Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Monitor temperature changes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

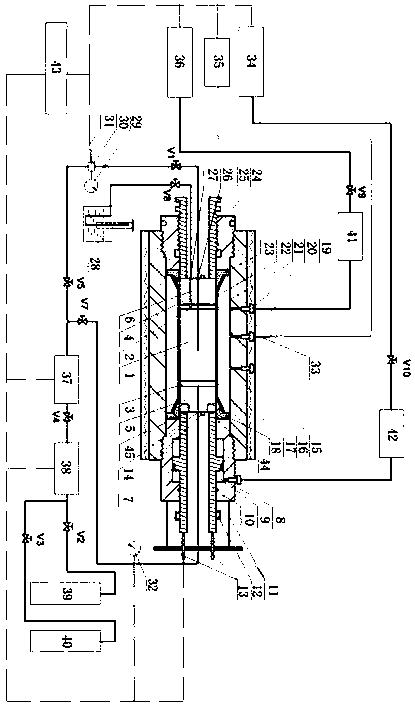

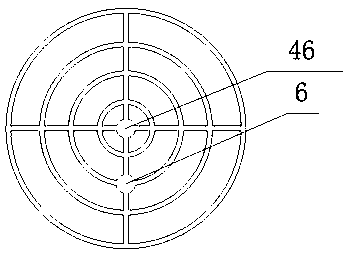

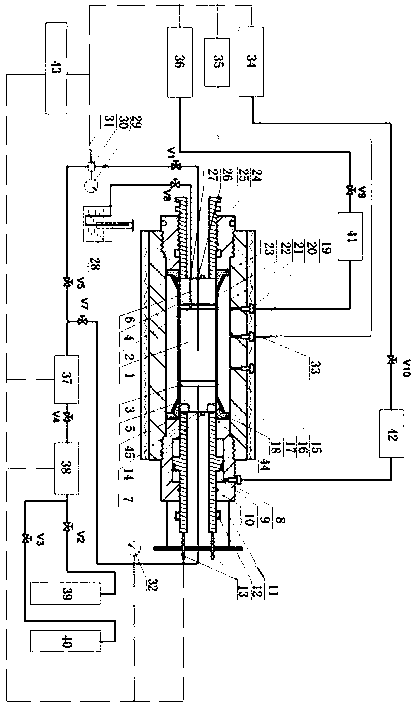

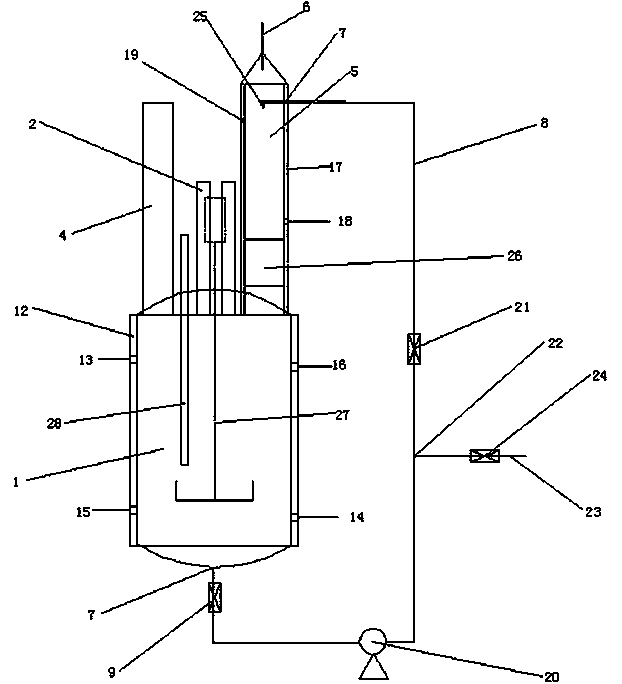

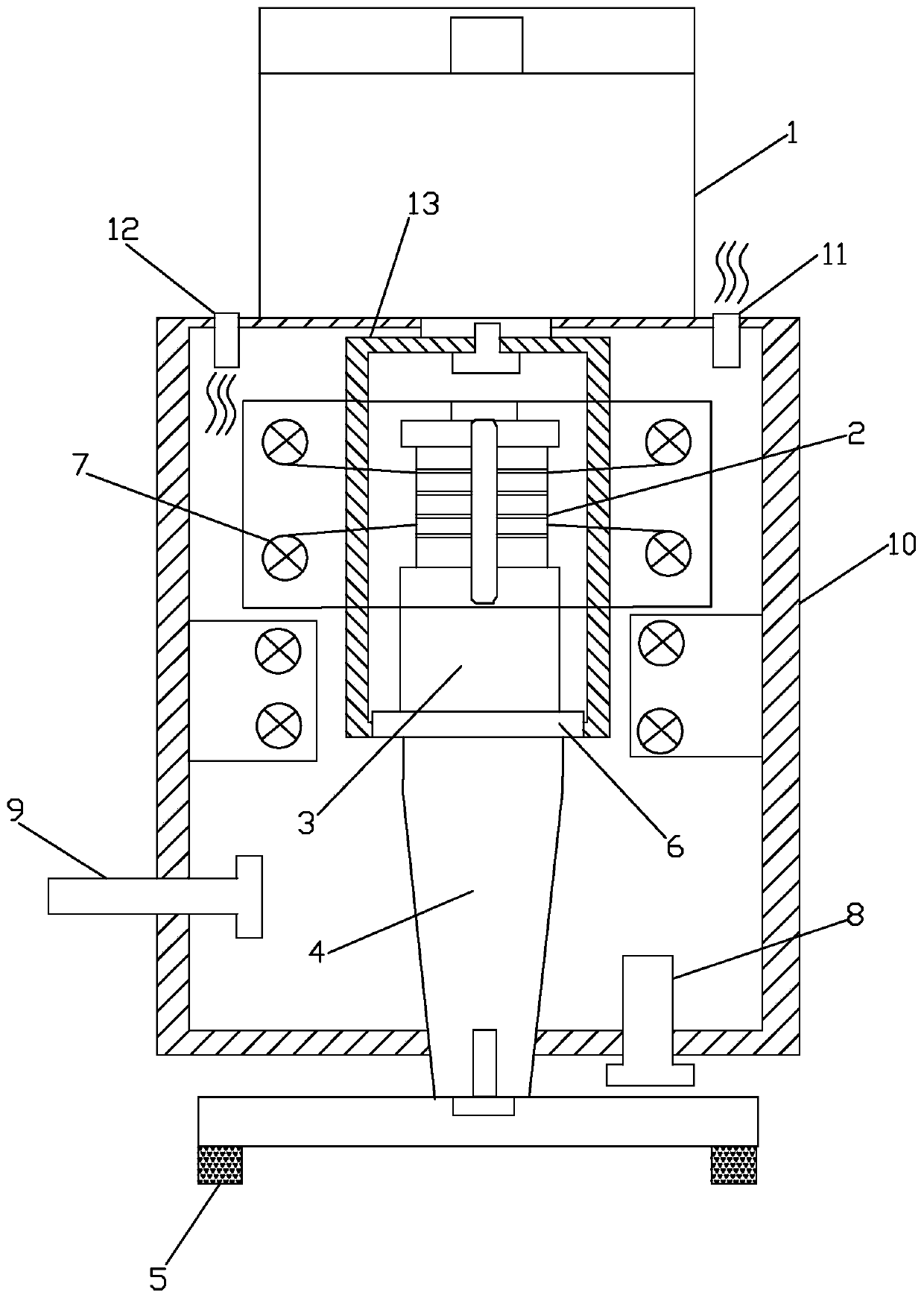

Supercritical carbon dioxide fracture-creepage-seepage test device for high-temperature high-pressure coal petrography

InactiveCN110057739AMonitor pressureRich researchPermeability/surface area analysisEngineeringHigh pressure

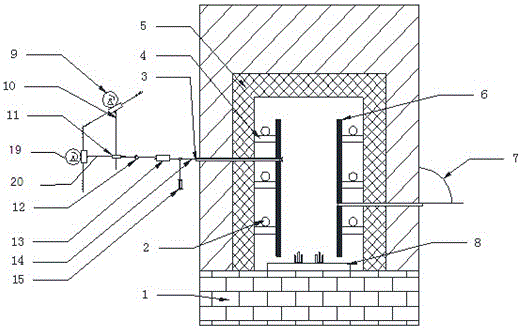

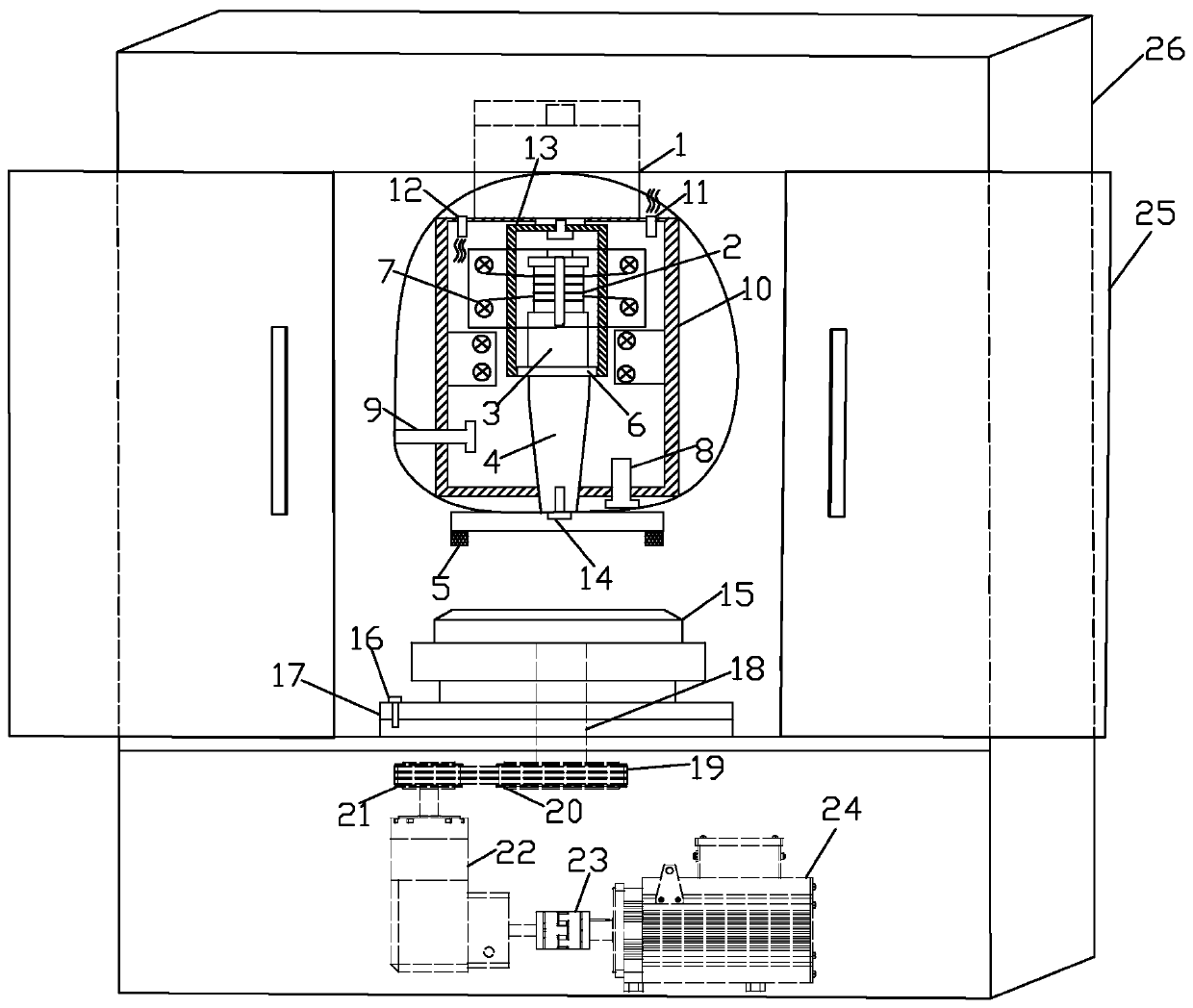

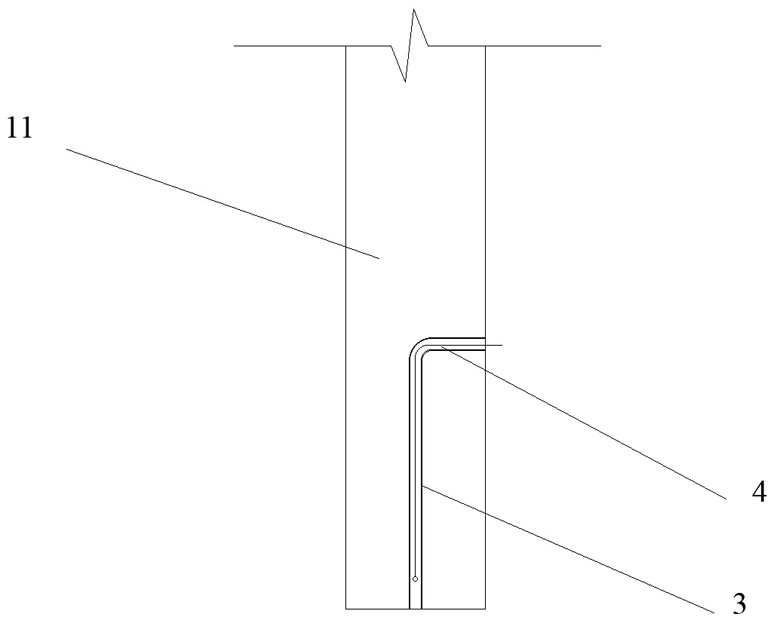

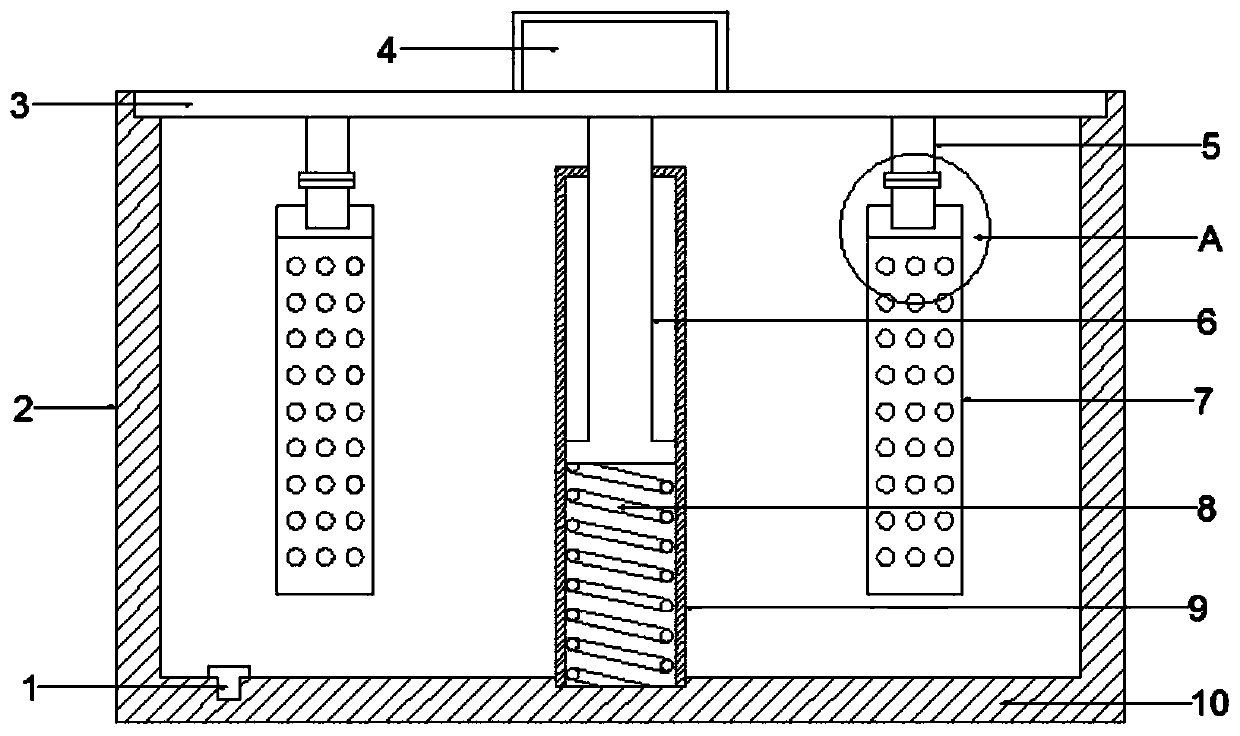

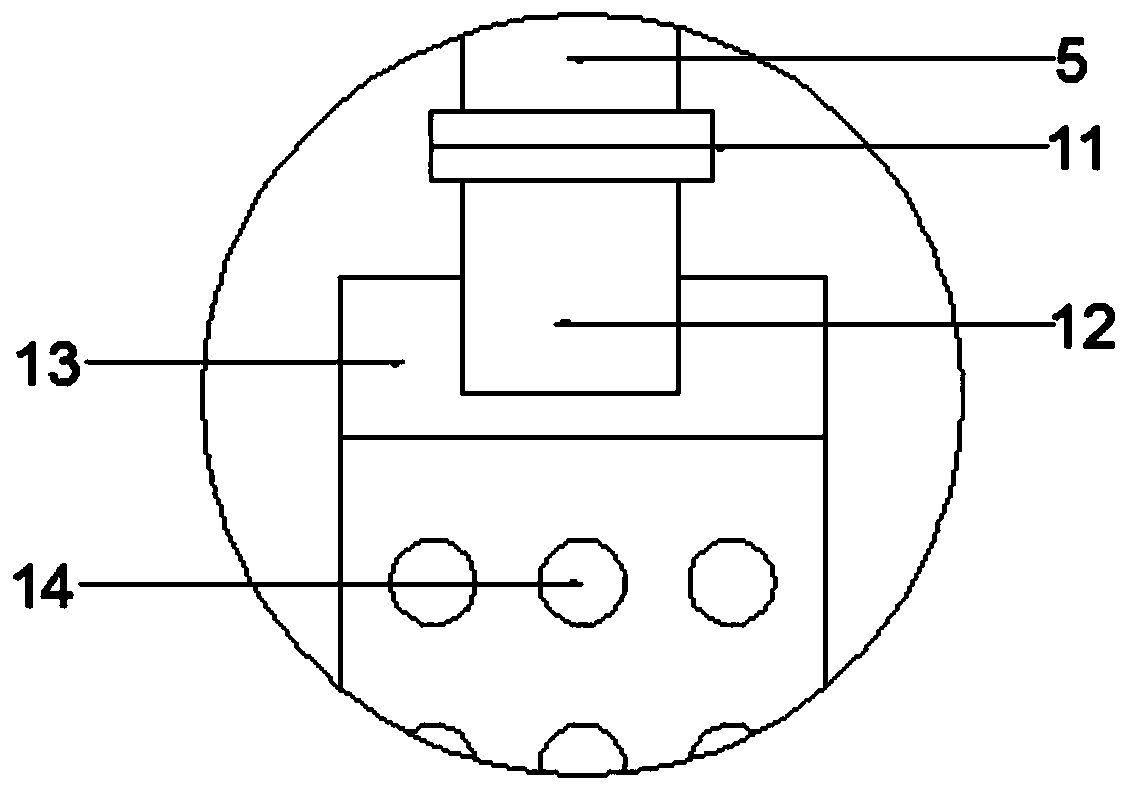

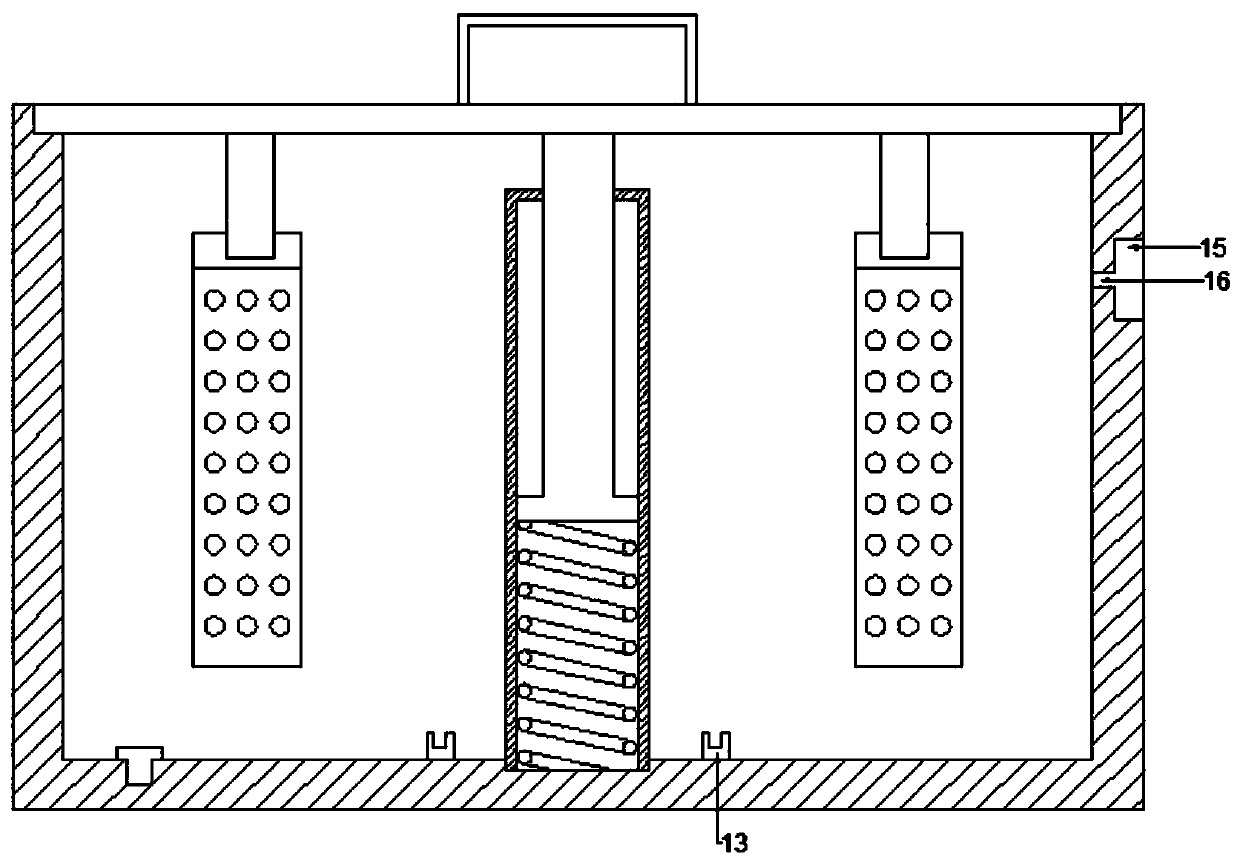

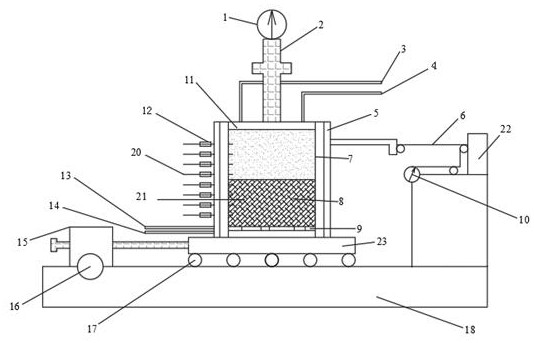

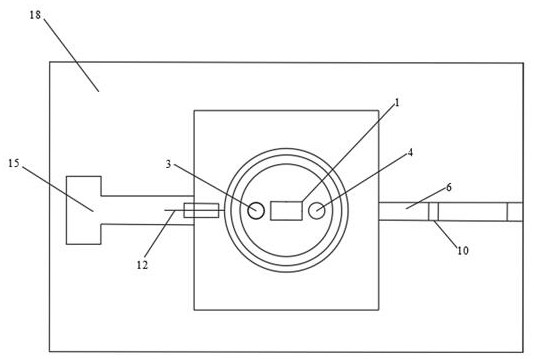

The invention discloses a supercritical carbon dioxide fracture-creepage-seepage test device for high-temperature high-pressure coal petrography. The device comprises a triaxial cell, a supercriticalcarbon dioxide generator system, an axle load and confining pressure loading system, an acoustic emission monitoring system, a temperature rise control system, a deformation-pressure monitoring systemand a permeability measuring system. The device is capable of realizing the supercritical carbon dioxide fluid fracture test of coal petrography under high temperature and high pressure, monitoring and recording the temperature and pressure changes of supercritical carbon dioxide and characteristics of fracture cracking and extension in the supercritical carbon dioxide fracture process in real time, monitoring and recording the axial and radial deformations of coal petrography samples in real time, directly and effectively measuring the DH4 permeability of the coal petrography before and after the fracture without unloading the coal petrography sample stress, and measuring the CH4 permeability of the coal petrography after the fracture under the action of creepage. The measurement methodis high in precision, intuitional and high in automation degree, and the device is simple in structure.

Owner:TAIYUAN UNIV OF TECH

High temperature and high pressure coal rock supercritical carbon dioxide fracturing-creep deformation-seepage experimental method

ActiveCN110057740AMonitor pressureRich researchPermeability/surface area analysisExperimental methodsRock sample

The invention discloses a high temperature and high pressure coal rock supercritical carbon dioxide fracturing-creep deformation-seepage experimental method. A supercritical carbon dioxide fluid fracturing-creep deformation-seepage experiment of coal rock is executed under high temperature and high pressure, change of temperature and pressure of the supercritical carbon dioxide and fracture crackinitiation and expansion features in a supercritical carbon dioxide fluid fracturing process are monitored and recorded in real time, and axial deformation and radial deformation of a coal rock sampleare monitored and recorded in real time, moreover, CH4 permeability of the coal rock before and after fracturing can be measured directly and effectively under a condition where coal rock sample stress is not cancelled, and measurement of the permeability of the CH4 of the coal rock under the creep deformation function after fracturing can be realized. The measurement method provided by the invention is high precise, visual and highly automatic, and devices used in the method are simple in structure.

Owner:TAIYUAN UNIV OF TECH

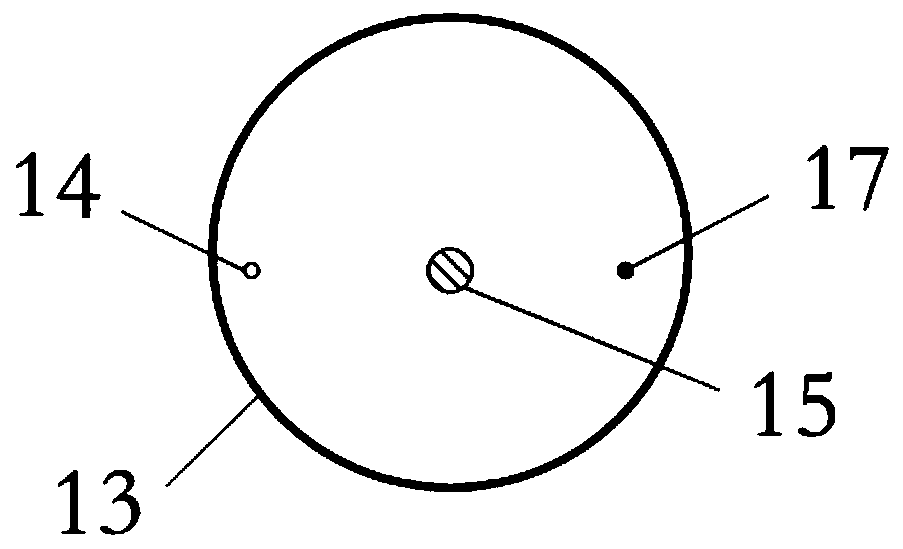

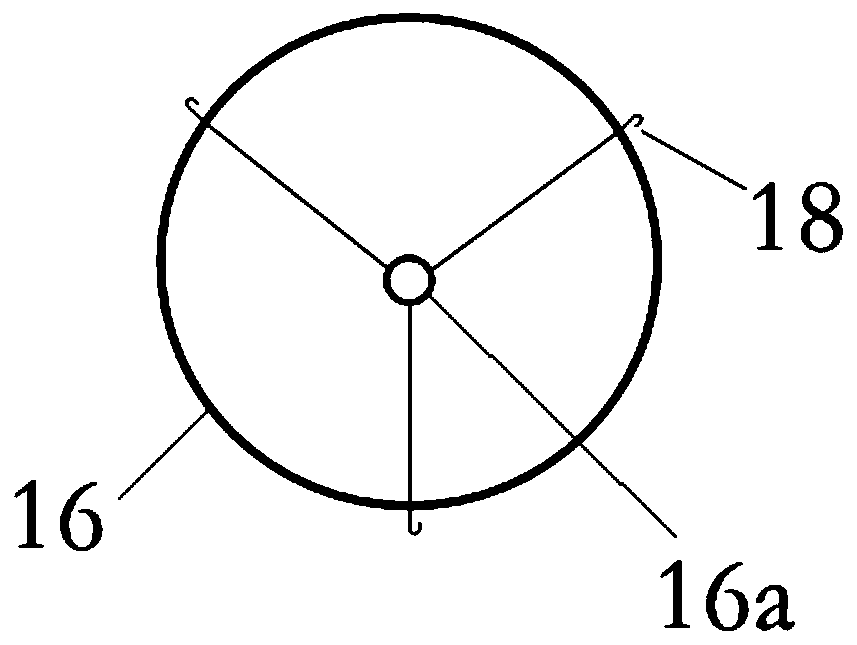

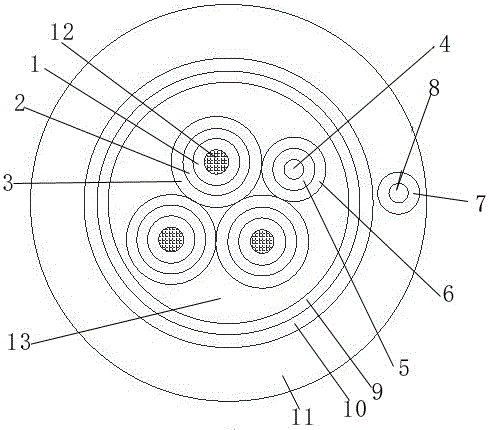

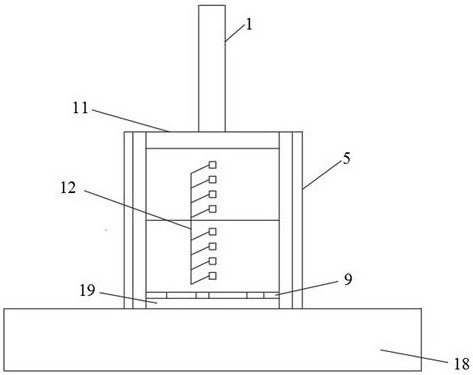

Wireless temperature measuring device for rotational molding equipment

ActiveCN102632577AGuaranteed temperature measurement environment and accuracyImprove rotational molding efficiencyCoatingsInstrumentationElectric signal

The invention relates to a wireless temperature measuring device for rotational molding equipment. The wireless measuring device mainly comprises an insulation box for a thermometer, an end cap for the thermometer, an information acquisition module, an FSK (frequency shift keying) radiofrequency transmitter, a power supply, a FSK radiofrequency receiver, an information processing module and a data processing system, wherein the information acquisition module acquires the temperature inside an oven of a rotational molding machine, the temperature of inside and outside walls of a mold and the temperature of materials, and converts the temperature into electric signals, the FSK radiofrequency transmitter transmits the converted signals to a receiving device, the FSK radiofrequency receivers receives the signals transmitted by the FSK radiofrequency transmitter, the data processing system processes and analyzes the temperature change signals received and acquired by the FSK radiofrequency receiver, and sends feedback the control system of the rotational molding equipment. A five-layer structure between the insulation box for the thermometer and the end cap for the thermometer can efficiently ensure the temperature measuring environment and precision of the equipment. The temperature measuring device can monitor the temperature change in real time, remarkably improve the efficiency of the rational molding, reduce the energy consumption, and improves the quality and the precision of the product.

Owner:BEIJING UNIV OF CHEM TECH

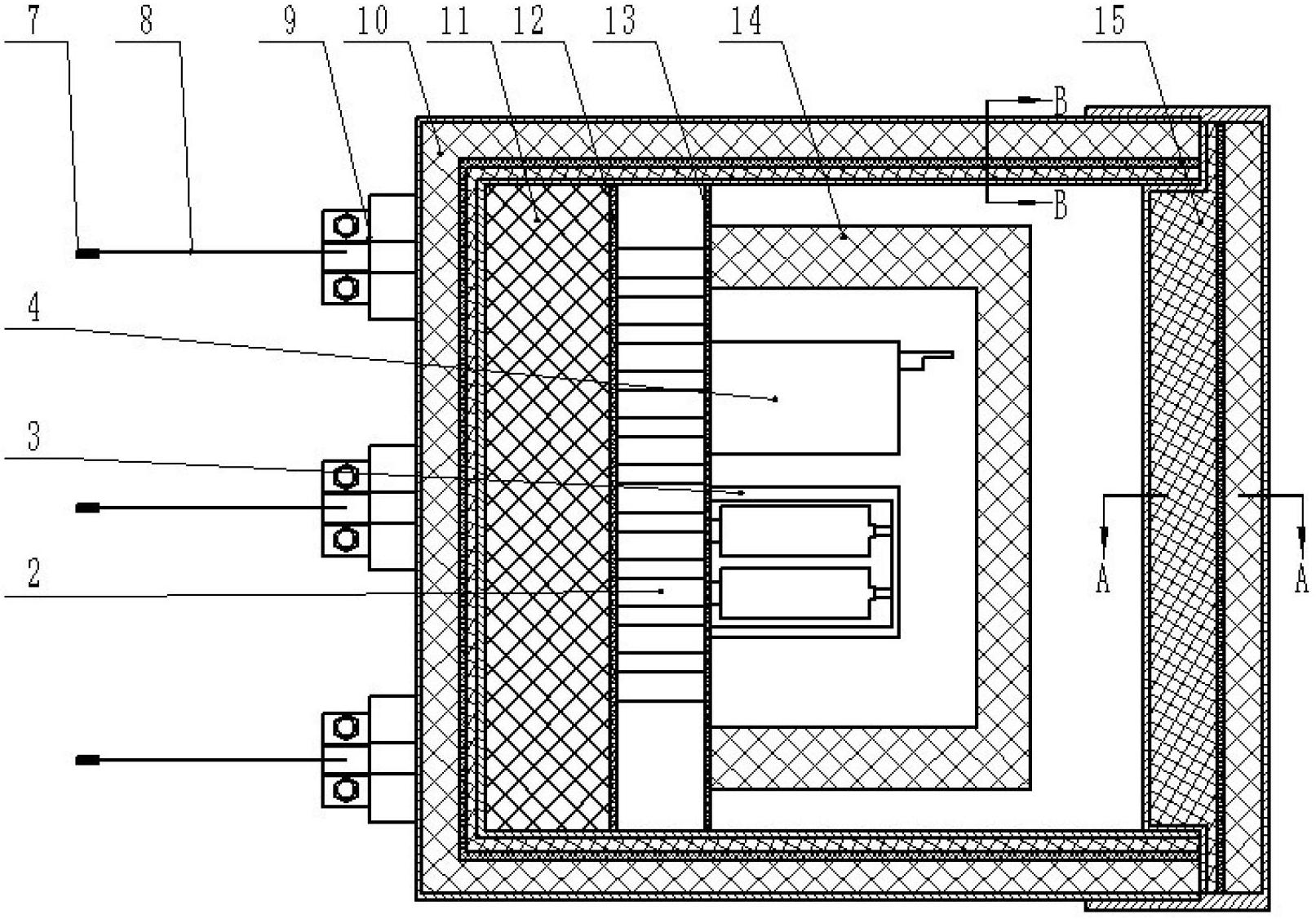

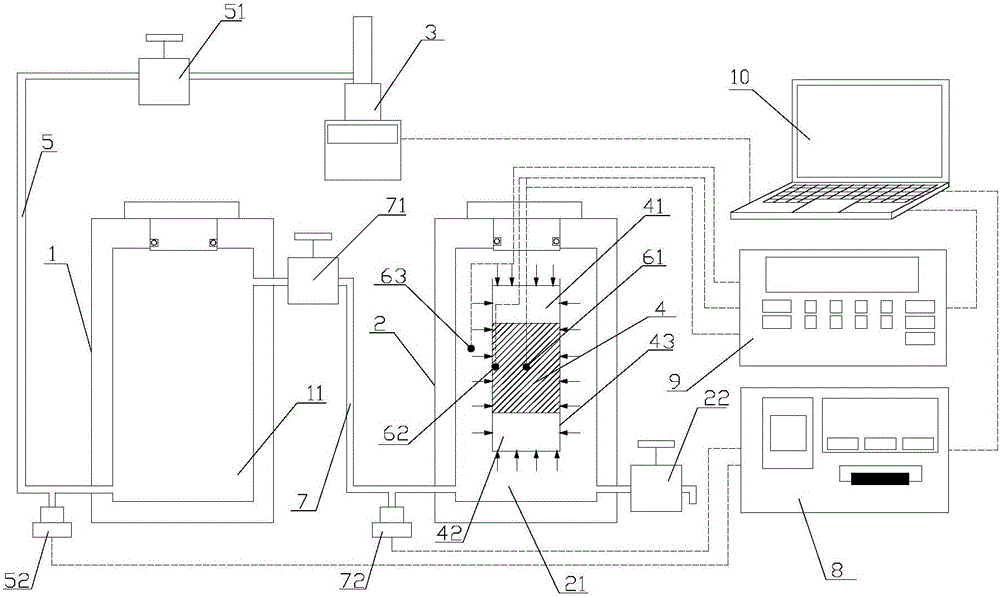

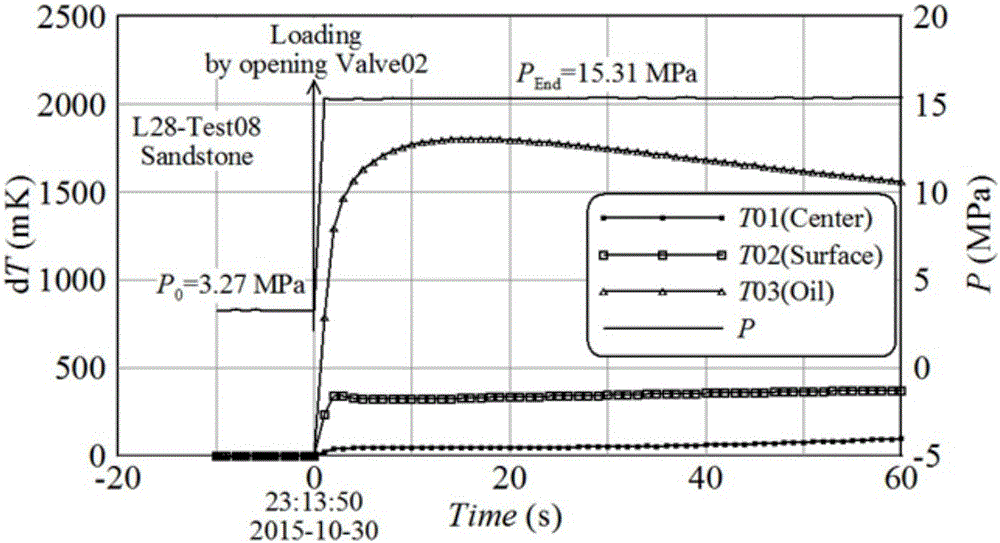

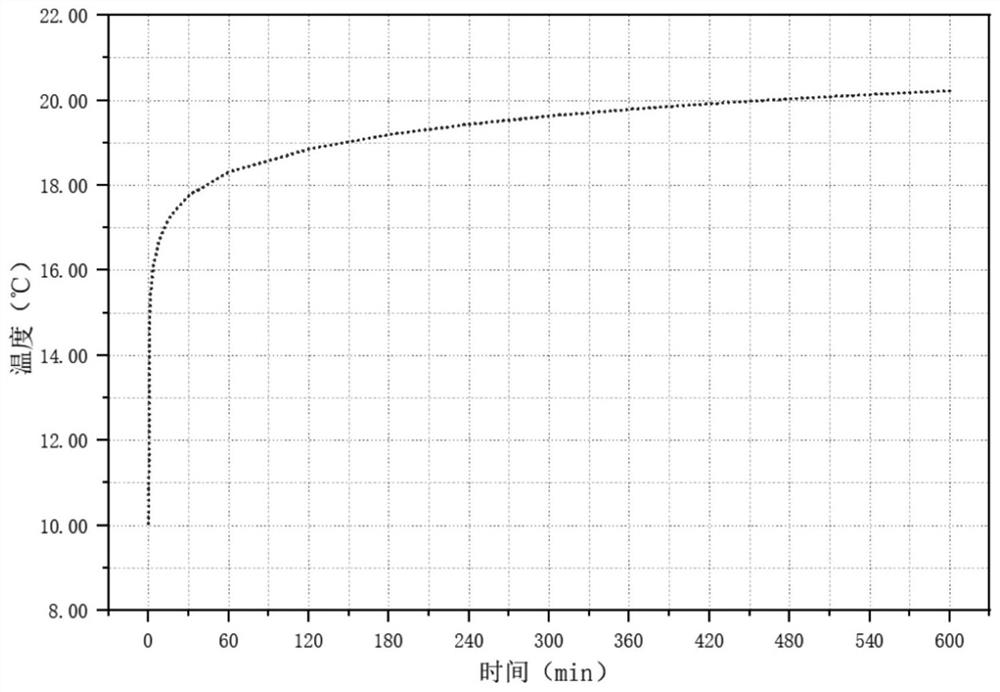

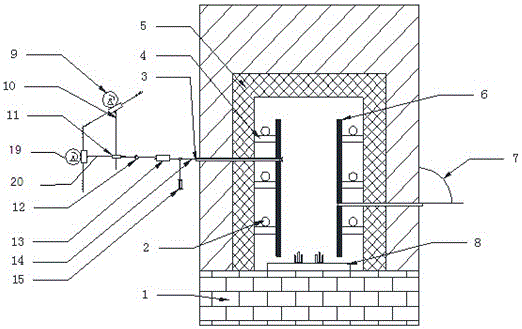

Testing system and method for thermophysical properties of rock at high pressure

InactiveCN105784756AMonitor temperature changesRealize transient thermal physical property testMaterial heat developmentTemperature monitoringEngineering

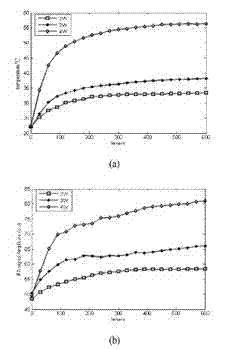

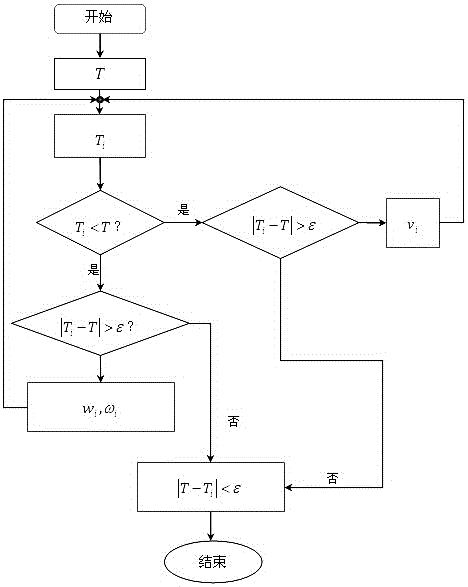

The invention discloses a testing system for the thermophysical properties of rock at high pressure.The testing system comprises two pressure-resisting tanks, a high-pressure pump, a temperature monitoring module and a confining pressure monitoring module.The high-pressure pump is connected with a first cavity through a first communicating pipeline, wherein a first bleeder valve and a first pressure sensor are installed on the first communicating pipeline.A rock sample is installed in a second cavity, and temperature sensors are installed in the center and on the outer surface of the rock sample and in the second cavity respectively.The first cavity and the second cavity are communicated through a second communicating pipeline, wherein a second bleeder valve and a second pressure sensor are installed on the second communicating pipeline.The invention further discloses a testing method for the thermophysical properties of rock at high pressure.According to the testing system and method for the thermophysical properties of rock at high pressure, no electric heating heat source is needed, instant loading of the rock sample is achieved by rapidly switching on the bleeder valves, and the thermophysical properties of the rock sample at high pressure can be obtained through an established finite element numerical inversion model in combination with a global optimization method.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

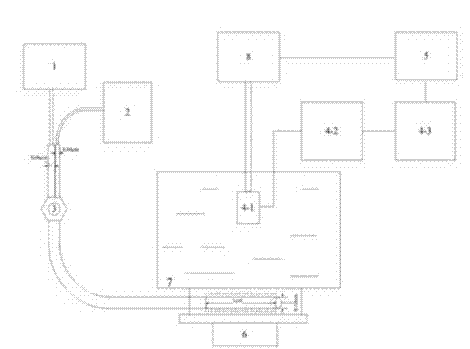

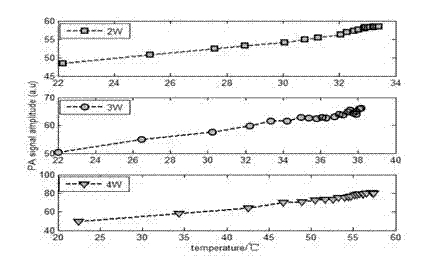

Photothermal effect tissue treatment optimizing and monitoring method and device

InactiveCN103919607AMonitor temperature changesGood photothermal effectSurgical instrument detailsDiagnostic recording/measuringMonitoring methodsMaterials science

The invention relates to a photothermal effect tissue treatment optimizing and monitoring method and device. Continuous intensive laser and pulse laser are transmitted through a flexible diffusion end multimode fiber which is inserted into tissue in a minimal invasion manner, and the same area of the tissue can be irradiated. The continuous intensive laser mainly produces the photothermal effect to cause tissue temperature to change; the pulse laser mainly produces photoacoustic signals, temperature changes of the tissue being monitored are changed according to the strength of the photoacoustic signals, dosage and irradiation time of the continuous intensity laser are regulated in time as required, and optimized photothermal effect is achieved.

Owner:李志芳

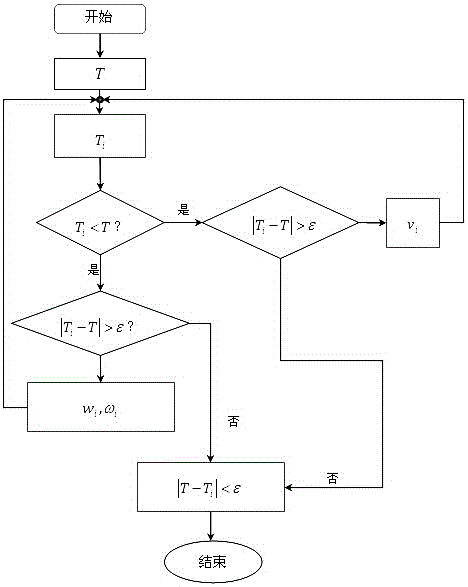

Tunnel kiln environment conditioning method and device of automatically adjusting temperature in kiln

ActiveCN106444914AImprove intelligenceGood energy saving effectTemperatue controlTunnel kilnEngineering

The invention discloses a tunnel kiln environment conditioning method and a device of automatically adjusting the temperature in a kiln. The tunnel kiln environment conditioning method includes the following steps: S1, environmental information acquisition equipment is arranged in a tunnel kiln, wherein the environmental information acquisition equipment is used for acquiring environmental parameters of the environment to be conditioned in the tunnel kiln and sending the environmental parameters to a controller; S2, the controller generates an environment conditioning command according to the environmental parameters acquired by the environmental information acquisition equipment, and sends the environment conditioning command to an environment conditioning execution mechanism; and S3, the environment conditioning execution mechanism conditions the environment in the tunnel kiln according to the environment conditioning command sent from the controller. The tunnel kiln environment conditioning method can control the angle of a temperature adjustment burner, the combustion gas injection rate, the angular rate of the temperature adjustment burner, the kiln tail blast rate, and the like, of the tunnel kiln, and can perform sintering research on various refractory materials, thus increasing diversity of research.

Owner:YANCHENG INST OF TECH

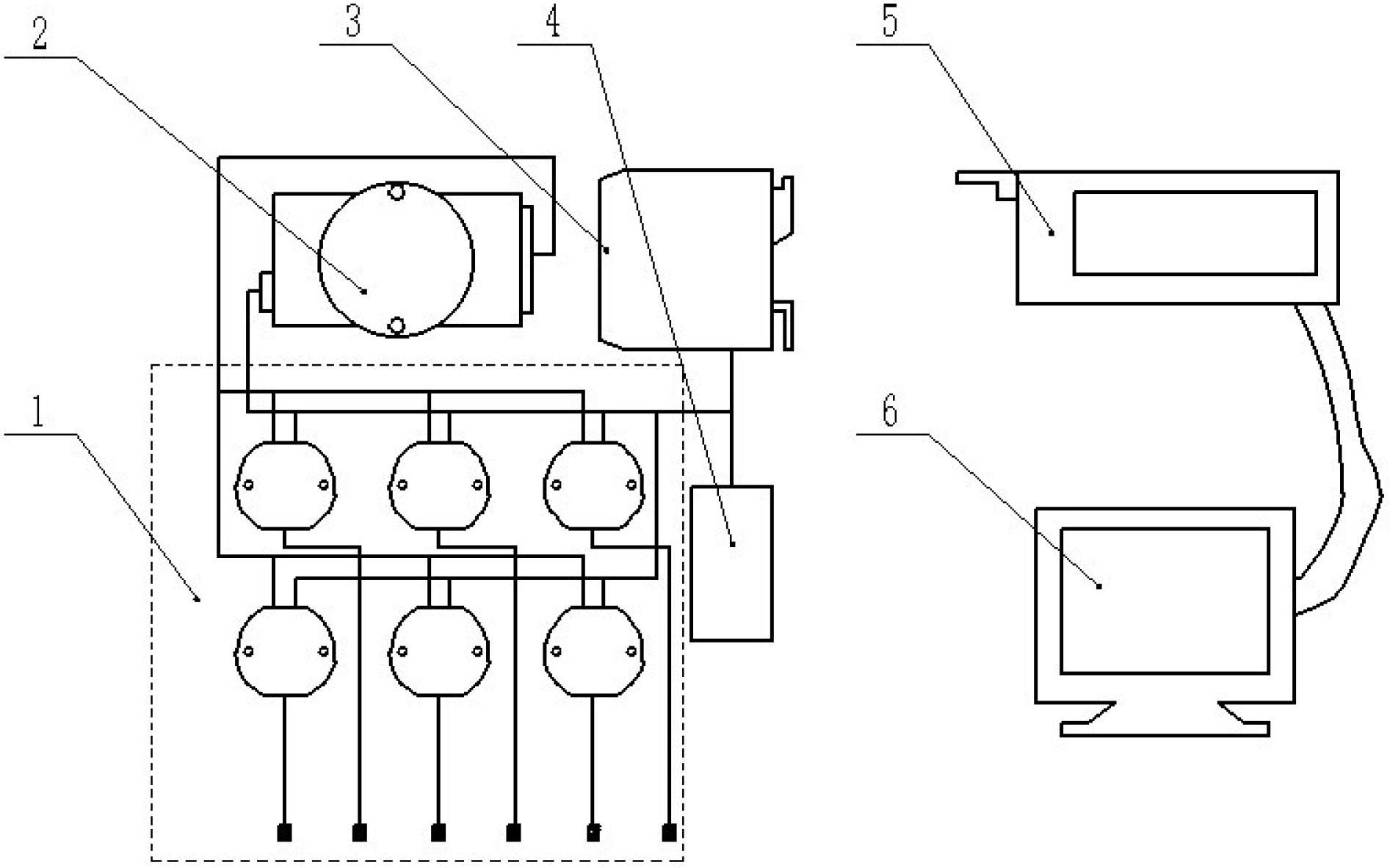

Concrete temperature control early warning system

InactiveCN109470372AMonitor temperature changesEasy accessThermometer detailsTemperature controlEarly warning system

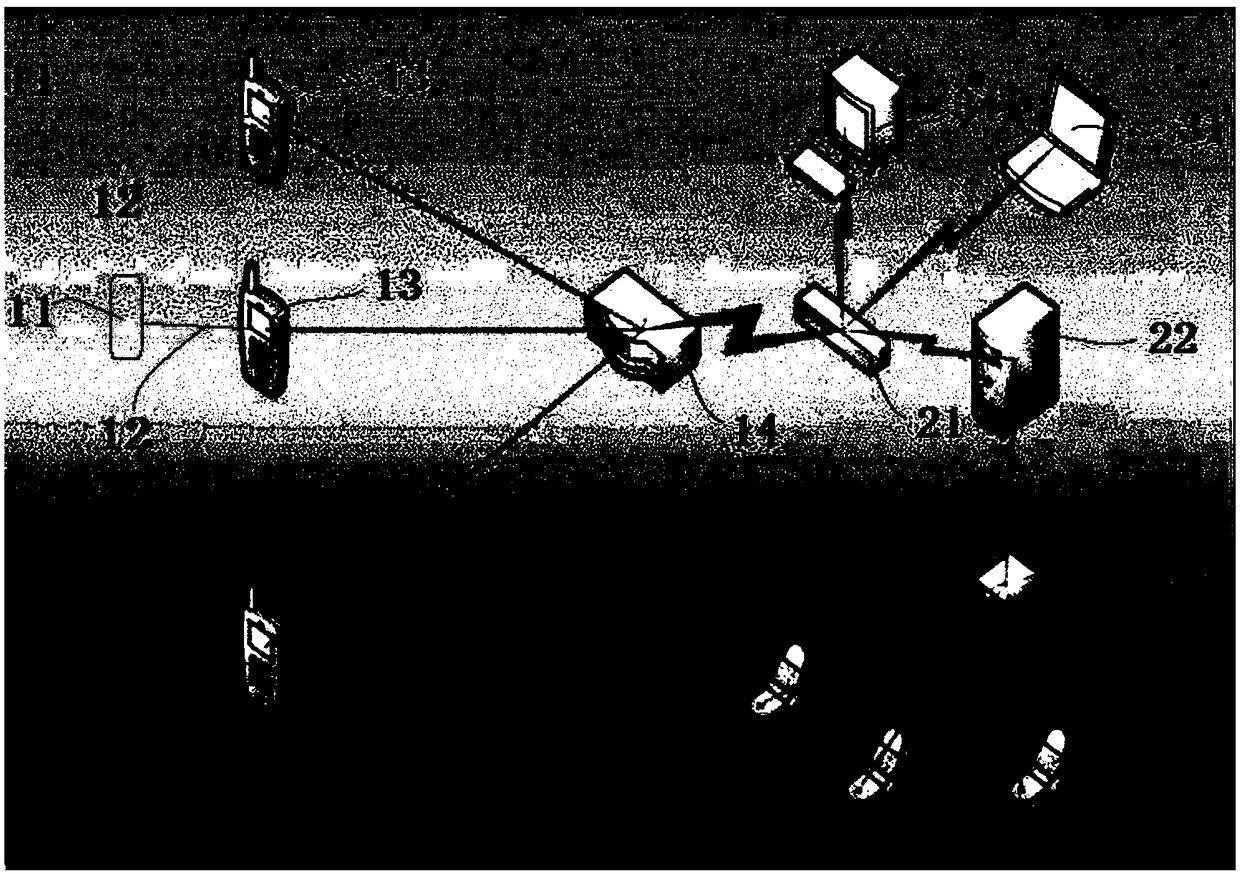

The invention relates to the field of concrete temperature monitoring in the construction process of railways and highways, in particular to a concrete temperature control early warning system. The system includes an on-site temperature acquisition system, a remote processing system and a use terminal, and the on-site temperature acquisition system is used for being placed in a concrete site and measuring the temperature of each placement point, and transmitting the measurement data to the remote processing system; the remote processing system is used for receiving the measurement data, performing arithmetic processing, and transmitting the operation result to the use terminal; the use terminal is used for receiving and displaying the operation result. The system automatically monitors andrecords the temperature data by setting a thermometer in the relevant part of the concrete, then wirelessly transmits the data to a remote server, automatically calculates and processes through software, generates a temperature time coordinate curve or a data record table, feeds back to the use terminal, and provides convenience for the use terminal to conveniently acquire and monitor temperaturechanges and quickly take effective countermeasures to avoid quality accidents.

Owner:ROAD & BRIDGE ENG CO LTD OF CHINA RAILWAY SEVENTH GRP

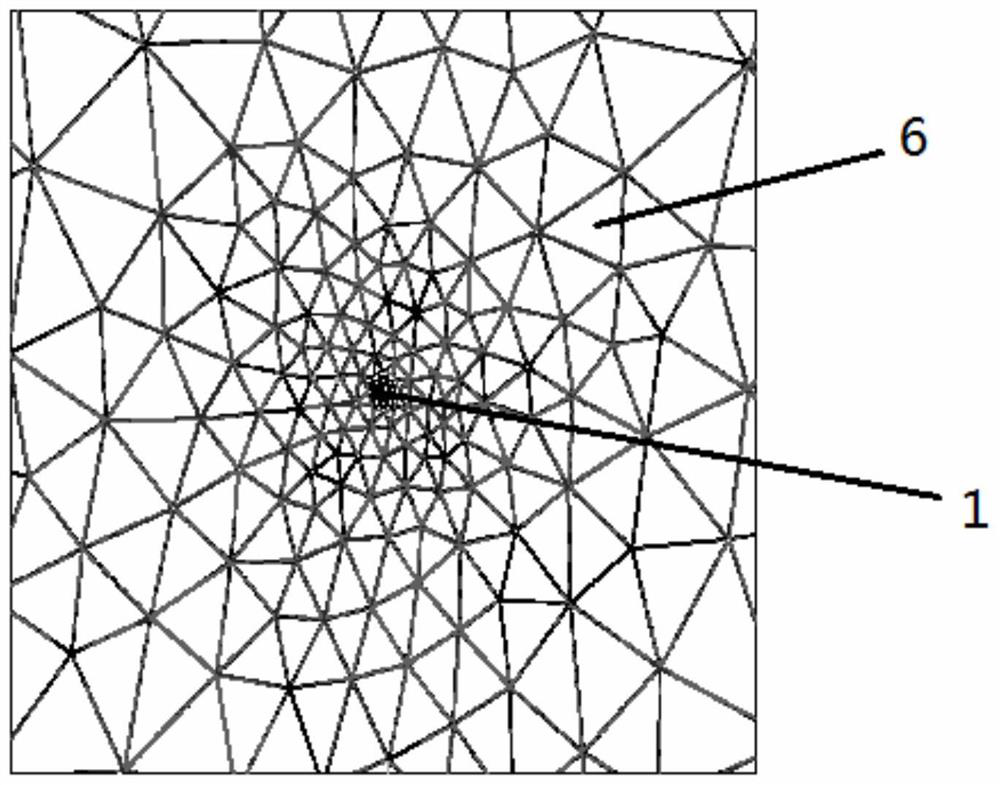

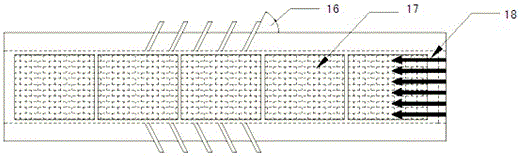

Distributed soil heat conductivity coefficient testing system and testing method thereof

ActiveCN111624227AReduce volumeEasy to carryMaterial heat developmentThermodynamicsThermal coefficient

The invention discloses a distributed soil heat conductivity coefficient testing method and testing system, and the testing method comprises the following steps: burying a composite optical cable in ato-be-tested soil body, wherein the composite optical cable comprises an optical fiber and a thermal resistance material layer wrapping the optical fiber; a heating control module is used for heatingthe to-be-measured soil body through the thermal resistance material layer, and an optical signal processing control module is used for continuously collecting heating temperature data of the stratum; processing the heating temperature data by using an optical signal processing control module, calculating and outputting heat conductivity coefficients of the soil body to be measured at different depths according to a heat conductivity coefficient calculation formula, and drawing a curve graph of the heat conductivity coefficients and the depths. According to the invention, the testing system is small in size, convenient to carry, long in testing distance, capable of monitoring the temperature change of the rock-soil body in a deeper range, high in testing efficiency, small in testing result error and capable of obtaining a refined stratum heat conductivity coefficient within a short testing time.

Owner:NANJING UNIV +1

Sulfonation reactor and use method thereof

ActiveCN103432978AIncrease reaction rateImprove liquidityChemical/physical/physico-chemical stationary reactorsTemperature controlReaction rate

The present invention discloses a sulfonation reactor and a use method thereof, and belongs to the field of sulfonation reaction equipment. The sulfonation reactor comprises a sealed reaction container, wherein the top of the reaction container is provided with a plurality of material inlet pipes, the bottom of the reaction container is provided with a material outlet, the top of the reaction container is vertically provided with an emptying pipe, and is further vertically provided with a co-current pipe, the top of the co-current pipe is sealed and is provided with a ventilation pipe, the side wall of the co-current pipe is provided with a material inlet, a circulation pipeline is connected and arranged between the material inlet and the material outlet, one circulation pipeline end close to the material outlet is provided with a material discharge valve, the circulation pipeline is further provided with a material feeding pipe, and the material feeding pipe is provided with a material feeding valve. According to the sulfonation reactor with the structure, during use, a material is subjected to a circulation reaction in the reactor through the circulation pipeline so as to increase a sulfonic acid concentration and improve product quality, and the sulfonation reactor is provided with a thermometer casing and a temperature control device so as to ensure a reaction rate and reaction quality of the sulfonation reaction.

Owner:安阳市双环助剂有限责任公司

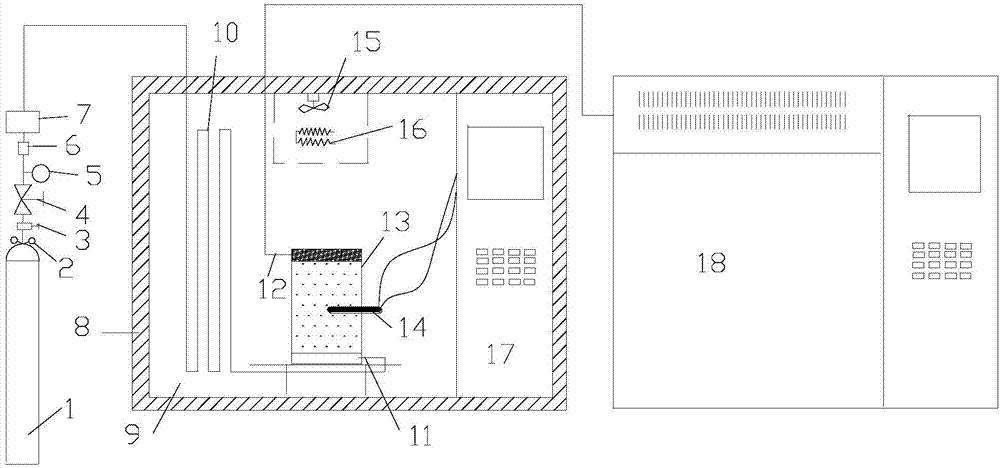

Chromatographic analysis and index optimization determinator for coal bed spontaneous combustion mark gas

PendingCN107449847AFast injection timeRealize the requirement of recycling the gas samples generated in the coal sample tankComponent separationSpontaneous combustionTemperature control

The invention discloses a chromatographic analysis and index optimization determinator for a coal bed spontaneous combustion mark gas. The chromatographic analysis and index optimization determinator comprises a temperature control box, wherein a coal sample tank is arranged in the temperature control box; a gas inlet pipe is arranged at the bottom of the coal sample tank; the gas inlet pipe is connected with a gas intake system arranged outside the temperature control box; a gas delivery pipe of the gas intake system is connected with a preheating tube after entering the temperature control box; the preheating tube is connected with the gas inlet pipe; a gas outlet pipe is arranged at the upper part of the coal sample tank and connected with a gas chromatographic instrument; a temperature sensor I for detecting the temperature in the coal sample tank is mounted on the coal sample tank in an inserting manner; a temperature sensor II is arranged in the temperature control box; and the temperature sensor I and the temperature sensor II are connected with a controller; and the controller is used for controlling the temperature in the temperature control box according to the detected temperature, and simultaneously monitors and records temperature changes of the temperature control box and the coal sample tank.

Owner:SHANDONG DINGAN TESTING CO LTD

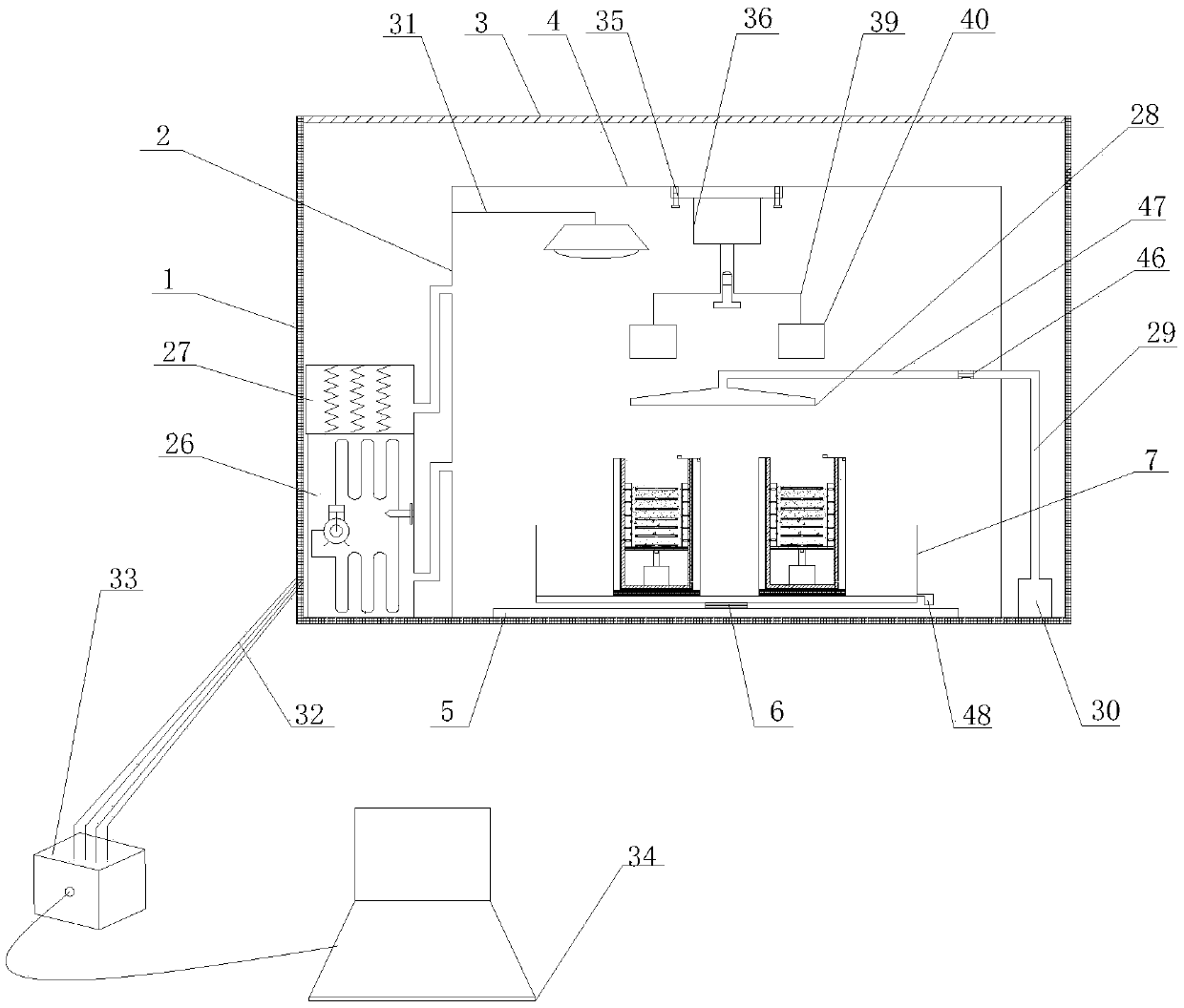

Frozen soil upper limit change rule testing method

ActiveCN109668923AMonitor temperature changesThe test result is accurateMaterial heat developmentSurface/boundary effectFreeze thawingData acquisition

The invention discloses a frozen soil upper limit change rule testing method. A frozen soil upper limit change rule testing device comprises an outer tank body, an inner tank body, a data collection model and a system control and data collection computer, wherein the inner tank body is located at the inner part of the outer tank body; an outer tank cover and an inner tank cover are respectively arranged on the upper ends of the outer tank body and the inner tank body; a heating module and a refrigerating module are arranged in a position between the outer wall of the left side of the inner tank body and the inner wall of the outer tank body; the heating module and the refrigerating module are respectively communicated with the inner tank body. The invention relates to the technical field of geotechnical testing and measuring. A monitoring sensor buried in a soil sample can be used for monitoring the soil sample temperature change and a moisture migration situation during frozen soil freeze thawing, initial conditions and boundary conditions of a soil temperature conduction and moisture conduction differential equation can be determined according to measured data of the monitoring sensor, analytic solution can be solved according to a variable separation method, an upper limit position change rule can be obtained by combining temperature and moisture judgment criterion and substituting the analytic solution into an analytic solution formula, testing is controlled by a computer system, and a testing result is more accurate.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Electric tracer heating system online monitoring and management scheme

InactiveCN104019923AGood compatibilitySignal output is accurateThermometers using physical/chemical changesElectric heatingHeating system

The invention discloses an electric tracer heating system online monitoring and management scheme and relates to a monitoring and management scheme. The electric tracer heating system online monitoring and management scheme comprises a monitoring host, an optical fiber converter, a temperature measurement host, a pipeline from a temperature sensing optical fiber to a furnace detection instrument, an alarm output unit and a DCS alarm input system, wherein the temperature measurement host is connected with the optical fiber converter, the pipeline from the temperature sensing optical fiber to the furnace detection instrument, and the alarm output unit; the optical fiber converter is connected with the monitoring host; the alarm output unit is connected with the DCS alarm input system. A communication platform with the remote monitoring function is designed, so that a good application basis is provided for the monitoring system. The optical fiber is installed on the measured instrument pipeline, and by the utilization of the characteristics that the optical fiber is high in temperature measurement precision and rapid in response, the changes of temperature of the instrument pipeline can be accurately mastered. A passing path is defined in a subsection mode, and data are collected continuously in a concentrated mode. Alarm output points are set freely within the working range according to actual demands, so that a whole-process management target of an electric tracer heating system is achieved.

Owner:李军

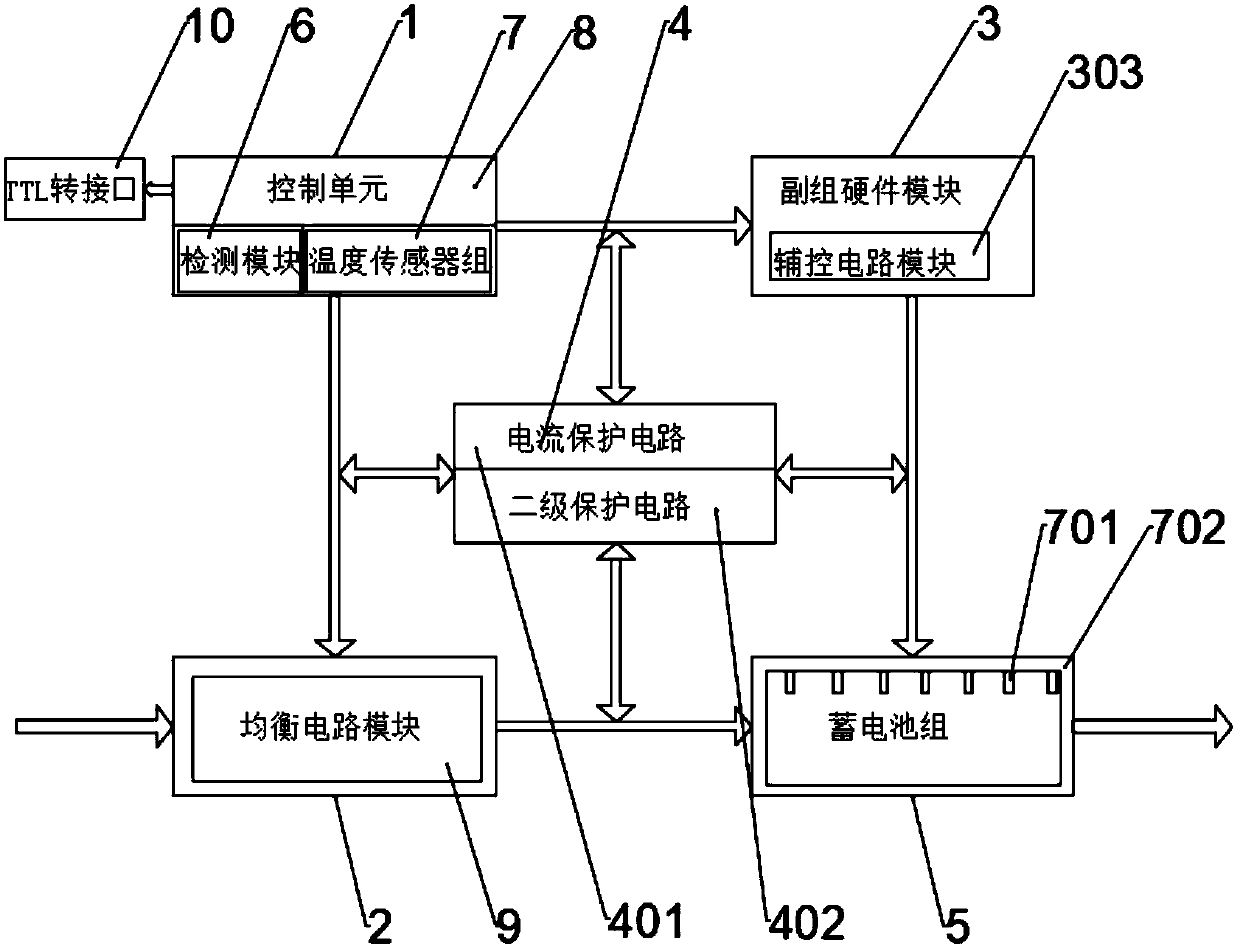

Battery management system suitable for low-temperature operation

ActiveCN108032745AEffective heating and insulationImprove working conditionSecondary cells charging/dischargingElectric vehicle charging technologyData informationElectrical battery

The invention discloses a battery management system suitable for low-temperature operation. The battery management system comprises a detection and control module, a charging and adjusting module, anauxiliary hardware module and a protection module, wherein the detection and control module comprises a voltage and current detection module and a temperature sensor assembly used for a storage battery pack; the data analysis of data signals of the detection module are performed through a control unit in the detection and control module and the data signals are compared with preset data values; the control unit transmits compared execution signals to an equalization circuit module in the charging and adjusting module; after analyzing detection data of the temperature sensor assembly, the control unit drives the operation of the auxiliary hardware module through electric signals; data information and an execution process are packed into a log file and the log file is sent to the control unit; and the control unit realizes data communication through a TTL transform interface provided by a single-chip microcomputer. The effective heating for heat preservation of the storage battery is achieved by virtue of the comprehensive detection and circuit interference of the charging and discharging process of the storage battery and by virtue of the auxiliary hardware module, so that the storage battery is maintained in a good operation condition.

Owner:安徽特凯新能源科技有限公司

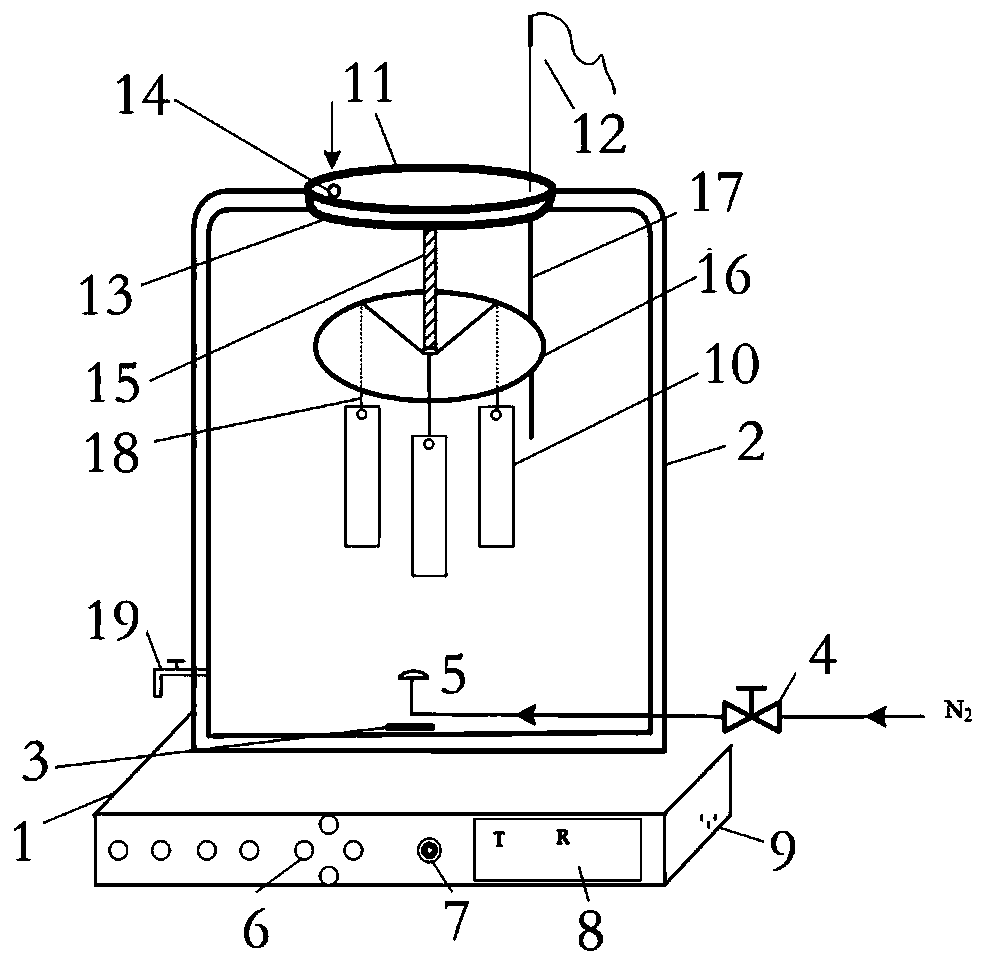

Corrosion inhibitor evaluation integrated device and using method thereof

PendingCN109724911AEvaluation data is reliableSimple structureWeather/light/corrosion resistanceEngineeringCorrosion inhibitor

The invention discloses a corrosion inhibitor evaluation integrated device and a using method thereof. The corrosion inhibitor evaluation integrated device comprises a constant temperature magnetic stirring device, a bottle body device, an aeration device, a venting device, an outer cover inner cover and bracket device, and a dosing and temperature monitoring device; the bottle body is detachablyfixed to a heating panel of the constant temperature magnetic stirring device; the aeration device comprises an aeration port extending from the bottom of the bottle body into the bottle body, and a shut-off valve connected to an aeration port pipe; the venting device is disposed at the bottom of the bottle body; the inner cover inner cover and the bracket device further comprises an outer cover,an inner cover and a bracket; and the dosing and temperature monitoring device comprises a ceramic hollow column, a temperature sensor placed in the ceramic hollow column and the induction probe is inserted into the bottle solution, and a dosing hole. The invention has the advantages of simple structure, convenient operation and high degree of automation; therefore, the problems that the laboratory corrosion inhibitor evaluation is difficult and the parallel degree of the experimental data is poor are effectively solved, the time and space of the experiment evaluation are saved, and the detection level is improved.

Owner:KARAMAY SANDA NEW TECH +1

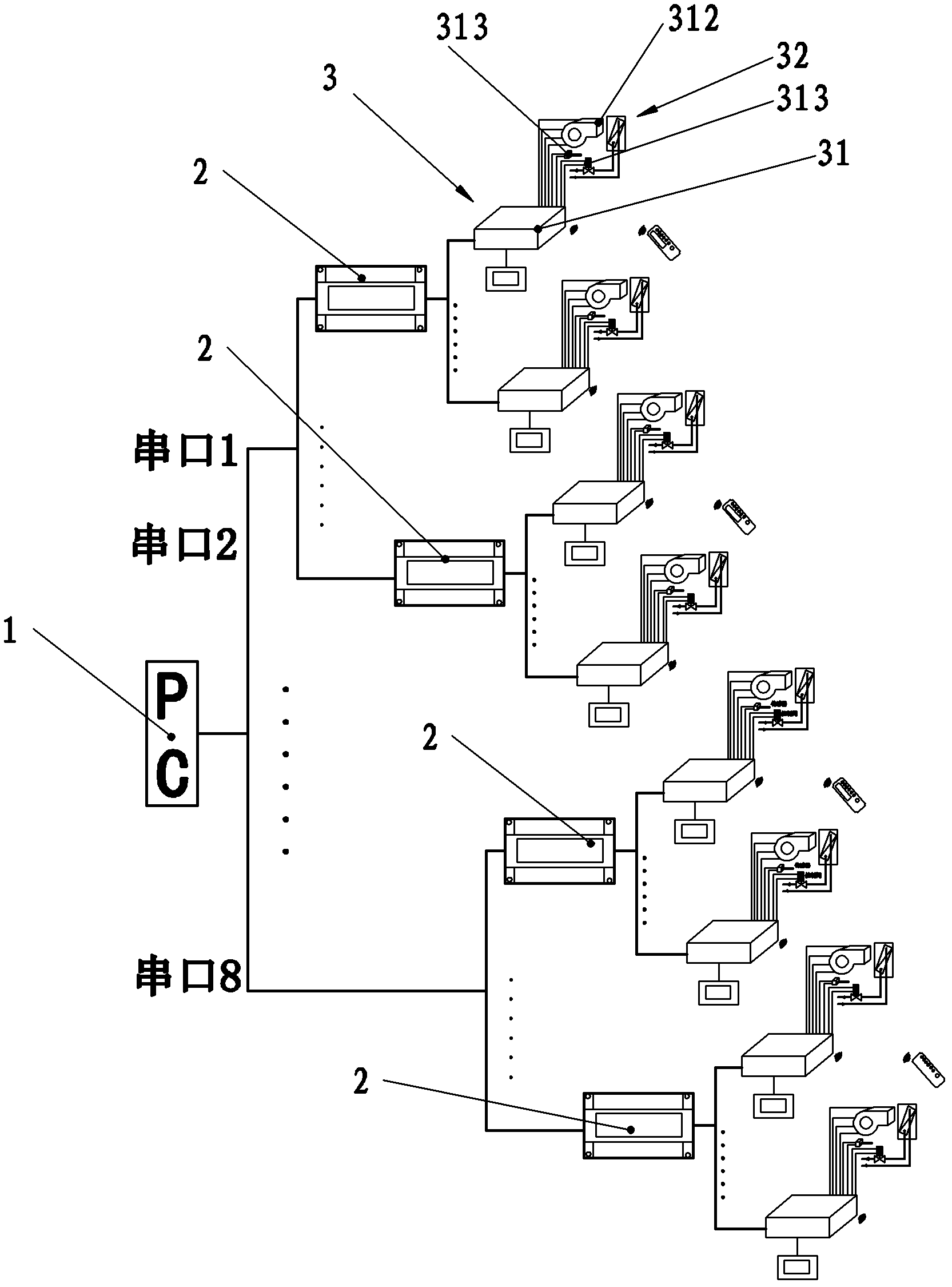

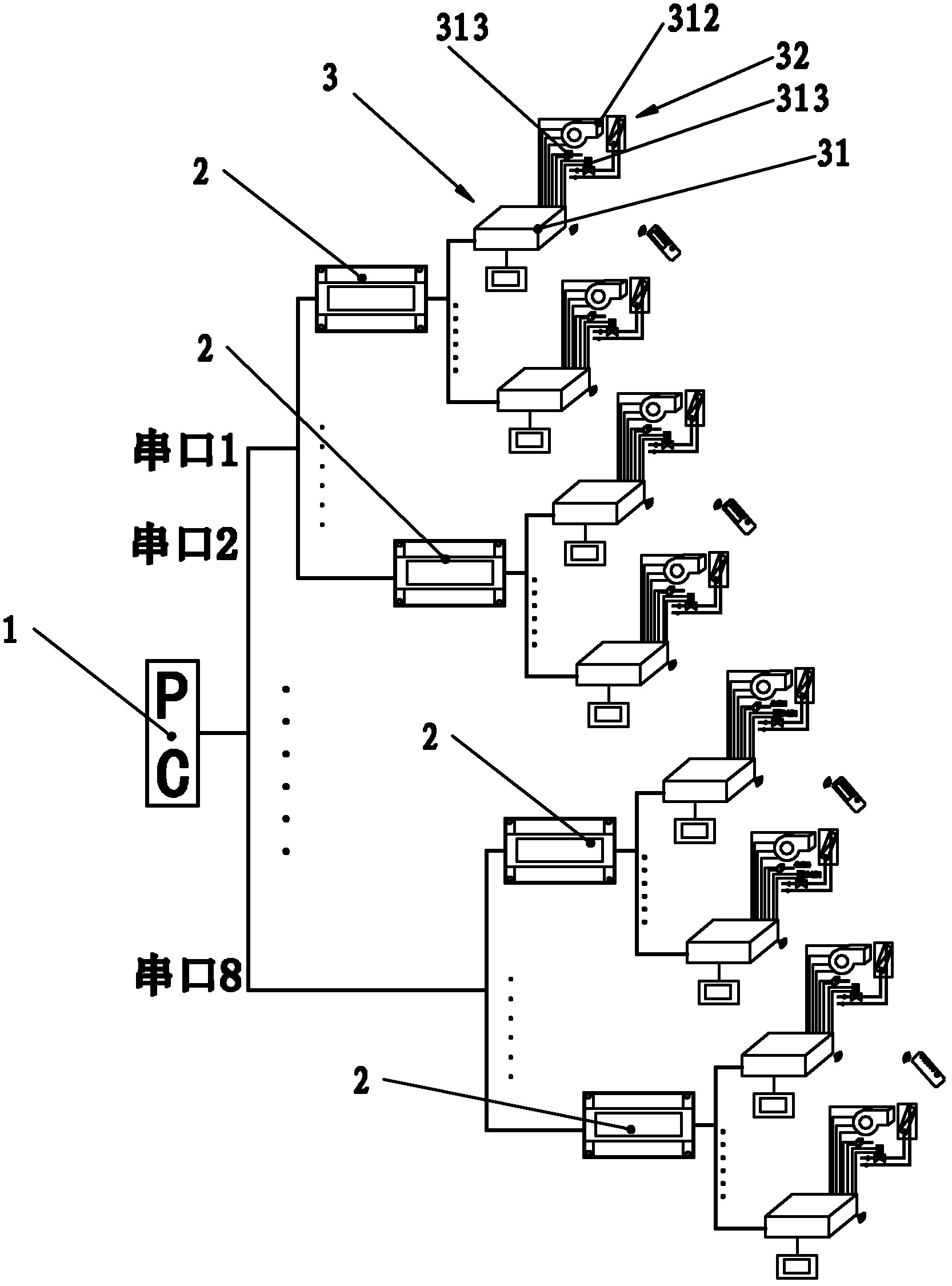

Water resource heat pump central air conditioner centralized control system and charging method

InactiveCN102322674AMonitor usage statusMonitor temperature changesSpace heating and ventilation safety systemsTariff metering apparatusWater source heat pumpControl system

The invention relates to a water resource heat pump central air conditioner centralized control system and a charging method. The invention provides the following technical scheme that: the water resource heat pump central air conditioner centralized control system is characterized by comprising a computer host, a repeater and a user control module, wherein the user control module comprises a central air conditioner fan coil control system and a room controller. The technical scheme of the charging method is that the charging method comprises the following steps of: 1, inputting; 2, system data acquiring; and 3, data processing, namely calculating the refrigerating or heating total power WZi of the ith user fan in a unit time and the energy charge Wi distributed to the ith user in a unit time according to a formula. The invention provides a novel sub-room temperature control system and the charging method which are convenient in wiring, simple in maintenance, suitable for exposed and concealed installation and low in cost.

Owner:曼瑞德自控系统(乐清)有限公司

Method for welding martensite heat-resistant steel

ActiveCN109794668APrevent oxidationLow costArc welding apparatusWorkpiece edge portionsThick wallMartensite

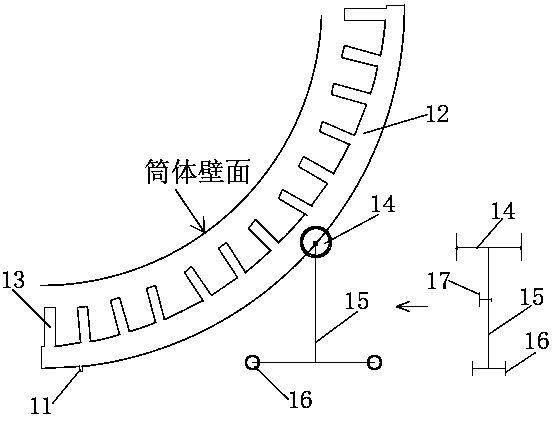

The invention relates to a method for welding martensite heat-resistant steel, and belongs to the field of high-parameter container manufacturing. For solving the problems that the closed seam weldingconstruction of the high-parameter container martensite heat-resistant steel used in a secondary reheating unit is prone to occur the conditions of crack defect, post-welding low hardness and the like, the method comprises the following steps that 1, a welding groove is machined; 2, pre-welding predation is performed; 3, pre-welding is preheated; 4, argon is filled; and 5, welding is performed; if a barrel body is too large, a weld joint is too long, an interlayer temperature is difficult to control, and then a flame heating temperature compensator is adopted to heated in a following mode soas to compensate for temperature loss, if the volume of the barrel body is too large, root oxidation cannot be prevented by establishing a large-scale closed gas protection chamber, and then a specialargon gas protection device is adopted for protection; and in the welding process of the high-alloy steel thick-wall container barrel body, the welding joint is heated in a flame preheating mode, thechange condition of the temperature is difficult to continuously measure, and a temperature monitoring device is arranged at the front end of the to-be-welded weld joint of the container barrel body.According to the method, the number of rework times and the probability can be reduced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Solar heating wireless monitoring and positioning system for oil storage tank

InactiveCN106395175ASolve monitoring problemsSolve positioningProgramme controlComputer controlSignal processing circuitsSolenoid valve

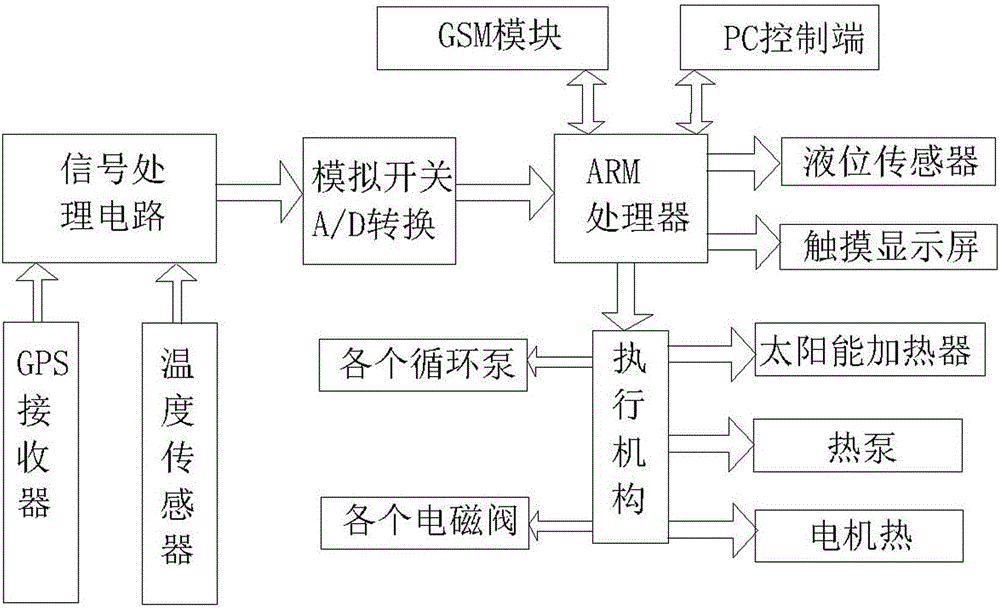

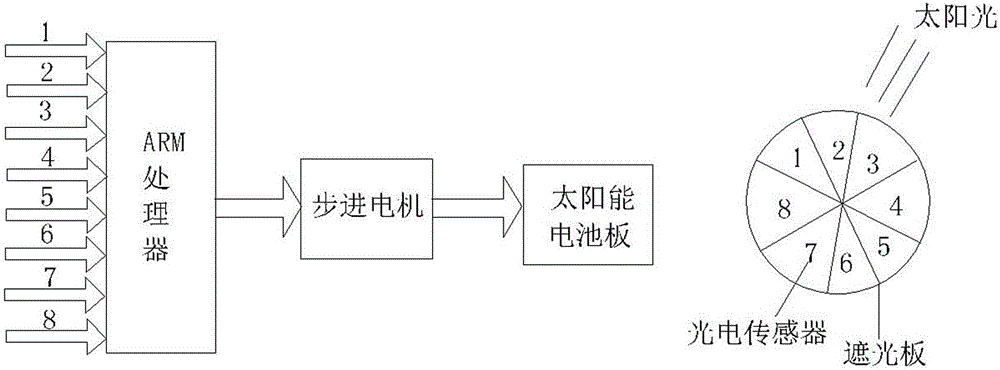

The invention discloses a solar heating wireless monitoring and positioning system for an oil storage tank. By adoption of the solar heating wireless monitoring and positioning system for the oil storage tank, energy waste can be greatly reduced, energy is saved, the environment is protected, and good application and popularization value is achieved. The solar heating wireless monitoring and positioning system for the oil storage tank comprises an ARM processor, a GSM module, a PC control terminal, an A / D convertor, a signal processing circuit, a GPS receiver, a temperature sensor, a circulating pump, a solenoid valve, an execution mechanism, a liquid level sensor and a touch display screen. The ARM processor is connected with the GSM module and the PC control terminal. The signal output end of the ARM processor is connected with the liquid level sensor and the touch display screen. The signal input end of the ARM processor is connected with the A / D convertor. The signal output end of the ARM processor is further connected with the execution mechanism. The input end of the A / D convertor is connected with the signal processing circuit. The input end of the signal processing circuit is connected with the GPS receiver and the temperature sensor. The output end of the execution mechanism is connected with the circulating pump and the solenoid valve. The output end of the execution mechanism is further connected with a solar heating module.

Owner:田荣侠

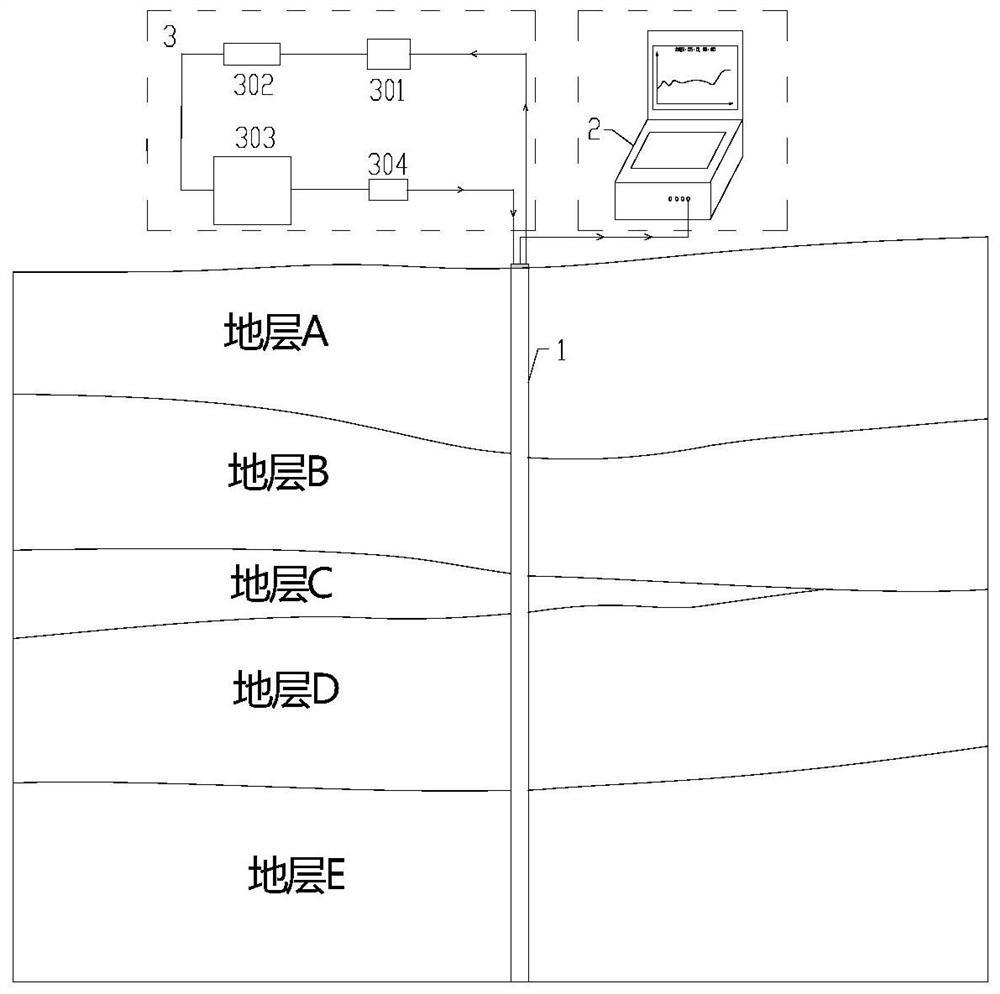

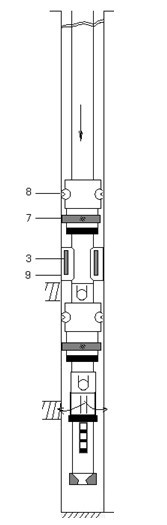

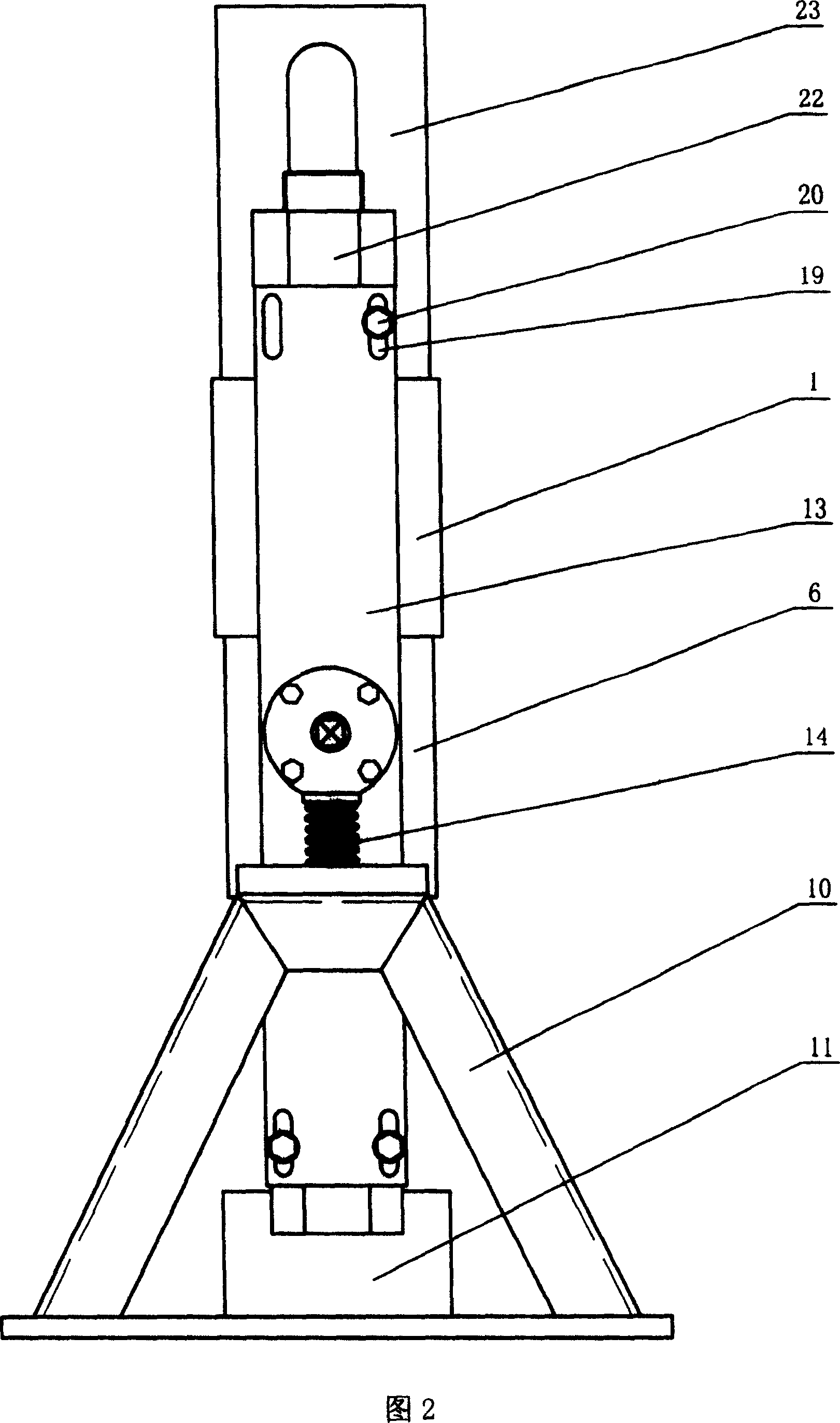

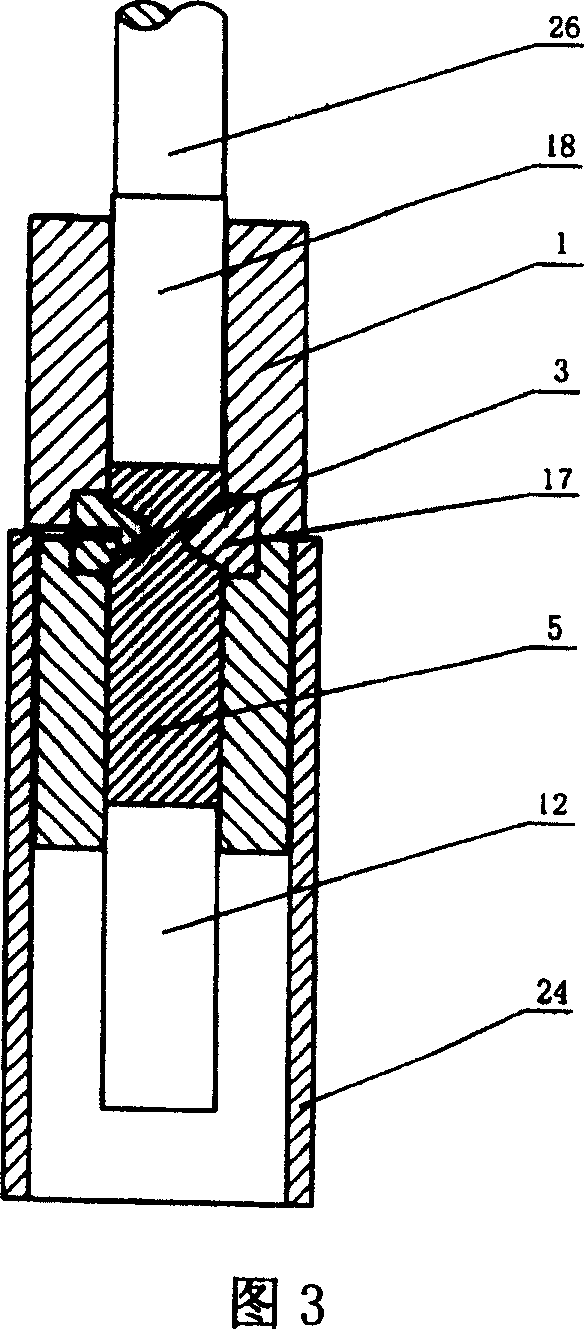

Hydrofracture bottom-hole pressure monitoring process

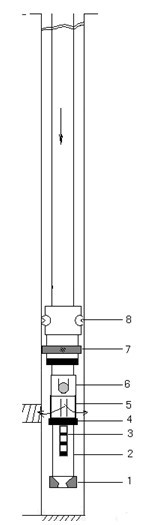

InactiveCN102518426AAccurate recordMonitor temperature changesSurveyFluid removalBottom hole pressureDesign software

The invention relates to a protection technology in the field of exploration and development of oil and gas fields, in particular to a hydrofracture bottom-hole pressure monitoring process, which includes the steps of firstly, tripping in a pressure monitoring device with a high-precision electronic pressure gauge (3) to the bottom of a fractured well near a measure stratum along with drilling; secondly, using the high-precision electronic pressure gauge (3) to monitor bottom-hole pressure and temperature change in the full fracturing course; and thirdly, tripping out the pressure monitoring device along with drilling or fishing the pressure monitoring device through wireline operation after fracturing is complete. By the process, the bottom-hole temperature and pressure change in the full fracturing course can be monitored in real time, and pressure and temperature data of the mass nearby a reservoir stratum in the process of fracturing, opening the well for gushing and swabbing can be recorded truly and accurately. The measure stratum is estimated accurately, and basis for utilizing fracturing design software to scientifically compile new fracturing schemes for a new well is provided. The process is applicable to monitoring of single-stratum and double-stratum hydrofracture bottom-hole pressure of oil wells and single-stratum hydrofracture bottom-hole pressure of gas wells.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

Temperature measurement soft fire resistant transmission signal cable

InactiveCN106057351AStrong fire resistanceSmall outer diameterCommunication cablesInsulated cablesTemperature measurementMetal

The invention discloses a temperature measurement soft fire resistant transmission signal cable which comprises a cable core which is formed by twisting three insulating wire cores and a fiber unit. The gap of the cable core is filled with glass fibers. A flame retardant fireproof layer is extruded outside the cable core. A metal conductive tube is extruded outside the flame retardant fireproof layer. An outer sheath is arranged outside the metal conductive tube. A temperature monitoring wire core is also arranged in the outer sheath and can monitor the temperature change of the cable in use, and external monitoring equipment is connected through a monitoring cable to carry out alarming.

Owner:JIANGSU YUANFANG CABLE FACTORY

Temperature self-adjusting device for inner tunnel kilns

ActiveCN106440777AIncreased mixed combustion areaReduce generationFurnace typesTunnel kilnReaction rate

The invention discloses a temperature self-adjusting device for inner tunnel kilns. The device comprises a kiln body, a temperature adjustment burner which is installed on the side wall of the kiln body, a blower which is installed at the end part of the kiln body, a temperature sensor which is installed inside the kiln body, a PID controller and a central controller, and a temperature adjustment burner angle adjusting mechanism. The device of the invention can control the angle of the temperature adjustment burner nozzle, the fuel gas injection speed, the speed of temperature adjustment burner nozzle, and the kiln tail blowing rate of the tunnel kiln; sintering researches on various refractory materials can be carried out, which increases the diversity of researches; compared with the original tunnel kilns, the accuracy of temperature adjustment is increased, the efficiency is increased, the reaction rate of execution mechanism is faster, the automatic degree is higher with less pollution, and environmental protection and energy saving performance are improved.

Owner:YANCHENG INST OF TECH

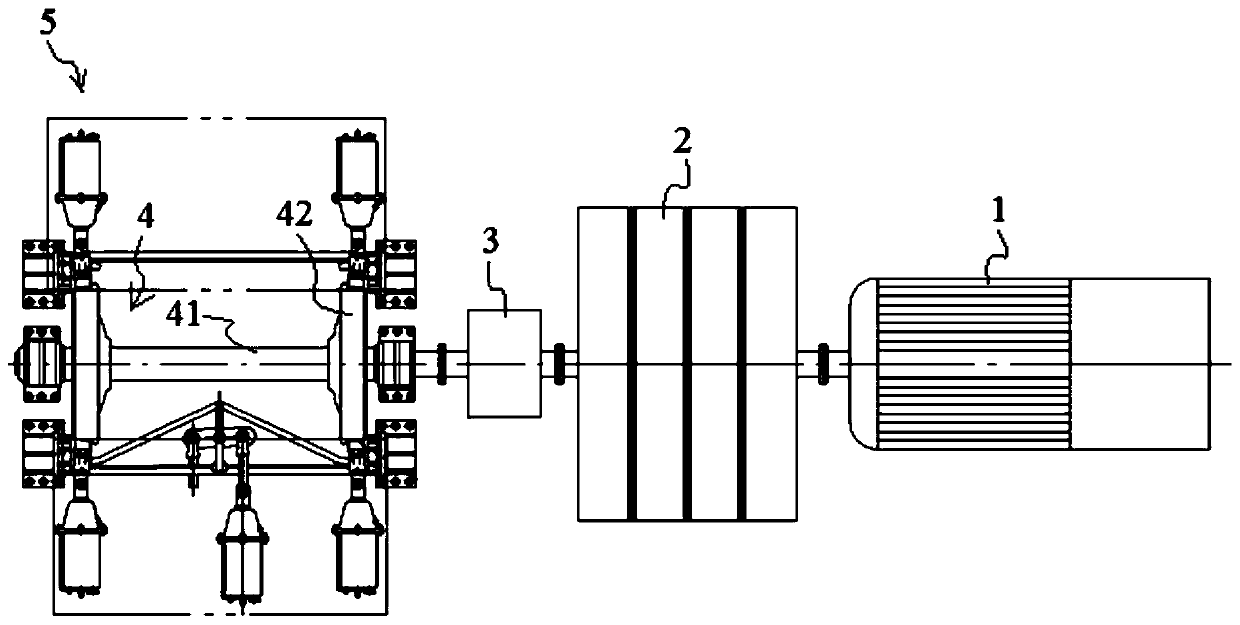

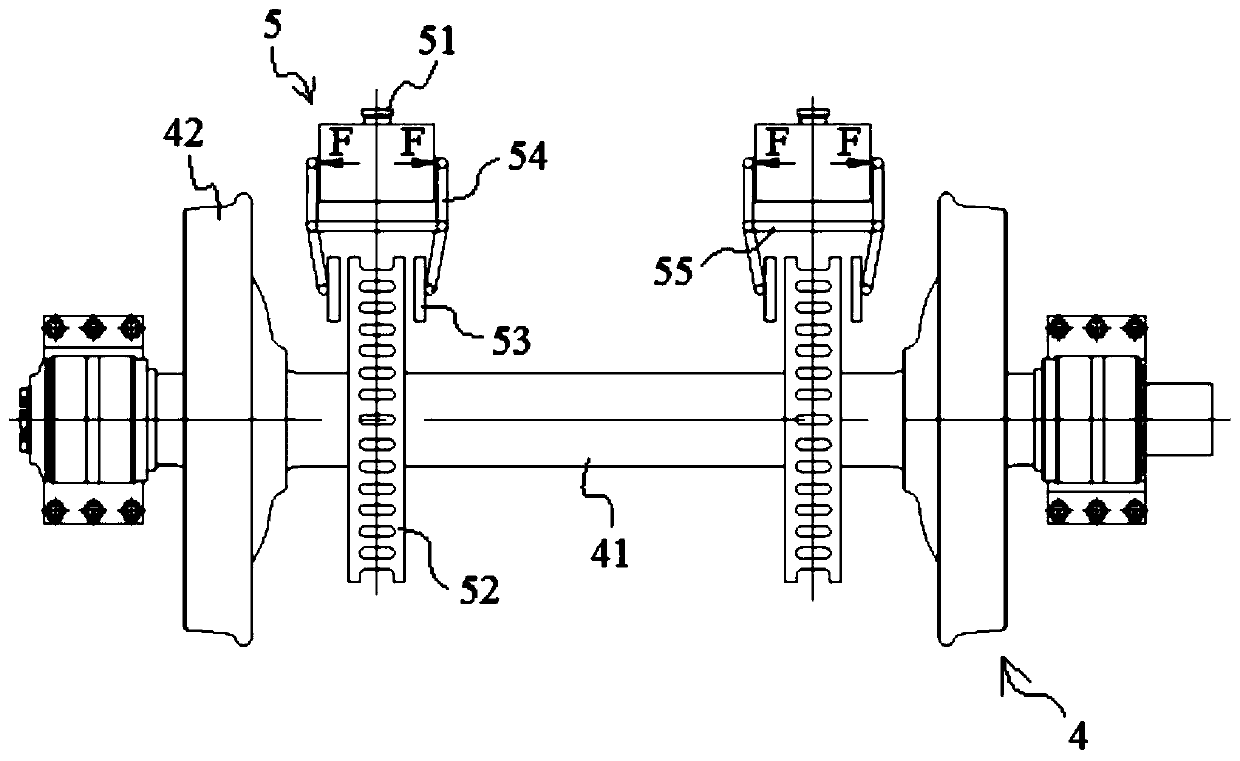

Dynamic performance testing system for basic braking device

The invention discloses a dynamic performance testing system for a basic brake device. The dynamic performance testing system comprises a driving part, an inertia wheel set, a gearbox and a wheel set,and the driving part is in transmission connection with the wheel set through the inertia wheel set and the gearbox; the dynamic performance testing system further comprises a foundation braking device, the foundation braking device comprises a brake cylinder and a brake output component; and the brake cylinder is in transmission connection with the brake output component and can drive the brakeoutput component to brake the wheel set, and the brake output component is further provided with a first sensor used for monitoring the brake force of the brake output component acting on the wheel set. Such a structure, the driving part, the inertia wheel set, the gearbox and the wheel set are arranged, the actual running state of the railway vehicle can be accurately simulated, then the brakingforce output by the braking output component is monitored through the first sensor, and the braking force transmission efficiency of the basic braking device of the railway vehicle under the dynamic condition can be obtained by comparing the braking force with the air pressure of the braking cylinder.

Owner:CRRC QIQIHAR ROLLING CO LTD

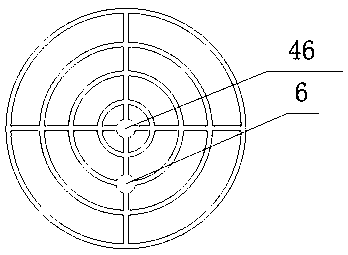

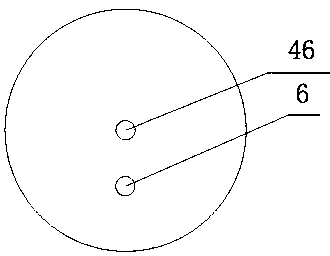

Ultrasonic vibration assisted self-rotating grinding machine and main shaft device thereof

PendingCN111168485AAvoid cloggingImprove grinding efficiencyGrinding drivesGrinding feed controlUltrasonic assistedMachined surface

The invention discloses an ultrasonic vibration assisted self-rotating grinding machine body and a main shaft device thereof. The main shaft device comprises a rotating main shaft part and an ultrasonic vibration part, and the ultrasonic vibration part is fixedly arranged on the rotating main shaft part; the ultrasonic vibration part comprises an ultrasonic generator, a transducer, an ultrasonic amplitude horn, a grinding wheel and an induction coil; and the ultrasonic generator is connected with the induction coil, the induction coil is arranged on the transducer, the transducer is connectedwith the ultrasonic amplitude horn, the grinding wheel is fixedly arranged at the tail end of the ultrasonic amplitude horn, the ultrasonic generator generates an ultrasonic signal, the ultrasonic signal is transmitted to the transducer through the induction coil to generate ultrasonic vibration, and then axial vibration is converted into radial vibration of the grinding wheel through the ultrasonic amplitude horn. The ultrasonic vibration assisted self-rotating grinding machine body and the main shaft device thereof have the following advantages that the grinding efficiency can be improved, the quality of a machining surface can be improved, the grinding wheel can also be prevented from blocking, and great significance is achieved for promoting wide application of ultrasonic assisted grinding technology.

Owner:HUAQIAO UNIVERSITY

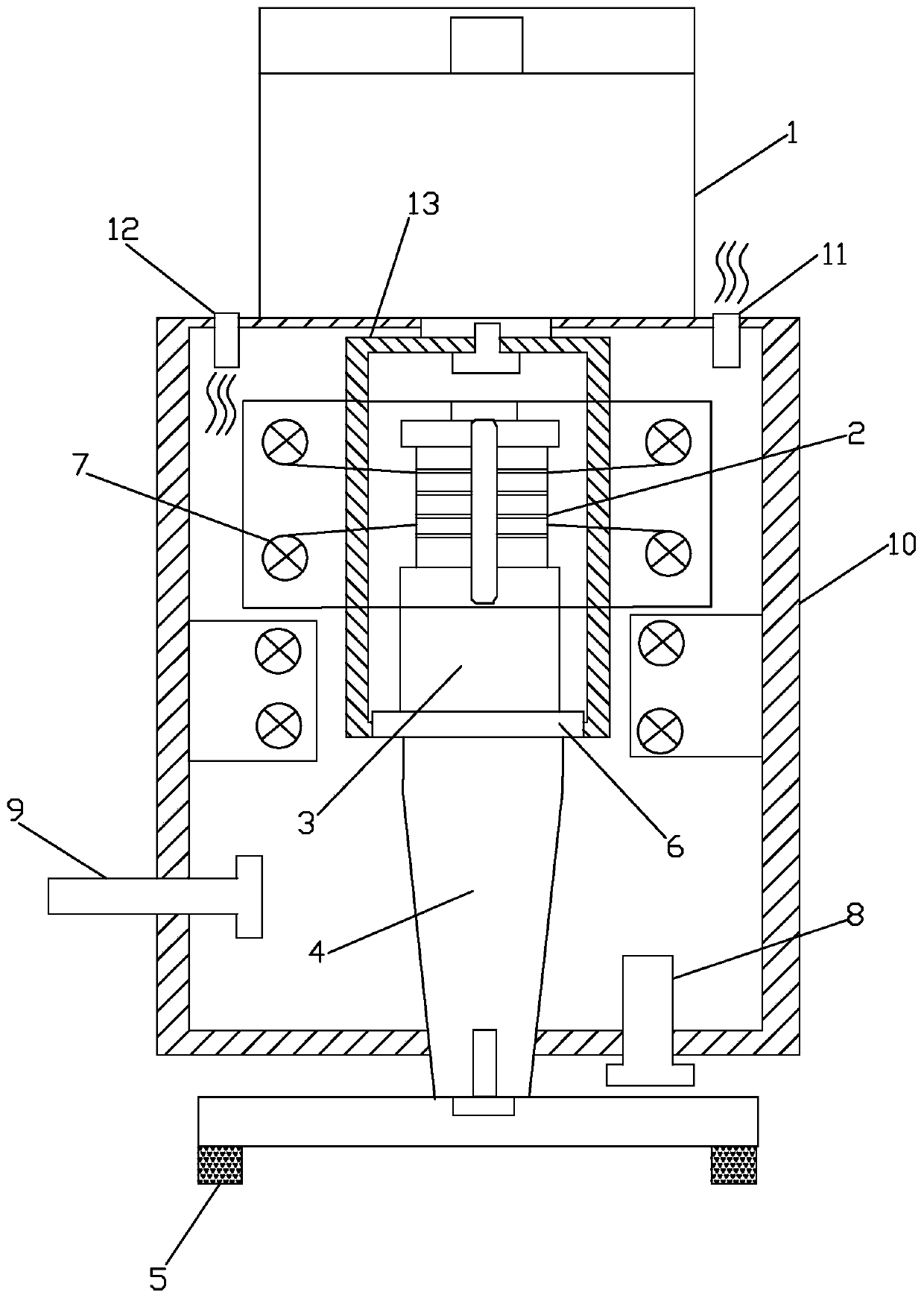

High-voltage electrical equipment temperature monitoring device

InactiveCN105784137AMonitor temperature changesReal-time monitoring of temperature changesThermometer detailsTransmission systemsEquipment temperatureElectric power equipment

The invention discloses an electrical equipment temperature monitoring device, and particularly relates to a high-voltage electrical equipment temperature monitoring device. The high-voltage electrical equipment temperature monitoring device comprises electrical equipment, wherein the electrical equipment is provided with a wireless temperature transmitter, the wireless temperature transmitter transmits a signal to a wireless temperature receiver, the wireless temperature receiver transmits the signal to a signal processor, the signal processor transmits the processed signal to a control host, and the control host stores the signal and transmits the signal to an alarm when the signal is abnormal. According to the high-voltage electrical equipment temperature monitoring device disclosed by the invention, the wireless temperature transmitter is installed on the high-voltage electrical equipment, temperature change of the high-voltage electrical equipment can be monitored in real time, the staff can be prompted timely through the alarm when the temperature is abnormal and not in a normal range, and the staff can handle the abnormal condition the first time, thereby avoiding the occurrence of major perils.

Owner:张敬敏

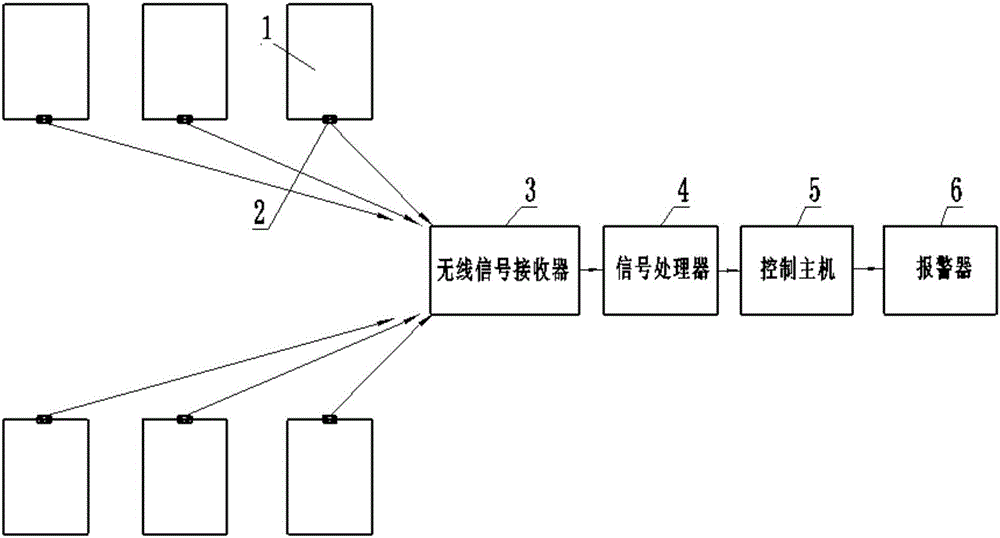

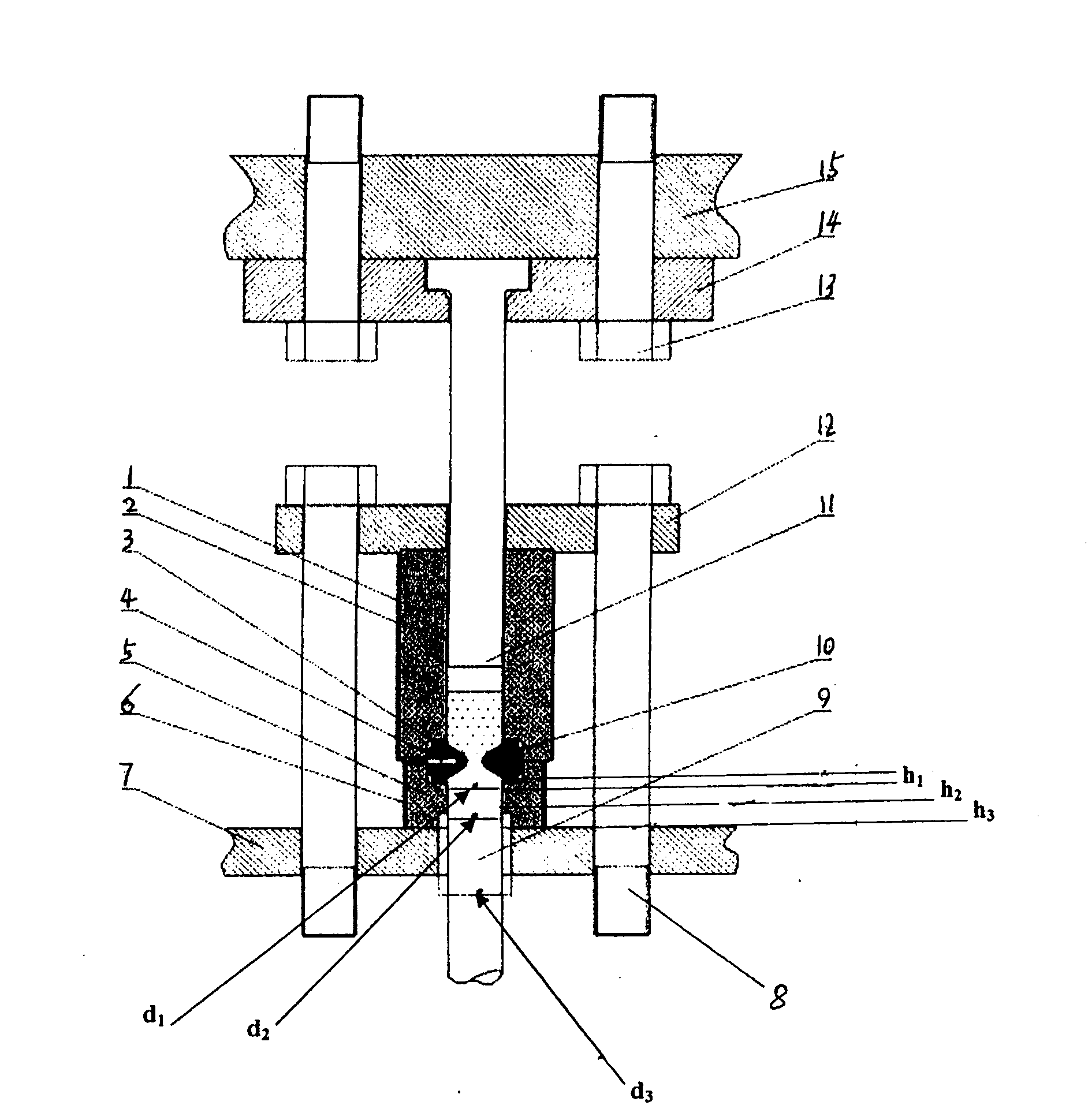

Reciprocating extrusion grain refining equipment and extrusion refining method therewith

InactiveCN100349664CSave energyReduce manufacturing costExtrusion diesExtrusion mandrelsEngineeringPlastic property

A reciprocating squeezer for fining crystal grains is composed of squeezing cylinder, die set consisting of male die and female die, upper and lower transverse connecting beams of dies, two screw bolts at both sides of die set and passing through said transverse beams, two transverse beams for turning the die set over, axles and its frame, and springs. Its squeezing method includes such steps as closing die set, squeezing and upsetting, turning the die set over by 180 deg, and squeezing and upsetting again.

Owner:XIAN UNIV OF TECH

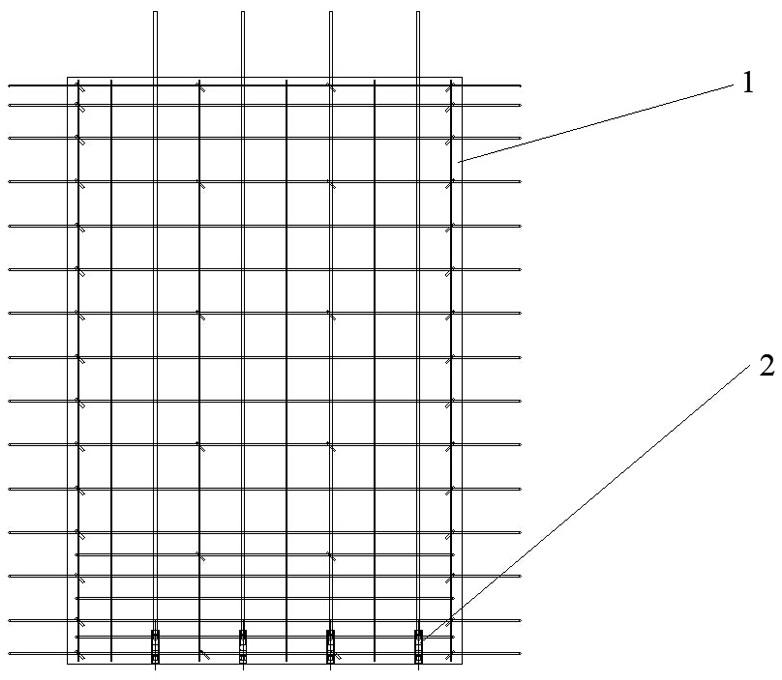

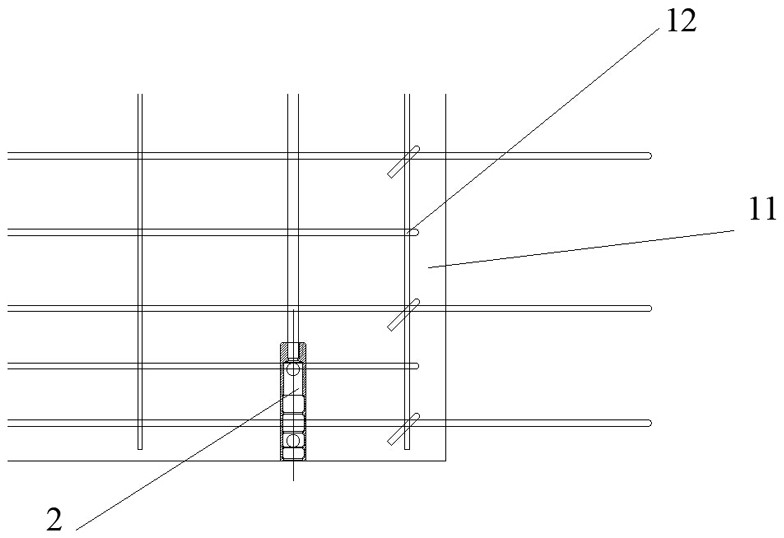

Winter grouting low-consumption construction method for fabricated building

InactiveCN113882672AEffective Grouting Construction OrganizationGuaranteed construction timeWallsBuilding reinforcementsArchitectural engineeringHeat conservation

The invention discloses a winter grouting low-consumption construction method for a fabricated building. The building is of a fabricated integral shear wall structure, prefabricated wall bodies are connected through grouting sleeves, a grouting operation area is totally closed and is subjected to heat preservation treatment, and a low-temperature grouting material is adopted for construction. According to the winter grouting low-consumption construction method, the low-temperature time in winter is divided, grouting construction organization can be effectively carried out, and corresponding heat preservation measures and construction methods are adopted in combination with the temperature difference of different time; the heat preservation measures are set, so that a certain amount of construction is conducted at low temperature, the construction time can be effectively guaranteed, and the heat preservation cost can be saved by combining the heat preservation measures with the structure; and a heat preservation monitoring facility is arranged, so that the temperature change during construction in winter can be effectively monitored, and a data basis is provided for construction methods and organizations.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU

Reagent pipe storage device for biological preparation

InactiveCN110721757ASimple structureReduce usageTest tube stands/holdersEnvironmental engineeringMonitor equipment

The invention discloses a reagent pipe storage device for a biological preparation. The reagent pipe storage device comprises a shell, which is connected to a shell cover through threads, wherein a vertical column is arranged in the center of the interior of the shell, a spring and an ejection rod located at the upper end of the spring are arranged in the vertical column, a plurality of barrel bodies are arranged on the shell cover, and pipe holes for fixing reagent pipes are uniformly distributed in the barrel bodies. According to the invention, the barrel bodies are placed in the shell, so that the reagent pipes on the barrel bodies can be protected, and the reagent pipes on the barrel bodies can be prevented from being polluted; the plurality of the pipe holes are formed in the barrel bodies, so that the more reagent pipes can be accommodated in the device at the same time so as to ensure the effective storage of the reagent pipes; based on a certain biological reagents sensitive totemperatures, a separation layer is arranged in the shell of the device and used for storing a refrigerant, so that the temperature in the shell is reduced through the refrigerant; and monitoring equipment can be arranged on the shell and used for monitoring the temperature change in the shell, so that the device is worthy of popularization.

Owner:VISION BIOLOGICAL TECH HEFEI CO LTD

A method of producing particle reinforced aluminum-base compound material continuously by using extrusion-upsetting and device thereof

InactiveCN101444802BSave energyReduce manufacturing costExtrusion diesExtrusion containersCoaxial lineEngineering

A method of producing particle reinforced aluminum-base compound material continuously by using extrusion-upsetting and device thereof, characterized in that the device comprises a machine frame that is composed of a extruding press base(7), upper platen (12) and abrasive tools connection conductor bar (8) connecting the base and the upper platen, a extrusion barrel provided between base and upper platen, and a lower pressing stem (9) provided inside the central axis hole of the base with its upper end extends to inner cavity of the extrusion barrel, and a upper pressing stem (11) provided inside the central axis hole of the upper platen with its lower end downwardly extends to the inner cavity of the extrusion barrel, wherein the extrusion barrel consists of upper and lower extrusion barrel(1, 5) in coaxial line which locked together, and a annular groove is processed on the inner wall of lock part of upper and lower extrusion barrel which is used for embedding left and right semi-circular cavity die (3, 10). The left and right semi-circular cavity die (3, 10) embedded in the annular groove forms compose demountable extrusion inner cavity.

Owner:HENAN POLYTECHNIC UNIV

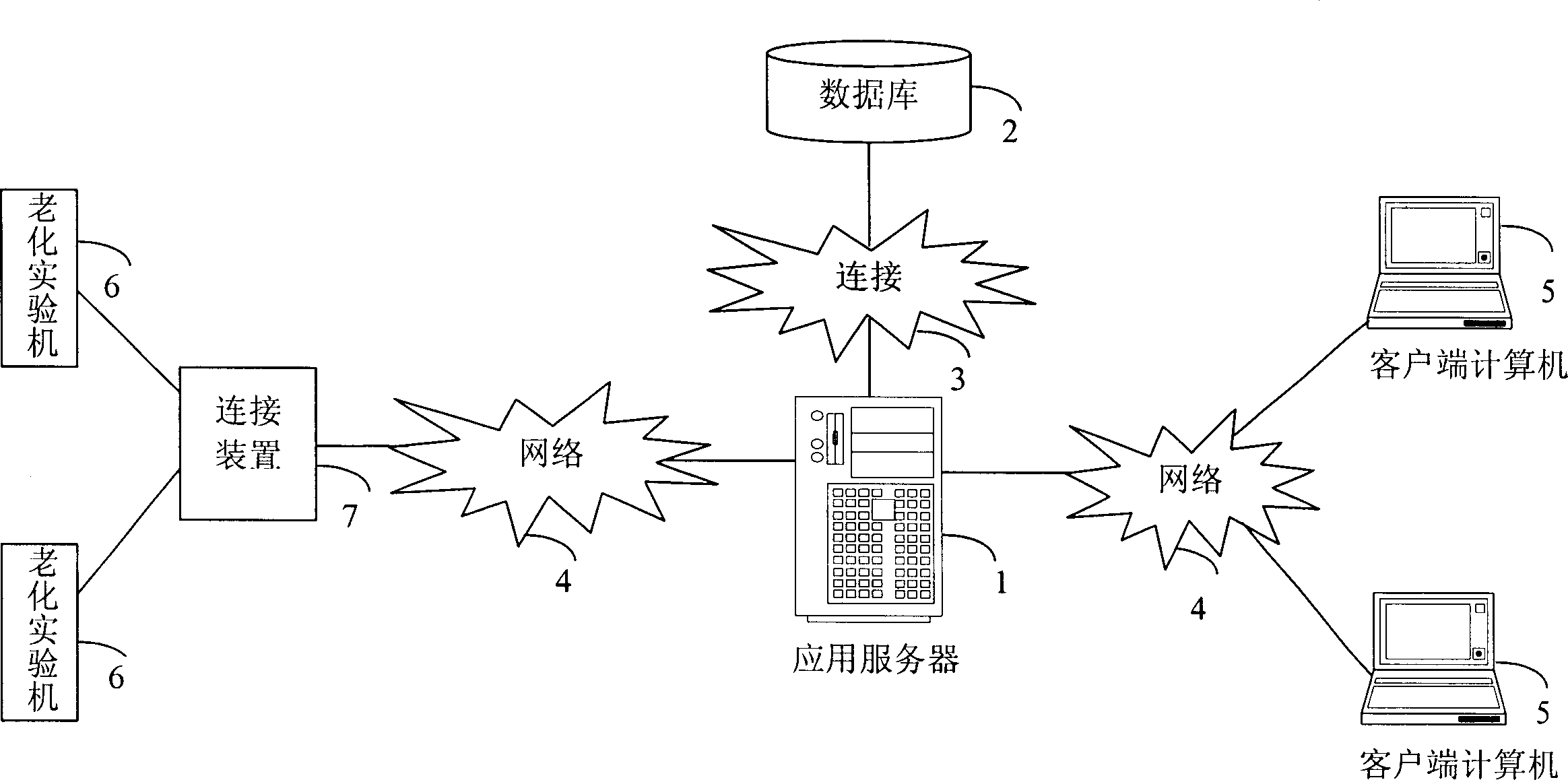

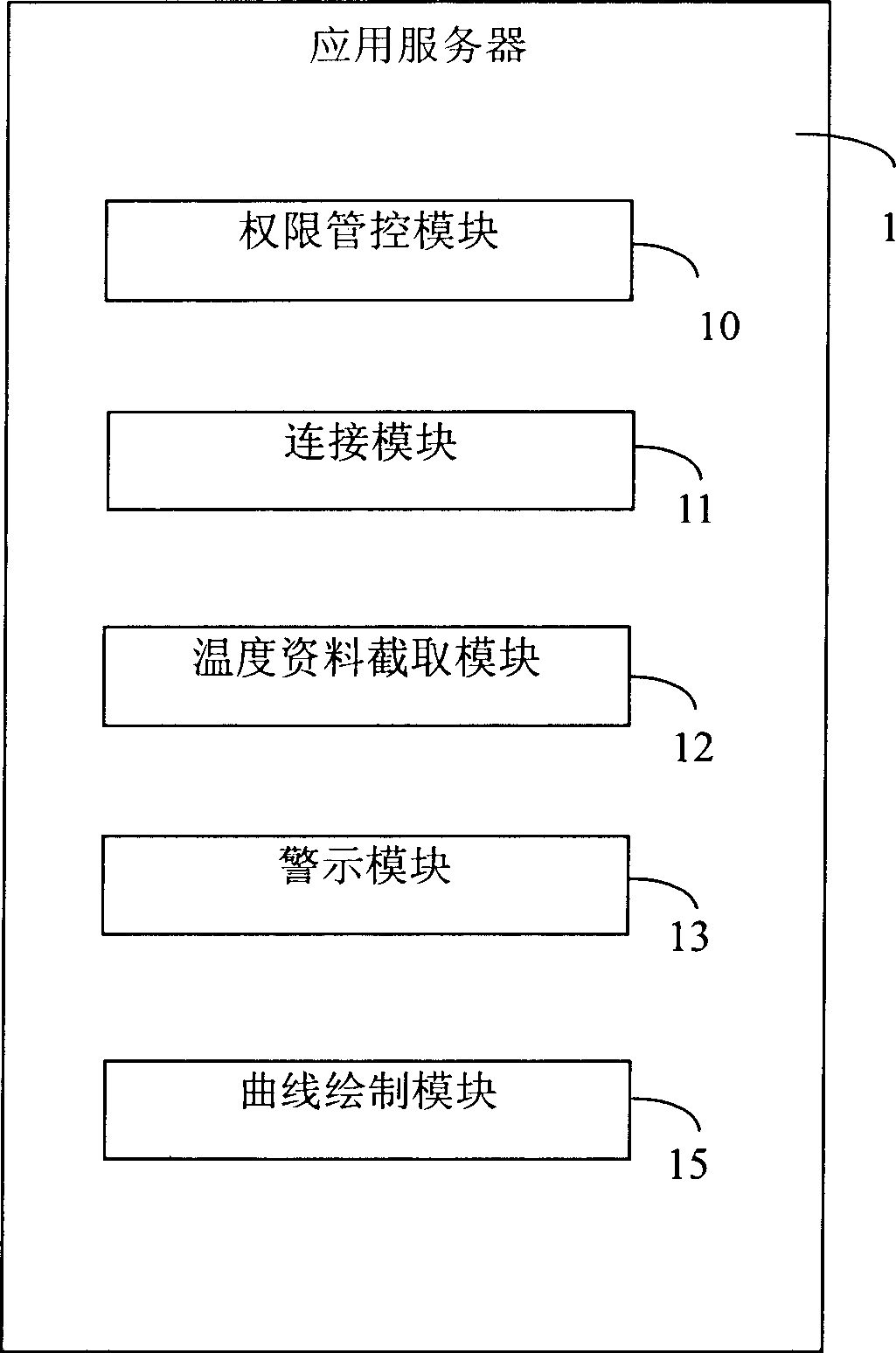

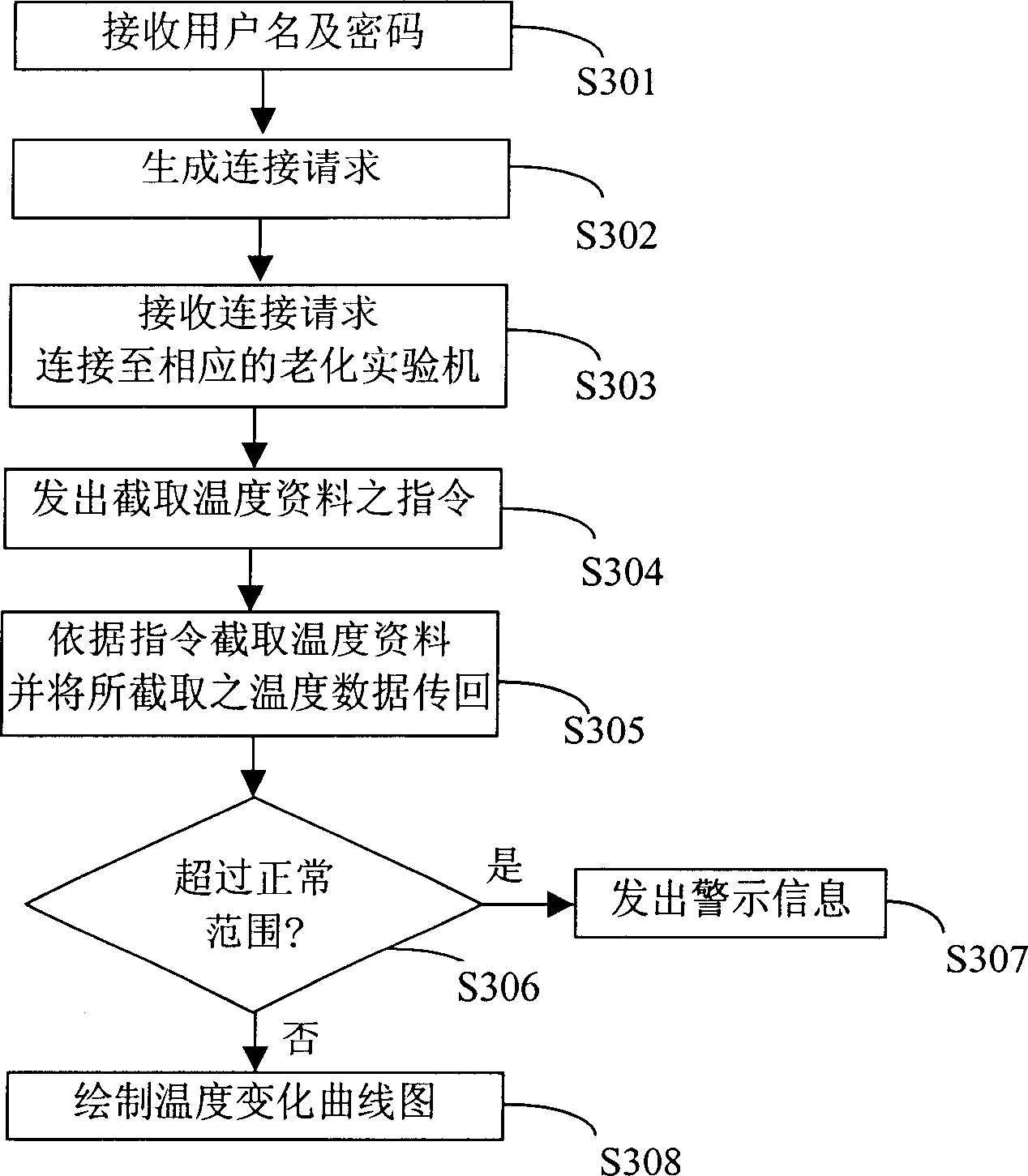

Temperature monitoring system and method

InactiveCN1680898ARemote monitoring of temperature changesImprove work efficiencyComputer controlTemperatue controlTemperature controlRelevant information

A temperature control system comprises an application server including right control module, connection module, temperature pick - up module, warning module and curve plotting module; a databank; a connection unit; multiple ageing test instruments and computers at client end. The control method includes using server to control using right of client, switching on ageing test instruments according to client requirement, picking up temperature data of said instruments and plotting out curve diagram of temperature variation.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

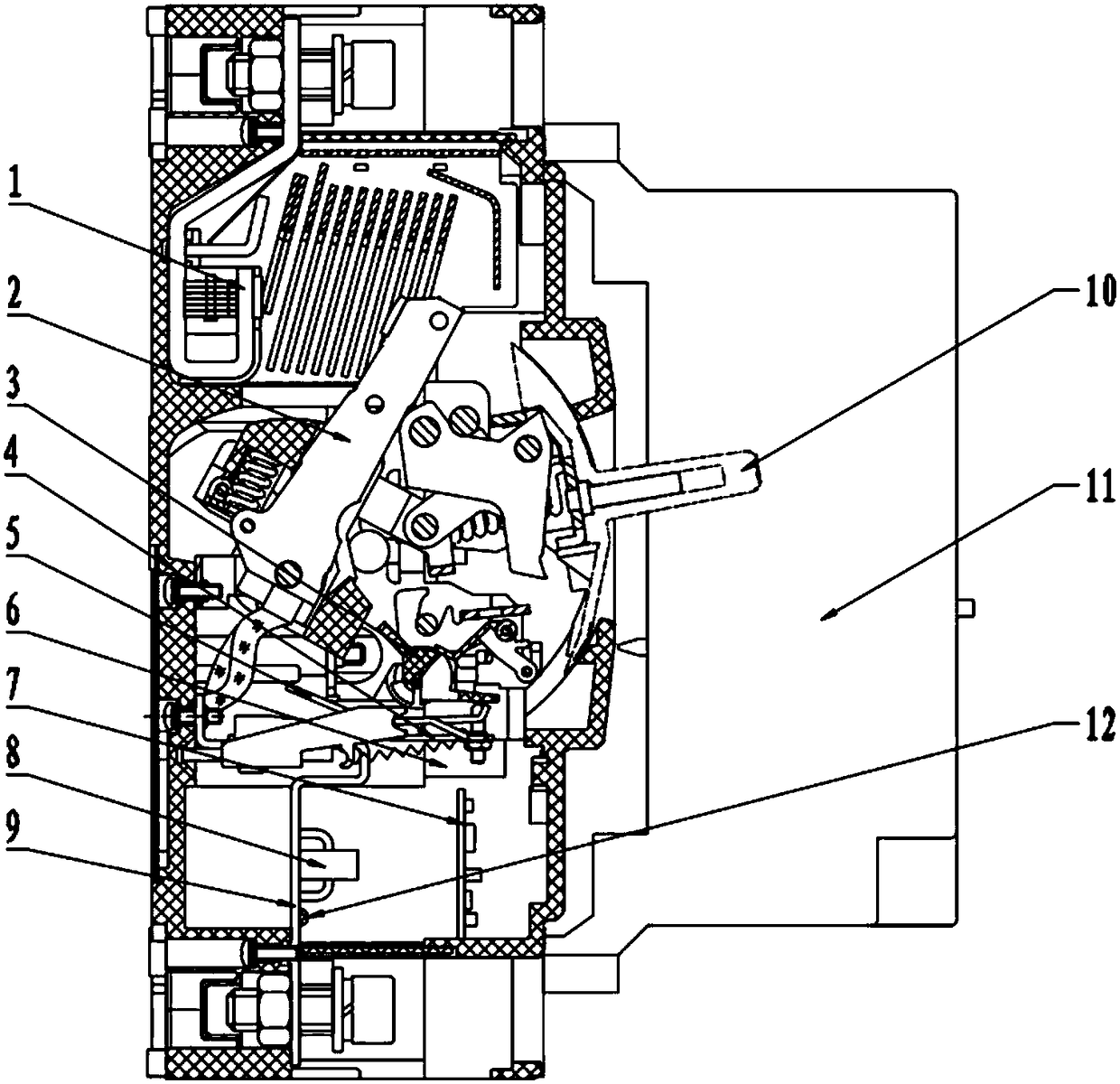

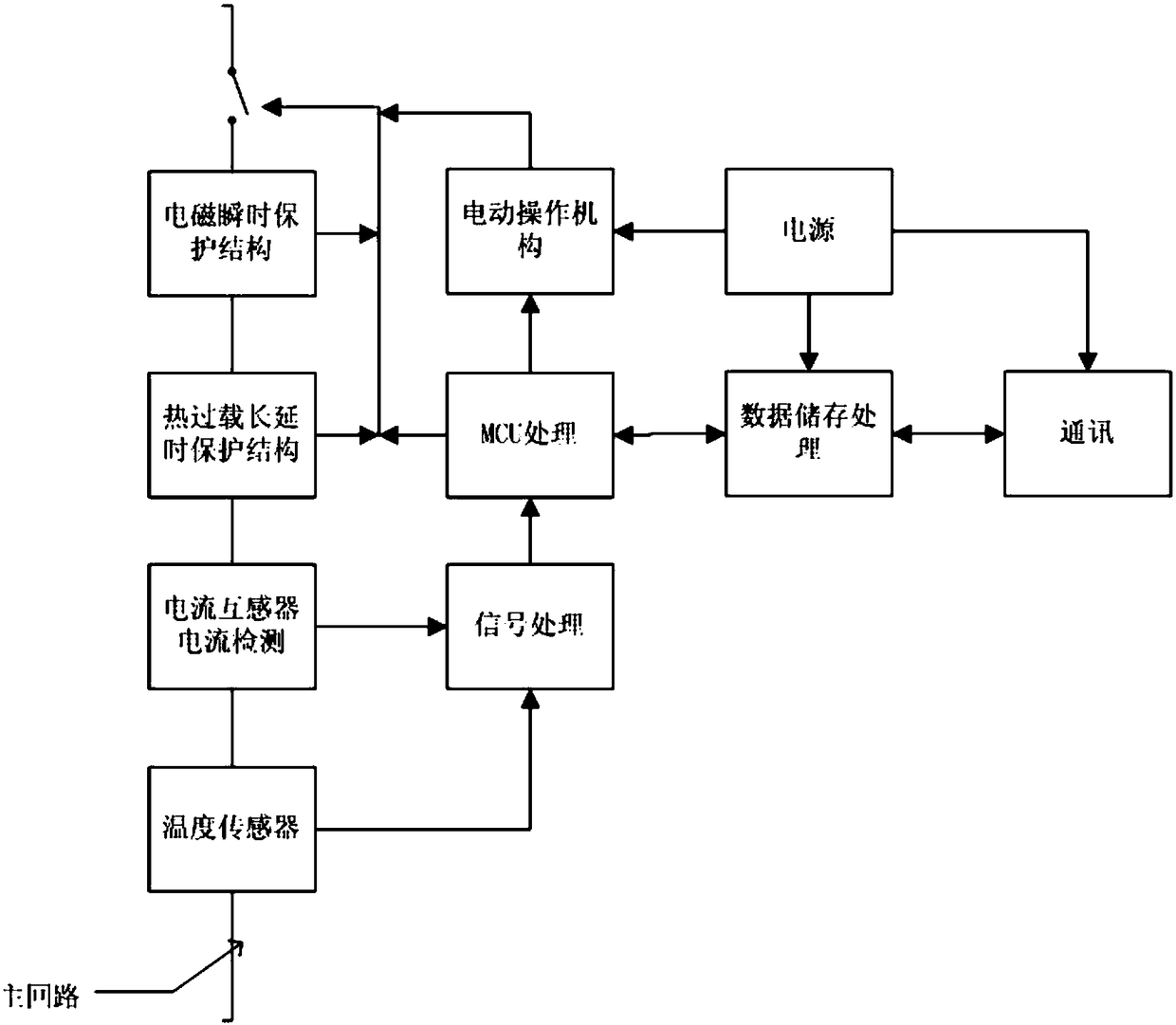

Circuit breaker adapting to user terminal of smart grid, and protection method thereof

PendingCN108512202AMonitor temperature changesAvoid damageEmergency protective circuit arrangementsInformation technology support systemCurrent sampleElectrical resistance and conductance

The invention discloses a circuit breaker adapting to a user terminal of a smart grid, and a protection method thereof. The circuit breaker comprises contacts, a tripping mechanism and a main lip busbar, wherein the fixed contact is fixed in the circuit breaker, and the tripping mechanism drives a movable contact to rotate; when the tripping mechanism is positioned in a non-tripping state, the movable contact touches the fixed contact, and when the tripping mechanism is positioned in a tripping state, the movable contact is separated from the fixed contact; the main loop busbar is connected with the movable contact; a branch lead parallel to the main loop busbar is installed on the main loop busbar; a current transformer is installed on the branch lead; a thermistor is installed on the main loop busbar; and an electromagnetic instantaneous protection structure, a thermal overload delay protection structure and an electronic protection structure are also installed in the circuit breaker. According to the circuit breaker provided by the invention, besides the protection function, the high precision instrument transformer with full current range measurement is increased, and the highprecision current sample can be applied to protecting the circuit breaker and can also be applied to big data computation.

Owner:JIANGSU KAILONG ELECTRONICS

Shearing instrument for freeze-thaw cycle shear test and test method

PendingCN114428024AImprove cooling effectStable jobMaterial strength using steady shearing forcesRefrigeration plantSoil science

The invention relates to the technical field of test devices and test methods thereof, in particular to a shear apparatus for a freeze-thaw cycle shear test and a test method, the shear apparatus comprises a shear apparatus main body, a refrigeration system and a data acquisition system; according to the invention, the shearing instrument is connected with external refrigeration equipment, so that intelligent control of the internal environment temperature of the shearing box is realized, and automatic acquisition of dynamic reaction values in the freezing and thawing cycle and shearing process of the soil sample is realized through a temperature sensor embedded in the soil sample and a pressure sensor, a dynamometer and a horizontal displacement meter which are mounted at the top of a pressure rod; the device is mainly used for the freezing and thawing cycle shear test of frozen soil and thawed soil interfaces of roads or railways in cold regions, can simulate the forming process of the frozen soil freezing and thawing interfaces, has the advantages of low cost and high similarity, and can remarkably improve the efficiency of the soil freezing and thawing cycle shear test.

Owner:LANZHOU JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com