Range type reaction kettle using hydroxy fuels

A reaction kettle and fuel technology, applied in the field of stoves, can solve the problems of inability to burn fuel, inability to react with hydroxyl fuel energy additives, etc., and achieve the effect of good reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

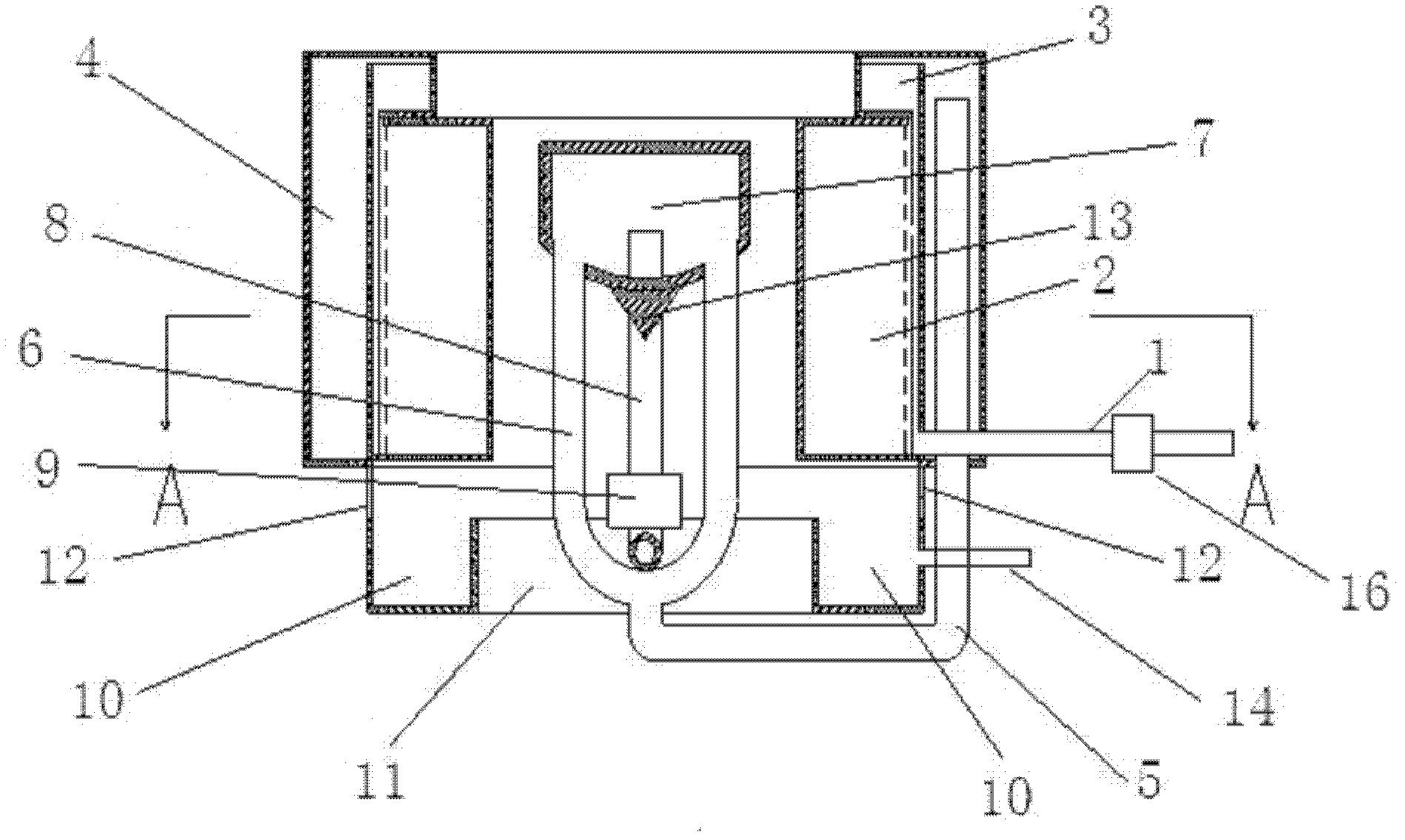

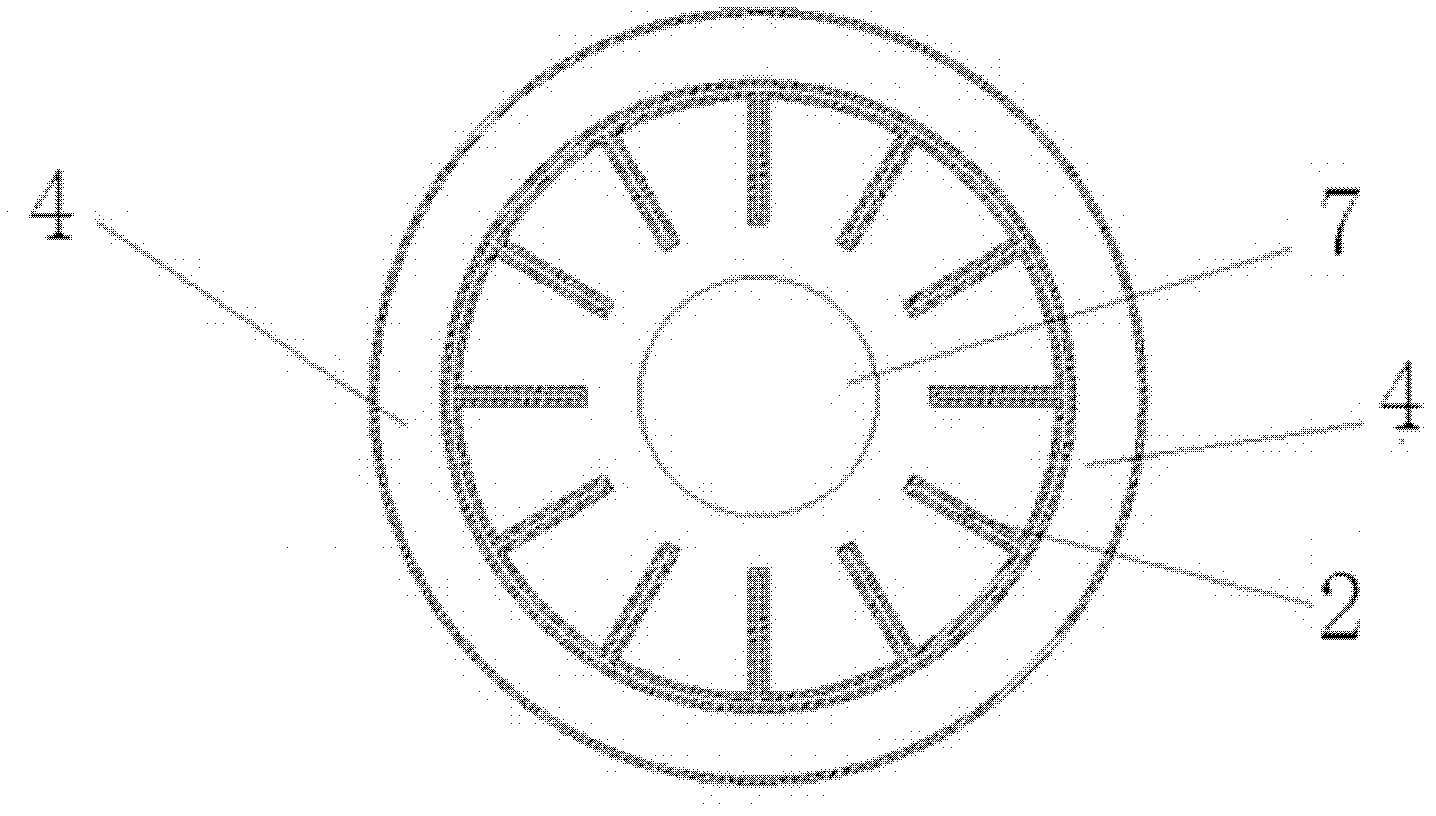

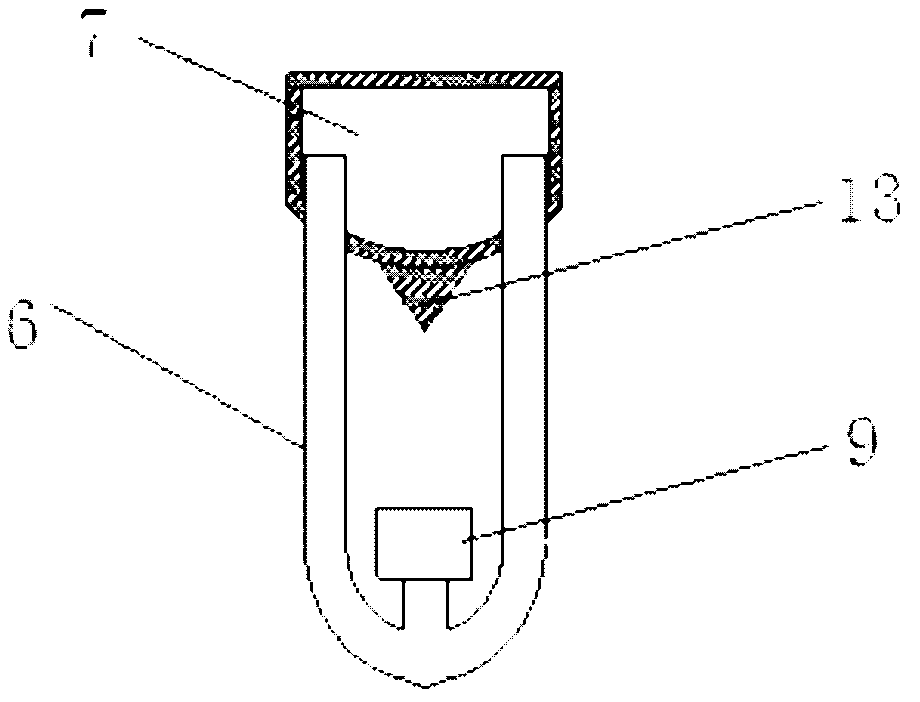

[0032] as attached figure 1 , attached figure 2 As shown, the stove-type reactor for the base fuel in this embodiment is circular, including a preheating oil pan 10, an annular air storage chamber 4 is arranged on the top of the preheating oil pan 10, and the annular air storage chamber 4 The inner side is provided with an annular primary vaporization chamber 2 and a secondary vaporization chamber 3, the secondary vaporization chamber 3 is located above the primary vaporization chamber 2, the primary vaporization chamber 2, the secondary vaporization chamber 3 and the gas storage chamber 4 are connected in sequence, The inner wall of the primary vaporization chamber 2 is folded, the outer wall of the primary vaporization chamber 2 extends upwards, and the extension part forms the outer wall of the secondary vaporization chamber 3, the outer wall of the primary vaporization chamber 2 and the extension part of the outer wall are The inner wall of the air storage chamber 4; as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com