Constant volume combustion bomb system for simulating multiple combustion modes of methanol/diesel oil dual-fuel engine and method thereof

A dual-fuel engine, constant volume incendiary bomb technology, applied in engine testing, control/regulation systems, internal combustion engine testing and other directions, can solve the problems of uncontrollable methanol addition time, prone to stratification, different physical and chemical properties, etc. The pressure is flexible and adjustable, and the effect of automatic heating and accurate heating temperature is realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The present invention will be described in further detail below through specific examples. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any form.

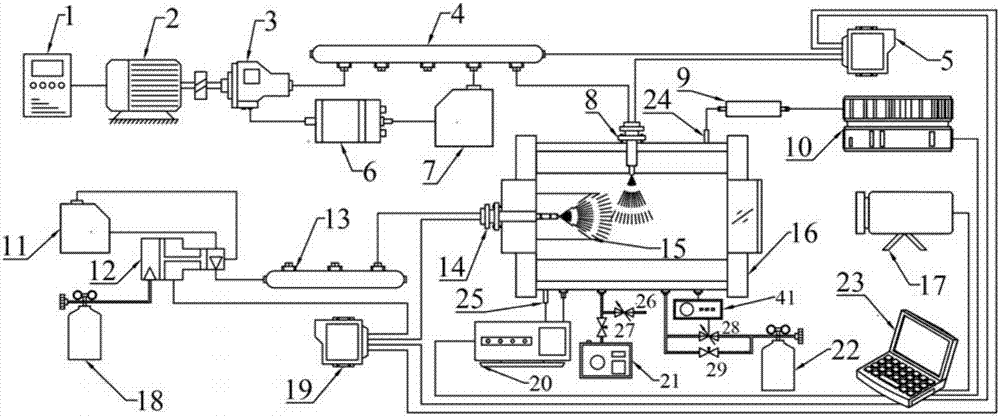

[0040] Such as figure 1 As shown, this embodiment discloses a constant-volume incendiary bomb system that simulates multiple combustion modes of a methanol / diesel dual-fuel engine, including: constant-volume incendiary bombs, diesel injectors, a diesel injection system connected to the diesel injectors, methanol Injector, methanol injection system connected with methanol injector, intake system, exhaust system, pressure sensor, synchronous data acquisition card, high-speed camera; the diesel injection system, methanol injection system, pressure sensor are all controlled by synchronous data acquisition card Realize control; upper computer;

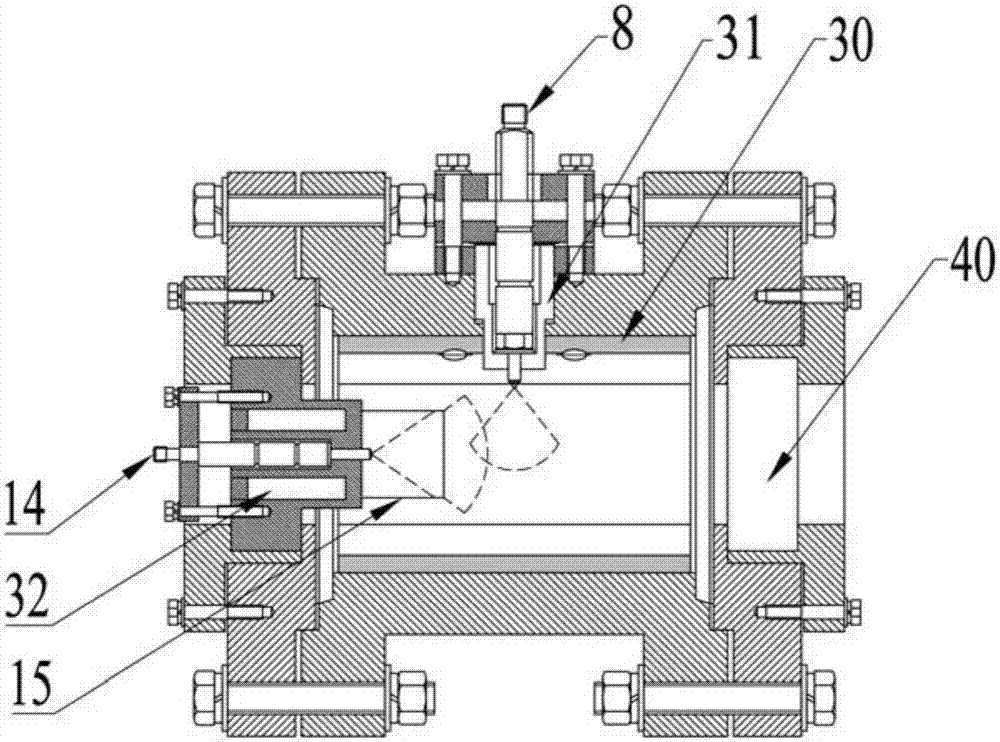

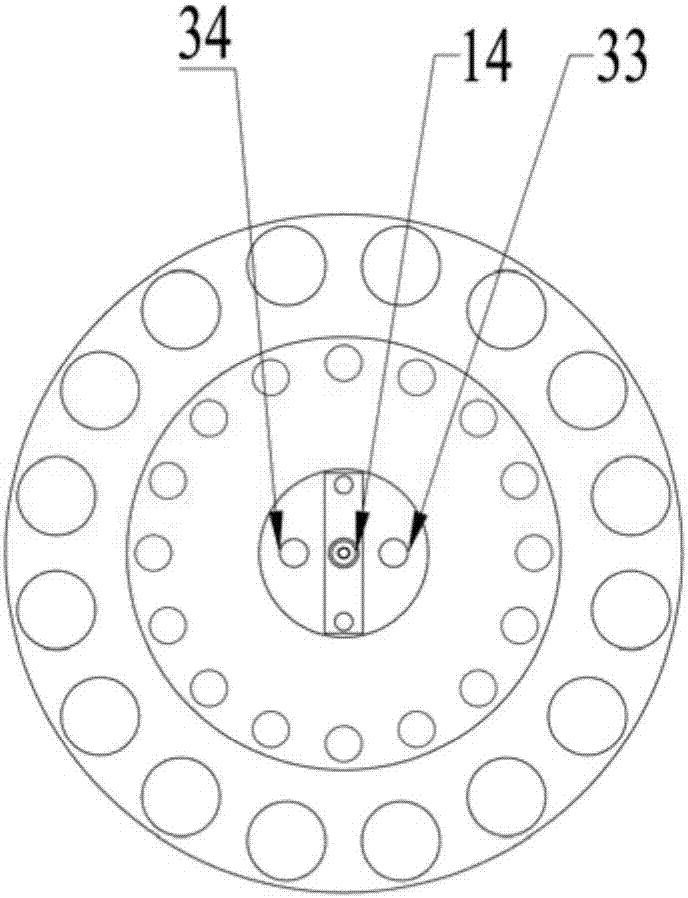

[0041] The constant-volume incendiary bomb 16 is a hollow cylindrical ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com