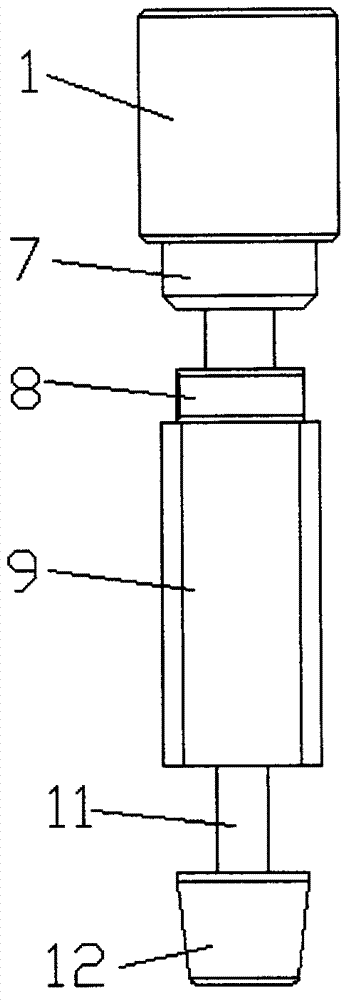

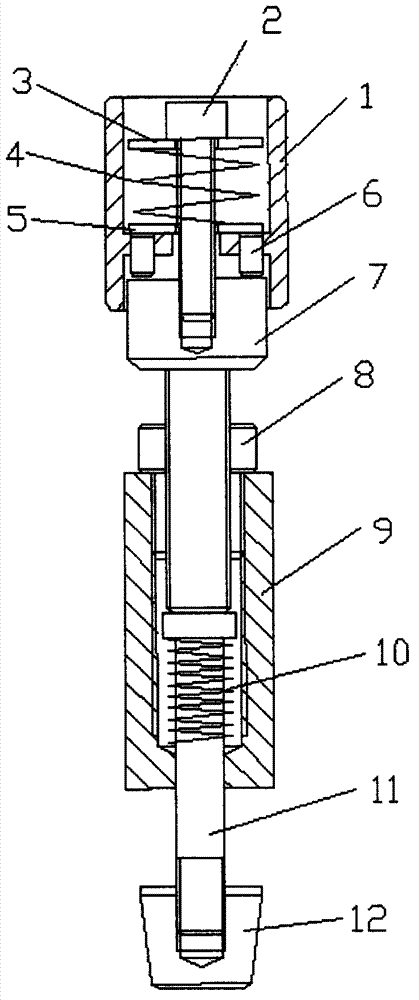

Combined type ultrasonic-eddy current detection probe clamping structure

ActiveCN104749244AImprove fitUniform pressing forceMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial magnetic variablesCoaxial cableCoupling

The invention belongs to a nuclear power station primary loop system and the field of the nondestructive testing technology in other industries and in particular relates to a combined type ultrasonic-eddy current detection probe clamping structure. The combined type ultrasonic-eddy current detection probe clamping structure comprises a base body structure and a probe driving four-link mechanism, wherein the base body structure comprises a water level measurement ultrasonic wave normal probe (1), a miniature coaxial cable socket (3), a guide housing (4), a cable socket mounting base (5), a probe cable and a miniature coaxial cable plug (10), a multi-core cable plug (17) and a coaxial cable bundle (18); the probe driving four-link mechanism comprises a compressed spring nut (6), a compression spring (7), an upper part compression ring (8), a probe lining plate (9), a core pipe (11), a novel combined probe (12), a connecting rod (13), an ejection rod (15) and a base (20). The combined type ultrasonic-eddy current detection probe clamping structure has the beneficial effects that the detection probe and the surface of a detected object are enabled to be fitted well, the compression force is enabled to be uniform, the probe is tightened up and is enabled not to be damaged when in installation, water-leaching coupling water is guaranteed to be sufficient and superfluous water is prevented from overflowing.

Owner:CHINA NUCLEAR POWER OPERATION TECH +1

Air cannon high-speed impact test tool for composite material plate and application method thereof

The invention discloses an air cannon high-speed impact test tool for a composite material plate and an application method thereof. The test tool comprises a test base, a test piece placement platformand an overturning buckle plate; a sliding rail is arranged at the bottom of the test base, the test piece placement platform is rotatably arranged on the test base, and a first test piece test window is formed in the test piece placement platform; runway grooves are formed in the two sides of the first test piece testing window, test piece fixing assemblies are arranged on the runway grooves ina sliding mode, one end of an overturning buckle plate is hinged to the test piece containing platform, the other end of the overturning buckle plate is detachably connected with the test piece containing platform, and a second test piece testing window is formed in the overturning buckle plate. A pressing frame is arranged on the inner side of the overturning buckle plate. The test tool is simplein structure and convenient to operate, the impact angle and the impact position of the test piece can be conveniently adjusted, a new test piece can be conveniently replaced, flexible posture adjustment of the test piece is achieved, and the test precision and the test efficiency of the test piece are improved.

Owner:CENT SOUTH UNIV

Wire feeding device

The invention relates to the field of welding equipment, in particular to a wire feeding device. A wire feeding device, comprising a frame, the frame is provided with a frame groove, the frame groove is provided with a cover plate, and a wire feed wheel is arranged in the frame groove, and the wire feed wheel is set On the output shaft of the motor, a pressing mechanism is provided on one side of the frame groove, and the pressing mechanism includes a pressing wheel frame, a pressing wheel, an adjusting differential head and a pressing block, and the adjusting differential head and the pressing wheel frame The bumps on the top are connected, the pressure roller frame is set in the groove at the bottom of the pressure block, and can slide along the length direction of the pressure block, the pressure wheel frame is provided with a pinch wheel, and the pinch wheel Corresponding to the wire feed roller, the welding wire is sandwiched between the wire feed roller and the pressing roller, and a wire feeder and a wire outlet are also provided on the upper and lower side walls of the frame groove. The invention provides a wire feeding device with good wire feeding stability, high production efficiency and good applicability.

Owner:苏州嘉孚朗自动化设备有限公司

High-capacity electric reactor multi-point pressing method and device

InactiveCN103943349APrevent core deformationSimple structureTransformers/inductances magnetic coresInductances/transformers/magnets manufactureNuclear engineeringLarge capacity

The invention relates to a high-capacity electric reactor multi-point pressing method and device and belongs to the technical field of high-capacity electric reactor devices. The technical scheme is that the device comprises a cross beam (3) and a pull rod extending device, wherein U-shaped notches (8) are arranged at two ends of the cross beam (3), the pull rod extending device comprises a nut (1), a screw (4) and a threaded sleeve (5), the screw (4) penetrates the U-shaped notches (8) at two ends of the cross beam (3), one end of the screw (4) is arranged in the threaded sleeve (5), the nut (1) is arranged at the other end, and the threaded sleeve (5) is connected with a fixing nut (6) though an electric reactor iron core pull rod. The position between an electric reactor iron core foot pad and the ground is leveled up by using a supporting cushion block, the nut is higher than the ground for a certain height, a hydraulic oil cylinder is started, an electric reactor iron yoke clamp is pressurized through the cross beam, and the fixing nut of the electric reactor iron core pull rod is locked after authorised pressure is reached. The pressing force is even, and an electric reactor iron core can be effectively prevented from deforming.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

Torsional pressing clamp structure

The invention discloses a torsional pressing clamp structure which comprises a tightening handle, an inner hexagon screw, an upper gasket, a first spring, a lower gasket, a limiting pin, a pressing threaded rod, a threaded bushing, a pressing mechanism support, a second spring, a pressing-head connecting rod and a pressing head. The rod of the inner hexagon screw is sleeved on the upper gasket, the first spring, the lower gasket and the upper end surface of the pressing threaded rod in sequence; the tightening handle is sleeved at the periphery of the inner hexagon screw, the upper gasket, the first spring, the lower gasket and the upper end of the pressing threaded rod; the limiting pin is located between the compressing threaded rod and the lower gasket and fixedly arranged on the tightening handle; the upper end surface of the pressing threaded rod is provided with a stop structure; the pressing threaded rod is sleeved in the threaded bushing and the pressing mechanism support in sequence through thread engagement; the lower end of the pressing threaded rod is connected with the second spring, the pressing-head connecting rod and the pressing rod in sequence. The torsional pressing clamp structure is easy to operate and can be used for pressing appropriately and uniformly.

Owner:ROYAL GAUGE IND

Woodworking machining center

PendingCN111958710AAvoid damageGuaranteed stabilityMulti-purpose machinesStructural engineeringMechanical equipment

The invention provides a woodworking machining center, and belongs to the technical field of mechanical equipment. The woodworking machining center solves the problem that an existing woodworking machining center is poor in stability of synchronously pressing and positioning a plurality of workpieces. The woodworking machining center comprises a rack and a machining platform horizontally arrangedon the rack, the rack is connected with a lifting frame capable of ascending and descending, the lifting frame is in a long strip shape and is arranged above the machining platform, the lifting frameis connected with a plurality of pressing rollers, the pressing rollers are sequentially arranged in the length direction of the lifting frame, and the lower portions of the pressing rollers are lowerthan the lower portion of the lifting frame; the multiple pressing rollers can independently ascend and descend relative to the lifting frame, and elastic pieces capable of enabling the pressing rollers to have the downward movement trend are arranged between the multiple pressing rollers and the lifting frame. The woodworking machining center is good in stability of synchronously pressing and positioning a plurality of workpieces.

Owner:吴善旺

Double-layer sealing bypass valve with air-tight device

ActiveCN107084251AGuaranteed tightnessGuaranteed isolation effectSpindle sealingsOperating means/releasing devices for valvesPositive pressureEngineering

The invention relates to a double-layer sealing bypass valve with an air-tight device. A valve body (3) is mounted on an air flue top plate (14) through a valve base (13), a filler sealing device (4) is mounted on the valve base (13) and an upper air flue partition plate (15), and a first valve plate (6), a compression elastic element (7) and a second valve plate (8) are mounted on a connecting rod (2); an air cylinder (1) is mounted on the valve body (3), the connecting rod (2) is connected with the air cylinder (1) and penetrates through the filler sealing device (4) under acting force of the air cylinder (1) to drive the first valve plate (6), the compression elastic element (7) and the second valve plate (8) to vertically move; and a hollow sealing ring (9), an inclined face sealing face (11) and a guiding device (12) are mounted on an air pipe (10) to form a double-layer sealing structure, an air-tight pipeline (5) communicates with the air pipe (10), and under the valve-closed state, compressed air enters the enclosed space formed by the air pipe (10), the first valve plate (6) and the second valve plate (8) through the air-tight pipeline (5) so as to form a positive-pressure chamber, and thus the air-tight effect is achieved. According to the double-layer sealing bypass valve with the air-tight device, zero leakage of an air flue bypass pipeline can be achieved, which is a prerequisite for dust removal equipment to achieve ultra-clean emission.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

Test device for working pressure inspection of thin hydraulic rubber capsule and test method thereof

ActiveCN109556966AAvoid influence of test resultsUniform pressing forceMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesHydraulic pumpTest fixture

The invention provides a testing device for working pressure inspection of a thin hydraulic rubber capsule and a test method thereof. The test device for working pressure inspection of the thin hydraulic rubber capsule includes a pressure bearing box, a top cover clamping plate, a base clamping plate and an auxiliary device. The pressure bearing box is placed in a center position between the top cover clamping plate and the base clamping plate through the auxiliary device, and is fastened and pressed by bolt fasteners passing through the corresponding bolt holes of the upper and lower clampingplates. The top cover clamping plate is provided with a pressure test hole and a pressure-filling hole, the pressure test hole is connected with the pressure meter, and the pressure-filling hole is externally connected with a hydraulic pump. The invention can carry out a pressure-filling test on the thin hydraulic rubber capsule, so as to test whether the capsule can reach a designed working pressure and keep the working state stable; and meanwhile, the invention can measure the maximum working pressure of the capsule, and check the tightness of the contact joints of each component.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Electronic plate cutting machine assembly

InactiveCN110605758AHigh mobile synchronization accuracyGuaranteed positioning accuracyGripping devicesClamping devicesBall screwEngineering

The invention relates to the technical field of plate cutting machines, in particular to an electronic plate cutting machine assembly. The electronic plate cutting machine assembly comprises a mounting plate, sliding seats, air cylinders, pressing blocks and a driving device; and the driving device comprises a ball screw, a screw nut, a hinge rod and a transmission piece. The electronic plate cutting machine assembly has the beneficial effects that the driving device drives the four sliding seats to move relatively, namely, relatively close to and far away, so that the pressing positions of the four pressing blocks can be adjusted, the device is suitable for cutting a wood plate in a large area range, the compatibility of equipment is improved, the operation efficiency is improved, in addition, the structure is simple, the manufacturing cost is low, the moving synchronization precision of the four sliding seats is high, and the position precision of the four pressing blocks is guaranteed, in addition, the pressing positions of the four pressing blocks on the wood plate can ensure that the four pressing blocks are symmetrically arranged with the appearance of the wood plate, so thatthe pressing force on the wood plate is uniform, the phenomenon that the wood plate is stressed unevenly to cause swings when the wood plate is cut is avoided, and the influence on the cutting quality is avoided.

Owner:合肥恒业家具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com