Intelligent control application of motor

A technology of intelligent control and motor, applied in the direction of motor control, pump control, control system, etc., can solve the problems of shortening, damage of sensor or control switch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

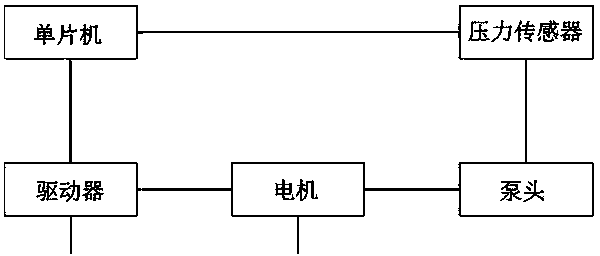

[0013] In this example, if figure 1 As shown, an intelligent control application of a motor of the present invention includes a single-chip microcomputer, a driver and a pressure sensor that are electrically connected to the single-chip microcomputer respectively, a motor that is electrically connected to the driver, and a pump head that is connected to the motor drive. The sensor of the pump head is connected to the pressure sensor; the external connection of the driver is provided with a energized wire with a large load; wire.

[0014] Wherein, the pump head is provided with a water inlet (not shown) and a water outlet (not shown), and the water in the pump head generates a pressure perpendicular to the flow direction of the pressure sensor.

[0015] Wherein, the single-chip microcomputer and the pressure sensor are electrically connected with bidirectional micro-current, and the micro-current pulse signal is transmitted between the single-chip microcomputer and the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com