Automatic press-fit detecting device for sensor

A technology of testing equipment and sensors, which is applied in the direction of instruments, measuring devices, and measuring electrical variables, etc., can solve problems such as defective products entering the market, affecting later use, and degumming of sensor belts, so as to save manpower, improve production efficiency, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

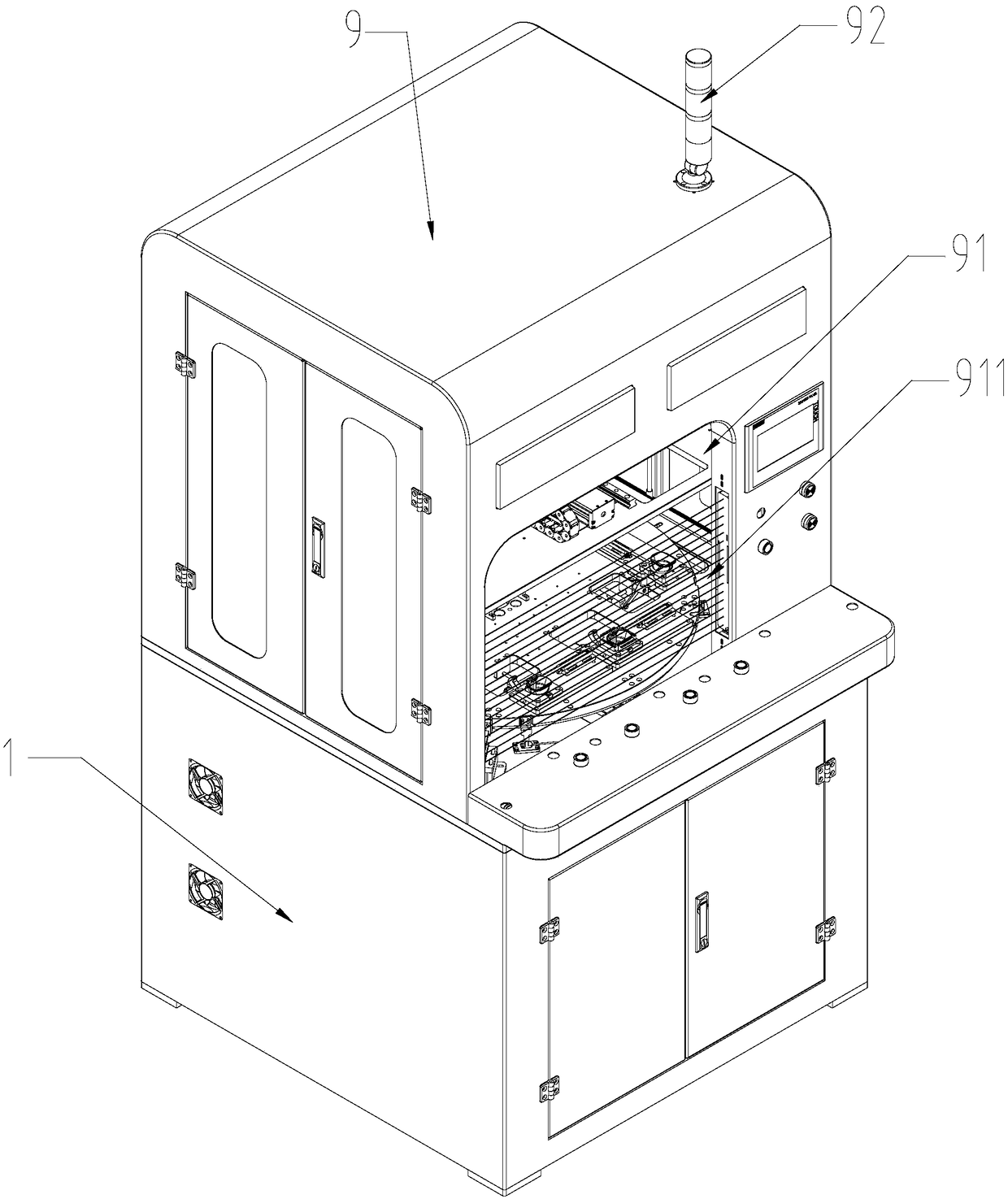

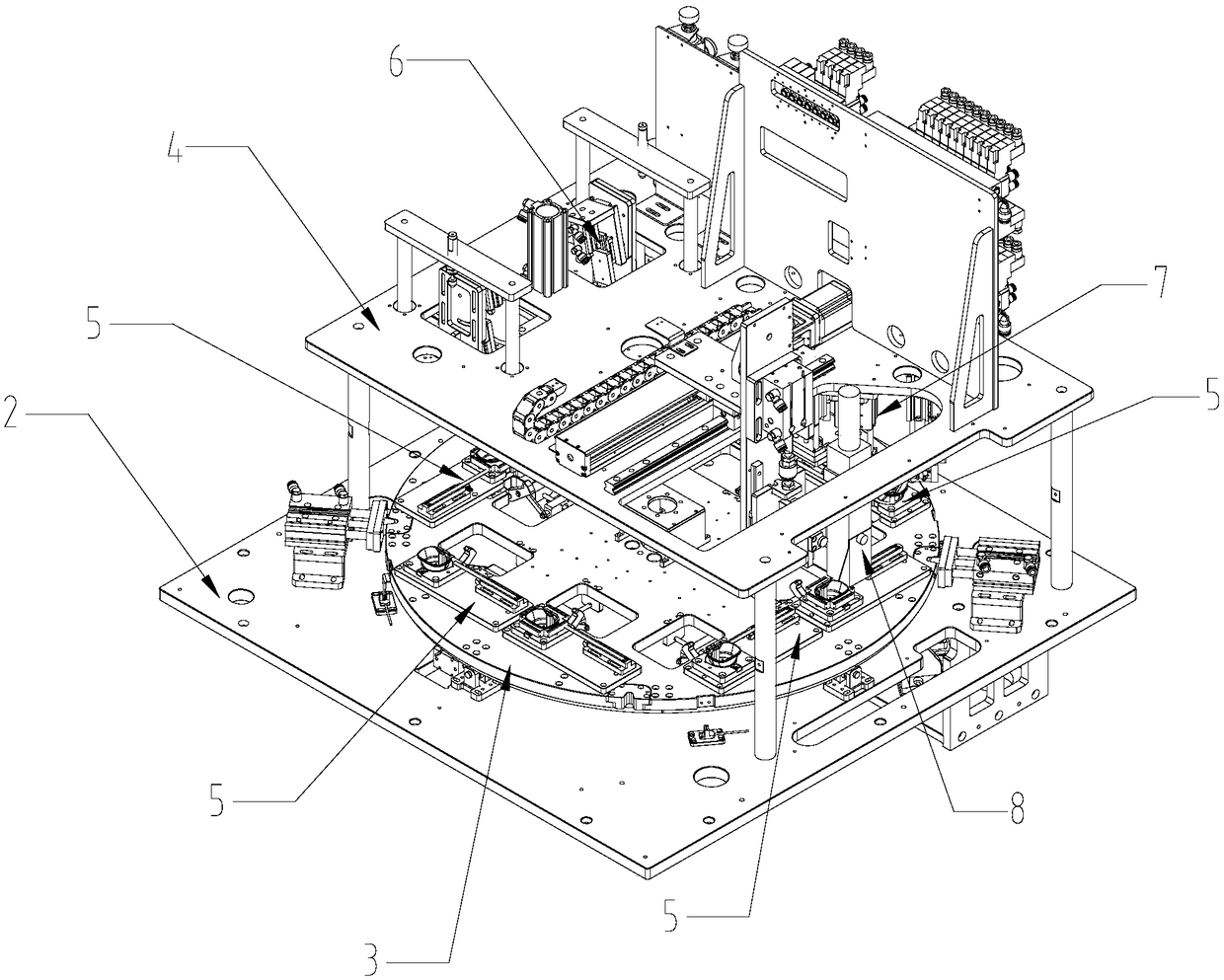

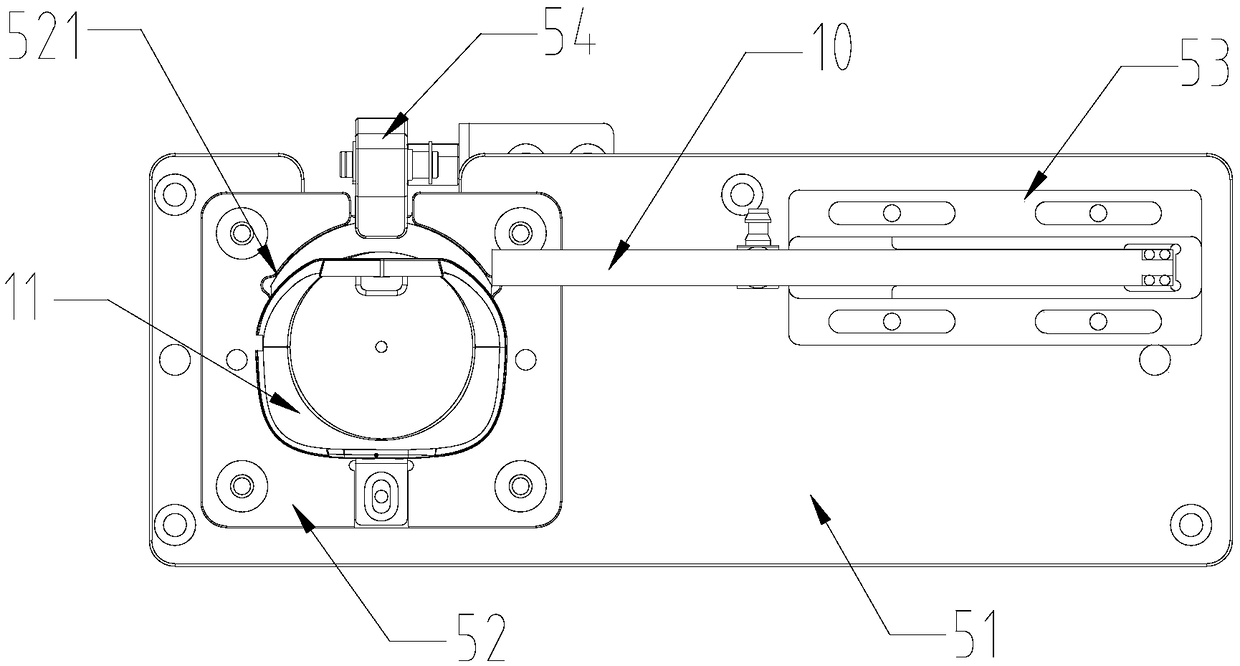

[0032] Embodiment 1: refer to figure 1 and figure 2 As shown, a sensor automatic pressure detection equipment includes a lower frame 1, a workbench 2 arranged on the lower frame 1, and a rotating disk 3 and a mounting bracket 4 arranged on the workbench 2; Four groups of profiling positioning mechanisms 5 are arranged on the disk 3 in equal parts, and a clamping and pressing mechanism 6, a performance testing mechanism 7 and a coding mechanism 8 are arranged on the mounting bracket 4, and the rotating disk 3 drives the profiling positioning mechanism on it. 5 rotates according to a circular trajectory, and the clamping and pressing mechanism 6, the performance testing mechanism 7 and the coding mechanism 8 are located above the circular trajectory, when the profiling positioning mechanism 5 rotates to the clamping and pressing mechanism 6, the performance testing mechanism 7, When the position of the coding mechanism 8 is below, pressing, testing and coding operations are ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com