Vehicle pre-exhaust control system

A control system and pre-exhaust technology, applied in electrical control, charging system, engine control, etc., can solve problems such as misfire jitter, affecting production efficiency, and the engine cannot be started normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

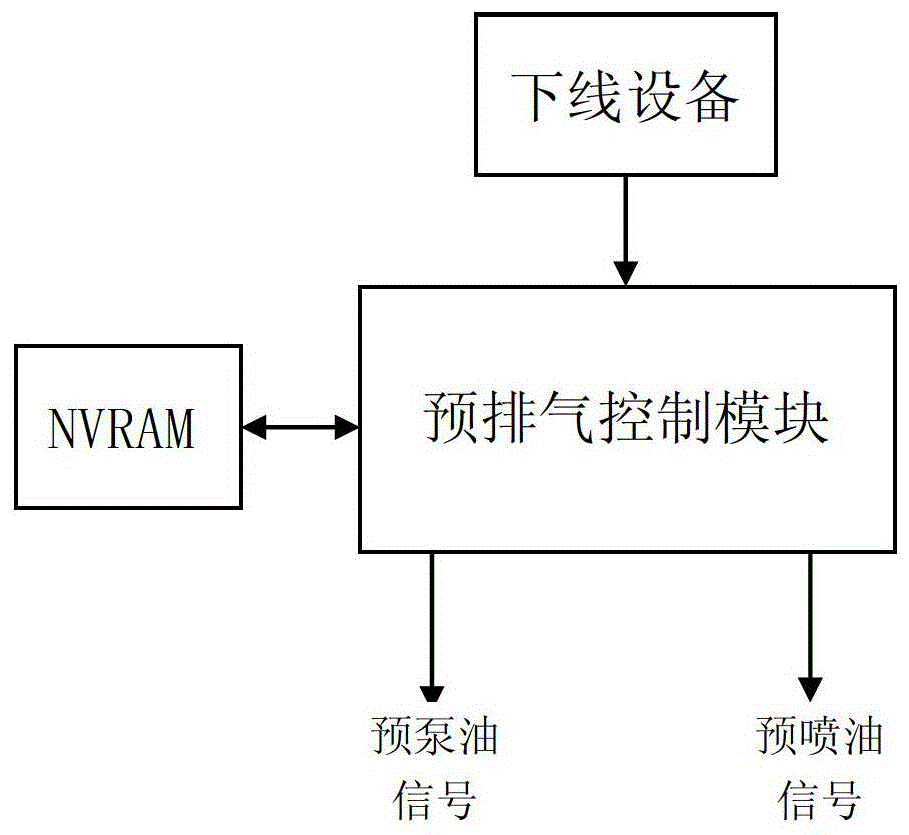

[0023] The vehicle pre-exhaust control system, including a pre-exhaust control module, a NVRAM (Non-VolatileRandomAccessMemory, non-volatile random access memory);

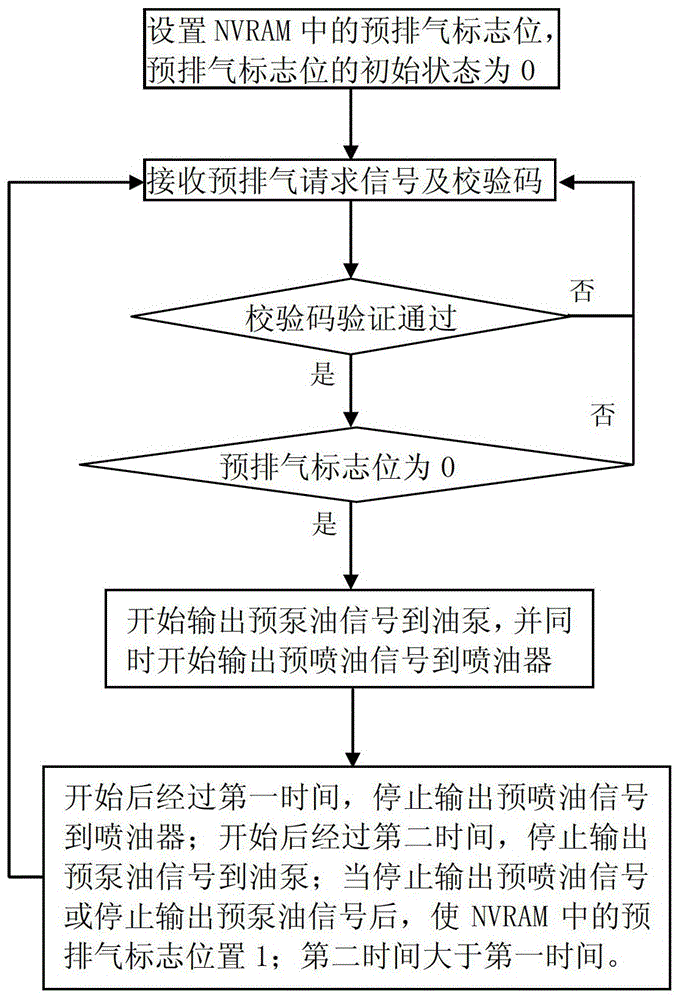

[0024] The NVRAM is provided with a pre-exhaust flag, and the initial state of the pre-exhaust flag is 0;

[0025] The pre-exhaust control module is calibrated with a first time and a second time, and the second time is greater than the first time;

[0026] If the pre-exhaust control module receives the pre-exhaust request signal, and the state of the pre-exhaust flag in the NVRAM is 0, then output the pre-pump oil signal to the oil pump, control the oil pump to start pre-pump oil, and At the same time, the pre-injection signal is output to the injector, and the injector is controlled to open to exhaust; after the first time after the output of the pre-injection signal, stop outputting the pre-injection signal to the injector, thereby controlling the fuel injection The device is turned off; after the second time ...

Embodiment 2

[0030] Vehicle pre-exhaust control system, such as figure 1 As shown, including the first-line equipment, a pre-exhaust control module, and an NVRAM;

[0031] The off-line equipment is used to simultaneously send a pre-exhaust request signal and a check code to the pre-exhaust control module;

[0032] The NVRAM is provided with a pre-exhaust flag, and the initial state of the pre-exhaust flag is 0;

[0033] The pre-exhaust control module is calibrated with a first time and a second time, and the second time is greater than the first time;

[0034] The pre-exhaust control module, such as figure 2 As shown, after receiving the pre-exhaust request signal and the check code, first verify the check code, if the verification is passed, then respond to the pre-exhaust request signal sent at the same time as the check code, otherwise do not respond to the The pre-exhaust request signal sent by the check code at the same time, thereby prohibiting the output of the pre-pump oil sign...

Embodiment 3

[0039] A calibration method for the first time and the second time is: replace the fuel line of the new car with the same transparent fuel line, install a fuel pressure gauge at the end of the fuel distribution pipe, and control the oil pump to start pumping oil through the calibration tool. At the same time, the fuel injector is controlled to open, the air in the fuel pipeline will be gradually discharged from the fuel injector under the operation of the fuel pump, and the fuel will also gradually reach the fuel distribution pipe from the fuel tank. At the end of the fuel distribution pipe, close the fuel injector. The time from the opening to the closing of the fuel injector is the first time; after the fuel injector is closed, the fuel pump continues to pump fuel to increase the fuel pressure in the fuel pipeline. When the fuel The pressure gauge indicates that the fuel pressure has risen to the specified pressure, and the oil pump is controlled to stop pumping oil. The time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com