Plasma synthetic jet exciter suitable for high-pressure condition

A plasma and synthetic jet technology, applied in the direction of plasma, electrical components, etc., can solve the problems of high breakdown voltage, poor jet effect, low flexibility, etc., to reduce breakdown voltage, improve performance, and improve jet effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

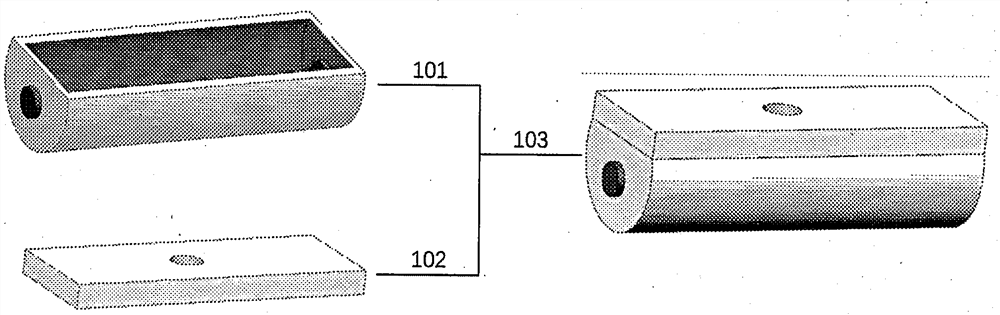

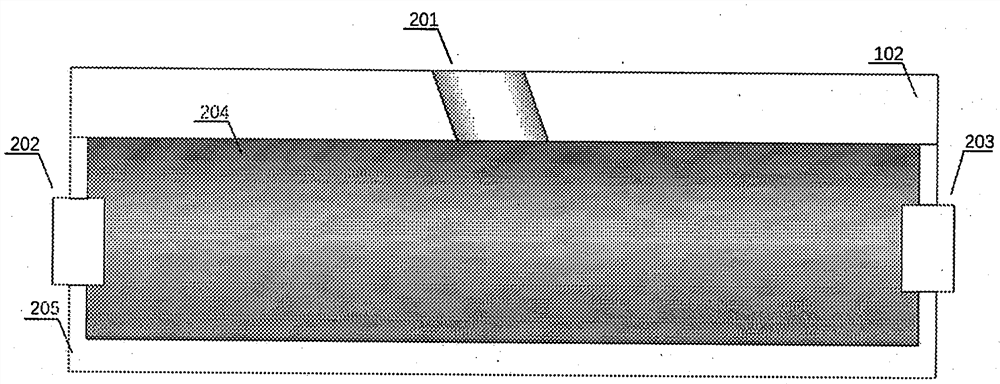

[0026] Considering that the use environment is mainly the inner wall of the engine with high temperature and pressure, the main body 101 and the cover plate 102 of the plasma synthetic jet actuator are made of alumina ceramics. The inner cavity of the exciter housing 205 has a diameter of 5 mm, a length of 9 mm, a wall thickness of 2 mm, and a chord length of 6 mm on the vertical section. The cover plate is 13 mm long, 12 mm wide, and 1.5 mm thick. The jet hole 201 forms an angle of 15 degrees with the normal direction of the upper surface of the cover plate 102 . The anode discharge electrode 202 and the cathode discharge electrode 203 are made of tungsten needles with a radius of 1 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com