Full-automatic aluminum alloy casement window hinge drilling machine

A hinge drilling, fully automated technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problems of reducing production efficiency, wasting labor and labor efficiency, increasing processing costs, etc. , to achieve the effect of improving product quality, reducing labor costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

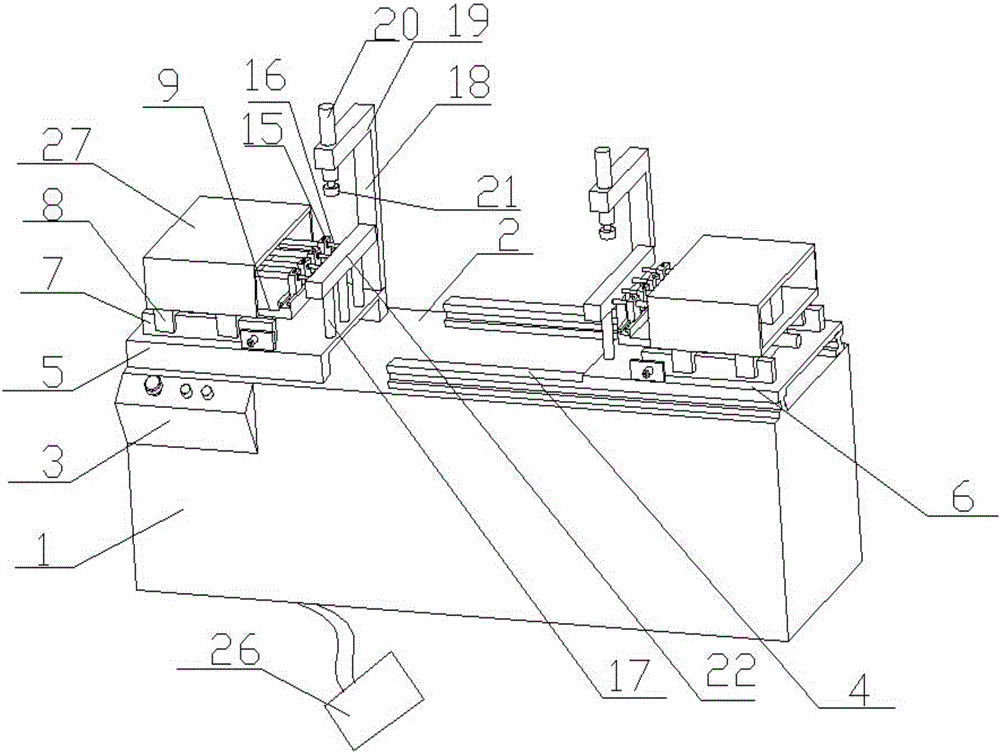

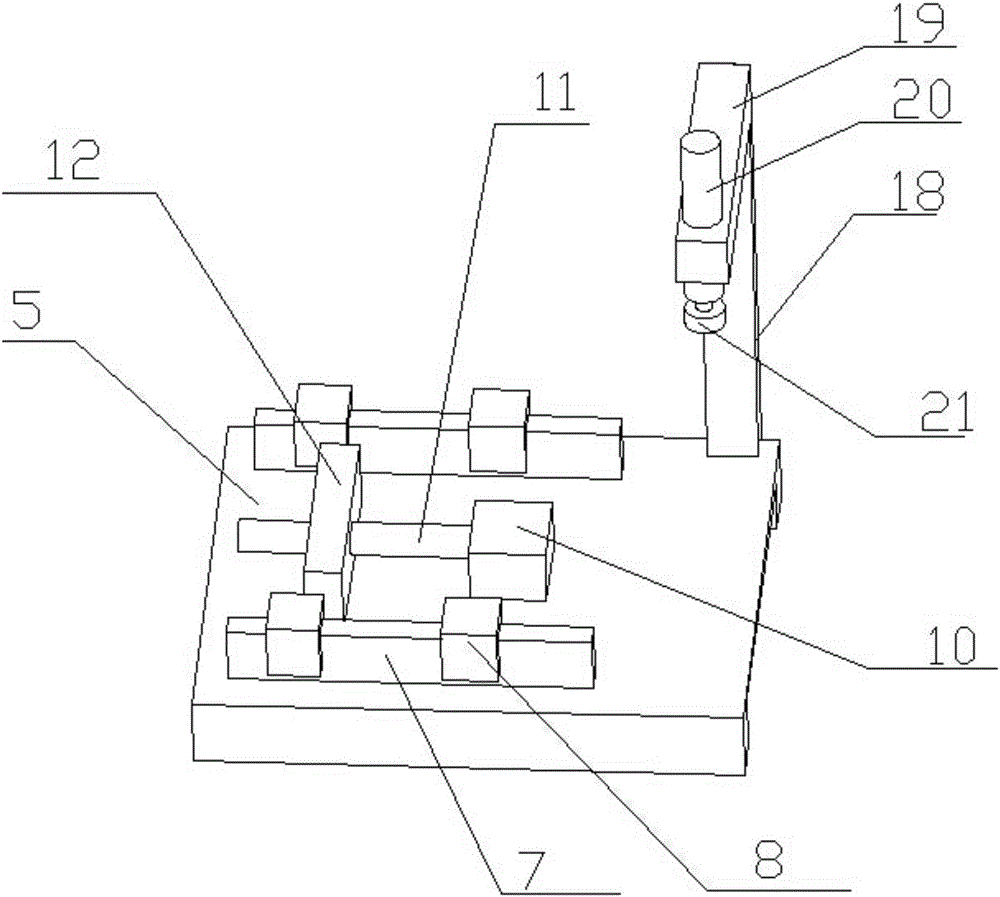

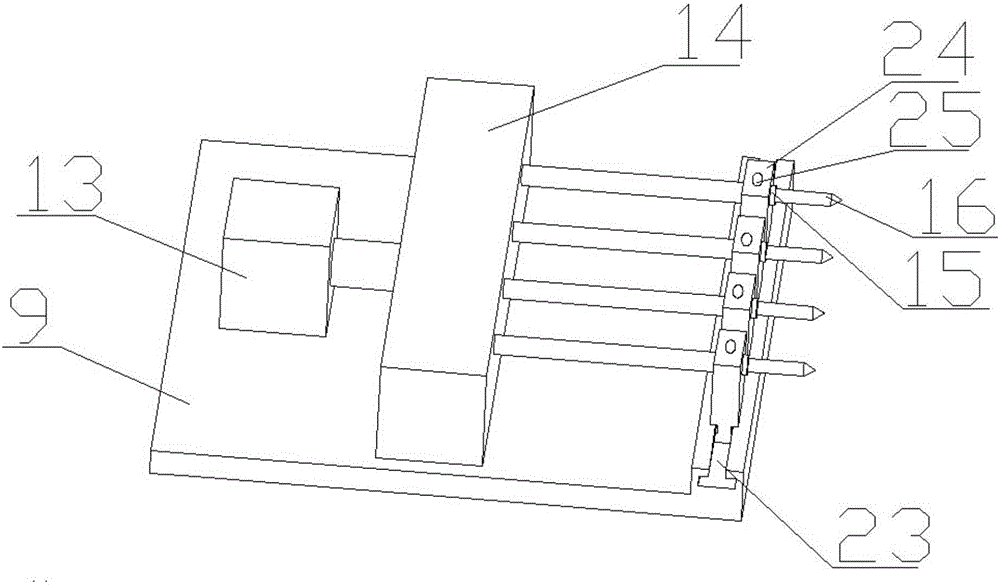

[0020] figure 1 , figure 2 , image 3 with Figure 4 The specific embodiment of the present invention is shown: a fully automated aluminum alloy casement window hinge drilling machine, comprising a frame 1 and a workbench 2 installed on the frame 1, and the frame 1 is provided with a control switch 3, One end of the workbench 2 is provided with a left drilling device, the other end is provided with a right drilling device, one end of the workbench is provided with a long slide rail 4, the left drilling device and the right drilling device respectively include a left The fixed plate 5 and the right fixed plate 6. The right fixed plate 6 is arranged on the long slide rail 4 and can be moved on the long slide rail 4. The left fixed plate 5 and the right fixed plate 6 are respectively provided with fixed slide rails 7. A slider 8 is provided on the fixed slide rail 7, a support plate 9 is provided on the slider 8, and the left fixed plate 5 and the right fixed plate 6 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com