Torsional pressing clamp structure

A technology of stop structure and pressing mechanism, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of difficult control and adjustment of the clamping force of the clamp, and achieve simple structure, uniform pressing force and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following examples, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

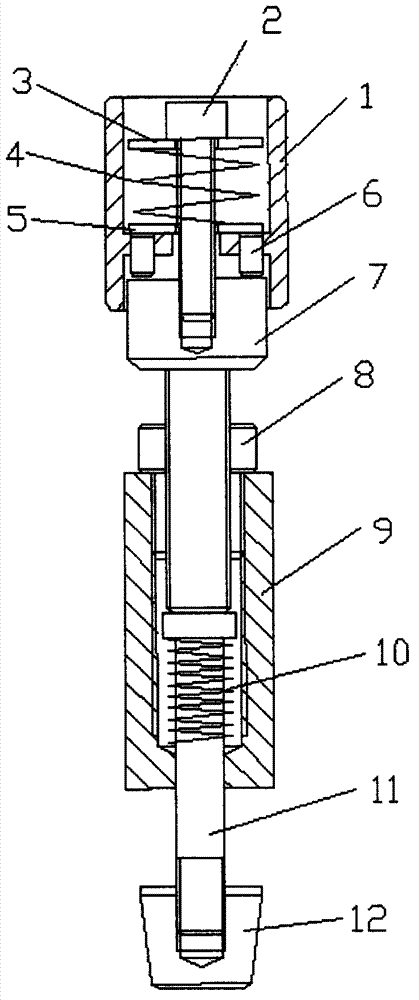

[0020] A torsion clamp structure, such as figure 1 , 2 As shown, it includes: tightening handle 1, inner hexagon screw 2, upper gasket 3, first spring 4, lower gasket 5, limit pin 6, compression threaded rod 7, threaded bushing 8, compression mechanism bracket 9 , the second spring 10, the pressure head connecting rod 11 and the pressure head 12, the screw rod of the hexagon socket screw is sequentially set in the upper end surface of the upper gasket, the first spring, the lower gasket and the compression threaded rod and is connected with the The upper end of the compression threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com