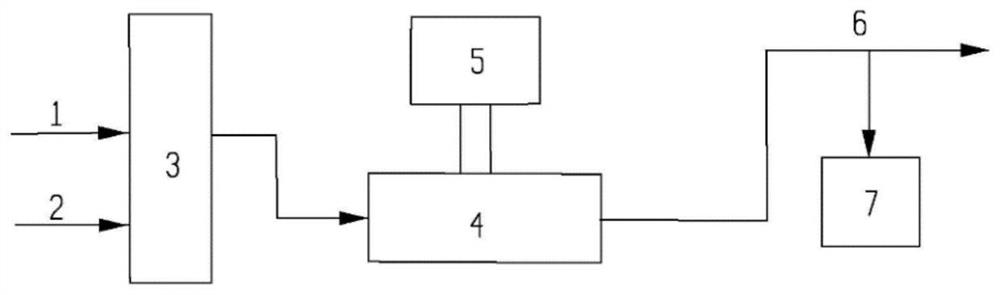

A method and device for producing synthesis gas by plasma-catalyzed dry reforming of methane

A methane dry reforming and plasma technology, applied in chemical instruments and methods, hydrogen/synthesis gas production, inorganic chemistry, etc., can solve problems such as catalyst deactivation, complex devices, pipeline blockage, etc., to improve selectivity, prolong Longevity, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

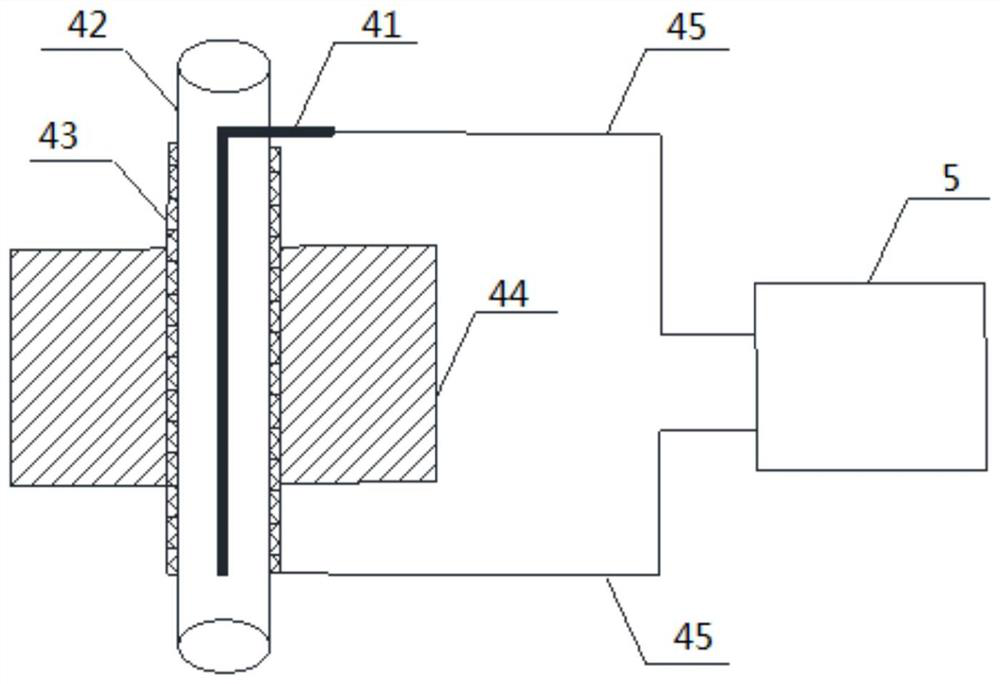

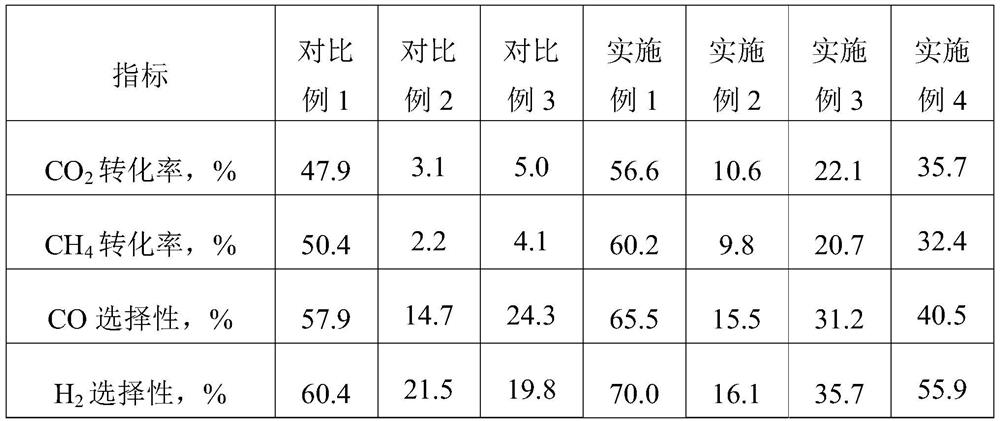

Embodiment 1

[0077] The reaction pressure is 140kPa (absolute pressure), the flow rate of carbon dioxide 1 is 0.5L / min, and the flow rate of methane 2 is 1.5L / min. After mixing, it enters the ionization chamber of the low-temperature plasma reactor, and the low-temperature plasma reactor is filled with alumina with a diameter of 3mm. Small balls (supporting metal silver 2.5wt%), the heating furnace 44 outside the low-temperature plasma reactor is kept at 260° C., and the low-temperature plasma power supply 5 is connected to perform dielectric barrier discharge. The low-temperature plasma reactor adopts a needle-cylinder electrode structure, and the cylindrical barrier medium is made of ceramics with an outer diameter of 25 mm and an inner diameter of 20 mm. The ground electrode 43 is an annular stainless steel mesh, and the high-voltage electrode 41 is a stainless steel rod with a diameter of 8 mm. The (discharge distance) is 6 mm, and the effective discharge length of the low-temperature p...

Embodiment 2

[0080] The difference from Example 1 is only that the discharge distance is 10 mm.

[0081] The reaction results are: the carbon dioxide conversion rate is 10.6%, the methane conversion rate is 9.8%, the carbon monoxide selectivity is 15.5%, and the hydrogen selectivity is 16.1%. After reacting for 48 hours, a small amount of carbon was deposited on the catalyst. The catalyst can still maintain the reactivity after regeneration.

Embodiment 3

[0083] The difference from Embodiment 1 is only that the input power is 100W.

[0084] The reaction results are: the carbon dioxide conversion rate is 22.1%, the methane conversion rate is 20.7%, the carbon monoxide selectivity is 31.2%, and the hydrogen selectivity is 35.7%. After reacting for 48 hours, a small amount of carbon was deposited on the catalyst. The catalyst can still maintain the reactivity after regeneration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com