Multifunctional assembling rotary pressing machine and pressing method thereof

A pressing machine, multi-functional technology, applied in the direction of material gluing, mechanical equipment, metal processing, etc., can solve the problems of low efficiency of pressing and assembly, and achieve the effect of avoiding testing and inspection, smooth movement, and small resistance to movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

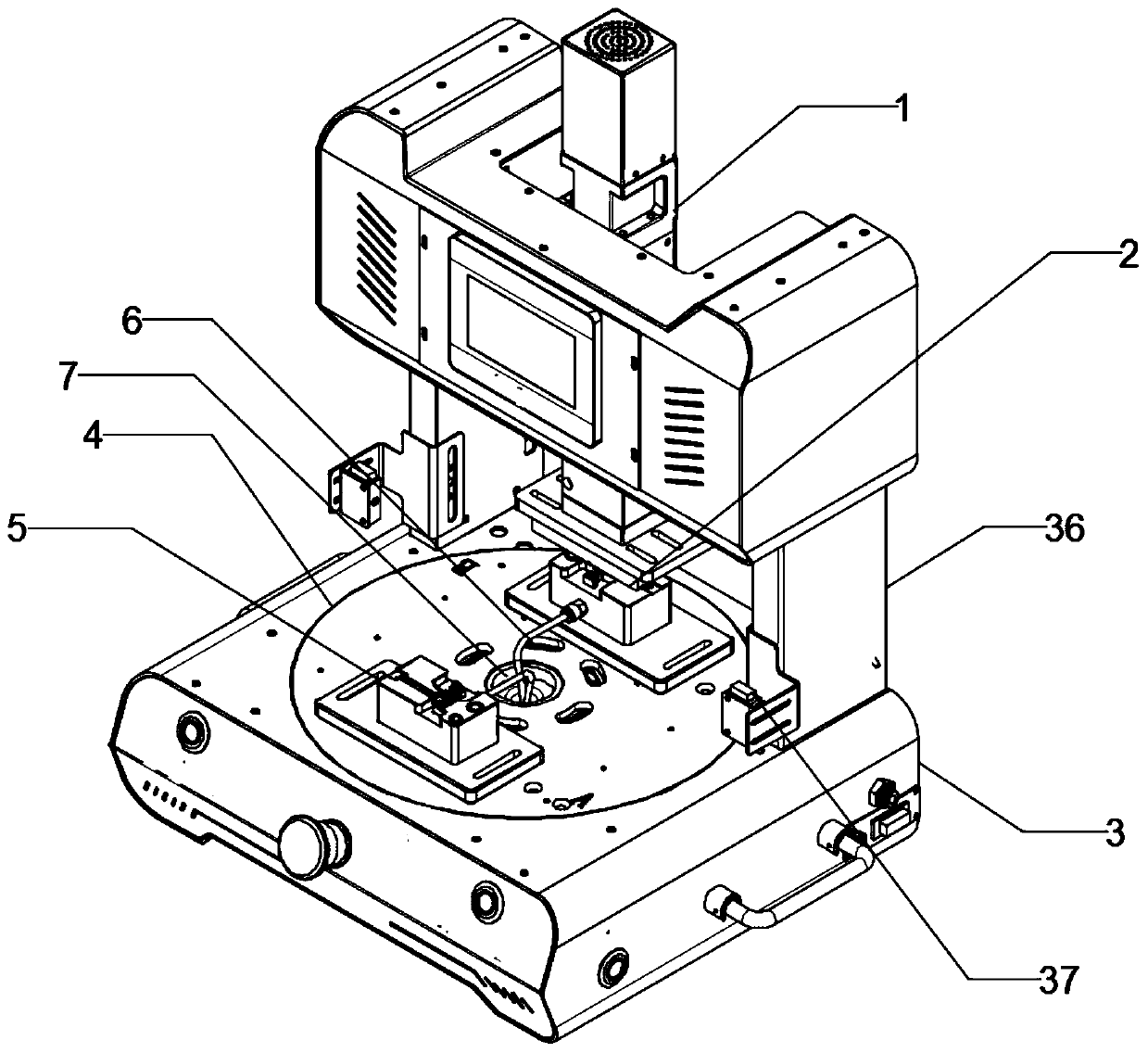

[0049] A multifunctional assembled rotary pressing machine, including a feeding part and the pressing part located directly above the feeding part, wherein:

[0050] The pressing part includes a Z-axis linear lifting device 1 and a pressure head 2 fixed on the driving end of the Z-axis linear lifting device 1;

[0051] The feeding part includes a base 3, a turntable 4 assembled on the base 3 through a bushing 7, two positioning tools 5 symmetrically fixed on the turntable 4, and a device for driving the bushing 7. The driving device for the connecting shaft to perform 180° reciprocating rotation, the vacuum pipeline 6 that passes through the hollow cavity of the connecting shaft and communicates with the adsorption hole on the positioning tool 5, wherein the turntable 4 is fixed on the connecting shaft top.

[0052] The pressing method of the rotary pressing machine: place the workpiece to be pressed on the positioning tool A, start the vacuum system connected with the vacuum...

Embodiment 2

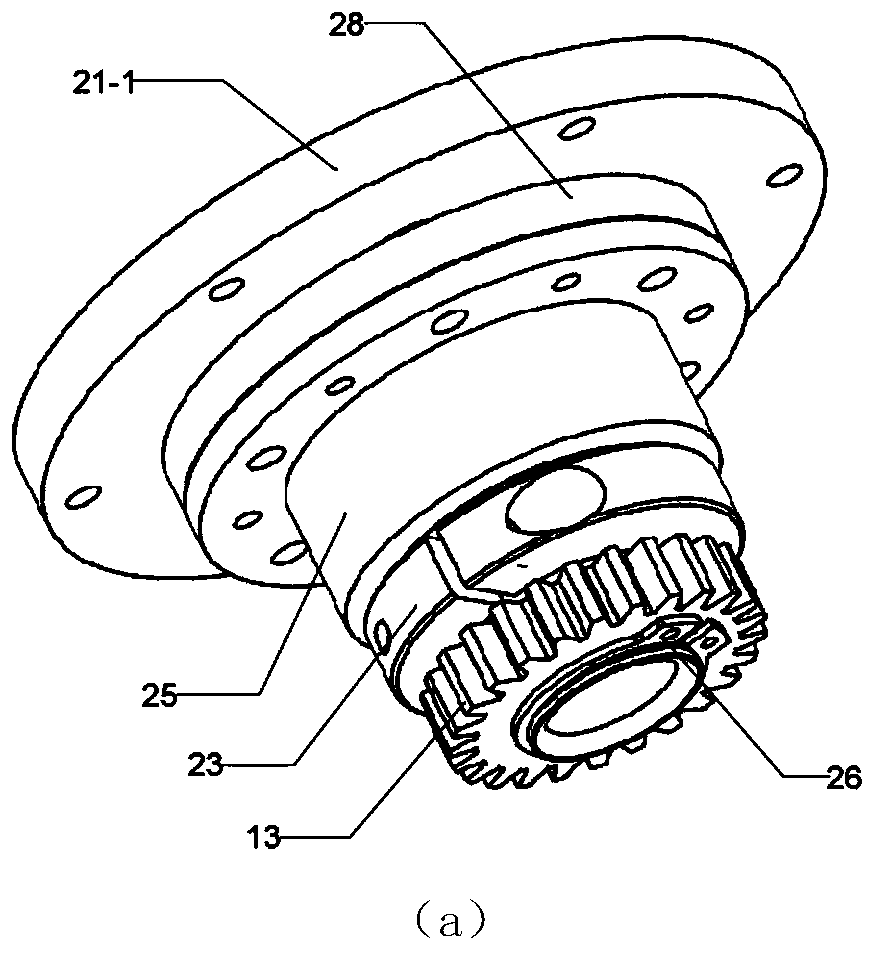

[0054] In order to realize the smooth rotation of the turntable 4, an assembly base plate 8 is fixed inside the base 3, and the driving device includes a drive cylinder 9 fixed on the back of the assembly base plate 8, and a piston rod 10 fixed to the drive cylinder 9 through a connecting assembly. The lower rack 11 moving parallel with it and the two buffers 12 fixed on the back of the assembly base plate 8 and used to limit the movement position of the lower rack 11;

[0055] The center of the sleeve part 7 is a connecting shaft, the turntable 4 is fixedly connected with the connecting shaft, and the lower rack 11 is engaged with the gear 13 fixed on the connecting shaft.

[0056] When the piston rod 10 of the driving cylinder 9 stretches, it drives the lower rack 11 to reciprocate, and the lower rack 11 drives the gear 13 to perform 180° forward rotation and reverse rotation, thereby driving the connecting shaft to perform 180° forward rotation and reverse rotation motion, ...

Embodiment 3

[0065] In order to fix the workpiece to be pressed well, the positioning tool 5 includes a positioning seat 31 fixed on the assembly base plate 8 and a fixing table 32 fixed on the positioning seat. The positioning groove 33 enters, and a plurality of adsorption holes 34 are formed on the bottom of the positioning groove, and the adsorption holes 34 communicate with the connection port 35 formed on the side of the fixing table.

[0066] The vacuum pipeline 6 passes through the hollow cavity in the center of the connecting shaft 21 and is connected to the connecting port, and absorbs the workpiece through the adsorption hole.

[0067] The housing of the Z-axis linear lifting device 1 is fixed on the top of the base 3 through a positioning frame 36, and two oppositely arranged on-beam sensors 37 are fixed on the bottom of the positioning frame, and the on-beam sensor can adopt the model E3Z -T61A, to protect the position of possible pressing hand.

[0068] Handles are fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com